Professional Documents

Culture Documents

United States Patent: (75) Inventors: Guy Joseph Clamen, Opio (FR)

Uploaded by

Long An DoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent: (75) Inventors: Guy Joseph Clamen, Opio (FR)

Uploaded by

Long An DoCopyright:

Available Formats

US007150787B2

(12) United States Patent (10) Patent No.: US 7,150,787 B2

Clamen et al. (45) Date of Patent: Dec. 19, 2006

(54) POLYMER-MODIFIED GYPSUM 3,947,398 A 3, 1976 Williams

COMPOSITION 4,157,264 A 6/1979 Kennedy-Skipton

4,661,161 A 4, 1987 Jakacki et al.

(75) Inventors: Guy Joseph Clamen, Opio (FR): 4,804,688 A 2, 1989 Vassieff

Bruno Pollet, Valbonne (FR) 5,746,822 A 5/1998 Espinoza et al.

5,779,786 A 7, 1998 Patel

(73) Assignee: Rohm and Haas Company, 6,228,163 B1 5/2001 Espinoza et al.

Philadelphia, PA (US)

FOREIGN PATENT DOCUMENTS

(*) Notice: Subject to any disclaimer, the term of this

patent is extended or adjusted under 35 EP O562651. A 9, 1993

U.S.C. 154(b) by 0 days. EP 1054.046 11 2000

GB 1432157 A 4f1976

(21) Appl. No.: 10/665,281 WO WO99/48833 9, 1999

(22) Filed: Sep. 18, 2003

OTHER PUBLICATIONS

(65) Prior Publication Data

US 2004/OO55511 A1 Mar. 25, 2004

Singh et al., “Retarding Action Of Various Chemicals On Setting

And Hardening Characteristics Of Gypsum Plaster At Different

pH'. Cement and Concrete Research, vol. 27. No. 6, pp. 947-950;

(30) Foreign Application Priority Data (1997), no month.

Sep. 20, 2002 (FR) ................................. O2 292326 Boisvert et al.; “Hydration of calcium sulfate hemihydrate (CaSO

/2 H2O) into gypsum (CaSO-H2O). The influence of the sodium

(51) Int. Cl. poly(acrylate)/Surface interaction and molecular weight'; vol. 220

C04B II/00 (2006.01) pp. 579-591; (2000), no month.

C04B 24/24 (2006.01) Primary Examiner Elizabeth D. Wood

C09K 8/00 (2006.01) (74) Attorney, Agent, or Firm—Kim R. Jessum; Ronald

(52) U.S. Cl. ...................... 106/778; 106/772; 106/775; Bakule

106/790: 523/130; 524/2:524/3:524/4; 524/5:

524/6; 524/7; 524/8 (57) ABSTRACT

(58) Field of Classification Search ................ 106/772,

106/775, 776, 778,790, 523/130; 524/2, A composition including two components is provided. When

524/3, 4, 5, 6, 7, 8 the two components are admixed in the method of the

See application file for complete search history. invention a polymer-modified gypsum composition is pro

(56) References Cited vided. The admixture exhibits a useful balance of setting

time and stability.

U.S. PATENT DOCUMENTS

3,388,022 A 6, 1968 Bloom et al. 8 Claims, No Drawings

US 7,150,787 B2

1. 2

POLYMER-MODIFIED GYPSUM hemihydrate is conventionally prepared by placing lump

COMPOSITION gypsum into an autoclave and calcining it at controlled

Superatmospheric pressure in the presence of steam. In

This invention relates to a two component composition contrast, beta hemihydrate is prepared by heating the dihy

including gypsum and two addition polymers. More particu drate at atmospheric pressure in either a kettle or rotary

larly, the invention relates to a composition including Com calciner. Although the physical appearances of these two

ponent A and Component B: Component A includes: gyp types of gypsum can be the same, they differ in the water/

Sum, an alkaline first polymer, an alkaline agent, and a gypsum ratio required to produce workable products. The

hydration inhibitor; and Component B includes: an second dissimilarity in the physical nature of the gypsum particles

polymer, a filler, and an activator. When the components are 10 of the two forms arises from the differences in their respec

combined, the admixture, optionally including fibers, is tive Surface properties. The larger alpha crystals have low

useful in the manufacture of structures and composite con water absorption and Smaller Surface area per unit weight.

struction components including structural and decorative This translates into a lower water requirement to cause

architectural materials such as laminated panels for use in setting up, or curing, of the gypsum. The lower the weight

cladding and solid Surfaces such as counter-tops; for drill 15

of water in proportion to the weight of dry gypsum solids,

bore applications, patching and repair, grouting for anchor the greater the strength of the final product after curing. The

ing bolts and the like, statues, open and closed cell foam, amount of gypsum used in the formulation of Component A

model making, and rigid tooling; and as a rapid setting is typically from 50 to 80 wt %, based on the total weight of

coating for sandwich panels, molding, duct-work, piping Component A. Preferably, 60–70 wt %, based on the total

and cladding systems, and traffic paint applications. It is of weight of Component A is used.

particular value as a semi-impervious reinforcing coating on Component A includes an alkaline first polymer, i.e., a

the internal Surfaces of Subterranean mines. polymer which is provided at a pH of 7 or higher. The

Particular problems exist in underground mining opera alkaline first polymers useful in this invention are typically

tions for coal, gold, platinum and the like in which it is addition polymers of ethylenically unsaturated monomers

necessary to provide Support to the wall and ceiling Surfaces and include vinyl polymers and polymers of acrylates and

of the mine shafts as soon after excavation as possible. This 25 methacrylates. Examples of polymerized monomers can

is because the recently excavated rock facing can be sus include methyl acrylate, butyl acrylate, ethyl acrylate,

ceptible to cracking and spalling. If exposed for too long a methyl methacrylate, ethyl methacrylate, butyl methacry

period of time, rock fragments will begin to fall away from late, hexyl methacrylate and lauryl methacrylate. Other

the wall and ceiling Surfaces of the newly excavated rocks. monomers which can be used are styrene, vinyl acetate,

An additional problem is the passage of gas, such as 30 vinyl versatate and vinyl chloride. Copolymers of two or

methane, from the newly exposed rock surfaces. Further, more of these monomers can be employed as desired

any coating must be relatively impervious to moisture. depending on the properties required in the final composi

WO99/48833 discloses a two-component gypsum plaster tion. The term “copolymer as used herein is intended to

jointing compound including gypsum and a polymeric include polymer blends as well as true copolymers. The

retarder in one component and a setting accelerator in a 35

polymer can be an emulsion polymer or it can be in the form

second component. Improvements in the stability of the two of a water redispersible powder. Preferred are copolymers

components without materially affecting the setting time of formed by emulsion polymerization, which can contain

the admixture of the components are sought. It has now been about 35 to 65% solids, by volume.

found that a composition including two components one of When selecting monomers or monomer blends for use in

which includes certain neutralizing agents. the alkaline first polymer of Component A of the composi

In a first aspect of the present invention there is provided 40 tion, it is necessary to keep in mind the various properties

a composition comprising Component A and Component B; imparted by each monomer. For example, polymerized

wherein Component A comprises: gypsum, an alkaline poly styrene is alkali-resistant and water resistant, but its long

mer (also referred to as “an alkaline first polymer), an term aging properties are not very good. For some applica

alkaline agent, and a hydration inhibitor, and wherein Com tions, this negative feature can be an acceptable accommo

ponent B comprises: a second polymer (also referred to as 45 dation. Polymerized vinyl acetate has low water resistance

“an addition polymer), a filler, and an activator. but in certain applications, e.g., when the composition is

In a second aspect of the present invention there is applied to a Subterranean Surface which is Substantially

provided a method of forming a polymer-modified gypsum devoid of moisture, this can be acceptable. Acrylate and

comprising forming Component A and Component B; methacrylate polymers have good long term aging properties

wherein Component A comprises: gypsum, an alkaline first 50 and good water and alkali resistance. The amount of poly

polymer, an alkaline agent, and a hydration inhibitor; and mer present in Component A is typically from 20–99 wt %,

wherein Component B comprises: a second polymer, a filler, based on the total weight of Component A.

and an activator, and admixing Component A and Compo One of the properties which should be considered in the

nent B. choice of a polymer is the 'glass transition temperature' or

In a third aspect of the present invention there is provided 55

“Tg as measured by differential scanning calorimetry

a polymer-modified gypsum formed by the method of the (DSC) using the mid-point in the heat versus temperature

second aspect of the present invention. transition as the Tg value, using a heating rate for the DSC

Component A of the composition of the present invention measurement of 20° C./minute. The preferred Tg for the

includes gypsum, an alkaline first polymer, an alkaline alkaline first polymer is in the range of -20°C. to 50° C.

agent, and a hydration inhibitor. with a more preferred range being from 0°C. to 40° C. An

The gypsum used in this invention can be selected from 60 example of a suitable alkaline first copolymer is PRIMALTM

a wide variety of settable forms of calcium sulphate which AC-339, which is an acrylic polymer having a Tg 26°C.,

include anhydrous calcium Sulphate and/or chemical gyp available from the Rohm and Haas Co. of Philadelphia, Pa.

Sum, commonly called synthetic gypsum, as well as calcium Component A includes an alkaline agent. The alkaline

Sulphate hemihydrate. agent is selected from amines and alkaline earth bases.

There are primarily two types of hemihydrate (CaSO4*1/ 65 Suitable amines include ammonia, primary amines, second

2H2O) which are commercially available and convention ary amines, and tertiary amines. Suitable alkaline earth bases

ally referred to as the alpha and beta forms. The alpha include the hydroxide, carbonate, bicarbonate, and acetate

US 7,150,787 B2

3 4

salts of alkaline metals. Preferred are aminomethyl propanol cally present in an amount of 30–50%, preferably 35–45%,

and the hydroxides of calcium, magnesium, and barium. by wt based on the total weight of Component B.

More preferred is calcium hydroxide. The alkaline agent is An activator is included in Component B of the compo

added in an amount Sufficient to provide Component A at a sition. The amount of activator required will be related to the

pH of 7 or higher. Typically the alkaline agent is present at amount of alpha gypsum and hydration inhibitor present in

a level of 0.05 to 1 wt %, preferably 0.1 to 0.3 wt % based the composition. The activator will preferably be added in an

on the total weight of Component A. amount of from 0.1 to 6.0 weight percent, and more pref

Component A includes a hydration inhibitor to prevent the erably from 0.1 to 4.0 weight percent, based on the total

setting of the gypsum. The hydration inhibitor is typically a weight of Component B. Suitable activators include metallic

polymer or copolymer of a polycarboxylic acid. Examples 10 salts which can provide acidic cations. Preferable metallic

include polymers and copolymers of acrylic acid, meth salts are aluminum sulfate, calcium sulfate, ferric Sulfate,

acrylic acid, itaconic acid and fumaric acid. Copolymers of Zinc sulfate and ferric chloride. The most preferred activator

acrylic acid or methacrylic acid with an alkyl ester or amide for this composition is aluminum Sulfate.

of acrylic acid or methacrylic acid and polycarboxylic acid

anhydrides are preferred hydration inhibitors. The polymeric In the second aspect of the present invention there is

hydration inhibitor can conveniently be in the form of the provided a method of forming a polymer-modified gypsum

sodium or ammonium salt. A preferred hydration inhibitor comprising forming Component A and component B as

includes, as polymerized units, from 50 to 99.9% acrylic described hereinabove; admixing Component A and Com

acid and 0.1 to 50% acrylamide, by weight. More preferably, ponent B; and, optionally, applying the admixture to a

the hydration inhibitor includes 95 to 98% acrylic acid, by substrate. Components A and B are preferably each fluid

weight, and 2 to 5%, by weight, of acrylic acid. Most dispersions in an aqueous medium. By a "dispersion in an

preferably, the hydration inhibitor is polyacrylic acid. An aqueous medium' is meant that the constituents of the

examples of a suitable hydration inhibitor is OROTANTM Component are admixed with a medium which is a single

963, sold by the Rohm and Haas Co., Philadelphia, Pa. The continuous phase containing greater than 50% water, by wit

hydration inhibitor is incorporated into Component A in an based on the weight of the medium. It is contemplated that

amount of from 0.1 to 2.0 wt %, based on the total weight 25

such constituents which are soluble or partially soluble in

of Component A. the aqueous medium will dissolve and the balance of the

Component B of the composition of the present invention material will be dispersed in the aqueous medium. Compo

includes a second polymer, a filler, and an activator. Com nents A and B are typically applied at a volume ratio of from

ponent B includes a second polymer, second polymers 95:5, respectively, to 5:95. The optimum ratio can be deter

useful in this invention are typically addition polymers of 30

mined by considering factors such as the Surface to be

ethylenically unsaturated monomers and include vinyl poly treated, the time required for cure, equipment capability, and

mers and polymers of acrylates and methacrylates. other processing concerns. Other ingredients can be added to

Examples of polymerized monomers can include methyl the composition, many of them can be added to either

acrylate, butyl acrylate, ethyl acrylate, methyl methacrylate, Component A or Component B or to the admixture, in order

ethyl methacrylate, butyl methacrylate, hexyl methacrylate 35

to aid processing, handling or formulating. Ingredients

and lauryl methacrylate. Other monomers which can be used which are traditionally utilized in coatings include anti

are styrene, vinyl acetate, vinyl versatate and vinyl chloride.

Copolymers of two or more of these monomers can be foamers, Surfactants, rheology modifiers, set control agents,

employed as desired depending on the properties required in coalescents, natural and synthetic fibers, and expansion

the final composition. The term “copolymer as used herein agents.

40

is intended to include polymer blends as well as true When the admixture is used to form a thick section, it can

copolymers. The polymer can be an emulsion polymer or it be discharge into a mold or the like.

can be in the form of a water redispersible powder. Preferred When the admixture is applied to a substrate in the form

are copolymers formed by emulsion polymerization, which of a coating it is typically from 0.1 to 10 mm thick,

can contain about 35 to 65% solids, by volume. 45 preferably from 0.5 to 5 mm and most preferably from 1 to

The pH of the second polymer in Component B is not 2 mm. Application is most conveniently done by use of

critical since it does not come into contact with the gypsum pressurized spray applicators. Component A and Component

until the two components are blended with the intent of B can be fed via separate hose or duct systems to either a

causing the gypsum to set up. The second polymer can be single or dual applicator nozzles, where both are sprayed

either acidic or alkaline. However, it is preferable to use an either simultaneously, as through dual nozzles, or as a blend,

acidic polymer i.e., a polymer having a pH-7. Component B 50

typically has pH-7. via a single nozzle, onto the Substrate.

When selecting monomers or monomer blends for use in A coating formed by the application of the present com

the second polymer of Component B of the composition, position provides resistance to the passage of gases, such as

similar guidelines to those included for the alkaline first methane, which might leach out from newly exposed rock in

polymer of Component A pertain. The amount of second 55 a mining tunnel application. Further, it provides a coating

polymer present in Component B is typically from 20–99 wit which is substantially impervious to moisture. The present

%, based on the total weight of Component B. composition readily adheres to various Substrates, especially

The preferred Tg for the second polymer is in the range newly excavated subterranean rock, which helps to reinforce

of -20° to 50° C., with the most preferred range being from the exposed facing of these rocks so as to prevent fragments

0° to 40°C. An example of a suitable second copolymer is 60 from "calving off and falling onto either mining personnel

PRIMALTM HA-16, which is an acidic acrylate/acrylamide or their equipment. A coating thickness in the range of 1 to

polymer having a Tg 35° C., available from the Rohm and 2 mm can set up in less than 3 minutes.

Haas Co. of Philadelphia, Pa. In the third aspect of the present invention there is

Component B of the composition includes a filler. provided a polymer-modified gypsum formed by the method

Examples of suitable fillers, also called extenders, are sand, 65 of the second aspect of the present invention.

mica, silica aluminate and fly ash. A low density fly ash is The following examples are presented to Illustrate the

commercially available as “Hollowfill”. The filler is typi invention and the results obtained by the test procedures.

US 7,150,787 B2

5 6

EXAMPLE 1. EXAMPLE 2

Preparation of a Composition of the Invention Effecting the Method of the Invention

(Component A and Component B) Component A and Component B of Example 1 were

admixed in a 1:1 ration, by volume (weight ratio of

A/B-52.7/47.3). The admixture had a solids content of

81.7%, by weight, calculated density of 1.74, pH-6, healing

time<5 min; set time<10 min.

Ingredient parts by weight

10 EXAMPLE 3

Component A

Effect of Alkaline Agent Type and Amount

Alkaline first polymer (PRIMALTMAC-339) 27.68

Antifoam (Wacker S-882) O.29 Compositions according to Example 1 with various alka

Surfactant (TRITONTMX-405) (1:1 in water) 1.03 line agent type and amounts were prepared and admixed to

provide the results of Table 3.1

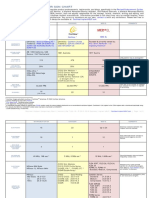

TABLE 3.1

Effect of alkaline agent type and amount

Sample No.

3-1 3-2 3-3 3-4 3-5 3-6 3-7

Alkaline agent None AMP NaOH NaSi Ca(OH)2 Ca(OH)2 Ca(OH)2

90 (50%) (50%)

Wt 96 on total O O.13 O.OS O.13 O.O7 O.12 O16

comp.

PH 7.1 8.4 8.4 8.3 8.4 NA 9.8

Viscosity (KU) 112 113 114 125 118 NA 120

Set time 16 2O 18 19 19 NA 50

Composition +

3% set gypsum

(I)

PH 7.1 8.4 8.4 8.2 8.4 9.4 9.6

Viscosity (KU) 118 120 122 133 122 124 123

Gel Strength 40 40 50 70 60 50 60

Composition +

3% set gypsum

(II)

Viscosity (KU) >140 >140 >140 cc.140 >140 >140 >140

Gel Strength 370 270 >440 >440 100 85 70

Notes:

Viscosity in Krebs units (KU). Set time measured with needle (Vicat, using Prolabo appara

tus ASTM No. 23.6 according to ASTM C-191 with a 1 mm needle, reported in min.).

Composition + 3% set gypsum (I) = Initial composition + 3 wt % previously set gypsum.

45 Composition+3% set gypsum (II) Initial composition+3

-continued wt % previously set gypsum after 10 days of low/high

temperature cycles (10 cycles, each cycle including a high

Ingredient parts by weight and a low temperature interval; low temperature=5°C.; high

temperature=40° C.; time to change temperature=30 min:

Alkaline agent (AMP-90) C. 50 time held at each temperature=12 hours. Gelstrength via Gel

Hydration inhibitor (OROTAN TM 963

Coalescent (Butyl CARBITOLTM) (2:1 in water) 1. 18 Strength Tester from Sheen Instruments, Ltd. Using the 4x2

Gypsum (Crystalcal; alpha hemi-hydrate) 6923 cm paddle on a 300 cc minimum volume sample, reported

Pigment (M1 Black Pigment; GK 5493) 0.03 in g-cm. AMP-90-2-aminomethyl propanol

Rheology modifier (ACRYSOLTM RM-1020) (1:1 in O.O6 55 Admixtures of the invention, samples 3–2, 3–5, 3–6, and

water) 3–7 exhibit a useful balance of set time, and gel strength

Component B stability as measured in the stress test, Composition+3% set

gypsum (II), relative to the admixtures of comparative

Second (acidic) polymer (PRIMALTM HA-16) 31.90 samples 3–1, 3–3, and 3–4.

Defoamer (Wacker S-882) O.24

Surfactant (TRITONTMX-405) (1:1 in water) 0.99 60 EXAMPLE 4

Water 1.39

Activator (Al2SO4.18 H2O (1:1 in water)

Filler (ATH Nyala M20-G so Effect of Amine Alkaline Agent Type and Amount

Rheology modifier (ACRYSOLTM SCT-275) (1:1 in O.20

water) 65 Compositions according to Example 1 with various

amounts of AMP90 were prepared and admixed to provide

the results of Table 4.1

US 7,150,787 B2

TABLE 4.1

Effect of alkaline agent type and amount

Sample No.

4-1 4-2 4-3 4-4 4-5 4-6 4-7 4-8

Wt 96 AMP90 on total O O.O3 O.O6 O.1 O.13 O.17 O.2 O.3

comp. wit

PH 7.1 7.5 7.8 8.1 8.4 8.6 8.8 9.4

Viscosity (KU) 112 113 112 112 112 111 112 110

Set time 16 17 17 17 18.5 19.5 23 40

Composition + 3% set

gypsum (I)

PH 7.1 7.5 7.8 8.O 8.4 8.5 8.8 9.4

Viscosity (KU) 118 119 118 119 119 117 118 115

Gel Strength 40 40 45 40 40 40 35 35

Composition + 3% set

gypsum (II)

pH 7.1 7.4 7.8 8.O 8.2 8.4 8.7 9.2

Viscosity (KU) >140 >140 >140 >140 >140 >140 >140 113

Gel Strength 370 400 330 340 270 240 130 100

Notes as in Table 3.1

25

Admixtures of the invention, Samples 4–3, 4–4, 4–5, 4–6, 4. The composition of claim 1 wherein Component B

4–7 and 4-8 exhibit a useful balance of set time, and gel comprises: 20–70 wt.% second polymer; 30–50 wt.% filler

strength stability as measured in the stress test, Composi and 0.1–6.0 wt'/6 activator, based on the total weight of

tion+3% set gypsum (II), relative to the admixtures of Component B.

comparative samples 4-1 and 4–2.

We claim: 30 5. A method of forming a polymer-modified gypsum

1. A composition comprising Component A and Compo comprising forming Component A and Component B;

nent B; wherein Component A comprises: gypsum, an alkaline poly

wherein Component A comprises: gypsum, an alkaline mer, an alkaline agent selected from ammonia, primary

polymer, an alkaline agent selected from the group amines, secondary amines, tertiary amines, hydroxide, car

consisting of ammonia, primary amines, secondary 35

bonate, bicarbonate, and acetate salts of alkaline metals, and

amines, tertiary amines, hydroxide, carbonate, bicar a hydration inhibitor selected from polymers and copoly

bonate, and acetate salts of alkaline metals, and a mers of acrylic acid, rnethacrylic acid, itaconic acid and

hydration inhibitor selected from the group consisting fumaric acid; wherein Component B comprises: an addition

of polymers and copolymers of acrylic acid, meth polymer, a filler, and an activator, the alkaline polymer,

acrylic acid, itaconic acid and fumaric acid; 40

hydration inhibitor, and addition polymer differing from one

wherein Component B comprises: an addition polymer, a

filler, and an activators, the alkaline polymer, hydration another; and wherein both Components A and B are dis

inhibitor, and addition polymer differing from one persed in an aqueous medium; and

another, and admixing Component A and Component B.

wherein both Components A and B are dispersed in an 45 6. The method of claim 5 further comprising applying said

aqueous medium. admixture to a Substrate.

2. The composition of claim 1 wherein the volume ratio 7. The method of claim 6 wherein the substrate is the

of Component A to Component B is from 95:5 to 5:95. excavated rock Surface of a Subterranean mine.

3. The composition of claim 1 wherein Component A

comprises: 20–50 wt'/6 alkaline first polymer, 50–80 wt'/6 50 8. A polymer-modified gypsum formed by the method of

gypsum, 0.05—1.0 wit% alkaline agent, and 0.1-2.0 wt'/6 claim 5.

hydration inhibitor, based on the total weight of Component

A.

You might also like

- Polyurethane foam catalyst compositionDocument10 pagesPolyurethane foam catalyst compositiondewiNo ratings yet

- US7390358Document8 pagesUS7390358lic.escobar2018No ratings yet

- US7387748Document7 pagesUS7387748MaboodNo ratings yet

- Us8367752 PDFDocument11 pagesUs8367752 PDFEnrique EscobarNo ratings yet

- United States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010Document6 pagesUnited States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010turnipNo ratings yet

- United States Patent (10) Patent No.: US 8,076,507 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,076,507 B2Manuel Gonzalez GalvezNo ratings yet

- United States Patent (10) Patent No.: US 6,455,142 B1: Heberger Et Al. (45) Date of Patent: Sep. 24, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,455,142 B1: Heberger Et Al. (45) Date of Patent: Sep. 24, 2002Thuận LêNo ratings yet

- Patent 5Document8 pagesPatent 5ALEXANDER FRANCO CASTRILLONNo ratings yet

- United States Patent: (10) Patent No.: US 8,846,787 B2Document7 pagesUnited States Patent: (10) Patent No.: US 8,846,787 B2marcela walterosNo ratings yet

- US6235961Document11 pagesUS6235961Sidharth SinghNo ratings yet

- United States Patent (10) Patent No.: US 6,616,743 B1: Yap Et Al. (45) Date of Patent: Sep. 9, 2003Document5 pagesUnited States Patent (10) Patent No.: US 6,616,743 B1: Yap Et Al. (45) Date of Patent: Sep. 9, 2003alejandroNo ratings yet

- US6607694Document9 pagesUS6607694MaboodNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7482.410 B2Document15 pagesUnited States Patent: (12) (10) Patent No.: US 7482.410 B2ariefNo ratings yet

- Proceso de HidrocarburosDocument14 pagesProceso de Hidrocarburosingeniomeca8800No ratings yet

- CMC Gel Formation in Drilling FluidsDocument6 pagesCMC Gel Formation in Drilling Fluidslive streamNo ratings yet

- Brass PolishDocument11 pagesBrass PolishfsarfrazNo ratings yet

- United States Patent: Zhang Mar. 8, 2011Document8 pagesUnited States Patent: Zhang Mar. 8, 2011rosarioNo ratings yet

- Smoke Suppressants 01Document14 pagesSmoke Suppressants 01Vansala GanesanNo ratings yet

- US7384892B2Document11 pagesUS7384892B2live streamNo ratings yet

- United States Patent: (10) Patent No.: US 8,026.401 B2Document8 pagesUnited States Patent: (10) Patent No.: US 8,026.401 B2jonathanNo ratings yet

- US7906591Document7 pagesUS7906591caf.henryNo ratings yet

- US6539870Document5 pagesUS6539870glorymobile5362No ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument4 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentAPEX SONNo ratings yet

- United States Patent (10) Patent No.: US 8,372,899 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,372,899 B2Alexander Franco CastrillonNo ratings yet

- Spotting FluidsDocument16 pagesSpotting FluidsEduardo PeraltaNo ratings yet

- United States Patent: Yorifuji Et AlDocument16 pagesUnited States Patent: Yorifuji Et AlErin GokNo ratings yet

- Us8261906 - SBRDocument8 pagesUs8261906 - SBRLOAN PHẠM THỊ PHƯƠNGNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,183,661 B2 Bogner Et Al. (45) Date of Patent: Feb. 27, 2007Document7 pagesUnited States Patent: (12) (10) Patent No.: US 7,183,661 B2 Bogner Et Al. (45) Date of Patent: Feb. 27, 2007Vansala GanesanNo ratings yet

- United States Patent: Hagemeyer Et Al. (45) Date of Patent: Jul. 31, 2001Document7 pagesUnited States Patent: Hagemeyer Et Al. (45) Date of Patent: Jul. 31, 2001arif ihwandaNo ratings yet

- Carbonization PanDocument21 pagesCarbonization PanRATNA YULYANTINo ratings yet

- United States Patent (10) Patent No.: US 6,809,154 B2: Lindahl Et Al. (45) Date of Patent: Oct. 26, 2004Document6 pagesUnited States Patent (10) Patent No.: US 6,809,154 B2: Lindahl Et Al. (45) Date of Patent: Oct. 26, 2004ariefNo ratings yet

- United States Patent (10) Patent No.: US 6,692,544 B1: Grillenzoni (45) Date of Patent: Feb. 17, 2004Document20 pagesUnited States Patent (10) Patent No.: US 6,692,544 B1: Grillenzoni (45) Date of Patent: Feb. 17, 2004rianne nabilahNo ratings yet

- Acido PropionicoDocument6 pagesAcido Propionicoromina orellanaNo ratings yet

- Nat. Gas ReformingDocument6 pagesNat. Gas Reformingabdullah farhanNo ratings yet

- United States Patent: Burd Et A) - (45) Date of Patent: Jul. 10, 2012Document10 pagesUnited States Patent: Burd Et A) - (45) Date of Patent: Jul. 10, 2012ShameekaNo ratings yet

- United States Patent (10) Patent No.:: Huynh-Ba (45) Date of Patent: Jan. 13, 2004Document11 pagesUnited States Patent (10) Patent No.:: Huynh-Ba (45) Date of Patent: Jan. 13, 2004Alexander Franco CastrillonNo ratings yet

- Us 6838499Document7 pagesUs 6838499Pranshu JainNo ratings yet

- US8658823Document16 pagesUS8658823Santiago BorgesNo ratings yet

- US6953534Document13 pagesUS6953534MaboodNo ratings yet

- Us 7977524Document8 pagesUs 7977524bazil17No ratings yet

- United States Patent: Palicka Et Al. (45) Date of Patent: Jul.18, 2006Document10 pagesUnited States Patent: Palicka Et Al. (45) Date of Patent: Jul.18, 2006Mary HullNo ratings yet

- Membrane Process Yields High-Purity Hydrogen and LPG StreamsDocument9 pagesMembrane Process Yields High-Purity Hydrogen and LPG StreamsBóng Đá- Quán bia tổng hợpNo ratings yet

- Us 7081229Document11 pagesUs 7081229duraid ahmadNo ratings yet

- Us5799507 - ScoreDocument19 pagesUs5799507 - ScoreDiego1980bNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,344,071 B1Document20 pagesUnited States Patent: (12) (10) Patent N0.: US 6,344,071 B143No ratings yet

- Additive Composition For Release of Stuck Drill Pipe - (Fatty Alcohol Propoxylate and SMO Based Pipe Free Agent ExxonMobil)Document6 pagesAdditive Composition For Release of Stuck Drill Pipe - (Fatty Alcohol Propoxylate and SMO Based Pipe Free Agent ExxonMobil)Pothiraj KrishnanNo ratings yet

- Ojo Patente Del Proceso Cryomax MreDocument10 pagesOjo Patente Del Proceso Cryomax MrerubenpeNo ratings yet

- Process and installation for separation of a gas mixture containing methane by distillationDocument10 pagesProcess and installation for separation of a gas mixture containing methane by distillationRuben PerezNo ratings yet

- United States Patent (10) Patent No.: US 8.471,082 B2Document10 pagesUnited States Patent (10) Patent No.: US 8.471,082 B2Hazeq AzaharNo ratings yet

- United States Patent: (12) (10) Patent No.: US 8,075,651 B2Document11 pagesUnited States Patent: (12) (10) Patent No.: US 8,075,651 B2maaathanNo ratings yet

- Process for Producing Methylcobalamin Using Reducing Agent and Methylating AgentDocument6 pagesProcess for Producing Methylcobalamin Using Reducing Agent and Methylating AgentVandit KhareNo ratings yet

- US8178353 - Method For Determination of Polymer Concentration in Water SystemsDocument15 pagesUS8178353 - Method For Determination of Polymer Concentration in Water SystemsKhanh Nguyen TuanNo ratings yet

- Composite Fiberboard with Improved Acoustic PropertiesDocument8 pagesComposite Fiberboard with Improved Acoustic PropertiesGuillermoNo ratings yet

- Us8455685 UseDocument10 pagesUs8455685 UseRefi RahmanNo ratings yet

- Prevent Cellular Gamma Prime Formation in Cast Nickel SuperalloysDocument4 pagesPrevent Cellular Gamma Prime Formation in Cast Nickel SuperalloyswalkerbhoNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7.225,900 B2Document8 pagesUnited States Patent: (12) (10) Patent No.: US 7.225,900 B2flavioNo ratings yet

- US9302971 Terephthalic AcidDocument23 pagesUS9302971 Terephthalic AcidnamoNo ratings yet

- United States Patent: Et Ai. Patent No.: Date PatentDocument15 pagesUnited States Patent: Et Ai. Patent No.: Date Patentnalin_gupta_1No ratings yet

- Us8367867 PDFDocument12 pagesUs8367867 PDFTamiris CandiaNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiNo ratings yet

- MRI Safety: of Cochlear Implants, Middle Ear Implants, and Bone Conduction ImplantsDocument3 pagesMRI Safety: of Cochlear Implants, Middle Ear Implants, and Bone Conduction ImplantsLong An DoNo ratings yet

- FUN2799 ISS2 OCT17 MAY17 CI Fact SheetDocument3 pagesFUN2799 ISS2 OCT17 MAY17 CI Fact SheetLong An DoNo ratings yet

- AW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebDocument64 pagesAW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebLong An DoNo ratings yet

- Summary of Safety and Effectiveness Data (Ssed) : I. General InformationDocument36 pagesSummary of Safety and Effectiveness Data (Ssed) : I. General InformationLong An DoNo ratings yet

- RONDO 2 Audio Processor: Product CatalogueDocument24 pagesRONDO 2 Audio Processor: Product CatalogueLong An DoNo ratings yet

- Aw31902 - 10 - Sonnet User Manual en English UsDocument76 pagesAw31902 - 10 - Sonnet User Manual en English UsLong An DoNo ratings yet

- Van de Heyning 2021 Two Phase Survey On The Frequency oDocument9 pagesVan de Heyning 2021 Two Phase Survey On The Frequency oLong An DoNo ratings yet

- Aw31902 - 10 - Sonnet User Manual en English UsDocument76 pagesAw31902 - 10 - Sonnet User Manual en English UsLong An DoNo ratings yet

- Cochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesDocument9 pagesCochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesLong An DoNo ratings yet

- Rondo 2: Quick GuideDocument32 pagesRondo 2: Quick GuideLong An DoNo ratings yet

- 2016 BASF ArchitecturalCoatingsBrochure ELDocument64 pages2016 BASF ArchitecturalCoatingsBrochure ELLong An DoNo ratings yet

- 003244v3 FullDocument91 pages003244v3 FullLong An DoNo ratings yet

- Mi1210 Synchrony ST: Surgical GuideDocument64 pagesMi1210 Synchrony ST: Surgical GuideLong An DoNo ratings yet

- 24315CE r4 1-synchronyImplantFS WEBDocument4 pages24315CE r4 1-synchronyImplantFS WEBLong An DoNo ratings yet

- ANSD Guidelines V 2-2 0608131Document29 pagesANSD Guidelines V 2-2 0608131Long An DoNo ratings yet

- Rondo 2: It's Never Been EasierDocument4 pagesRondo 2: It's Never Been EasierLong An DoNo ratings yet

- CG Op200Document1 pageCG Op200Long An DoNo ratings yet

- Fibers 08 00048Document14 pagesFibers 08 00048Long An DoNo ratings yet

- Catalogue Surfactants PDFDocument16 pagesCatalogue Surfactants PDFMukesh KumarNo ratings yet

- Desmodur L 75 - en - 82358391 12978387 13422316Document3 pagesDesmodur L 75 - en - 82358391 12978387 13422316Long An DoNo ratings yet

- Cancers 13 02731Document17 pagesCancers 13 02731Long An DoNo ratings yet

- Lamberti Brochure Additives Constructions v4!1!2020 BQDocument8 pagesLamberti Brochure Additives Constructions v4!1!2020 BQLong An DoNo ratings yet

- 6 Mertens Thursday July 11 1Document16 pages6 Mertens Thursday July 11 1Long An DoNo ratings yet

- Cells 10 02400Document16 pagesCells 10 02400Long An DoNo ratings yet

- Cellosize QP 100mhDocument2 pagesCellosize QP 100mhca_rl_4No ratings yet

- BASF Waterproofing Product Guide LRDocument4 pagesBASF Waterproofing Product Guide LRLong An DoNo ratings yet

- 407 3 Emmanuelleyvonx PTDocument46 pages407 3 Emmanuelleyvonx PTLong An DoNo ratings yet

- Defoamers. Dispersions & Pigments Division Formulation AdditivesDocument51 pagesDefoamers. Dispersions & Pigments Division Formulation AdditivesLong An DoNo ratings yet

- Materials 14 02736 v2Document12 pagesMaterials 14 02736 v2Long An DoNo ratings yet

- Dynamic Simulation of Volume Fraction and Density PDFDocument6 pagesDynamic Simulation of Volume Fraction and Density PDFArpit DwivediNo ratings yet

- Airplane Dimensions and Areas - Description and Operation 1. GeneralDocument17 pagesAirplane Dimensions and Areas - Description and Operation 1. GeneralKEVINNo ratings yet

- Calculation of Renal Tubular Reabsorption of Phosphate: The Algorithm Performs Better Than The NomogramDocument3 pagesCalculation of Renal Tubular Reabsorption of Phosphate: The Algorithm Performs Better Than The Nomogrammonday125No ratings yet

- SAE 660 Bronze - Technical InformationDocument2 pagesSAE 660 Bronze - Technical Informationtanha56313955No ratings yet

- Primetals - The New Global Competence in Hot Rolling PDFDocument13 pagesPrimetals - The New Global Competence in Hot Rolling PDFAlejandro JimenezNo ratings yet

- PVT ModellingDocument6 pagesPVT ModellingFan JackNo ratings yet

- 500+ Free Mock Test Visit:: Join Telegram Channel: Join Telegram GroupDocument16 pages500+ Free Mock Test Visit:: Join Telegram Channel: Join Telegram GroupKaushik Karthikeyan KNo ratings yet

- Energies 14 02285Document28 pagesEnergies 14 02285David Gustavo Duran TangoNo ratings yet

- Arithmetic-Geometric Mean Inequality Proof by Induction and CalculusDocument2 pagesArithmetic-Geometric Mean Inequality Proof by Induction and CalculusRitoprovo RoyNo ratings yet

- 12-LS6 DL Identify The Process of Inserting Symbols or Special CharactersDocument14 pages12-LS6 DL Identify The Process of Inserting Symbols or Special CharactersjosefadrilanNo ratings yet

- Waffle SlabsDocument5 pagesWaffle Slabseugenia omuhindiNo ratings yet

- Low-strain integrity testing of concrete pilesDocument2 pagesLow-strain integrity testing of concrete pilesRaj MaNo ratings yet

- MJB 20 Pile CapDocument24 pagesMJB 20 Pile CapRaoNo ratings yet

- General Education Reviewer With Answer KeyDocument22 pagesGeneral Education Reviewer With Answer KeyAltheaGuanzon94% (16)

- Acoustic Doppler Effect With Universal Counter: (Item No.: P2150405)Document7 pagesAcoustic Doppler Effect With Universal Counter: (Item No.: P2150405)Muhammad IshfaqNo ratings yet

- Unit 6 Applications of COnductometry Electrogravemetry and CoulometryDocument28 pagesUnit 6 Applications of COnductometry Electrogravemetry and CoulometryNatalia Rosa Simanjuntak50% (2)

- Rock Cycle Review WorksheetDocument2 pagesRock Cycle Review Worksheetdrakopowell46No ratings yet

- Nokia Networks: VoLTE Optimization GuideDocument20 pagesNokia Networks: VoLTE Optimization GuideKamil KocNo ratings yet

- Differentiating Aldehydes and KetonesDocument12 pagesDifferentiating Aldehydes and KetonesNurul Hasanah100% (1)

- DMSO Solvent PropertiesDocument2 pagesDMSO Solvent PropertiesSunny YangNo ratings yet

- CHAPTER I 1newDocument35 pagesCHAPTER I 1newsabel sardilla100% (1)

- Duct Sizing and HVAC CalculationDocument21 pagesDuct Sizing and HVAC Calculationsardarmkhan80% (5)

- Trigonometry: Section 4.1 Radian and Degree MeasureDocument4 pagesTrigonometry: Section 4.1 Radian and Degree Measuresarasmile2009No ratings yet

- CRE Notes PDFDocument61 pagesCRE Notes PDFKrunal ThakarNo ratings yet

- Basics of Boolean AlgebraDocument21 pagesBasics of Boolean AlgebraKabhiNo ratings yet

- hw2s MfokDocument2 pageshw2s MfokKhalid TeslaNo ratings yet

- Pressure Drop and Flooding in A Packed ColumnDocument7 pagesPressure Drop and Flooding in A Packed ColumnEdu Cordon50% (2)

- SAP 4.7 Installation Guide Windows Server 2003Document2 pagesSAP 4.7 Installation Guide Windows Server 2003mkumarshahiNo ratings yet

- Spyn Audio Catalog-1589913182Document28 pagesSpyn Audio Catalog-1589913182Jose Gregorio Ortega CarrilloNo ratings yet

- Pulp and Paper Tech - I Introduction and History of Pulping ProcessDocument62 pagesPulp and Paper Tech - I Introduction and History of Pulping ProcessVishnu KollarethNo ratings yet