Professional Documents

Culture Documents

AWS-d1 1

Uploaded by

mayank pandyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AWS-d1 1

Uploaded by

mayank pandyaCopyright:

Available Formats

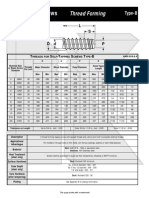

Root Opening of Groove Camber Tolerance (in inches)

Joints without Angle of

Root Face of Joint Steel Backing Joint a/S

Span 0.1 0.2 0.3 0.4 0.5

in. mm in. mm deg

100 ft 1/4 1/2 5/8 3/4 3/4

SMAW ±1/16 ±2 ±1/16 ±2 ±5 < 100 ft 1/8 1/4 5/16 3/8 3/8

GMAW ±1/32 ±1 ±1/16 ±2 ±5

FCAW ±1/16 ±2 ±1/16 ±2 ±5 Camber Tolerance (in millimeters)

Note: Root openings wider than allowed by the above tolerances, but a/S

not greater than the thickness of the thinner part, may be built up by Span 0.1 0.2 0.3 0.4 0.5

welding to acceptable dimensions prior to the joining of the parts by

welding.

30 m 7 13 17 19 20

< 30 m 4 6 8 10 10

Minimum Size

Base-Metal Thickness (T)a of Fillet Weldb

in. mm in. mm

11/8 3

Camber Tolerance (in inches) T 1/4 T 6

(Note c) (Note c)

a/S

1/4 < T 1/2 6<T 12 3/16 5

Span 0.1 0.2 0.3 0.4 0.5

1/2 < T 3/4 12 < T 20 1/4 6

100 ft 9/16 1 1-1/4 1-7/16 1-1/2

3/4 < T 20 < T 5/16 8

< 100 ft 1/4 1/2 5/8 3/4 3/4

a For non-low-hydrogen processes without preheat calculated in

Camber Tolerance (in millimeters) conformance with 4.7.4, T equals thickness of the thicker part joined;

single-pass welds shall be used.

a/S For non-low-hydrogen processes using procedures established to pre-

Span 0.1 0.2 0.3 0.4 0.5 vent cracking in conformance with 4.7.4 and for low-hydrogen pro-

cesses, T equals thickness of the thinner part joined; single-pass

requirement shall not apply.

30 m 14 25 34 38 40 b Except that the weld size need not exceed the thickness of the thinner

part joined.

< 30 m 7 13 17 19 20 c Minimum size for cyclically loaded structures shall be 3/16 in. [5 mm].

204

You might also like

- Tamano de Catetos - Aws D1.1 PDFDocument1 pageTamano de Catetos - Aws D1.1 PDFAngelTinocoNo ratings yet

- Tabla de FileteDocument1 pageTabla de FileteRicardo PonceNo ratings yet

- Connections 1 - Ch.3 Welds Notes (94-153)Document15 pagesConnections 1 - Ch.3 Welds Notes (94-153)travis8zimmermannNo ratings yet

- Sttype ABDocument1 pageSttype ABSean YangNo ratings yet

- SocketspipeflushDocument1 pageSocketspipeflushLuís Felipe GuimaraesNo ratings yet

- SocketspipedryDocument1 pageSocketspipedryLuís Felipe GuimaraesNo ratings yet

- U Channel Steel Astm A36 Lac: Mechanical PropertiesDocument1 pageU Channel Steel Astm A36 Lac: Mechanical PropertiesElvis Alcántara C.No ratings yet

- 5 - K. Horova, J. Tomsu, F. Wald - To Base Plates of Hollow Sections ColumnsDocument36 pages5 - K. Horova, J. Tomsu, F. Wald - To Base Plates of Hollow Sections ColumnsAnonymous bqV7MbFSuNo ratings yet

- 1.7 - Is 12779Document6 pages1.7 - Is 12779vrgohilNo ratings yet

- Aluminum Ref DataDocument5 pagesAluminum Ref DataDiego SarmientoNo ratings yet

- Microplan - Katalog 2008 ENDocument10 pagesMicroplan - Katalog 2008 END.T.No ratings yet

- Malleable Iron Pipe Fittings: Gourd BrandDocument11 pagesMalleable Iron Pipe Fittings: Gourd BrandAamer Abdul MajeedNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- Sttype BDocument1 pageSttype BSean YangNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2janithNo ratings yet

- 35m Tower CheckDocument68 pages35m Tower CheckHarold Jackson MtyanaNo ratings yet

- RCC94 Two-Way Slabs (Tables) - RS2Document1 pageRCC94 Two-Way Slabs (Tables) - RS2Arnold TunduliNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Capac Ity (Kva) Dimension Tank (MM) L B H Grade of Materia L Core Weight of Stampin Gin Core and Yoke (KG)Document3 pagesCapac Ity (Kva) Dimension Tank (MM) L B H Grade of Materia L Core Weight of Stampin Gin Core and Yoke (KG)UPPCLNo ratings yet

- sc10mnx 104h8075 r290 220v 50hz 06-2023 DsDocument4 pagessc10mnx 104h8075 r290 220v 50hz 06-2023 Dsangel1573065412No ratings yet

- Sammy Kamau Njunguna-1Document7 pagesSammy Kamau Njunguna-1NewtonNo ratings yet

- MAM STD - B3 - 02 - 17 - 04 - Arc WeldingDocument3 pagesMAM STD - B3 - 02 - 17 - 04 - Arc WeldingMohanrajMJNo ratings yet

- Self-Drilling Screws: Key BenefitsDocument8 pagesSelf-Drilling Screws: Key BenefitsGabriel MacedoNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- 2002 07 02 Duct Design Proforma ED1Document3 pages2002 07 02 Duct Design Proforma ED1Mohammed HaniNo ratings yet

- Especificaciones Kwik BoltDocument12 pagesEspecificaciones Kwik BoltjaimepwpsNo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- RCC94 Two-Way Slabs (Tables)Document1 pageRCC94 Two-Way Slabs (Tables)curiosity12No ratings yet

- Strap Brace: Product Data SheetDocument5 pagesStrap Brace: Product Data SheetSolomon Castañares JrNo ratings yet

- 765/400 PARLI PGCIL S/S BBS detailsDocument3 pages765/400 PARLI PGCIL S/S BBS detailsnirajNo ratings yet

- Technical Features: Medium: Mounting: MaterialsDocument10 pagesTechnical Features: Medium: Mounting: MaterialsValourdos LukasNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEnokarajuNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Document1 pageSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNo ratings yet

- Porous Plastic Silencers Reduce NoiseDocument2 pagesPorous Plastic Silencers Reduce NoiseMichaelNooijNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Paut Table 341.3.2 Below 25 MM ThicknessDocument2 pagesPaut Table 341.3.2 Below 25 MM Thicknessvijay vickyNo ratings yet

- Design of Two Way Slab with Short Span of 3.62m and Long Span of 3.92mDocument1 pageDesign of Two Way Slab with Short Span of 3.62m and Long Span of 3.92mPipoy ReglosNo ratings yet

- In House Test Report 3.2mmDocument3 pagesIn House Test Report 3.2mm胡大威No ratings yet

- Astm A370Document1 pageAstm A370Gerangaya Ray AngeloNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Fane HP ClassicDocument1 pageFane HP ClassicferdinandNo ratings yet

- Pages From Neta 2007 PDFDocument3 pagesPages From Neta 2007 PDFPablo GonzalesNo ratings yet

- Influence of Deep Cryogenic TreatmentDocument14 pagesInfluence of Deep Cryogenic TreatmentBojan PodgornikNo ratings yet

- Acceptence Criteria IMTEDocument12 pagesAcceptence Criteria IMTEdanaka007100% (1)

- TEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low WeightDocument4 pagesTEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low Weightalexander_1985No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- MW Microwhirl Misting NozzleDocument1 pageMW Microwhirl Misting NozzleblondtumbalaNo ratings yet

- Material Specifications: Table 1 - Hilti HSL-3 SpecificationsDocument1 pageMaterial Specifications: Table 1 - Hilti HSL-3 SpecificationsVenkatesh HebbarNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- MINIMAT Screwdrivers: Handheld Screwdriver PneumaticDocument4 pagesMINIMAT Screwdrivers: Handheld Screwdriver Pneumaticgoran1No ratings yet

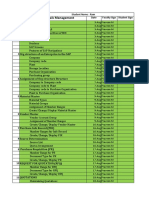

- Project Management Tracker: Project Start Date Display WeekDocument8 pagesProject Management Tracker: Project Start Date Display Weekmayank pandyaNo ratings yet

- The Hot Dip Galvanizing Process: Technical SeminarDocument13 pagesThe Hot Dip Galvanizing Process: Technical Seminarmayank pandyaNo ratings yet

- Cswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Document43 pagesCswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007claytoninf87% (30)

- Fabrication CalculationDocument40 pagesFabrication CalculationRamesh mudunuri100% (1)

- Piping Presentation Components and DesignDocument52 pagesPiping Presentation Components and Designmayank pandya100% (2)

- Critical Equipment Fabrication GuideDocument103 pagesCritical Equipment Fabrication Guidemayank pandyaNo ratings yet

- Quiz ME 1Document4 pagesQuiz ME 1Radytia BimantaraNo ratings yet

- Log-PASSAT IMMO-WVWZZZ3CZ7E064873-266870km-165825miDocument13 pagesLog-PASSAT IMMO-WVWZZZ3CZ7E064873-266870km-165825miMihalciuc AlexandruNo ratings yet

- Cem-FIL GRC Technical DataDocument91 pagesCem-FIL GRC Technical Datacbler100% (1)

- Technical Data About The Production of Steel StructuresDocument2 pagesTechnical Data About The Production of Steel StructuresPress EscapeNo ratings yet

- Tech Note FormatDocument2 pagesTech Note FormatUgonna OhiriNo ratings yet

- International Financial Law Reforms After Global CrisisDocument5 pagesInternational Financial Law Reforms After Global CrisisВладиславNo ratings yet

- 5 Short MustWatch Motivational Videos For TeachersrccymDocument4 pages5 Short MustWatch Motivational Videos For Teachersrccymfoxpeak8No ratings yet

- Gunning 2009Document7 pagesGunning 2009juan diazNo ratings yet

- CV (Muhammad Irfan Khan)Document3 pagesCV (Muhammad Irfan Khan)Niazi_sabNo ratings yet

- Tata Consulting Engineers Design Guide For Auxiliary Steam HeaderDocument10 pagesTata Consulting Engineers Design Guide For Auxiliary Steam HeadervijayanmksNo ratings yet

- AarDocument2 pagesAarkomar agusNo ratings yet

- Full download book Neurology Neonatology Questions And Controversies Neonatology Questions Controversies Pdf pdfDocument41 pagesFull download book Neurology Neonatology Questions And Controversies Neonatology Questions Controversies Pdf pdfzelma.lansberry528100% (12)

- Water Supply NED ArticleDocument22 pagesWater Supply NED Articlejulie1805No ratings yet

- Instructions To Employee For Submitting Online Application For Transfer Under Rule - 38 of Postal Manual Vol.-IVDocument6 pagesInstructions To Employee For Submitting Online Application For Transfer Under Rule - 38 of Postal Manual Vol.-IVSankarMathi VaigundhamNo ratings yet

- Get started with Power BI DesktopDocument34 pagesGet started with Power BI Desktopbhargavc7No ratings yet

- Automatic Transfer Switch (ATS) : I. History and BackgroundDocument3 pagesAutomatic Transfer Switch (ATS) : I. History and BackgroundJon Lorde BolivarNo ratings yet

- Ram SAP MM Class StatuscssDocument15 pagesRam SAP MM Class StatuscssAll rounderzNo ratings yet

- SE John Deere 6020 Series Filter Overview and Capacities 6120 6120L 6220 6220L 6320 6320L 6420 6420L 6520L NOV20Document2 pagesSE John Deere 6020 Series Filter Overview and Capacities 6120 6120L 6220 6220L 6320 6320L 6420 6420L 6520L NOV20marianNo ratings yet

- Ansys Workbench Tutorial: Structural & Thermal Analysis Using The ANSYS Workbench Release 11.0 EnvironmentDocument5 pagesAnsys Workbench Tutorial: Structural & Thermal Analysis Using The ANSYS Workbench Release 11.0 EnvironmentMuhammad HaroonNo ratings yet

- Manual Flowpet 5GDocument56 pagesManual Flowpet 5GRahkmat DanizarNo ratings yet

- Crim Cases MidtermsDocument76 pagesCrim Cases MidtermsCoreine Valledor-SarragaNo ratings yet

- Hydraulic Shovel: Engine BucketDocument32 pagesHydraulic Shovel: Engine BucketJulio CRNo ratings yet

- Patient-Centred CareDocument15 pagesPatient-Centred CareMwanja MosesNo ratings yet

- OriginalDocument4 pagesOriginalJob ValleNo ratings yet

- The Spanish-American War (History 70)Document11 pagesThe Spanish-American War (History 70)Tine AtaamNo ratings yet

- Shangri La Hotels and Resorts SWOTDocument2 pagesShangri La Hotels and Resorts SWOTHadi Agustana100% (1)

- B.Tech Digital Principles and System Design Exam Question BankDocument24 pagesB.Tech Digital Principles and System Design Exam Question Bankdigital1206No ratings yet

- NHBC Standards 2011 Bre SD 1 SRCDocument5 pagesNHBC Standards 2011 Bre SD 1 SRCSuresh RaoNo ratings yet

- Zara Marketing Mix Four PsDocument3 pagesZara Marketing Mix Four PsHaniyeh ShojaeiNo ratings yet

- Accounting for Business CombinationsDocument52 pagesAccounting for Business CombinationsEliza BethNo ratings yet