Demo Script: (Internal Document)

Uploaded by

Gabriel NetoDemo Script: (Internal Document)

Uploaded by

Gabriel Neto- Demo Script Overview

- Technical Requirements

- Story Flow

- Step-By-Step Guide

- Document Updates Notes

- Appendix One: Document Number Template

- Appendix Two: Working in the SCM Demo Cloud

DEMO SCRIPT (INTERNAL DOCUMENT)

EWM Transportation Cross Docking

Scenario ID 8100

Cross Industry

General Information Extended Warehouse Management

Logistics and Fulfillment Management

All regions

Authors Jörg Michaelis, SAP Consulting

Frank Overgoor, SAP Consulting

Hanna Huelss, SAP CoE Value Prototyping

Date Last Updated April 2, 2012

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

2

© COPYRIGHT 2012 SAP AG. ALL RIGHTS RESERVED.

No part of this publication may be reproduced or transmitted in any form or for any purpose without the express

permission of SAP AG. The information contained herein may be changed without prior notice. Some software

products marketed by SAP AG and its distributors contain proprietary software components of other software vendors.

Microsoft, Windows, Excel, Outlook, and PowerPoint are registered trademarks of Microsoft Corporation.

IBM, DB2, DB2 Universal Database, System i, System i5, System p, System p5, System x, System z, System z10,

System z9, z10, z9, iSeries, pSeries, xSeries, zSeries, eServer, z/VM, z/OS, i5/OS, S/390, OS/390, OS/400, AS/400,

S/390 Parallel Enterprise Server, PowerVM, Power Architecture, POWER6+, POWER6, POWER5+, POWER5,

POWER, OpenPower, PowerPC, BatchPipes, BladeCenter, System Storage, GPFS, HACMP, RETAIN, DB2 Connect,

RACF, Redbooks, OS/2, Parallel Sysplex, MVS/ESA, AIX, Intelligent Miner, WebSphere, Netfinity, Tivoli and Informix

are trademarks or registered trademarks of IBM Corporation. Linux is the registered trademark of Linus Torvalds in the

U.S. and other countries.

Adobe, the Adobe logo, Acrobat, PostScript, and Reader are either trademarks or registered trademarks of Adobe

Systems Incorporated in the United States and/or other countries.

Oracle is a registered trademark of Oracle Corporation.

UNIX, X/Open, OSF/1, and Motif are registered trademarks of the Open Group.

Citrix, ICA, Program Neighborhood, MetaFrame, WinFrame, VideoFrame, and MultiWin are trademarks or registered

trademarks of Citrix Systems, Inc.

HTML, XML, XHTML and W3C are trademarks or registered trademarks of W3C®, World Wide Web Consortium,

Massachusetts Institute of Technology.

Java is a registered trademark of Sun Microsystems, Inc.

JavaScript is a registered trademark of Sun Microsystems, Inc., used under license for technology invented and

implemented by Netscape.

SAP, R/3, xApps, xApp, SAP NetWeaver, Duet, PartnerEdge, ByDesign, SAP Business ByDesign, and other SAP

products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of

SAP AG in Germany and in several other countries all over the world. All other product and service names mentioned

are the trademarks of their respective companies. Data contained in this document serves informational purposes only.

National product specifications may vary.

These materials are subject to change without notice. These materials are provided by SAP AG and its affiliated

companies ("SAP Group") for informational purposes only, without representation or warranty of any kind, and SAP

Group shall not be liable for errors or omissions with respect to the materials. The only warranties for SAP Group

products and services are those that are set forth in the express warranty statements accompanying such products and

services, if any. Nothing herein should be construed as constituting an additional warranty.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

3

TABLE OF CONTENTS

1 Demo Script Overview............................................................................................................5

1.1 Demo Description 5

1.2 Protagonists 5

1.3 Business Pain Points 5

1.4 Key Messages and Value Proposition 5

1.5 Story Flow Summary 5

2 Technical Requirements........................................................................................................7

2.1 Prerequisites 7

2.2 System Access Information 7

2.2.1 System Landscape 7

2.2.2 System Access 7

2.2.3 Users 7

2.2.4 Data 7

2.3 Release for Used Components 8

3 Story Flow................................................................................................................................9

4 Step-By-Step Guide..............................................................................................................10

4.1 Step by Step Demo Script 10

4.1.1 Creating the Sales Order in ECC 10

4.1.2 Creating the Outbound Delivery in ECC 11

4.1.3 Warehouse Processing in EWM12

4.1.4 Looking up the Warehouse Order in the EWM Warehouse Monitor 13

4.1.5 Confirm the Stock Removal with RF 14

4.1.6 Posting the Goods Issue 15

4.1.7 Looking up the Cross Docking Delivery Pair 16

4.1.8 Looking up the Delivery in the Cross Docking Warehouse 17

4.1.9 Creating the Unloading Warehouse Task 18

4.1.10 Confirming the Unloading Warehouse Task by RF 18

4.1.11 Looking up the Cross Docking Delivery Pair and Checking the GR 19

4.1.12 Confirming the Cross Docking Warehouse Task by RF 20

4.1.13 Looking up the Outbound Delivery Order 22

4.1.14 Confirming the Loading Warehouse Task by RF 22

4.1.15 Posting the Goods Issue in the Cross Docking Warehouse 23

4.1.16 Looking up the Cross Docking Delivery Pair 24

5 Document Updates Notes....................................................................................................26

6 Appendix One: Document Number Template....................................................................27

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

4

7 Appendix Two: Working in the SCM Demo Cloud.............................................................28

7.1.1 Using the RF Device in the Demo Cloud 28

7.1.2 Using the Access Points in the Cloud 28

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

5

1 DEMO SCRIPT OVERVIEW

2 Demo Description

Transportation cross-docking supports the consolidation of deliveries from different supplying warehouses into

common shipments to a customer or to another receiving warehouse. This consolidation can take place at one or more

intermediate warehouses along the route to the destination; you can forward the goods at intermediate warehouses

without needing to store or pack them (in essence, moving the goods “across the dock” from receiving to shipping).

The demo scenario here starts with a sales order and in turn an outbound delivery created in ECC system. Based on

the shipping plant and ship-to-party, system decides a cross-docking route and the delivery is routed through an

intermediate warehouse. We use the Transportation Cross-Docking Monitor in the ECC system at any time to see the

current transportation route for a given shipment. The report reflects the information as of goods receipt by a

warehouse; when the warehouse processes the delivery and posts goods issue to the next warehouse, the ECC

system receives the updated information. This scenario uses RF to perform warehouse tasks and also tracks the

planned and expected events in SAP Event Management (EM).

3 Protagonists

Sales executive

Warehouse Manager

Warehouse Operator

4 Business Pain Points

Transportation chain efficiency, with consolidation of shipments over same route/s

Material handling efficiency in the warehouse

Monitoring of the shipment over the transportation route

RF based process execution

5 Key Messages and Value Proposition

With SAP EWM you can reduce warehouse costs by minimizing product handling. Cross docking lets you transport

products directly from goods receipt to goods issue, thereby increasing the number of handling units processed and

expediting the fulfillment of urgent orders while reducing processing and storage costs. Either SAP EWM gets the

information, if cross-docking is to be executed from another system such as SAP ERP, or it makes this decision itself,

such as in opportunistic cross docking that SAP EWM triggers itself. SAP EWM offers a number of cross docking

functionalities, including:

Pick from goods receipt and push deployment

Transportation cross-docking (highlighted in this scenario)

Retail merchandise distribution

SAP EWM–triggered opportunistic cross-docking

6 Story Flow Summary

The scenario demonstrates transportation cross-docking process starting with a sales order and in turn an outbound

delivery created in ECC system. Based on the shipping plant and ship-to-party, system decides a cross-docking route

and the delivery is routed through an intermediate warehouse. The various steps in the demo flow are summarized as

below:

Sales executive creates a sales order, in the ECC system and in turn creates a corresponding outbound delivery.

The delivery is replicated in EWM to create corresponding EWM Outbound delivery order.

Picking task is automatically created for the delivery.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

6

The picking warehouse task is confirmed and goods are packed during picking.

Goods issue is posted against the delivery.

A pair of cross-docked deliveries is created to route the material through an intermediate warehouse.

The pair is replicated into EWM to create corresponding inbound delivery and outbound delivery order in the EWM.

Inbound delivery is unloaded and a follow up cross-docking task is created.

Cross-docking task is confirmed to move the HU from receipt area to issue staging area.

The HU is loaded and issue is posted against the outbound delivery.

The movement of the stock and status progress against the deliveries can be monitored in the cross-docking monitor

using SAP Event Management.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

7

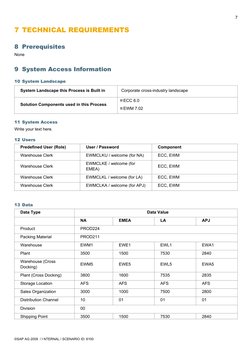

7 TECHNICAL REQUIREMENTS

8 Prerequisites

None

9 System Access Information

10 System Landscape

System Landscape this Process is Built in Corporate cross-industry landscape

ECC 6.0

Solution Components used in this Process

EWM 7.02

11 System Access

Write your text here.

12 Users

Predefined User (Role) User / Password Component

Warehouse Clerk EWMCLKU / welcome (for NA) ECC, EWM

EWMCLKE / welcome (for

Warehouse Clerk ECC, EWM

EMEA)

Warehouse Clerk EWMCLKL / welcome (for LA) ECC, EWM

Warehouse Clerk EWMCLKA / welcome (for APJ) ECC, EWM

13 Data

Data Type Data Value

NA EMEA LA APJ

Product PROD224

Packing Material PROD211

Warehouse EWM1 EWE1 EWL1 EWA1

Plant 3500 1500 7530 2840

Warehouse (Cross

EWM5 EWE5 EWL5 EWA5

Docking)

Plant (Cross Docking) 3800 1600 7535 2835

Storage Location AFS AFS AFS AFS

Sales Organization 3000 1000 7500 2800

Distribution Channel 10 01 01 01

Division 00

Shipping Point 3500 1500 7530 2840

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

8

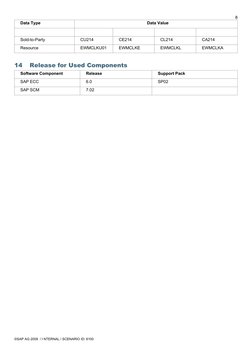

Data Type Data Value

Sold-to-Party CU214 CE214 CL214 CA214

Resource EWMCLKU01 EWMCLKE EWMCLKL EWMCLKA

14 Release for Used Components

Software Component Release Support Pack

SAP ECC 6.0 SP02

SAP SCM 7.02

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

9

15 STORY FLOW

The scenario demonstrates transportation cross-docking process starting with a sales order and in turn an outbound

delivery created in ECC system. Based on the shipping plant and ship-to-party, system decides a cross-docking route

and the delivery is routed through an intermediate warehouse. We use the Transportation Cross-Docking Monitor in the

ECC system at any time to see the current transportation route for a given shipment. The report reflects the information

as of goods receipt by a warehouse; when the warehouse processes the delivery and posts goods issue to the next

warehouse, the ECC system receives the updated information.

Sales executive creates a sales order, in the ECC system and in turn creates a corresponding outbound delivery. The

delivery is replicated in EWM to create corresponding EWM Outbound delivery order.

Picking task is automatically created for the delivery. The picking warehouse task is confirmed and goods are packed

during picking. Goods issue is posted against the delivery.

A pair of cross-docked deliveries is created to route the material through an intermediate warehouse. The pair is

replicated into EWM to create corresponding inbound delivery and outbound delivery order in the EWM.

Inbound delivery is unloaded and a follow up cross-docking task is created. Cross-docking task is confirmed to move

the HU from receipt area to issue staging area. The HU is loaded and issue is posted against the outbound delivery.

The scenario uses RF to perform warehouse tasks and also tracks the planned and expected events in SAP Event

Management (EM).

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

10

16 STEP-BY-STEP GUIDE

17 Step by Step Demo Script

18 Creating the Sales Order in ECC

Note that you always log on to NWBC via the ECC System. This is because the roles for all systems

are maintained in ECC.

This script requires you to note down several document numbers. Here is a handy template that you

can can use.

1. Log on to the ECC System with your user and password welcome.

1. You now create a sales order:

NWBC: Logistics > Sales and Distribution > Sales > Order > Create

In the ECC system: SAP Easy Access Logistics > Sales and Distribution > Sales > Order > Create

Favorite: Create Sales Order

TA: VA01

2. Enter the following data:

Field Data

Order Type OR

Sales

Organ

3000 (NA), 1000 (EMEA), 2800 (APJ) 7500 (LA)

izatio

n

Distribution

10 (North America), 01 (EMEA), 01 (Asia Pacific) 01 (Latin

Chan

America)

nel

Division 00 in all regions

3. Choose Enter.

4. Enter the following data:

Field Data

Sold-to-

CU214 (North America), CE214 (EMEA), CA214 (Asia

Part

Pacific) CL214 (Latin America)

y

Material PROD224

Quantity 4

3500 (North America), 1500 (EMEA), 2840 (Asia Pacific)

Plant

7530 (Latin America)

5. Choose Enter.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

11

6. Choose .

7. Write down the Sales Order number.

19 Creating the Outbound Delivery in ECC

1. On the Create Standard Order screen, from the menu choose Sales Document > Deliver.

or

NWBC: Logistics > Logistics Execution > Outbound Delivery > Create > Single Document >

Create Outbound Dlv. with Order Ref.

In the SAP Easy Access: Logistics > Logistics Execution > Outbound Process > Goods Issue

for Outbound Delivery > Outbound Delivery > Create > Single Document > With Reference to

a Sales Order

Favorite: Create Outbound Dlv. with Order Ref.

TA: VL01N

8. Enter the following data:

Field Data

Shippi

n

g

P 3500 (North America), 1500 (EMEA), 2840 (Asia Pacific) 7530

o (Latin America)

i

n

t

Selecti Today’s date + seven days

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

12

o

n

D

a

t

e

Order Sales order noted earlier

9. Choose Enter.

10. Choose .

11. Write down the Outbound Delivery number.

20 Warehouse Processing in EWM

1. If required, log on to the EWM System client 890 with your user and password welcome.

You now look up the EWM outbound delivery.

12. NWBC: Extended Warehouse Management > Delivery Processing > Outbound Delivery > Maintain

Outbound Delivery Order

SAP Easy Access: Extended Warehouse Management > Delivery Processing > Outbound Delivery >

Maintain Outbound Delivery Order

Favorites: Maintain Outbound Delivery Order

TA: /N/SCWM/PRDO

You should be in warehouse EWM1, EWE1, EWA1 or EWL1 depending on your region

13. If you are not in the correct warehouse choose , enter the correct warehouse then choose .

14. In the Find field, select ERP Document then enter the ERP Outbound Delivery order number created in

the ERP system.

15. Choose .

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

13

16. Note the EWM Outbound Document number.

21 Looking up the Warehouse Order in the EWM Warehouse Monitor

1. To call up the warehouse monitor

NWBC: Extended Warehouse Management > Monitoring > Warehouse Monitor

In the EWM system: SAP Easy Access: Extended Warehouse Management > Monitoring >

Warehouse Monitor

Favorites: Warehouse Management Monitor

TA: /SCWM/MON

17. In your Warehouse Monitor session choose Outbound > Documents then double-click on Outbound

Delivery Order.

18. In the Outbound Delivery Order field enter your EWM Outbound Document number.

19. Choose .

20. Select the line if required.

21. Choose .

22. Note the Warehouse Order number.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

14

22 Confirm the Stock Removal with RF

1. To log on to the RF environment:

NWBC: Extended Warehouse Management > Execution > RF Device or Log on to RF

Environment

In the EWM System: SAP Easy Access: Extended Warehouse Management > Execution >

Log on to RF Environment

Favorites: RF Environment

TA: /N/SCWM/RFUI

23. Enter the following data:

Field Data

Warehouse EWM1 (NA), EWE1 (EMEA), EWA1 (APJ), EWL1 (LA)

EWMCLKU01 (NA), EWMCLKE01 (EMEA), EWMCLKA01

Resource

(APJ) EWMCLKL01 (LA)

Device Pres

24. Choose Enter.

25. Choose .

26. Choose .

27. Enter the your noted Warehouse Order number.

28. Choose Enter twice.

29. Enter packaging material “PACK211” in the field “Pack. Mat.

30. Choose .

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

15

31. Choose .

32. To verify the fields, copy and paste them into the input fields.

33. Choose Enter twice.

After the verification the system shows the destination where to bring the pallet.

34. To verify the fields, copy and paste them into the input fields.

35. Choose ENTER twice.

36. Choose F7.

37. Choose F1 to logoff.

38. Choose F1 (not required in the Cloud with RF Device).

23 Posting the Goods Issue

1. NWBC: Extended Warehouse Management > Delivery Processing > Outbound Delivery >

Maintain Outbound Delivery Order

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

16

In the EWM system: SAP Easy Access: Extended Warehouse Management > Delivery

Processing > Outbound Delivery > Maintain Outbound Delivery Order

Favorites: Maintain Outbound Delivery Order

TA: /N/SCWM/PRDO

39. In the Find field select Outbound delivery order, then enter your three figure EWM document number.

40. Choose .

41. Choose .

24 Looking up the Cross Docking Delivery Pair

1. NWBC: Logistics > Logistics Execution > Transportation Cross Docking > Transportation

Cross Docking Monitor

In the ECC system: SAP Easy Access Logistics : Logistics > Logistics Execution >

Transportation Cross Docking > Transportation Cross Docking Monitor

Favorites: Transportation Cross-Docking Monitor

TA: /SPE/CDMON

42. Enter the ERP Outbound Delivery number. 8********** in the field Delivery Number.

43. Choose .

44. Choose to expand all nodes

For one plant – the cross docking plant - you see two document numbers: The upper number is the

ERP Inbound Delivery, the lower number is the second ERP Outbound Delivery.

45. Note down the ERP Inbound Delivery number and the second ERP Outbound Delivery number.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

17

46. Double click on the outbound delivery with the green light.

47. At the top right of the screen, choose to show the delivery details.

48. Choose and then the tab “SAP Event Mgmt.”

25 Looking up the Delivery in the Cross Docking Warehouse

1. NWBC: Extended Warehouse Management → Delivery Processing > Inbound Delivery >

Maintain Inbound Delivery

In the EWM system: SAP Easy Access: Extended Warehouse Management →Delivery

Processing > Inbound Delivery > Maintain Inbound Delivery

Favorites: Maintain Inbound Delivery

TA: /SCWM/PRDI

49. Choose .

50. Enter the cross docking warehouse for your region EWM5 (NA), EWE5 (EMEA), EWA5 (APJ), EWL5

(LA).

51. Choose .

52. In the Find field, select ERP Document.

53. Enter your ERP Inbound Delivery number.

54. Choose .

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

18

55. Note your EWM Inbound Document number.

56. On the HU tab, note the number of the Handling Unit.

26 Creating the Unloading Warehouse Task

1. On the Maintain Inbound Delivery screen, select the Inbound Delivery.

57. From the menu, choose Inbound Delivery Follow-On Functions Warehouse Task.

58. Choose the Handling Units tab.

59. Choose .

27 Confirming the Unloading Warehouse Task by RF

1. To log on to the RF environment:

NWBC: Extended Warehouse Management > Execution > RF Device or Log on to RF

Environment

In the EWM system: SAP Easy Access: Extended Warehouse Management > Execution >

Log on to RF Environment

Favorites: RF Environment

TA: /N/SCWM/RFUI

60. Enter the following data:

Field Data

Warehouse EWM5 (NA), EWE5 (EMEA), EWA5 (APJ), EWL5 (LA)

Resource EWMCLKCDU01 (NA), EWMCLKCDE01 (EMEA),

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

19

EWMCLKCDA01 (APJ) EWMCLKCDL01 (LA)

Device Pres

61. Choose Enter.

62. Choose .

63. Choose .

64. Choose .

65. Enter your three figure EWM Inbound Document number from the cross docking warehouse.

66. Choose Enter twice.

67. Enter the Handling Unit from the cross docking warehouse .

68. Choose Enter twice.

69. Copy and paste into the validation field.

70. Choose Enter twice.

71. To confirm that the unloading is completed, choose F1 Yes.

72. Choose F7

73. Choose F1 to logoff.

74. Choose F1.

28 Looking up the Cross Docking Delivery Pair and Checking the GR

1. NWBC: Logistics > Logistics Execution > Transportation Cross Docking > Transportation

Cross Docking Monitor

In the ECC system: SAP Easy Access Logistics : Logistics > Logistics Execution >

Transportation Cross Docking > Transportation Cross Docking Monitor

Favorites: Transportation Cross Docking Monitor

TA: /SPE/CDMON

75. Enter your first ERP Outbound Delivery number. 8**********.

76. Choose .

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

20

77. Choose to expand all nodes

78. Double click on the outbound delivery with the green light.

79. At the top right of the screen, choose to show the delivery details.

80. Choose and then the tab “SAP Event Mgmt.”

Note: The goods receipt has been posted

29 Confirming the Cross Docking Warehouse Task by RF

1. To log on to the RF environment:

NWBC: Extended Warehouse Management > Execution > RF Device or Log on to RF

environment

In the EWM system: SAP Easy Access: Extended Warehouse Management > Execution >

Log on to RF Environment

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

21

Favorites: RF Environment

TA: /N/SCWM/RFUI

81. If required, enter the following data:

Field Data

Warehouse EWM5 (NA), EWE5 (EMEA), EWA5 (APJ), EWL5 (LA)

EWMCLKCDU01 (NA), EWMCLKCDE01 (EMEA),

Resource

EWMCLKCDA01 (APJ) EWMCLKCDL01 (LA)

Device Pres

82. Choose Enter.

83. Choose .

84. Choose .

85. Enter the Handling Unit number..

86. Choose Enter twice

87. Copy and paste into the verification fields.

88. Choose Enter twice.

89. Copy and paste into the verification fields.

90. Choose Enter twice.

91. Choose F7

92. Choose F1 to logoff.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

22

93. Choose F1.

30 Looking up the Outbound Delivery Order

1. NWBC: Extended Warehouse Management > Delivery Processing > Outbound Delivery >

Maintain Outbound Delivery Order

In the EWM system: SAP Easy Access: Extended Warehouse Management > Delivery

Processing > Outbound Delivery > Maintain Outbound Delivery Order

Favorites: Maintain Outbound Delivery Order

TA: /N/SCWM/PRDO

94. Choose .

95. Enter the cross docking warehouse for your region EWM5 (NA), EWE5 (EMEA), EWA5 (APJ), EWL5

(LA).

96. Delete the shipping office and Entitled to Dispose entries.

97. Choose .

98. In the Find field, select ERP Document.

99. Enter the number of your second Outbound Delivery.

100. Choose .

101. Note down your second EWM Outbound Document number.

31 Confirming the Loading Warehouse Task by RF

1. To log on to the RF environment:

NWBC: Extended Warehouse Management > Execution > RF Device or Log on to RF

Environment

In the EWM system: SAP Easy Access: Extended Warehouse Management > Execution >

Log on to RF Environment

Favorites: RF Environment

TA: /N/SCWM/RFUI

102. If required, enter the following data:

Field Data

Warehouse EWM5 (NA), EWE5 (EMEA), EWA5 (APJ), EWL5 (LA)

EWMCLKCDU01 (NA), EWMCLKCDE01 (EMEA),

Resource

EWMCLKCDA01 (APJ) EWMCLKCDL01 (LA)

Device Pres

103. Choose Enter.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

23

104. Choose .

105. Choose .

106. Choose .

107. Enter your second EWM Outbound Document number from the previous process step.

108. Choose Enter twice.

109. Enter your HU number.

110. Choose Enter twice.

111. Copy and paste into the verification fields.

112. Choose Enter twice.

113. Choose F7.

114. Choose Yes.

115. Choose F1.

32 Posting the Goods Issue in the Cross Docking Warehouse

1. NWBC: Extended Warehouse Management > Delivery Processing > Outbound Delivery >

Maintain Outbound Delivery Order

In the EWM system: SAP Easy Access: Extended Warehouse Management > Delivery

Processing > Outbound Delivery > Maintain Outbound Delivery Order

Favorites: Maintain Outbound Delivery Order

TA: /N/SCWM/PRDO

116. In the Find field select ERP Document, then enter your second ERP Outbound Delivery number.

117. Choose .

118. Choose .

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

24

33 Looking up the Cross Docking Delivery Pair

1. NWBC: Logistics > Logistics Execution > Transportation Cross Docking > Transportation

Cross Docking Monitor

In the ECC system: SAP Easy Access Logistics : Logistics > Logistics Execution >

Transportation Cross Docking > Transportation Cross Docking Monitor

Favorites: Transportation Cross Docking Monitor

TA: /SPE/CDMON

119. Enter your first ERP Outbound Delivery number. 8**********.

120. Choose .

121. Choose to expand all nodes

122. Double click on the outbound delivery with the green light.

123. Choose to show the delivery details.

124. Choose and then the tab “SAP Event Mgmt.”

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

25

Note that the Goods Issue has been posted.

You have completed the demo.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

26

34 DOCUMENT UPDATES NOTES

Month DD, YYYY Type your notes here

Month DD, YYYY Type your notes here

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

27

35 APPENDIX ONE: DOCUMENT NUMBER TEMPLATE

This script requires you to note down several document numbers. Here is a handy template that you

can can use.

Document

Document Type

Number

Sales Order

ERP Outbound Delivery 1

EWM Outbound 1

Warehouse Order

ERP Inbound Delivery

ERP Outbound Delivery 2

Handling Unit

EWM Outbound 2

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

28

36 APPENDIX TWO: WORKING IN THE SCM DEMO CLOUD

37 Using the RF Device in the Demo Cloud

In the Demo Cloud you have the option of using the RF Device as follows:

2. On your desktop, choose .

125. Choose .

126. Log on to the RF Device with your user and password welcome.

127. Choose LogOn.

Continue the demo as normal, but note that you only to choose F1 once to log off.

38 Using the Access Points in the Cloud

In the Demo Cloud you have the option of logging on to systems via the Access Points.

If you want to use the NWBC, you must log on via the ECC system using the NWBC

Desktop. See the example below:

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

29

You also have the option of logging on to the systems directly using the Access Point

SAPGUI.

Note that System EC3 client 800 is for ECC and system EWM client 890 is for EWM.

System EWM and client 800 can be used for Event Management.

©SAP AG 2009 / I NTERNAL / SCENARIO ID: 8100

You might also like

- SCM Extended Warehouse Management 7.0 Overview: Solution Management EWM Sap AgNo ratings yetSCM Extended Warehouse Management 7.0 Overview: Solution Management EWM Sap Ag44 pages

- CenterPoint Energy EWM on HANA OverviewNo ratings yetCenterPoint Energy EWM on HANA Overview28 pages

- Pickup and Account Assignment Direct ODO Issue To Cost CenteNo ratings yetPickup and Account Assignment Direct ODO Issue To Cost Cente20 pages

- HANA Heroes 1 - EWM Lessons Learned (V2)No ratings yetHANA Heroes 1 - EWM Lessons Learned (V2)40 pages

- DNP GDC Venlo EWM Functional Specification - v13100% (1)DNP GDC Venlo EWM Functional Specification - v13176 pages

- How - To - Guide - List - Classic - Cloud - S4 - Solution ManagerNo ratings yetHow - To - Guide - List - Classic - Cloud - S4 - Solution Manager11 pages

- Decentralized Ewm: Setup Reports For Configuration of Idoc CommunicationNo ratings yetDecentralized Ewm: Setup Reports For Configuration of Idoc Communication7 pages

- 3103 Graingers SAP EWM Implementation at A Large Highly Automated Distribution CenterNo ratings yet3103 Graingers SAP EWM Implementation at A Large Highly Automated Distribution Center29 pages

- SAP EWM 2020 Roadmap: Logging and Tracing of RF TransactionsNo ratings yetSAP EWM 2020 Roadmap: Logging and Tracing of RF Transactions5 pages

- SAP S4HANA Embedded EWM VS Decentralized EWMNo ratings yetSAP S4HANA Embedded EWM VS Decentralized EWM13 pages

- SAPSTROOM White Paper WM-Vs-EWM - Receiving-PutawayNo ratings yetSAPSTROOM White Paper WM-Vs-EWM - Receiving-Putaway16 pages

- SAP WM To EWM Migration: The Deloitte Success RecipeNo ratings yetSAP WM To EWM Migration: The Deloitte Success Recipe8 pages

- C - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 90% (1)C - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 94 pages

- Customer Returns With Quality Inspection (EWM)No ratings yetCustomer Returns With Quality Inspection (EWM)6 pages

- Differences Between IM - WM and EWM - LinkedIn100% (1)Differences Between IM - WM and EWM - LinkedIn5 pages

- EWM Basic Integration For SAP S4HANA 1909 FPS1 and SAP Extended Warehouse ManagementNo ratings yetEWM Basic Integration For SAP S4HANA 1909 FPS1 and SAP Extended Warehouse Management37 pages

- Sap Ewm and Sap S/4Hana: Frequently Asked QuestionsNo ratings yetSap Ewm and Sap S/4Hana: Frequently Asked Questions21 pages

- Production Integration With SAP EWM: Course Outline Course Version: 16 Course Duration: 2 Day(s)No ratings yetProduction Integration With SAP EWM: Course Outline Course Version: 16 Course Duration: 2 Day(s)17 pages

- SAP Yard Management & Cross Docking GuideNo ratings yetSAP Yard Management & Cross Docking Guide66 pages

- Fundamentals of Python:: Chapter 2: Software Development, Data Types, and ExpressionsNo ratings yetFundamentals of Python:: Chapter 2: Software Development, Data Types, and Expressions30 pages

- #11 Working With Excel File Using PandasNo ratings yet#11 Working With Excel File Using Pandas16 pages

- Itm University Gwalior: Major Project (MCA-401) Car Showroom SNo ratings yetItm University Gwalior: Major Project (MCA-401) Car Showroom S14 pages

- Assignment No1 of Principles OF Software EngineeringNo ratings yetAssignment No1 of Principles OF Software Engineering7 pages

- Control Structures in Python ProgrammingNo ratings yetControl Structures in Python Programming27 pages

- Object-Oriented Analysis & Design GuideNo ratings yetObject-Oriented Analysis & Design Guide50 pages

- UML Object Modeling & Use Case DiagramsNo ratings yetUML Object Modeling & Use Case Diagrams29 pages

- CSCI 420: Computer Science Diploma ProgramNo ratings yetCSCI 420: Computer Science Diploma Program2 pages