Professional Documents

Culture Documents

MAM STD - B3 - 02 - 17 - 04 - Arc Welding

Uploaded by

MohanrajMJOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAM STD - B3 - 02 - 17 - 04 - Arc Welding

Uploaded by

MohanrajMJCopyright:

Available Formats

1/3

DIVISION Scope of operation Classified

MAS No. B3-2-17 [Revision 4]

NAME

Competent

Arc welding section

1. Scope of application

These standards specify regarding arc welding (Includes CO2 shield welding ).

2.Welding machines and welding equipment

(1) Welding machine must enable stable arc formation and excellent welding.

(2) Welding machine and welding equipment should be compatible with JIS.

3. Welding bar and wires

(1) Welding bar and wire should be JIS compliant.

(2) Welding bar and wire should be considered as Table 1.

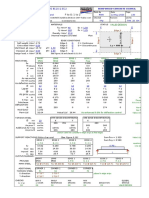

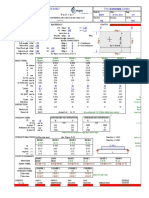

Table 1 Types of Welding bar and wire

Welding bar Model & Bland code (Reference)

( Wire ) Application Remarks

as per JIS A B C D E F

Z3312 YCW 1 For thin sheet (t=0.8~3.2) MG50T YM28 DS1A SCO YM50T1

Wire

〃 〃 2 For thick sheet (t=1.6~ ) MG50 YM26 DS1 SCT YM50T

Z3211 D4313 For thin sheet (t=0.8~2.3) D33 F13

〃 D4301 〃 〃 B10 A100 200

〃 D4316 Parts requiring strength of LB26 Ⓢ-16 LF16

which thickness is thick sheet

(2.3 ~) Bar

Steel with a carbon equivalent

of 0.3 or more

Z3212 D5016 Thick sheet LB52 H50G LT52

or high tension steel

Bland code are as bellows.

A: KOBELCO, B: NIPPON STEEL WELDINGS, C: DAIDO STEEL, D: SUMITOMO ELECTRIC,

E: JFE STEEL, F: PANASONIC

(3) For welding bar and wire diameter, based on sheet thickness (Shaft diameter) of welding material,

consider Table 2 as standard.

Table 2 Welding bar and wire diameter

Sheet thickness

Welding bar (φmm) Wire diameter (φmm)

(Shaft diameter) (mm)

(0.8 ~ 1.2) 2.0 0.9

1.3 ~ 2.3 2.6 0.9 (1.2)

2.4 ~ 3.2 1.2

For sheet thickness (Shaft diameter) consider thinner sheet side (Small shaft diameter) as a standard.

Issued 3rd Oct., 1975 APPROVED

History Revision 4 11th Nov., 2008 Yamao

Koshino

Mitsubishi Mahindra Agricultural Machinery Co., Ltd.

MAS Classified No. B3-2-17 [Revision 4] 2/3

4.Welding

(1) General items

(a) All the jigs and fixed tools must be well maintained.

(b) Welding bar and wires must not have harmful defects such as transformations, moisture absorption and

bends etc.

(c) Welded joints must be kept in clean state.

(d) Take proper considerations to prevent tack welding from deformation, inconsistency and blowholes.

(e) There should be no extreme ventilation in CO2 shield welding.

(f) In prototype part where spot welding or other such processes are specified, should not have large impact

of tacking which is done to decide position according to arc welding.

Example

When regular spot welding is done after tacking by arc welding on iron plate made pulley which is

specified with spot welding, it surpasses drawing specifications and the joint becomes strong.

Therefore, even if it does not satisfy the originally required strength, it does not show any failures

during quality check however, it is evaluated wrongly.

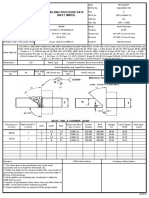

(2) Operating conditions

Operating condition should be considered as Table 3.

Table 2 Operating condition

Sheet Welding bar CO2 shield

Type of joint thickness Amperage Speed Amperage Voltage Speed Remarks

(mm) (A) (cm/min) (A) (V) (cm/min)

Fillet joint 0.8 50~60 16 105~115 Wire 0.9φ

1.2 70 16.5 40 〃 〃

1.6 110 19 40 〃 1.2φ

2.3 - - 135 20 60 〃 〃

3.2 170 21 60 〃 〃

4.5 170 21.5 40 〃 〃

6.0 200 22 40 〃 〃

Edge joint 0.8 60~65 16.5~17.5 110~120 〃 0.9φ

1.2 80 18 40 〃 〃

1.6 90 19 40 〃 〃

2.3 - - 90 18 40 〃 1.2φ

3.2 90 19.6 30 〃 〃

4.5 190 22 40 〃 〃

6.0 100 22 45 〃 〃

Butt joint 0.8 60~ 70 16~17 Approx. 40 〃 0.9φ

1.2 65~ 75 17~18 Approx. 40 〃 〃

1.6 120~130 19~20 50~60 〃 1.2φ

2.3 - - 130~150 20~21 45~55 〃 〃

3.2 130~150 20~23 30~40 〃 〃

4.5 150~180 21~23 30~35 〃 〃

6.0 180~200 22~25 32~40 〃 〃

Mitsubishi Mahindra Agricultural Machinery Co., Ltd.

MAS Classified No. B3-2-17 [Revision 4] 3/3

5. Quality

Follow MAS B1-5-84 Standard for arc welding quality.

Mitsubishi Mahindra Agricultural Machinery Co., Ltd.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 12F0011X0-Stainless-Steel-Fastener-Mechanical-PropertiesDocument2 pages12F0011X0-Stainless-Steel-Fastener-Mechanical-PropertiespkdscdubaiNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-08 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-08 Column Section DesignAlpha ScimathNo ratings yet

- 01 PDFDocument2 pages01 PDFAlpha ScimathNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2ery achjariNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- SF-1 Flux-cored wire for mild steel and 490N/mm2 steelDocument1 pageSF-1 Flux-cored wire for mild steel and 490N/mm2 steelHoque AnamulNo ratings yet

- Two-Way Slab V2Document4 pagesTwo-Way Slab V2Eric AbedaniaNo ratings yet

- Spreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68Document1 pageSpreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68roshan034No ratings yet

- Semi-Automatic GMAW Welding Procedure for Complete Penetration Bevel Groove Welds in Carbon and Low Alloy SteelsDocument1 pageSemi-Automatic GMAW Welding Procedure for Complete Penetration Bevel Groove Welds in Carbon and Low Alloy SteelsWael AlmahdiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Felicia GhicaNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Ujol PraNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- ETABS 2016 column design summaryDocument2 pagesETABS 2016 column design summaryjccajamarcaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- Web Datasheet b4.1Document3 pagesWeb Datasheet b4.1Reza Khatibi NasabNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- RCC95 Continuous Beams (Tables)Document7 pagesRCC95 Continuous Beams (Tables)Mohammad Twaha JaumbocusNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNo ratings yet

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)christi SNo ratings yet

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerNo ratings yet

- 7023exq Lecture 3 Bolted Steel ConnectionsDocument17 pages7023exq Lecture 3 Bolted Steel ConnectionsAkhil SurendranNo ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- TATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)Document2 pagesTATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)Mayank UkaniNo ratings yet

- 2 Way Slab DesignDocument3 pages2 Way Slab DesignAhmedNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Document1 pageSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNo ratings yet

- 12779_1989_Reff2019Document6 pages12779_1989_Reff2019Raju Singh ShekhawatNo ratings yet

- Conformances: Type: NeutralDocument2 pagesConformances: Type: NeutralsampathkumarNo ratings yet

- 2024 Aluminium SheetDocument1 page2024 Aluminium SheetGeorge ChachlakisNo ratings yet

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Document4 pages2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNo ratings yet

- Hes Hot-Dip Galvannealed Steel SheDocument23 pagesHes Hot-Dip Galvannealed Steel ShejleikNo ratings yet

- RCC95 Continuous Beams (Tables)Document9 pagesRCC95 Continuous Beams (Tables)christi SNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document1 pageRCC94 Two-Way Slabs (Tables)curiosity12No ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- (JISF) : Japanes E IndustrialDocument19 pages(JISF) : Japanes E IndustrialTrịnh Thanh TùngNo ratings yet

- EGW Welding Wire Guide for 490MPa SteelDocument2 pagesEGW Welding Wire Guide for 490MPa SteelpratishgnairNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2janithNo ratings yet

- Thermal Cracking CalcDocument1 pageThermal Cracking Calcbogdan_danuletNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- RCC95 Continuous Beams (Tables)Document9 pagesRCC95 Continuous Beams (Tables)Murthy GunaNo ratings yet

- Mat 07000-07149 200411Document5 pagesMat 07000-07149 200411Ronaldo Bandeira RodriguesNo ratings yet

- 35m Tower CheckDocument68 pages35m Tower CheckHarold Jackson MtyanaNo ratings yet

- THG Hooks Forged Hooks Catalogue Sheet PDFDocument5 pagesTHG Hooks Forged Hooks Catalogue Sheet PDFjhonNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetjhonNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675No ratings yet

- Company Name: Design Specifications Nozzles Couplings / SupportsDocument21 pagesCompany Name: Design Specifications Nozzles Couplings / Supportsmohsen ranjbarNo ratings yet

- ETABS 2016 Concrete Frame DesignDocument24 pagesETABS 2016 Concrete Frame DesignFRADESUS De LeonNo ratings yet

- h2066-HASTELLOY C-22 Welding DataDocument4 pagesh2066-HASTELLOY C-22 Welding DataGovindarajalu PadmanabhanNo ratings yet

- IS 5517 - 1993-Hardening & Tempering GradesDocument15 pagesIS 5517 - 1993-Hardening & Tempering GradesMohanrajMJ100% (1)

- 9.50170 - Fiat Auto Welding STDDocument14 pages9.50170 - Fiat Auto Welding STDMohanrajMJNo ratings yet

- MIL-I-17563C - Impregnation StdsDocument18 pagesMIL-I-17563C - Impregnation StdsMohanrajMJNo ratings yet

- MIL-I-17563B - Impregnation STDDocument15 pagesMIL-I-17563B - Impregnation STDMohanrajMJNo ratings yet

- ISO 5700-2013 - Tractors For Agriculture and Forestry - Roll-Over Protective Structures - Static Test Method and AcceptanceDocument44 pagesISO 5700-2013 - Tractors For Agriculture and Forestry - Roll-Over Protective Structures - Static Test Method and AcceptanceMohanrajMJNo ratings yet

- ISO 630-6-2014 - Technical Delivery Conditions For Seismic-Improved Structural Steels For BuildingDocument22 pagesISO 630-6-2014 - Technical Delivery Conditions For Seismic-Improved Structural Steels For BuildingMohanrajMJNo ratings yet

- Gbtâ 3524-2015 enDocument11 pagesGbtâ 3524-2015 enMohanrajMJNo ratings yet

- Haber Process Task 1Document9 pagesHaber Process Task 1Benjamin WatsonNo ratings yet

- Intergard 400+eng+A4+Y+20141215Document2 pagesIntergard 400+eng+A4+Y+20141215salman GtrNo ratings yet

- Astm A571mDocument5 pagesAstm A571mtingNo ratings yet

- Hindustan Petroleum Corporation Limited Chain Link Corporation Limited Chain Link Fencing (Typical)Document1 pageHindustan Petroleum Corporation Limited Chain Link Corporation Limited Chain Link Fencing (Typical)MMNo ratings yet

- 3M Tape SOPDocument2 pages3M Tape SOPManmohan singh ThindNo ratings yet

- Saudi Aramco pipe inspection requirementsDocument2 pagesSaudi Aramco pipe inspection requirementsAbu Anas M.SalaheldinNo ratings yet

- Current MSDS Aluminium Powder Sept2014 (English) PDFDocument7 pagesCurrent MSDS Aluminium Powder Sept2014 (English) PDFSuarez Nuñez ElizabethNo ratings yet

- 21748webtoc - Technology ForumDocument22 pages21748webtoc - Technology ForumapitbhuNo ratings yet

- Civil Engineering Chart Subjectwise in A3 SizeDocument16 pagesCivil Engineering Chart Subjectwise in A3 SizeEr Aman RaahiNo ratings yet

- Asme Hydrotest Pressure Ug 99Document1 pageAsme Hydrotest Pressure Ug 99Vaisakh Somakumar100% (3)

- Glass Fiber Reinforced Gypsum Composites: Standard Specification ForDocument2 pagesGlass Fiber Reinforced Gypsum Composites: Standard Specification ForJesús Luis Arce GuillermoNo ratings yet

- Advanced Materials - JNTUK (R16)Document7 pagesAdvanced Materials - JNTUK (R16)uday kiran thagirchi50% (2)

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorld100% (1)

- Introduction To Electrocoagulation Kaselco: Presented by Bruce J. Lesikar V.P. EngineeringDocument24 pagesIntroduction To Electrocoagulation Kaselco: Presented by Bruce J. Lesikar V.P. Engineeringazerfaz100% (1)

- Pa66 GF30 - Ultramid A3wg6Document2 pagesPa66 GF30 - Ultramid A3wg6armandoNo ratings yet

- Eriks-Technical Manual OringsDocument219 pagesEriks-Technical Manual OringstuprimonvNo ratings yet

- Industrial Practice Report on Bashundhara Paper MillsDocument154 pagesIndustrial Practice Report on Bashundhara Paper MillsMubashwir Billah KhanNo ratings yet

- Law of Multiple Proportions ExplainedDocument7 pagesLaw of Multiple Proportions ExplainedPrecious Owusu-BediakoNo ratings yet

- Catalog From Homey SealantDocument16 pagesCatalog From Homey SealantKelly WuNo ratings yet

- Gorilla Glass Victus PI SheetDocument2 pagesGorilla Glass Victus PI SheetSMITH DESIGN STUDIONo ratings yet

- for Concrete Classification PaperDocument21 pagesfor Concrete Classification PaperJOSE BERRU USHIÑAHUANo ratings yet

- Idges 25-28 PDFDocument37 pagesIdges 25-28 PDFjaganramNo ratings yet

- Is 4031 Part 6 - Compressive StrengthDocument6 pagesIs 4031 Part 6 - Compressive Strengthbhustlero0o75% (4)

- Heartlands Wrought Iron Brochure 2021 Digital v1 Converted Logo Fix CDocument16 pagesHeartlands Wrought Iron Brochure 2021 Digital v1 Converted Logo Fix CZiad MohamedNo ratings yet

- A02 41 (Highlighted)Document1 pageA02 41 (Highlighted)HasmukhNo ratings yet

- List of DIN Standards Pipe Tube and Fittings Standards and SpecificationsDocument14 pagesList of DIN Standards Pipe Tube and Fittings Standards and SpecificationsRakeshKumarSinghNo ratings yet

- Maintenance Painting of Steelwork Manual Provides GuidanceDocument33 pagesMaintenance Painting of Steelwork Manual Provides GuidancerohanZorbaNo ratings yet

- Hydrocarbon For JEE Main and Advanced (ALP)Document10 pagesHydrocarbon For JEE Main and Advanced (ALP)Er. Vineet Loomba (IIT Roorkee)No ratings yet

- Masonry Workshop PracticeDocument126 pagesMasonry Workshop Practicemikeygena1879No ratings yet

- Styrock Brochure ENGDocument6 pagesStyrock Brochure ENGGeorge NakanishiNo ratings yet