Professional Documents

Culture Documents

Specifications: - : User'S Operating Manual For Pid Digital Temperature Controller

Specifications: - : User'S Operating Manual For Pid Digital Temperature Controller

Uploaded by

Anjum ParkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifications: - : User'S Operating Manual For Pid Digital Temperature Controller

Specifications: - : User'S Operating Manual For Pid Digital Temperature Controller

Uploaded by

Anjum ParkarCopyright:

Available Formats

USER’S OPERATING MANUAL FOR PID DIGITAL TEMPERATURE CONTROLLER

(Models: AI 7482 / 7882 / 7782 / 7982 / 7682)

AI-7482 AI-7782 AI-7982 AI-7682 AI-7882

(48 X 48) (72 X 72) (96 X 96) (96 X 48) (48 X 96)

SPECIFICATIONS : - SAFETY INSTRUCTION :

1. DISPLAY TYPE : Dual 4- Digit 7 Segment LED This controller is meant for temperature control

4 Digit Bright White (PV) applications. It is important to read the manual prior to

4 Digit Luminous Green (SV) installing or commissioning of controller. All safety

Model no. AI-7482 AI-7782 AI-7982 AI-7682 AI-7882 related instruction appearing in this manual must be

Display height (PV) 0.36” 0.56” 0.80” 0.36” 0.36”

followed to ensure safety of the operating personnel as

well as the instrument.

Display height (SV) 0.24” 0.39” 0.56” 0.36” 0.36”

STATUS LED’S : OP 1 : Main Control Output GENERAL

OP 2 : Alarm Status v The controller must be configured correctly for intended

SOAK : Soak Timer operation. Incorrect configuration could result in

TUNE : Tuning Status (Only AI-7982) damage to the equipment or the process under control

2. INPUT or it may lead personnel injury.

Sensor input : TC:J,K,R,S,N,T,B & RTD: Pt-100 v The controller is generally part of control panel and in

such a case the terminals should not remain accessible

i

Range : Refer below table.

to the user after installation.

Sensor Type Range Resolution Accuracy

Fe-k(J) T/C 0 ~ 760oC 1 oC

}

MECHANICAL

Cr-AL(K) T/C -99 ~ 1300oC 1 oC v The Controller in its installed state must not come in

(R) T/C 0 ~ 1700oC 1 oC close proximity to any corrosive/combustible gases,

(S) T/C 0 ~ 1700 Co

1 oC caustic vapours, oils, steam or any other process by-

± 1 oC products.

TC - N -99 ~ 1300oC 1 oC

v The Controller in its installed state should not be

TC - T -99 ~ 400oC 1 oC

o

exposed to carbon dust, salt air, direct sunlight or

TC - B 0 ~ 1800 C 1 oC radiant heat.

Pt-100(RTD) -100 ~ 450oC 1 oC v Ambient temperature and relative humidity surrounding

o

Pt-100(RTD 0.1) -99.9 ~ 450.0 C 0.1 oC ± 0.3 oC the controller must not exceed the maximum specified

limit for proper operation of the controller.

Sampling Time : 125 msec. v The controller in its installed state must be protected

Resolution : 1°C/0.1°C(Only for RTD) against excessive electrostatic or electromagnetic

CJC for TC : Built in automatic interferences. Ventilation holes provided on the chassis

LWC for Pt-100 : Built in upto 18E max. of the instrument are meant for thermal dissipation

Digital Filter : 1 to 10 Sec. hence should not be obstructed in the panel.

3. RELAY OUTPUT ELECTRICAL

Contact type : N/O, CM, N/C v The controller must be wired as per wiring diagram & it

Contact Rating : 5A @ 250VAC or 30 VDC must comply with local electrical regulation.

Life expectancy : > 5,00,000 operations v Care must be taken not to connect AC supplies to low

Isolation : Inherent voltage sensor input.

v Circuit breaker or mains s/w with fuse (275V/1A) must

4. SSR DRIVE OUTPUT be installed between power supply and supply terminals

Drive Capacity : 12V @ 30mA. to protect the controller from any possible damage due

Isolation : Non-Isolated. to high voltage surges of extended duration.

5. FUNCTION v Circuit breaker and appropriate fuses must be used for

Output 1 : Main Control output driving high voltage loads to protect the controller from

Output 2 : Programmable any possible damage due to short circuit on loads.

v To minimize pickup of electrical noise, the wiring for low

1) Auxiliary control

voltage DC and sensor input must be routed away from

2) Alarm

high current power cables. Where it is impractical to do

3) Soak timer

this, use shielded ground at both ends.

4) Alarm + Soak timer

v The controller should not be wired to a 3-Phase supply

Control Action : ON-OFF/PID (Select) with unearthed star connection. Under fault condition

Control Mode : Heat/Cool (Select) such supply could rise above 264 VAC which will damage

Compliance : ---- the controller.

v The Electrical noise generated by switching inductive

6. ENVIRONMENTAL loads might create momentary Fluctuation in display,

Operating Range : 0 ~50°C, 5~90% Rh alarm latch up, data loss or permanent damage to the

Storage Humidity : 95% Rh (Non-condensing) instrument. To reduce this use snubber circuit across

7. POWER SUPPLY the load.

Supply Voltage : 90~270VAC, 50/60Hz. v It is essential to install a over Temp. Protection device

Consumption : 4W Maximum. to avoid any failure of heating system. Apart from

8. PHYSICAL spoiling the product, this could damage the process

Housing : ABS Plastic being controlled.

1 OIM AI-7X82 V2.1 Page 1 of 9

CAUTION: To prevent the risk of electrical shock, switch off the power before making/removing any connection or removing

the controller from its enclosure.

MECHANICAL INSTALLATION

The label on the controller identifies the serial number, wiring connections and batch number.

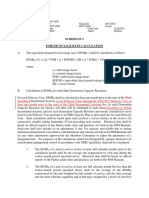

OVER ALL DIMENSIONS & PANEL CUT OUT (IN MM)

MODEL:-AI-7482/7782/7982

TABLE : 1

Dim A B C D E F G H

A E PANEL Model

F

CUTOUT

AI-7482 48 48 8 75 43 44 44 9

AI-7782 72 72 10 65 66 68 68 9

B D G AI-7982 96 96 10 45 89 92 92 9

C H AI-7682 96 48 10 45 89 92 44 9

MODEL : AI - 7882

AI-7882 48 96 10 45 43 44 92 9

PANEL

A E

CUTOUT

F

B D G

C H

MODEL : AI - 7682 INSTALLATION GUIDELINES :

PANEL 1. Prepare the cut-out with proper dimension as shown in figure.

A E CUTOUT F

2. Remove clamp from controller

3. Push the controller through panel cut-out and secure the

controller in its place by tightening the side clamp.

B D G

C H

ELECTRICAL INSTALLATION

The electrical connection diagram is shown on the controller enclosure as below.

SSR1 SSR2

i

SSR1 SSR1 SSR1 SSR2

1 2 3 4 5 6 7 8 9

1 2 3 4 5 1 2 3 4 5 6 1 2 3 4 5 6 7 8 9

11 14 L

NO

13 15

RELAY2

SUPPLY

SSR2

12 15

CM

SSR2

N 14 16

13 16

NC

6 7 8 9 10 7 8 9 10 11 12 10 11 12 13 14 15 16 17 18

L NNO CM NC L N NO CM NC NO CM NC

NO CM NC NO CM NC

10 11 12 13 14 15 16 17 18

SUPPLY SUPPLY

L N NO CM NC NO CM NC RELAY1 RELAY2

RELAY1 RELAY1 RELAY2

SUPPLY

RELAY1 RELAY2

AI-7482 AI-7782 AI - 7982 AI - 7682/7882

FRONT PANEL LAYOUT

i-therm AI-7782 i-therm AI-7982

AI-7682

AI-7482 2

1 2 PV 2

OP1 PV

1 OP1

2 PV

PV

OP2 OP2 SV

3

SOAK SV

3 SOAK SV SV 1

4 7 3 3 OP1 OP2 SOAK

SET AT RESET START

1

OP1 OP2 SOAK TUNE 5 6

5 4 7 AT RESET

SET AT RESET START

4 7

6 SET AT RESET START 4 7

SET START

5 6 5 6

AI - 7482 AI - 7782 AI - 7982 AI - 7682

FRONT PANEL LAYOUT DESCRIPTION :

Sr. NAME FUNCTION

Glows when OP1 is ON & flashes when delay time (dly1) is in operation (if selected mode is ON-

OP1 LED

OFF)

Glows when OP2 is ON & flashes when alarm condition persists even after acknowledged OR

2 5 1 OP2 LED delay time (dly2) is in operation & selected mode is ON-OFF.

AI-7882 SOAK LED Glows when Soak mode is selected & flashes when soak timer is in operation.

1 OP1 6

PV

UPPER It will display (1) Measured value of selected input or Error messages in run mode. (2) Parameters

OP2

AT RESET

2 DISPLAY value in program mode.

SV 7

SOAK

LOWER It will display (1) SP (Main set point) / SP2 (Auxiliary/Alarm) set value / Set Soak time value/

SET START

3 DISPLAY balance or elapsed soak time in run mode. (2) Parameter code in program mode.

SET (1) For SP programming. (2) To access Control mode. (3) To access Configuration mode along

3 4 4 KEY with UP key. (4) To scroll the parameter & to store its value.

SHIFT (1) To increase/alter parameter value in program mode with Up / Dn key.

5 KEY (2) Press for 3sec in programming, this will help to go back to previous parameter.

UP (1) To increase/alter parameter value in program mode. (2) To enter in configuration mode (with

6 KEY SET key). (3) To acknowledge Alarm. (4) To enter in tune mode (with DOWN key).

DOWN

AI - 7882 7 KEY

(1) To decrease/alter parameter value in program mode. (2) To enter in tune mode (with UP key).

2 OIM AI-7X82 V2.1 Page 2 of 9

POWER UP: At power on, following sequence will be prompted on the display till it reaches to Home display mode.

In home display mode, by pressing DOWN key, User can

view the set value of SP1 & SP2 (if OP2 = AUXILIARY or

UPPER

PV ALARM mode) or timer value(if OP2 = soak mode)

DISPLAY

sequentially.

LOWER Here, Lower display will show SP1-value, SP2-value,

SV

DISPLAY

Alarm SP-Value & Timer-value by pressing DOWN key and

VERSION MODEL HOME

it’s respective parameter code (SP1/SP2/AL.SP/SOAK

TIME) by pressing UP key.

PROGRAMMING

USER LIST : To access the user list press SET key once.

PARA LOWER UPPER

RANGE DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

User can change SP1 value using UP/ DOWN keys. Holding the key,

CONTROL

LSPL ~ HSPL will change the value at a faster rate. Press SET key to store the 0°C

SET POINT

desired value & move on to the next parameter.

0.0 °C This parameter will be available only if Enabled in Configuration List.

RAMP

RATE

to

User can set ramp rate/min for SP1 (Set Point) to minimize overshoot. Disable

25.0 °C

This parameter is prompted only if Control Logic for Output1 is

configured for Heat-Cool.

Output 2 will be automatically activated /de-activated w.r.t SP1 & HYS.

OP2 ----------

MODE Output 2 will be permanently Activated (ON). Auto

i

Output 2 will be permanently De-Activated (OFF).

This parameter is prompted if SP2 is Enable & output 2 is configured as

SET (1) Either absolute auxiliary control or as an alarm (High/Low) mode.

POINT 2

LSPL ~ HSPL

(2) Either deviation auxiliary control or as a deviation alarm mode.

0°C

(3) As a band alarm(For all above SP2 has to be enable).

This parameter is prompted only if output 2 is configured as soak timer.

SOAK 1 Sec to Controller starts the execution of soak time as per the mode selected.

TIME 9999 Hrs. Soak timer can be programmed using four different time base in Config.

1 min.

List.

CONTROL LIST : To enter in this mode, press SET & DOWN key simultaneously for 3 sec. User can then set the

following control parameters.

PARA LOWER UPPER

RANGE DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

Set this parameter to 15 (Default LOCK CODE) to access Control List.

LOCK User has a choice to set different Lock Code via USER LOCK CODE in

CODE

1 ~ 9999 0

Config. List.

This parameter will be prompted only if selected control action is PID. It

PROPOR 0.5 sets proportional band over which the output power is adjusted

TIONAL to 5.0°C

BAND 99.9°C depending upon the error (SV-PV). Value of this parameter is

automatically set by Auto tune function.

This parameter will be prompted only if selected control action is PID. It

0

INTEGRAL to sets the time taken by PID algorithm to remove steady state error. Value

TIME

240

3600 Sec. of this parameter is automatically set by auto tune function. If set to ‘0’,

this function will be disabled.

This parameter will be prompted only if selected control action is PID. It

DERIV 0

defines how strongly the controller will react to rate of change of PV.

ATIVE to 60

TIME 300 Sec. Value of this parameter is automatically set by auto tune function. If set

to ‘0’, this function will be disabled.

This parameter will be prompted only if selected control action is PID.

1.0 User can set this value based on process being controlled & type of

CYCLE

TIME

to 16.0 sec.

100.0 Sec. output being selected. For Relay O/P, cycle time should be more than

12sec & for SSR O/P, cycle time should be less than 10sec.

OUTPUT 0.0 % This parameter will be prompted only if selected control action is PID.

POWER to This parameter will decide the maximum output power in % applied to 100 %

LIMIT 100.0 % the load.

This parameter will be prompted only if selected control action is PID.

OUTPUT With this parameter O/P will be Completely OFF after the Set Point +

OFF

1 to10

Offset Value. If Disable, O/P will act Depending upon the PID Value Disable

after Set Point achieved.

3 OIM AI-7X82 V2.1 Page 3 of 9

PARA LOWER UPPER

RANGE DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

This parameter will be prompted only if selected control action is PID.

50 % This parameter allows the User to carry out Auto Tuning function below

TUNE

OFFSET

to the set point. (If tune offset is set to 50 %, tuning will be carried out at 100 %

100 % 50 % of the set point and if set to 100 %, tuning will be carried out at

100 % of the set point.)

This parameter will be prompted only if selected control action is ON -

OFF. It sets the dead band between ON & OFF switching of the Output.

CONTROL

1 to 25 oC Larger value of hysterisis minimize the number of ON-OFF operation to 2°C

HYS

the load. This increases life of actuators like contactors but, also

produces large errors (between PV & SV).

This parameter will be prompted only if selected control action is ON -

0 OFF. It sets the main output Delay time where O/P once turned OFF will

DELAY 1 to turn ON only after Delay time, regardless difference between PV & SP. 0 Sec.

500 Sec.

Also, Delay will be considered at every power ON.

This parameter will be prompted only if selected control mode for

HYS 2 1 to 99 oC output2 is Auxiliary control or an Alarm. The value of this parameter sets 2°C

the dead band between ON & OFF switching of output load.

This parameter will be prompted only if Output2 is configured as an

0 Auxiliary control output OR Control Logic is configured for Heat-Cool. In

DELAY 2 to this mode, it sets the output Delay time where O/P once turned OFF will 0 Sec.

500 Sec. turn ON only after Delay time, regardless difference between PV &

SP2. Also, Delay will be considered at every power ON.

-9.9 This parameter will be prompted only if Control Logic for Output1 is

configured for Heat-Cool.

i

GAP 1 to 0°C

9.9°C SP (set point) will be consider as (SP-Gap1) for heating.

-9.9 This parameter will be prompted only if Control Logic for Output1 is

GAP 2 to configured for Heat-Cool. 0°C

9.9°C SP (set point) will be consider as (SP+Gap2) for cooling.

This parameter will be prompted only if selected control mode for

SOAK 0 Output2 is Soak timer. Depending on end of soak strategy, the value of

TIME to this parameter sets the activation time for OP2 when Soak timer is over. 10 Sec.

DELAY 99 Sec. Setting this parameter to ‘0’ will make OP2 continuously ON at the end

of Soak time till User starts the next cycle.

This parameter defines the permissible deviation of PV from SP during

0.0 soak time cycle. If PV falls outside the Soak band during soak cycle,

SOAK

BAND

to

Timer halts. Timer will start only when PV falls within the soak band. 0 Sec.

99°C.

This parameter is ignored if set to ‘0’.

CONFIGURATION LIST : (1) To enter in this mode, press and hold SET & UP key simultaneously for 3 sec.

(2) Press UP or DOWN key to scroll between parameter options.

(3) Press SET key to store current parameter & move on to the next parameter.

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

Set this parameter to 15 (Default LOCK CODE) to access Config. List.

LOCK

CODE

User have a choice to set different Lock Code via USER LOCK CODE in Config. 0

List.

This parameter value is set according to the type of sensor (Thermocouple or RTD

input) connected to the controller's input terminals.

Sensor Type Range Resolution Accuracy

}

Fe-k(J) T/C 0 ~ 760oC 1 oC

INPUT

Cr-AL(K) T/C -99 ~ 1300oC 1 oC

TYPE

TC - J

o o

(R) T/C 0 ~ 1700 C 1 C

o

± 1 oC

(S) T/C 0 ~ 1700 C o

1 C

TC - N -99 ~ 1300oC 1 oC

TC - T -99 ~ 400oC 1 oC

4 OIM AI-7X82 V2.1 Page 4 of 9

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

This parameter value is set according to the type of sensor (Thermocouple or RTD

input) connected to the controller's input terminals.

INPUT Sensor Type Range Resolution Accuracy

TYPE o o o TC - J

TC - B 0 ~ 1800 C 1 C ±1 C

Pt-100(RTD) -100 ~ 450oC 1 oC ±1 C

o

Pt-100(RTD 0.1) o

-100.0 ~ 450.0 C 0.1 oC ± 0.3 oC

LOWER

SET Sets the minimum limit for set point adjustment. It can be set from minimum

POINT

0°C

specified range of selected sensor to HSPL value.

LIMIT

HIGHER

SET Sets the maximum limit for set point adjustment. It can be set from LSPL value to

400°C

POINT maximum specified range of selected sensor.

LIMIT

Function of this parameter is to add/subtract a constant value to the measured PV

to obtain Final PV for control applications. This parameter value needs to be

PROCESS altered for one of the following reason : -

VALUE 0°C

OFFSET (i) To compensate for known thermal gradient.

(ii)To match the display values with another recorder or indicator measuring the

same PV.

The controller is equipped with an adaptive digital filter which is used to filter out

i

INPUT any extraneous pulses on the PV. The filtered PV Value is used for all PV

6

FILTER dependent functions. If the PV signal is fluctuating due to noise, increase the filter

time constant value.

CONTROL User can select between PID or ON-OFF action algorithm to be adopted for

MODE output. PID

FOR O/P 1

User can select heating logic in which OP1 will remain ON till PV < SP.

(PV increases when output is ON.)

CONTROL

User can select cooling logic in which OP1 will remain ON till PV > SP.

LOGIC (PV decreases when output is ON.) Heat

FOR O/P 1

This parameter will be prompted only if selected input is RTD or RTD.1 and is

used for BOD application. Here OP1 acts as Heating control & OP2 as Cooling

control.

This parameter will be prompted only if selected control action is PID. Setting this

OVER parameter on higher side will proportionally slows down the rate of rise of PV to

SHOOT minimize overshoot (this may cause delay to reach SP). Setting on lower side will

CONTROL

Disable

proportionally or disabling this parameter will increase the rate of rise of PV

POINT (which may cause overshoot). Disable this option if delay is not required to reach

SP.

This parameter will be prompted only if OCP (over shoot control point) is disabled.

When enabled, User can set the desired RAMP rate in USER list.

RAMP

RATE

Disable

When disabled, this parameter will not be prompted in USER list.

This parameter will be prompted only if selected control action is PID.

If Enabled, this parameter will be prompted if user press Up & Down keys

AUTO Simultaneously for 3Sec.

TUNE

Enable

If Disabled, this parameter will not be prompted if user press Up & Down keys

Simultaneously for 3Sec.

5 OIM AI-7X82 V2.1 Page 5 of 9

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

If Enabled, User can View & edit the Set point (SP1) in USER list.

SET

POINT 1

Enable

If disabled, User can only View the Set Point (SP1) but Can not edit it in USER

list.

This parameter will appear only if Control logic is Heat-Cool.

If Enabled, User can set Diff. mode for OUTPUT 2 in USER list.

OUTPUT 2

MODE

Disable

If disabled, User can not set Diff. mode for OUTPUT 2 in USER list.

OUTPUT 2 This parameter will appear only if Control logic is Heat-Cool.

CONTROL 15.0

OP2 will be OFF at Ambient + OP2C value irrespective of output 2 mode.

When NONE is selected, Output 2 will be permanently de-activated.

This parameter allows the user to select output 2 as an ‘Auxiliary’ control.

For options refer Table 3.

OUTPUT 2

This parameter allows the user to select output 2 as an ‘Alarm’ control.

For options refer Table 4. Auxiliary

FUNCTION

This parameter allows the user to select output 2 as a ‘Soak’ mode.

For options refer Table 5.

i

This parameter allows the user to select output 2 to function as both ‘Alarm’ &

‘Soak’. For options refer Table 4 & 5.

By pressing DOWN key, Lower display will Toggle between SP1-value, SP2-

value, Alarm SP-Value(AL.SP) & Timer-value(SOAK).

By this parameter Lower display will only show the SP1-value.

LOWER

DISPLAY SP1

MESSAGE

By this parameter Lower display will only show the Timer value(SOAK TIME).

By this parameter Lower display will show Setpoint till soak timer has not started

and afterwards, it will display the Timer value(SOAK TIME).

This parameter will appear only if Output 2 is set as SOAK/ AL.ST

If Enabled, User can View ramping setpoint.

LOWER

This parameter will appear only if Ramp rate is enabled.

DISPLAY

RAMPING

Enable

If disabled, User can View target setpoint.

SETPOINT

This parameter will appear only if Ramp rate is enabled.

USER Default USER LOCK CODE is 15 to access Control & Configuration List.

LOCK User has a choice to set its own USER LOCK CODE between 1 to 9999, this is to 15

CODE prevent unauthorized access of Control & Configuration List.

TABLE 3 : Below listed options will appear only if OP2 is selected as an Auxiliary Control Mode .

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

If selected, User can set SP2 value independently, irrespective of SP1.

SET

POINT ABS

2 In this mode SP2 is always related with SP1.

User can set SP2 value with deviation of ± 99°C w.r.t SP1.

User can select Heat logic for control Output 2 in which OP2 will remain ON till

PV<SP2 (PV increases when output is ON).

OUTPUT 2

LOGIC

HEAT

User can select Cool logic for control Output 2 in which OP2 will remain ON till

PV> SP2 (PV decreases when output is ON).

If Enabled, User can View & edit the Set point (SP2) in USER list.

SET

POINT Enable

2

If disabled, User can not View or edit Set Point (SP2) in USER list.

6 OIM AI-7X82 V2.1 Page 6 of 9

TABLE 4 : Below listed points will appear only if O/P2 is selected as an Alarm mode. In Alarm mode, Controller

continuously compares PV with either SP (for deviation or Band -alarm) or an independent Alarm set points (for

process high and process low alarm). HYS2 in Control list decides when to switch OFF the Alarm.

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

Direct acting Reverse acting

Low Alarm : OP2 activates when PV<SP2.

OUTPUT-2 ON OUTPUT-2 OFF OUTPUT-2 OFF OUTPUT-2 ON PV

PV

SP2 SP2

High Alarm : OP2 activates when PV>SP2.

OUTPUT-2 OFF OUTPUT-2 ON OUTPUT-2 ON OUTPUT-2 OFF

PV PV

SP2 SP2

Low Deviation Alarm : OP2 activates when PV is less than SP1 ± set deviation

value +Ve +Ve

Sp1 dev SP1 dev

OUTPUT ON OUTPUT OFF OUTPUT OFF OUTPUT ON

PV

PV

SP2 SP2

-Ve -Ve

dev dev

ALARM OUTPUT ON OUTPUT OFF

TYPE PV OUTPUT OFF OUTPUT ON PV Low

SP2 SP2

i

High Deviation Alarm : OP2 activates when PV is greater than SP1 ± set

deviation value +Ve +Ve

SP1 dev SP1 dev

OUTPUT OFF OUTPUT ON OUTPUT ON OUTPUT OFF

PV

SP2 SP2 PV

-Ve -Ve

dev dev

OUTPUT OFF OUTPUT ON PV OUTPUT ON OUTPUT OFF

PV

SP2 SP2

Band Alarm : OP2 activates when PV falls outside the band w.r.t. SP1 in either

direction. SP1

SP1

OUTPUT ON OUTPUT OFF OUTPUT ON OUTPUT OFF OUTPUT ON OUTPUT OFF

PV PV

SP2 SP2 SP2 SP2

User can select direct Alarm Logic in which OP2 will be ON under alarm condition;

otherwise OFF (used for audio visual alarm).

ALARM

LOGIC User can select Reverse Alarm Logic in which OP2 will be ON in normal Direct

conditions & will be OFF under alarm conditions (used to trip the process in alarm

conditions).

If this parameter is set as ‘YES’ & Alarm condition persists, it will Disable Alarm

O/P at power ON.

ALARM

INHIBIT

No

If this parameter is set as ‘NO’ & Alarm condition persists, it will Enable Alarm O/P

at power up.

Once the Alarm is activated, User has following three options to de-activate it.

When PV falls within the programmed limits The Alarm will be de-activated

automatically.

ALARM

ACK. Once the alarm is activated, it remains activated until acknowledged manually by Auto

UP key.

Once the alarm is activated, it can be de-activated either by pressing UP key or

when PV falls within the alarm limits.

If Enabled, User can View & edit the Alarm Set point in USER list.

ALARM

SET Enable

POINT

If disabled, User can not View or edit Alarm Set Point in USER list.

7 OIM AI-7X82 V2.1 Page 7 of 9

TABLE 5 : Below listed option will appear only if OP2 is selected as a soak timer.

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

It defines the behaviour of the controller at the end of soak timer cycle . Options

are as below. If selected, the controller maintain PV at SP indefinitely irrespective

of start or end of a soak timer.

The controller de-energizes OP1 as soon as the soak time is over. Here upper

END OF display will continue to show PV & lower display will show message "start".Next

SOAK cycle will start only when user press START key for 3 sec. BOTH

STRATEGY

The controller energizes OP2 for a time period programmed via (StdL) parameter

at the end of a soak time cycle. User can utilise OP2 for audio/visual indication.

The controller executes both, the Heater OFF and Alarm ON function as

described above.

User can select the timer base of soak time among the four options as shown.

Minutes & Seconds (Range 99 minutes, 59 seconds).

TIME Minutes (Range 9999 minutes).

BASE

SOAK

MMMM

TIMER Hours & Minutes (Range 99 Hours , 59 minutes).

Hours (Range 9999 Hours).

i

If selected, soak timer will increment (from 0 to set value)

(Note:- User can alter the new time value which should be > elapsed time even if

soak timer is running. If user sets new time value < elapsed time, running timer

DIRECTION will be terminated & End of soak Strategy will be executed.

FOR

SOAK DN

TIME If selected ,soak timer will decrement (from set value to 0).

(Note:- User can alter the new time value even when soak timer is running. In this

case, balance time of previous set value will be ignored & new cycle will be

executed.

RESET

If set as ‘YES’, soak time value will not be stored at the time of power failure.

OF

RUNNING NO

SOAK

If set as ‘NO’ at power ON, soak time will continue from stored value.

TIME

(Note: Seconds will not be stored.)

User can define 4 different modes to start the soak timer as follows : -

In this mode, Timer will start after pressing START key for 3 sec., irrespective of

PV.

In this Mode, after power ON Timer starts when PV >= SV. To continue with next

cycle, user has to either switch Power on & off OR press START key for 3 sec

when STRT message is displayed on the lower display.

In this Mode, Timer will start only after pressing START key for 3 sec & PV>=SV

for any of the following conditions.

TIMER

START (1) At every Power ON. MOD 2

MODE (2) Completion of current soak time cycle.

(3) Power failure during soak time is in progress.

In this Mode, Timer will start only after pressing START key for 3 sec & PV>=SV

for any of the following conditions.

(1) At every Power ON.

(2) Completion of current soak time cycle.

After executing start command, if cycle doesn't complete due to power failure,

cycle will continue whenever PV >= SV after restore of power. No need to press

START key.

Note : - 1) User can restart soak time at any moment during its execution, by pressing START key for 3 sec.

8 OIM AI-7X82 V2.1 Page 8 of 9

AUTO TUNING MODE : To enter in this mode, Press and hold SHIFT key for minimum 3 sec.

PARA LOWER UPPER

DESCRIPTION DEFAULT

METER DISPLAY DISPLAY

This function will be executed only if selected control action is PID & Auto tune is

Enable.

AUTO The Auto-tuning function can be initiated by setting this parameter to YES. The

TUNING decimal of LSB flashes till auto tuning function is in progress. During Auto-tuning, NO

MODE The controller learns the process characteristics by itself & calculates required P, I

& D values.

User can cancel or abort this feature by setting this parameter to NO.

USER GUIDE : -

ON-OFF ACTION : In this mode, Output (Relay/SSR) remains ON till actual temperature reaches to the set point value. On

reaching to SP, Output turns OFF & remains OFF till actual temperature drops down (in Heat Logic) or raises (in Cool Logic)

equal to hysterisis set by user. (As shown in Fig. 3.1 & 3.2)

TEMP (°C)

TEMP (°C)

HYSTERISIS

SP AMB HYSTERISIS

SP

AMB

O/P ON OFF ON OFF ON O/P ON OFF ON OFF ON O/P

TIME TIME

HEAT LOGIC/ ON-OFF COOL LOGIC/ ON-OFF

i

Fig : 3.1 Fig : 3.2

AUTO TUNING MODE : In this mode, Controller learns the process characteristics by itself and calculates the required P,I & D

values. It can be performed at any time after power ON but, it is best to start it when the process is at Ambient temperature in order to

minimize overshoot & undershoot. Auto tuning is applied in case of :

(1) Initial set up for a new process.

(2) Substantial change in SP from previous auto tuning value.

(3) Control accuracy is not satisfactory.

If the control performance by using auto-tuning is still unsatisfactory, User can apply further adjustments of P,I & D values as shown in

Table:3 below.

Table: 3

Adjust Symptom Solution

Proportional Band Slow Response Decrease PB

Over Shoot or Oscillations Increase PB

Integral Time Slow Response Decrease Int

Instability or Oscillation Increase Int

Derivative Time Slow Response or Oscillation Decrease Dt

High Over Shoot Increase Dt

ABBREVIATION : C.A. : Control Action NC : Normally Close terminal of relay SP1 : Set Point Value (set temp.)

CJC : Cold junction compensation NO : Normally Open terminal of relay PV : Process Value (actual Tmp.)

CM : Common terminal of relay OP1 : Output 1 SSR : Solid State Relay

LWC : Lead wire (Length)- OP2 : Output 2 T/C : Thermocouple

compensation

Mfgd by: Innovative Instruments & Controls LLP

338, New Sonal Link Service Industrial Premises Co-op Society Ltd,

i Building No.2, Link Road, Malad (W), Mumbai - 400064.

Tel: 022-66939916/17/18;

E-mail : sales@itherm.co.in

Website : www.itherm.co.in

9 OIM AI-7X82 V2.1 Page 9 of 9

You might also like

- TTi Model QPX1200 DC Power Supply Service ManualDocument49 pagesTTi Model QPX1200 DC Power Supply Service ManualT3brzNo ratings yet

- Itc-100 Manual v1 1w57Document9 pagesItc-100 Manual v1 1w57mei krismahariyantoNo ratings yet

- Teacher Guide: Mystery Powder Analysis: Learning ObjectivesDocument3 pagesTeacher Guide: Mystery Powder Analysis: Learning Objectiveswilliam gomezNo ratings yet

- Medidas Eroelectronic PDFDocument4 pagesMedidas Eroelectronic PDFJuan Diego CondeNo ratings yet

- OracleDocument1 pageOracle山口 記世0% (1)

- Bedia Assembly ClsDocument1 pageBedia Assembly ClsezeizabarrenaNo ratings yet

- DTA4848ro delta-User-Manual PDFDocument12 pagesDTA4848ro delta-User-Manual PDFnoriegascribdNo ratings yet

- The Architecture of OmanDocument513 pagesThe Architecture of OmanPavneet Dua100% (17)

- Viewing Positions. Ways of Seeing Film (Linda Williams, (Editor) ) (Z-Library)Document308 pagesViewing Positions. Ways of Seeing Film (Linda Williams, (Editor) ) (Z-Library)Webber TangNo ratings yet

- Brochure SIMRAD Ecdis E5024 SystemDocument2 pagesBrochure SIMRAD Ecdis E5024 SystemwandersonNo ratings yet

- I Therm Temperature ControllerDocument6 pagesI Therm Temperature ControllerVaibhav ShrivastavNo ratings yet

- Ai 5982 Digital Temperature ControllerDocument6 pagesAi 5982 Digital Temperature ControllerAlex RestrepoNo ratings yet

- SYL-2342 ManualDocument8 pagesSYL-2342 ManualAbu SaifNo ratings yet

- Digital Indicating Controller: Db1000 SeriesDocument8 pagesDigital Indicating Controller: Db1000 SeriesChoirul MutamamNo ratings yet

- Tense DT-96EM DT-72EM DT-48EM enDocument4 pagesTense DT-96EM DT-72EM DT-48EM enavocelNo ratings yet

- E-70-Ö Digital Controller User Manual: 1. Description 3. DimensionsDocument2 pagesE-70-Ö Digital Controller User Manual: 1. Description 3. DimensionsHendra GunawanNo ratings yet

- Rob50 221 Siemens Temperature ControllerDocument5 pagesRob50 221 Siemens Temperature ControlleradamsvillanuevaNo ratings yet

- Autonics TCN Manual PDFDocument2 pagesAutonics TCN Manual PDFDiego AlanizNo ratings yet

- Tech Specs: Temperature ControllerDocument2 pagesTech Specs: Temperature Controllershruti JadhavNo ratings yet

- Syl-1512A2 Pid Temperature Controller Instruction Manual Instruction ManualDocument5 pagesSyl-1512A2 Pid Temperature Controller Instruction Manual Instruction ManualTony GaryNo ratings yet

- Tense DT-Y DT AX en PDFDocument4 pagesTense DT-Y DT AX en PDFAmri ChakerNo ratings yet

- Dt109a / Dt107a / Dt106a / Dt105a / Dt104a Auto-Tune Pid Temperature ControllerDocument4 pagesDt109a / Dt107a / Dt106a / Dt105a / Dt104a Auto-Tune Pid Temperature Controlleralaa suhailNo ratings yet

- Conversor Temperatura DATEXELDocument2 pagesConversor Temperatura DATEXELsimonNo ratings yet

- RS Temp Controller Instruction SheetDocument4 pagesRS Temp Controller Instruction SheetToni CorripioNo ratings yet

- PIM-120 Protectowire Single Zone Mini-Interface Module: Technical Data and Installation GuideDocument2 pagesPIM-120 Protectowire Single Zone Mini-Interface Module: Technical Data and Installation GuideAnonymous tCin8XNo ratings yet

- 2d Insulation Resistance Monitor 6Document6 pages2d Insulation Resistance Monitor 6john smithNo ratings yet

- 3300 Power Supplies DatasheetsDocument9 pages3300 Power Supplies DatasheetsSyed Mohammad NaveedNo ratings yet

- Multispan TC-19Document4 pagesMultispan TC-19Karan SolankiNo ratings yet

- Mks - TksDocument12 pagesMks - TksNguyen Duong HieuNo ratings yet

- Manualportugues Txrail Usb Transmitter 4-20ma v20x B enDocument4 pagesManualportugues Txrail Usb Transmitter 4-20ma v20x B enLizandro FernandesNo ratings yet

- Catalogue tr-7543Document2 pagesCatalogue tr-7543arupamguria05No ratings yet

- BN TACH100 Standalone Digital Tachometer Datasheet 176063Document9 pagesBN TACH100 Standalone Digital Tachometer Datasheet 176063Yasmine SalehNo ratings yet

- TC9102 ManualDocument16 pagesTC9102 Manualأياام زمانNo ratings yet

- English: Operating InstructionsDocument23 pagesEnglish: Operating InstructionsCarloxs YTNo ratings yet

- Temperature Monitoring & Protection: FeaturesDocument2 pagesTemperature Monitoring & Protection: FeaturesCARLOS LÓPEZNo ratings yet

- NL1150D 24Document1 pageNL1150D 24carolinammiyashiroNo ratings yet

- Smartline: Stt750 Smartline Temperature Transmitter Specification 34-Tt-03-16, January 2020Document17 pagesSmartline: Stt750 Smartline Temperature Transmitter Specification 34-Tt-03-16, January 2020lataNo ratings yet

- LP1100D 12mdaDocument1 pageLP1100D 12mdalucasmosnaNo ratings yet

- Dynalco SST-2000A.data SheetDocument2 pagesDynalco SST-2000A.data Sheetalimoya13No ratings yet

- Phase ProtektorDocument3 pagesPhase ProtektorChristopher WaltersNo ratings yet

- KLT11D en User-ManualDocument2 pagesKLT11D en User-ManualConstantin virgil RusuNo ratings yet

- Ch402 - 403 - OPDocument2 pagesCh402 - 403 - OPhp691550% (2)

- ETC100Document3 pagesETC100Arief KrisbiantoroNo ratings yet

- Compact General Purpose ControllersDocument12 pagesCompact General Purpose ControllersCarlos GusmaoNo ratings yet

- 1508333679MP 5200Document20 pages1508333679MP 5200engenhariahabNo ratings yet

- Raychem DS H56865 920series enDocument6 pagesRaychem DS H56865 920series ensasanchez3No ratings yet

- DT AX enDocument4 pagesDT AX enAbdou BouachraNo ratings yet

- Sra-T Indoor Temperature Sensor: FeaturesDocument2 pagesSra-T Indoor Temperature Sensor: FeatureschinitnNo ratings yet

- Service Manual: LCD Monitor Acer G185H&G195HDocument73 pagesService Manual: LCD Monitor Acer G185H&G195HRodolfo CarruyoNo ratings yet

- PID+Fuzzy Temperature ControllerDocument23 pagesPID+Fuzzy Temperature ControllerWilly TurdoNo ratings yet

- PC-programmable 2-Wire Transmitter C202/C202X: For Pt100 InputDocument2 pagesPC-programmable 2-Wire Transmitter C202/C202X: For Pt100 InputantonNo ratings yet

- D5072-087 DTS0434Document2 pagesD5072-087 DTS0434mojinjoNo ratings yet

- ST251 30MHzDocument18 pagesST251 30MHzTushar PatilNo ratings yet

- U5015 Specifcations 90 1217 2.2Document2 pagesU5015 Specifcations 90 1217 2.2julioNo ratings yet

- Tlc3-Fcr-T Intelligent Fan Coil Controller: FeaturesDocument10 pagesTlc3-Fcr-T Intelligent Fan Coil Controller: FeatureschinitnNo ratings yet

- Netsure 801 Ca7 DatasheetDocument4 pagesNetsure 801 Ca7 DatasheetALEX ALEXNo ratings yet

- Installation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92Document22 pagesInstallation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92carlos_sagitarioNo ratings yet

- Microprocessor-Based Digital Electronic Controller: Vr. 01 (I - GB) - Cod.: ISTR 00540Document5 pagesMicroprocessor-Based Digital Electronic Controller: Vr. 01 (I - GB) - Cod.: ISTR 00540Oscar Fuentes QuiñilenNo ratings yet

- Smart TripDocument2 pagesSmart TripkaicyemNo ratings yet

- PIDDocument33 pagesPIDinstind39No ratings yet

- Service Manuals LG TV PLASMA 42PB4D 42PB4D Service ManualDocument59 pagesService Manuals LG TV PLASMA 42PB4D 42PB4D Service Manual邱政鋒100% (1)

- Circuito Integrado TA8207KDocument11 pagesCircuito Integrado TA8207KIberê CamposNo ratings yet

- TS81B/TS84B/TS85B/TS87B/TS89B: Instruction ManualDocument6 pagesTS81B/TS84B/TS85B/TS87B/TS89B: Instruction Manualchienhuynh108No ratings yet

- T20 ENG r.1.2Document8 pagesT20 ENG r.1.2Gelu BordeaNo ratings yet

- Liftman Electric Pallet Truck-Lm Ept2500tDocument3 pagesLiftman Electric Pallet Truck-Lm Ept2500tAnjum ParkarNo ratings yet

- LIFTMAN HAND PALLET TRUCK LM HPT5000 550-685 x1150-1220 NY - PUDocument2 pagesLIFTMAN HAND PALLET TRUCK LM HPT5000 550-685 x1150-1220 NY - PUAnjum ParkarNo ratings yet

- Pneumatic Strapping ToolDocument1 pagePneumatic Strapping ToolAnjum ParkarNo ratings yet

- Recycling of Condensation Plastics: GPEC 2004 Paper Abstract #52Document8 pagesRecycling of Condensation Plastics: GPEC 2004 Paper Abstract #52Anjum ParkarNo ratings yet

- C9a Masses and Empirical FormulaDocument27 pagesC9a Masses and Empirical FormulaBaciu Florina GabrielaNo ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- From Research To Revenue: Module 3: Preparation of Patent Search & Analysis ReportDocument34 pagesFrom Research To Revenue: Module 3: Preparation of Patent Search & Analysis ReportBanty MehtaNo ratings yet

- Passmore - 100 Years PhilosophyDocument14 pagesPassmore - 100 Years Philosophyalfonsougarte0% (2)

- ABB OVRH SPD Catalog 090417 RebrandDocument20 pagesABB OVRH SPD Catalog 090417 RebrandIvan HerreraNo ratings yet

- How To Deploy EPGDocument6 pagesHow To Deploy EPGcavendisuNo ratings yet

- Lora (Long Range) and Lorawan Technology For Iot Applications in Covid-19 PandemicDocument4 pagesLora (Long Range) and Lorawan Technology For Iot Applications in Covid-19 Pandemicamjad khanNo ratings yet

- Resume DST Ritunesh KumarDocument2 pagesResume DST Ritunesh KumarRitunesh KumarNo ratings yet

- Transparency in Food Supply Chains A Review of Enabling Technology SolutionsDocument8 pagesTransparency in Food Supply Chains A Review of Enabling Technology SolutionsAnkitNo ratings yet

- Pareidolia: Why We See Faces in Hills, The Moon and ToastiesDocument4 pagesPareidolia: Why We See Faces in Hills, The Moon and ToastiesMichael SmithNo ratings yet

- Timetable 22-23 14 Juli 2022Document18 pagesTimetable 22-23 14 Juli 2022Luhut GultomNo ratings yet

- iNTRO TO TechnopreneurshipDocument8 pagesiNTRO TO Technopreneurshipjun junNo ratings yet

- Dagmar Richter Spazieren BerlinDocument15 pagesDagmar Richter Spazieren Berlinpescado13No ratings yet

- Frank Bunker Gilbreth Sr. - WikipediaDocument4 pagesFrank Bunker Gilbreth Sr. - WikipediajonNo ratings yet

- Top Engg CollegesDocument33 pagesTop Engg Collegessavan kalakarNo ratings yet

- Force Outage CalculationDocument3 pagesForce Outage CalculationLuthfi Yulian FikriNo ratings yet

- Test ReportDocument54 pagesTest ReportSiva NandhamNo ratings yet

- Evaluating Construction Project Success With Use of The M-Topsis MethodDocument8 pagesEvaluating Construction Project Success With Use of The M-Topsis MethodMagno A. GonzNo ratings yet

- Java Primer 1: Types, Classes and OperatorsDocument27 pagesJava Primer 1: Types, Classes and OperatorsArjun SinghNo ratings yet

- QFT Strategies For TeachersDocument8 pagesQFT Strategies For TeachersPierre TomaselloNo ratings yet

- Attacking Antivirus Software's Kernel DriverDocument33 pagesAttacking Antivirus Software's Kernel Driverdarkasterion2009No ratings yet

- Middlebrook S Extra Element TheoremDocument10 pagesMiddlebrook S Extra Element TheoremAnushree SaranNo ratings yet

- Unit 5: Prof. Praveen P. Rathod Praveen - Rathod@viit - Ac.inDocument50 pagesUnit 5: Prof. Praveen P. Rathod Praveen - Rathod@viit - Ac.inPraveen RathodNo ratings yet

- Tpc8074 Tpc8074 Tpc8074 Tpc8074: Mosfets Silicon N-Channel Mos (U-Mos )Document9 pagesTpc8074 Tpc8074 Tpc8074 Tpc8074: Mosfets Silicon N-Channel Mos (U-Mos )Alberto MattiesNo ratings yet

- ServiceManuals LG TV LCD 32LE5510 32LE5510 Service ManualDocument44 pagesServiceManuals LG TV LCD 32LE5510 32LE5510 Service Manualkemal127No ratings yet