Professional Documents

Culture Documents

Paut Table 341.3.2 Below 25 MM Thickness

Uploaded by

vijay vickyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paut Table 341.3.2 Below 25 MM Thickness

Uploaded by

vijay vickyCopyright:

Available Formats

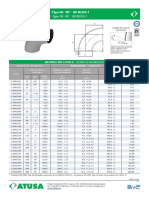

PAUT Acceptance standards Table - 341.3.

2 (Below 25 mm Thickness)

Types of Defect Acceptance Standards

Crack, Lack of

fusion, Incomplete ultrasonic examination to have discontinuities that produce

penetration an indication greater than 20% of the reference

Slag Piping Class 1 & 2 Piping Class 3 & 4

inclusion/Tungste Individual length ≤ T w /3 Individual length ≤ 2T w

n inclusion or Individual width ≤ 2.5 mm (3⁄32 in.) and ≤ T w /3 Individual width ≤ 3 mm (1⁄8 in.) and ≤ T w /2

elongated Cumulative length ≤ T w in any 12T w weld length Cumulative length ≤ 4T w in any 150 mm (6 in.) weld

indication (see length

Piping Class 1 & 2

Maximum Size of Acceptable Rounded Indication, mm Maximum Size of Nonrelevant

Thickness, t, mm

indication, mm

Random Isolated

Less than 3 1/4 t 1/3 t 1/10 t

3 0.79 1.07 0.38

Size and 5 1.19 1.6 0.38

Distribution of 6 1.6 2.11 0.38

rounded 8 1.98 2.64 0.79

indications 10 2.31 3.18 0.79

(Porosity) 11 2.77 3.71 0.79

(see note below) 13 3.18 4.27 0.79

14 3.61 4.78 0.79

16 3.96 5.33 0.79

17 3.96 5.84 0.79

19.0 to 50, incl. 3.96 6.35 0.79

Over 50 3.96 9.53 1.6

Piping Class 3 & 4

For T w ≤ 6 mm (1⁄4 in.), limit is same as above

For T w > 6 mm (1⁄4 in.), limit is 1.5 x above

Piping Class 1 & 2

Height of

For T w, mm (in.) Height, mm (in.)

reinforcement or

≤ 6 (1⁄4) ≤ 1.5 (1 ⁄16)

internal protrusion

> 6 (1⁄4), ≤ 13 (1⁄2) ≤ 3 (1 ⁄8)

(Excess

> 13 (1⁄2), ≤ 25 (1) ≤ 4 (5 ⁄32)

Penetration)

> 25 (1) ≤ 5 (3 ⁄16)

You might also like

- RT Acceptance CriteriaDocument3 pagesRT Acceptance CriteriaAndry Rimanov89% (18)

- Hydrotest Procedure For Pressure VesselDocument7 pagesHydrotest Procedure For Pressure Vesselvijay vickyNo ratings yet

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamedNo ratings yet

- ARE - Design For Welding - AWS Resources For Engineers PDFDocument86 pagesARE - Design For Welding - AWS Resources For Engineers PDFnelsonNo ratings yet

- Welding Positions: EN ISO 6947 & ASME Code, Section IX (QW 460) / AWS A3.0Document1 pageWelding Positions: EN ISO 6947 & ASME Code, Section IX (QW 460) / AWS A3.0Sharad ShahNo ratings yet

- Welding TechnologyDocument18 pagesWelding TechnologySanjoy Biswas100% (3)

- CBLM SmawDocument52 pagesCBLM SmawCE Einosas82% (60)

- Table 127.4.2 Reinforcement of Girth and Long. Butt Welds & Table 127.4.4Document2 pagesTable 127.4.2 Reinforcement of Girth and Long. Butt Welds & Table 127.4.4PamungkasNo ratings yet

- Acceptance Criteria Asme B31 3Document1 pageAcceptance Criteria Asme B31 3Hadi Allouche100% (9)

- (ASME Sec V Article 4 & 5) : UT - Ultrasonic TestingDocument31 pages(ASME Sec V Article 4 & 5) : UT - Ultrasonic Testingvijay vickyNo ratings yet

- d15.1-07 IO2Document1 paged15.1-07 IO2SagarPatel100% (1)

- Sample Welding Procedure Specification (WPS) FormDocument1 pageSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- AWS D1.1 Acceptance CriteriaDocument9 pagesAWS D1.1 Acceptance CriteriaNguyễn Giang Nam100% (1)

- Weld Defects Incomplete Root PenetrationDocument4 pagesWeld Defects Incomplete Root PenetrationMuhammed SulfeekNo ratings yet

- Uw-51 RT Acceptance CriteriaDocument12 pagesUw-51 RT Acceptance CriteriaSameer RajuNo ratings yet

- ASTM and ISO pipe tolerance standardsDocument1 pageASTM and ISO pipe tolerance standardsgame freakaNo ratings yet

- Radiographictesting Acceptance Standard Asme Section ViiiDocument1 pageRadiographictesting Acceptance Standard Asme Section ViiiAkhtarcmti1342No ratings yet

- Line - Pipe - IS - TOLERANCE ON OUTSIDE DIAMETER, WALL THICKNESS, WEIGHT AND LENGTH OF PIPEDocument3 pagesLine - Pipe - IS - TOLERANCE ON OUTSIDE DIAMETER, WALL THICKNESS, WEIGHT AND LENGTH OF PIPECristi DemNo ratings yet

- 6 p0410 0454tube - enDocument49 pages6 p0410 0454tube - enDannu YogaNo ratings yet

- ASME Section VIII radiographic weld acceptance standardsDocument2 pagesASME Section VIII radiographic weld acceptance standardsAkhtarcmti1342No ratings yet

- Tamano de Catetos - Aws D1.1 PDFDocument1 pageTamano de Catetos - Aws D1.1 PDFAngelTinocoNo ratings yet

- RT Acceptance Criteria: API-1104 AWS D1.1Document1 pageRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- RT Acceptance Criteria GuideDocument1 pageRT Acceptance Criteria GuidevikasNo ratings yet

- ASME SEC VIII DIV-1 RT CriteriaDocument4 pagesASME SEC VIII DIV-1 RT CriteriaBALA CHANDAR M100% (1)

- Triaxial Test Data Sheet MEGA IDocument121 pagesTriaxial Test Data Sheet MEGA ILao Nong NgoNo ratings yet

- RT Acceptance Criteria CodesDocument4 pagesRT Acceptance Criteria CodesnerdsarmyNo ratings yet

- AWS-d1 1Document1 pageAWS-d1 1mayank pandyaNo ratings yet

- Acceptance Criteria for Pipe WeldsDocument2 pagesAcceptance Criteria for Pipe WeldsMichael CovillNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Curvas de FerroDocument2 pagesCurvas de FerroJoão P. CardosoNo ratings yet

- Proximity Transducers, Seismic Sensors and Accessories: Case Expansion Transducer TM0602Document1 pageProximity Transducers, Seismic Sensors and Accessories: Case Expansion Transducer TM0602nino16041973No ratings yet

- Dripnet PC AS Thick Walled Dripperlines Product SheetDocument2 pagesDripnet PC AS Thick Walled Dripperlines Product SheetIgnacio RinaldiNo ratings yet

- GN 589 Lifting Points Continued: Safety InstructionsDocument1 pageGN 589 Lifting Points Continued: Safety InstructionsAlbertoNo ratings yet

- D265T063Document6 pagesD265T063adhyharmonypngNo ratings yet

- Typhoon 15040-003800Document2 pagesTyphoon 15040-003800Hernan RiosNo ratings yet

- MS ERW Pipes PDFDocument2 pagesMS ERW Pipes PDFPiyushiNo ratings yet

- U Channel Steel Astm A36Document1 pageU Channel Steel Astm A36Andrés RamírezNo ratings yet

- A Cero Princ in PalesDocument75 pagesA Cero Princ in PalesMarcos Luis Chuquilin VergaraNo ratings yet

- Dripnet PC Thick Walled Dripperlines Product SheetDocument2 pagesDripnet PC Thick Walled Dripperlines Product SheetIgnacio RinaldiNo ratings yet

- WallthicknessDocument1 pageWallthicknessGabriela MotaNo ratings yet

- SMC 6-7-p0464-ts - enDocument1 pageSMC 6-7-p0464-ts - enRup PurNo ratings yet

- Roof Sheeting Technical Data SheetDocument1 pageRoof Sheeting Technical Data SheetSyed AbuthahirNo ratings yet

- Angles ChecksDocument23 pagesAngles Checkshighway20049922No ratings yet

- Momentos de Por. PrincipalesssssssDocument62 pagesMomentos de Por. PrincipalesssssssMarcos Luis Chuquilin VergaraNo ratings yet

- Aries TWD PDocument2 pagesAries TWD PFelipe Dias AraújoNo ratings yet

- CHIYODA WELDING PRODUCTS Combination Welding and Cutting Torches GuideDocument13 pagesCHIYODA WELDING PRODUCTS Combination Welding and Cutting Torches Guideandi permanaNo ratings yet

- TMT401 EyhDocument28 pagesTMT401 EyhAlfredo UriarteNo ratings yet

- A500 Spec PDFDocument2 pagesA500 Spec PDFUgur SenNo ratings yet

- A500 Spec SheetDocument2 pagesA500 Spec SheetMikku KattaNo ratings yet

- Grinding MediaDocument3 pagesGrinding MediaKana RamNo ratings yet

- 3.5 Core Al Xlpe ArmdDocument1 page3.5 Core Al Xlpe ArmdRavindra JadhavNo ratings yet

- Cantidades de Obra Estructuras Warrutamana (Incluye M/O-Transporte)Document2 pagesCantidades de Obra Estructuras Warrutamana (Incluye M/O-Transporte)Katherin Cortes PerezNo ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- Tension and Compression Members PDFDocument41 pagesTension and Compression Members PDFDennis RangwetsiNo ratings yet

- USTER Quality Report: Total (40) Time To Break S B-Force GF Elongation % Tenacity RKM B-Work CN - CMDocument1 pageUSTER Quality Report: Total (40) Time To Break S B-Force GF Elongation % Tenacity RKM B-Work CN - CMIlhom ZakirovNo ratings yet

- Automatic Transmission Service SpecificationsDocument2 pagesAutomatic Transmission Service SpecificationsDang Tien PhucNo ratings yet

- Dewpoint Copper DPC-0118-C Product CatalogueDocument2 pagesDewpoint Copper DPC-0118-C Product Cataloguemye ryeNo ratings yet

- Expander System Dimension Sheet - Stepped Pin Type CDocument2 pagesExpander System Dimension Sheet - Stepped Pin Type CebraNo ratings yet

- Sanitary Tubes SMS 3008: SMS 3008 Practise Based SizesDocument1 pageSanitary Tubes SMS 3008: SMS 3008 Practise Based Sizesnang.tranNo ratings yet

- Victaulic 3-88.9-75 PDFDocument5 pagesVictaulic 3-88.9-75 PDFpjcs1974No ratings yet

- LabEx No. 5 Sieve Analysis of AggregatesDocument4 pagesLabEx No. 5 Sieve Analysis of AggregatesGerman BarlisNo ratings yet

- Victaulic Flexible Coupling Style 75: 1.0 Product DescriptionDocument5 pagesVictaulic Flexible Coupling Style 75: 1.0 Product DescriptionRobson CustódioNo ratings yet

- RoofDek D159-Acoustic Load TableDocument1 pageRoofDek D159-Acoustic Load TableЙордан ЛиляновNo ratings yet

- 3.5 Core Cu ArmdDocument1 page3.5 Core Cu ArmdJitendra KumarNo ratings yet

- Nes D2188Document6 pagesNes D2188prasannaNo ratings yet

- Hal 28Document1 pageHal 28DESSYNo ratings yet

- New CPVC Brochure 004Document12 pagesNew CPVC Brochure 004murtadha ahmedNo ratings yet

- Resume PDFDocument1 pageResume PDFvijay vickyNo ratings yet

- Annexure 1.0Document4 pagesAnnexure 1.0vijay vickyNo ratings yet

- Additional HnadoutDocument2 pagesAdditional Hnadoutvijay vickyNo ratings yet

- 009 Asme Sec V A 5Document12 pages009 Asme Sec V A 5vijay vickyNo ratings yet

- Required Tube and Probes For ECT& Saturated Probe /rfetDocument2 pagesRequired Tube and Probes For ECT& Saturated Probe /rfetvijay vickyNo ratings yet

- Exchanger Tubes-Ms Block - Exchanger.exchanger TubeDocument33 pagesExchanger Tubes-Ms Block - Exchanger.exchanger Tubevijay vickyNo ratings yet

- APPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRDocument3 pagesAPPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRMohamed Ahmed MaherNo ratings yet

- Detecting and preventing lack of sidewall and inter-run fusion in weldsDocument4 pagesDetecting and preventing lack of sidewall and inter-run fusion in weldsguru_terexNo ratings yet

- Carrier Selections RTU-1 and RTU-2Document16 pagesCarrier Selections RTU-1 and RTU-2Fidel CastroNo ratings yet

- WPS - 010Document12 pagesWPS - 010MAT-LIONNo ratings yet

- Welder (GMAW - GTAW) - CTS2.0 - NSQF-3Document32 pagesWelder (GMAW - GTAW) - CTS2.0 - NSQF-3sanjeevNo ratings yet

- Causes and Cures of Common Welding TroublesDocument1 pageCauses and Cures of Common Welding TroublesRathnakrajaNo ratings yet

- Everything You Need to Know About Electrical Welding MachinesDocument2 pagesEverything You Need to Know About Electrical Welding MachinesRajesh KumarNo ratings yet

- RT Film ReviewDocument1 pageRT Film Reviewpriti kumariNo ratings yet

- No No Matrik Nama KumpulanDocument4 pagesNo No Matrik Nama Kumpulantuan siti atirahNo ratings yet

- Recommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysDocument75 pagesRecommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysAMIT KUMAR100% (1)

- Contract Provison of Hook-Up and Commisioning of Petronas Carigali For YEAR 2012-2018Document6 pagesContract Provison of Hook-Up and Commisioning of Petronas Carigali For YEAR 2012-2018Faiz IshakNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Telwin GENERAL CATALOGUEDocument80 pagesTelwin GENERAL CATALOGUEFlorin LunguNo ratings yet

- Flanged Immersion Heaters Design GuideDocument7 pagesFlanged Immersion Heaters Design GuidecamspsNo ratings yet

- Price List Wintech AccesoriesDocument9 pagesPrice List Wintech AccesoriesAris WicaksonoNo ratings yet

- 0625 s11 QP 31Document20 pages0625 s11 QP 31Haider AliNo ratings yet

- Introduction Basic Welding TechnologyDocument17 pagesIntroduction Basic Welding TechnologyBenny Syahputra100% (1)

- What Is ASME IX and ISO 9606 and How Does It Apply To Welding - East African Institute of WeldingDocument4 pagesWhat Is ASME IX and ISO 9606 and How Does It Apply To Welding - East African Institute of Weldinger_wenNo ratings yet

- EnerVal TehniCki KatalogDocument18 pagesEnerVal TehniCki KatalogHasim BenziniNo ratings yet

- BC 80 628Document1 pageBC 80 628yutweldingNo ratings yet

- PQ 1Document2 pagesPQ 1rashidNo ratings yet

- Plug Weld :DDocument17 pagesPlug Weld :DKumarChirraNo ratings yet

- WeldingDocument32 pagesWeldingSüshãñt SåhâÿNo ratings yet