Professional Documents

Culture Documents

Acupoint: Anti-Cross-Threading Feature

Uploaded by

Paulo Henrique NascimentoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acupoint: Anti-Cross-Threading Feature

Uploaded by

Paulo Henrique NascimentoCopyright:

Available Formats

®

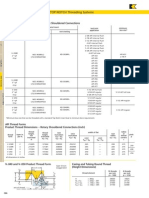

Acupoint Anti-Cross-Threading Feature

When a rotating fastener is misaligned with a Benefits

tapped hole, a no-start condition or cross thread- n resists cross-threading and no-start conditions

ing can occur. The Acupoint® feature was develop- to reduce assembly problems

ed to overcome both of these assembly problems. n rapid engagement improves productivity

n compansates for off-angle and off-center

As the fastener is driven, the Acupoint® feature conditions

locates the tapped hole and provides proper

alignment to ensure positive thread engagement

Features

n truncated spherical point quickly locates te hole

to help align the fastener

n point length minimizes application interference

n economical design since the point is roll formed

n point length and diameter designed to avoid

Specifications thread engagement in misaligned conditions

Thread Design:

metric

(others on request)

Size: Excellent Performance in Off-Angle and Off-

2.5 - 10 mm Center Conditions

During initial laboratory testing, the Acupoint®

Head Design: fastener has shown excellent perfomance in off-

n raised head n raised countersunk head angle and off-center positions when compared to

n countersunk head n hexacon head machine screws. Fasteners with the Acupoint®

(all types also as a round washer head screw) feature showed a 97% starting rate at an off-angle

of 30°. A machine screw had a 0% starting rate at

Drive System: 15°.

n cross recess n TORX®

®

n TORXplus n security drives In the off-center position, the Acupoint® design

(all cross recess and TORX® drives are also showed a good start 100% of the time at 2.40 mm

available as combi drives) off center and 91% at 2.90 mm. A machine screw

demonstrated a 73% starting rate at 2.40 mm and

Specials: 44% starting rate at 2.90 mm.

Special variations are available.

(double end studs, collar studs, external TORX®, ® ® ®

etc.) Acupoint , TORX und TORXplus are registered trademarks of

Fa. Camcar Textron, Rockford / Illinois.

For further information please contact T. Lückel, Tel. +49 2751 529-438, Fax 529-98 438, e-mail: tlueckel@ejot.de

You might also like

- EJOT - AcupointDocument1 pageEJOT - AcupointLucas VeronaNo ratings yet

- EN - Allround Technical BrochureDocument48 pagesEN - Allround Technical BrochuresivanaNo ratings yet

- ActiveMow en 209014770 WebDocument24 pagesActiveMow en 209014770 WebPaXoNNo ratings yet

- Mini Skalper W EZ Torque Rev9 152Document10 pagesMini Skalper W EZ Torque Rev9 152Dug1as GreyNo ratings yet

- ARP SeriesDocument12 pagesARP Seriest.meynoldsNo ratings yet

- Taptite Ii and Other TRILOBULAR™ Products: For Fastening Metals and PlasticsDocument24 pagesTaptite Ii and Other TRILOBULAR™ Products: For Fastening Metals and PlasticsPaulNo ratings yet

- Silent Tools: Productivity With Slender ToolsDocument12 pagesSilent Tools: Productivity With Slender Toolsxmen norNo ratings yet

- KRX NTNDocument4 pagesKRX NTNDj ́s Mix LiveNo ratings yet

- CAT Hammers H110 To H130E SDocument8 pagesCAT Hammers H110 To H130E Sfernandoalvesvnb100% (1)

- Stratos 100 200 300 PDFDocument14 pagesStratos 100 200 300 PDFLucian Catalin CalinNo ratings yet

- GP 180Document2 pagesGP 180yousufNo ratings yet

- Layher Allround Scaffolding - Technical BrochureDocument48 pagesLayher Allround Scaffolding - Technical BrochureEmaVanni100% (5)

- Wad Super400 500 1982 enDocument2 pagesWad Super400 500 1982 enJarda KaiserNo ratings yet

- SUCOOT Access Facade ScaffoldDocument24 pagesSUCOOT Access Facade ScaffoldhadipurnomoputraNo ratings yet

- C 1040 301 Aerospace Engine BrochureDocument20 pagesC 1040 301 Aerospace Engine BrochureJAIR JESUS GONZALEZ PLATANo ratings yet

- Tan Tzu enDocument68 pagesTan Tzu enLoc HuynhNo ratings yet

- Brochure Handpieces InstrumentsDocument28 pagesBrochure Handpieces InstrumentsKukinjosNo ratings yet

- Santorq ST Series Rev1Document5 pagesSantorq ST Series Rev1rupeshp1989No ratings yet

- Catalog TechnorollDocument24 pagesCatalog TechnorollSummA Learning CenterNo ratings yet

- Vermont Turning Insert CatalogDocument84 pagesVermont Turning Insert CatalogMann Sales & MarketingNo ratings yet

- Qui Cutter - Brochure 2022Document11 pagesQui Cutter - Brochure 2022William LauNo ratings yet

- Selecting and Customzing Implant Abutments For Cemented RestorationsDocument75 pagesSelecting and Customzing Implant Abutments For Cemented RestorationsAnonymous yHCKO5AP100% (1)

- PlastiteDocument24 pagesPlastitekeeblerkhanNo ratings yet

- SAK Venture Guide OnlineDocument73 pagesSAK Venture Guide OnlinejuanNo ratings yet

- Durilock Marketing Bulletin PELJ0343Document7 pagesDurilock Marketing Bulletin PELJ0343Patricio AlvaradoNo ratings yet

- Koken 201908ensp PDFDocument322 pagesKoken 201908ensp PDFLuis Fernando Losoya Cedeño100% (1)

- Koken 202308enspDocument338 pagesKoken 202308enspseppo tamminenNo ratings yet

- Crocodoff Crocodoff Forte: Clamping Crowns of New GenerationDocument4 pagesCrocodoff Crocodoff Forte: Clamping Crowns of New GenerationMohamed NaeimNo ratings yet

- PS Plugs and Connectors Brochure 2013Document16 pagesPS Plugs and Connectors Brochure 2013Bruno SantosNo ratings yet

- Enerpac Bolting ToolsDocument25 pagesEnerpac Bolting ToolsmichNo ratings yet

- Jaw Modules: Perfect For A Large Variety of PartsDocument11 pagesJaw Modules: Perfect For A Large Variety of Partsspcz scpzNo ratings yet

- 1 Part 1 Catalogue en LocknutDocument22 pages1 Part 1 Catalogue en Locknutehtisham khanNo ratings yet

- Enerpac S Series CatalogDocument5 pagesEnerpac S Series CatalogTitanplyNo ratings yet

- Deere Backhoe BH SeriesDocument2 pagesDeere Backhoe BH SeriesHeather SchintgenNo ratings yet

- Wedge Wire Screens & Tubes PROGRESSDocument8 pagesWedge Wire Screens & Tubes PROGRESSPhu, Le HuuNo ratings yet

- Lintech Conveyor Pulleys: Corporation - LimitedDocument11 pagesLintech Conveyor Pulleys: Corporation - LimitedJr RonaldeyriNo ratings yet

- Coromill® 390: End Mills With Size 07 Inserts Steel Grade Gc1130Document8 pagesCoromill® 390: End Mills With Size 07 Inserts Steel Grade Gc1130moonstarNo ratings yet

- tc-16 PRDocument10 pagestc-16 PREngenharia MansferNo ratings yet

- NL Original WashersDocument24 pagesNL Original Washersmohit_mgNo ratings yet

- Stauff Press Spr-Prc-Poc en 03-2016Document6 pagesStauff Press Spr-Prc-Poc en 03-2016onlymotieNo ratings yet

- Jig FixtureDocument59 pagesJig FixtureHrishikeshNo ratings yet

- Fy Smcs-1 Q. Bank Sem 1 2023-24Document12 pagesFy Smcs-1 Q. Bank Sem 1 2023-24raju.sharmqNo ratings yet

- 152.255-En - Low - SynOcta ProstheticDocument80 pages152.255-En - Low - SynOcta ProstheticansdkalsNo ratings yet

- MEP - Focus 12 - UkDocument5 pagesMEP - Focus 12 - UkLuiz HenriqueNo ratings yet

- D1 D19 (Vertex 33)Document19 pagesD1 D19 (Vertex 33)Giane NavasNo ratings yet

- UMT - MV SeriesDocument2 pagesUMT - MV SeriesTECH TALOSNo ratings yet

- PSA Series EngilshDocument66 pagesPSA Series EngilshTuấn NguyễnNo ratings yet

- P-50Ia Series: IaisaDocument2 pagesP-50Ia Series: IaisaDenilson MarinhoNo ratings yet

- Jig and FixtureDocument38 pagesJig and FixtureNaman Dave100% (1)

- Oc2 Dropper Bluepaper en EsDocument23 pagesOc2 Dropper Bluepaper en Esronare6613No ratings yet

- Oc2 Dropper Bluepaper En-EsDocument23 pagesOc2 Dropper Bluepaper En-EsAdolfo LeivaNo ratings yet

- 07 3 - CouplerDocument8 pages07 3 - CouplernahidNo ratings yet

- Duty Torque For ExtrudersDocument8 pagesDuty Torque For ExtrudersZaki SubehiNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Targon PFT Surgical TechniqueDocument68 pagesTargon PFT Surgical TechniquecrpcsxfdkgNo ratings yet

- Inner Ring Groove & Land Grinding ProcessDocument38 pagesInner Ring Groove & Land Grinding ProcessLateecka R Kulkarni100% (1)

- ch11 1Document96 pagesch11 1abdallah ghannamNo ratings yet

- Product-Overview-Fat 1190 enDocument20 pagesProduct-Overview-Fat 1190 enBulent KABADAYINo ratings yet

- Ejot ConlokDocument1 pageEjot ConlokPaulo Henrique NascimentoNo ratings yet

- Right of Way and Traffic Control Facilitites 000Document55 pagesRight of Way and Traffic Control Facilitites 000Paulo Henrique NascimentoNo ratings yet

- Right of Way and Traffic Control Facilitites 000Document55 pagesRight of Way and Traffic Control Facilitites 000Paulo Henrique NascimentoNo ratings yet

- Din en Iso 1157Document9 pagesDin en Iso 1157Paulo Henrique NascimentoNo ratings yet

- Aços Comp Aços Inox Torques (A1, A2, A4)Document3 pagesAços Comp Aços Inox Torques (A1, A2, A4)Paulo Henrique NascimentoNo ratings yet

- 18 Approximate Inter Equivalents AÇO INOX AISI 303Document1 page18 Approximate Inter Equivalents AÇO INOX AISI 303Paulo Henrique NascimentoNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument10 pagesEquivalents of Carbon Steel Qualitiessentilmech07No ratings yet

- AÇO - Material Specification Sheet SAE52100 CoilsDocument1 pageAÇO - Material Specification Sheet SAE52100 CoilsPaulo Henrique NascimentoNo ratings yet

- AÇO - DIN17100 St52-3Document1 pageAÇO - DIN17100 St52-3Paulo Henrique NascimentoNo ratings yet

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 pagesNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsNo ratings yet

- Acme Thread DataDocument1 pageAcme Thread Datadinesh_apkNo ratings yet

- Drill Size and Inch To Millimeter Table: Inches MM Drill Inches MM Drill Inches MM Drill Inches MM DrillDocument1 pageDrill Size and Inch To Millimeter Table: Inches MM Drill Inches MM Drill Inches MM Drill Inches MM DrillSolarysNo ratings yet

- Tightening TorqueDocument2 pagesTightening TorqueWONG TSNo ratings yet

- Literature Review of Drilling MachineDocument5 pagesLiterature Review of Drilling Machineea4hasyw100% (1)

- Measuring InstrumentsDocument55 pagesMeasuring InstrumentsNicolas SotoNo ratings yet

- 01 HPT Metric 2018Document164 pages01 HPT Metric 2018Haresh KapadiyaNo ratings yet

- 5 Foot Picnic Table PlansDocument15 pages5 Foot Picnic Table Plansgerardo mendezNo ratings yet

- NPT Vs NPTF 02Document3 pagesNPT Vs NPTF 02Rajendra SharmaNo ratings yet

- Thread CalloutDocument1 pageThread CalloutAryo WicaksonoNo ratings yet

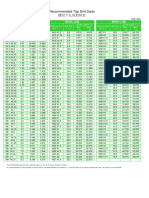

- Recommended Tap Drill SizesDocument4 pagesRecommended Tap Drill SizesJason-chungNo ratings yet

- Titanium Locking Screw and Bolts For Im Nails.J3686CDocument2 pagesTitanium Locking Screw and Bolts For Im Nails.J3686CDIEGO GOMEZNo ratings yet

- ConnectionsDocument82 pagesConnectionsseabrake83% (12)

- Technical Information: Thread Identification GuideDocument1 pageTechnical Information: Thread Identification GuideJaydev ManiarNo ratings yet

- Weld Fittings PipeDocument8 pagesWeld Fittings PipeJavier AffifNo ratings yet

- Active Learning Assignment (Manufacturing Process-I) (2131903) TopicDocument21 pagesActive Learning Assignment (Manufacturing Process-I) (2131903) TopicFredy AzizNo ratings yet

- NTP Thread Program Rev. ADocument1 pageNTP Thread Program Rev. Arajkumar931No ratings yet

- Project ME 21021 7 9 2023Document12 pagesProject ME 21021 7 9 2023pyae23062005No ratings yet

- Heavy Hex Bolts and Nuts: Brand UnitedDocument2 pagesHeavy Hex Bolts and Nuts: Brand Unitedrusli bahtiarNo ratings yet

- Min - TJL API RP 7g-2 - For MsDocument1 pageMin - TJL API RP 7g-2 - For MsEdwin MPNo ratings yet

- API v-.038 Thread Tech DetailsDocument1 pageAPI v-.038 Thread Tech DetailsabhijitrathiNo ratings yet

- 523 Excavator Parts ManualDocument184 pages523 Excavator Parts ManualAldrin BanaayNo ratings yet

- Sutton Tools Tapping Drill Size ChartDocument2 pagesSutton Tools Tapping Drill Size ChartcncmancomNo ratings yet

- 51 Faithfull Catalogue 2018Document1 page51 Faithfull Catalogue 2018Juvencio SobranoNo ratings yet

- Tools and Consumbales List: Mps Lontar Extension 315Mw ProjectDocument4 pagesTools and Consumbales List: Mps Lontar Extension 315Mw Projectfitri purwaniNo ratings yet

- Metric Screw Threads: Nissan Engineering StandardDocument90 pagesMetric Screw Threads: Nissan Engineering StandardBea RiveraNo ratings yet

- Inner Boom - T40.180SLPDocument3 pagesInner Boom - T40.180SLPvincent orengoNo ratings yet

- Socket Set Screw TypesDocument1 pageSocket Set Screw TypestylerstearnsNo ratings yet

- Appendex 2Document3 pagesAppendex 2nofal AdreesNo ratings yet