Professional Documents

Culture Documents

BASF Waterproofing Product Guide LR

Uploaded by

Long An DoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BASF Waterproofing Product Guide LR

Uploaded by

Long An DoCopyright:

Available Formats

Polymers and additives

for waterproof coatings

Providing innovative solutions for

waterproofing applications

After structural integrity, the next most important factor in building and construction is waterproofing. Waterproofing systems protect against water intrusion with the

goal of maintaining long-term structural durability, surface protection, mold and mildew prevention build-up due to dampness, and ultimately occupant comfort in

buildings.

BASF polymer dispersions and formulation additives offer a number of performance features for commercial and residential waterproofing membrane systems such

as water resistance, moisture vapor permeability, waterproofing membrane strength, elongation, flexibility, crack-bridging, and adhesion to the underlying substrate.

How polymers and additives contribute Staying dry with waterproofing coatings

to waterproofing performance BASF products are used in three main waterproofing technology categories:

Polymers and additives are necessary to achieve the performance properties of

Ready-to-use mastic waterproof coatings

an effective waterproofing coating.

One-component ready-to-use coatings that

can be rolled or sprayed onto horizontal and

vertical surfaces on various substrates. In

above-grade applications, these waterproofing

membranes prevent water intrusion into

construction elements.

Traditional polymer-modified asphaltic waterproof coatings

Bitumen-based, fluid-applied coatings are often used for

below-grade waterproofing applications since asphalt has

very good water resistive properties. Formulations using

polymer-modified asphaltic emulsions see major

improvements in coating strength at ambient temperature

and flexibility at lower temperatures.

High-performance two-component cementitious mortars

Used behind tile, over masonry patching, and over

concrete surfaces. These above- and below-grade

waterproofing coatings have good affinity to concrete and

masonry substrates due to their cementitious nature, and

thus strong bonding strength. The polymer modifier

contributes to the flexibility properties.

2 | Waterproofing polymers and additives selection guide

Dispersions for waterproofing applications

Water Testing

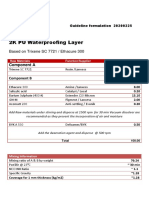

Product name Chemistry Tg (°C) Solids % pH Low VOC non-APEO absorption %* standard Description

Mastic waterproofing

For coatings on masonry/concrete surfaces. Formulated

ACRONAL® 4160 Styrene acrylic 38 45 7.2 Yes Yes 22% ASTM D 7088 coatings resists standing water, withstands negative-side

hydrostatic pressure, prevents water intrusion.

Styrene For flexible membranes used below tiles and over concrete.

STYROFAN® NX 1492 -8 50 8.5 Yes Yes 4% ASTM C 1306 Formulated coatings feature excellent water resistance, low

butadiene

moisture vapor transmission and good adhesion.

Multi-purpose copolymer dispersion for various low-emission

Styrene

ACRONAL 5041 5 52 7.5 Yes Yes 4% DIN EN 1062-7 applications including waterproofing over various substrates. Fast

acrylic drying with superior adhesion and good crack bridging properties.

Asphaltic waterproofing

Styrene Anionic, high molecular weight dispersion designed for use in asphalt

Butonal® NS 175 butadiene -53 71 10.4 Yes Yes 2% ASTM C 836 modification. For below-grade asphaltic waterproofing with excellent

elongation and water absorption properties.

Styrene High Tg copolymer suggested for use in below-grade asphaltic

BUTOFAN® NS 299 -17 54 11.4 Yes Yes 2% ASTM C 836

butadiene waterproofing.

Cementitious waterproofing

For two-component flexible cementitious waterproofing over

Styrene

ACRONAL S 400 -6 57 8.0 Yes – – – concrete. Formulated coatings feature low water absorption

acrylic and vapor permeable.

For cement-based waterproofing coatings used over concrete.

ACRONAL NX 4623 Acrylic 12 47 10.0 Yes – – – Formulated coatings feature good water resistance and freeze/

thaw capability.

High-performance polymer for flexible cementitious

Styrene waterproofing coatings. Potential for drinking water applications.

ACRONAL 5442 -15 53.5 7.0 Yes Yes 2% DIN EN 1062-7 Formulated coatings feature excellent crack-bridging properties,

acrylic

even at lower temperatures down to ca. -10° C to -20° C.

*Measured as % uptake of formulated film after 24 hours water exposure

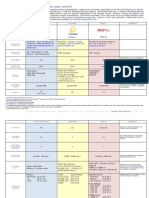

Formulation additives for waterproofing

Physical Recommended applications

Product name Chemistry form Solids % Low VOC non-APEO Asphaltic Cementitious Mastic Description

Dispersing agents

Carboxylic acid Polymeric dispersing agent for TiO2 and extender pigments.

DISPEX® CX 4320 copolymer Liquid 25 Yes Yes Efficiency and high water resistance.

Defoamers

General purpose, broad spectrum mineral oil defoamer for

FOAMASTER® MO NXZ Mineral oil Liquid > 88 – Yes water-based formulations.

FOAMSTAR® ST 2420 Defoamer for pigment dispersing. Low use level, excellent

Star polymer Liquid > 99 Yes Yes persistence, and good choice for very low VOC systems.

Rheology modifiers

Highly efficient low-shear viscosity builder. Highly shear

RHEOVIS® AS 1130 ASE, Ionic Liquid 30 Yes Yes

thinning for anti-sagging and anti-settling properties.

RHEOVIS PU 1341 Polyurethane Liquid 20 Yes Yes Excellent high-shear viscosity builder. Imparts excellent flow.

Surfactant

Low foaming, non-ionic surfactant. Extender pigment

HYDROPALAT® WE 3320 Polymer based Liquid 90 Yes Yes acceptance with improved substrate wetting.

Superplasticizer

Sulphonated Ideal for use with concrete. Optimized for plasticization and

MELMENT® L 10 melamine Liquid 40 – Yes water reduction of cement-based materials.

Waterproofing polymers and additives selection guide | 3

BASF’s Dispersions & Resins division

The Dispersions & Resins division of BASF develops, produces and markets a range of high-quality resins, additives, colorants and

polymer dispersions worldwide. These raw materials are used in formulations for a number of industries, including coatings, construction,

adhesives, printing and packaging, nonwovens and composites, electronics, and paper. With its comprehensive product portfolio and its

extensive knowledge of the industry, the Dispersions & Resins division offers its customers innovative and sustainable solutions and helps

them advance their formulations. For further information about the Dispersions & Resins division, please visit www.basf.us/dpsolutions.

About BASF

BASF Corporation, headquartered in Florham Park, New Jersey, is the North American affiliate of BASF SE, Ludwigshafen, Germany.

BASF has more than 20,000 employees in North America and had sales of around $20 billion in 2018. For more information about BASF’s

North American operations, visit www.basf.com.

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social

responsibility. The approximately 122,000 employees in the BASF Group work on contributing to the success of our customers in nearly

all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions,

Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of around €63 billion in 2018. BASF shares are

traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (BAS). Further information at www.basf.com.

Contacts

United States and Canada Mexico

BASF Corporation BASF Mexicana, S.A. de C.V.

11501 Steele Creek Road Av. Insurgentes Sur 975

Charlotte, NC 28273 Col. Ciudad de los Deportes

Phone: 1-800-251-0612 03710 Mexico, D.F.

Fax: 1-800-971-1123 Phone: 52-55-5325-2600

E-mail: dpsolutions@basf.com Fax: 52-55-5723-3011

Website: www.basf.us/ConstructionSolutions E-mail: contactoed@basf.com

Website: www.basf.com.mx

While the descriptions, designs, data and information contained herein are presented in good faith and believed to be accurate, they are provided for guidance only. Because many

factors may affect processing or application/use, BASF recommends that the reader make tests to determine the suitability of a product for a particular purpose prior to use. NO

WARRANTIES OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PUR-

POSE, ARE MADE REGARDING PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH, OR THAT THE PRODUCTS, DESCRIPTIONS, DESIGNS, DATA OR

INFORMATION MAY BE USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTY RIGHTS OF OTHERS. In no case shall the descriptions, information, data or designs provided

be considered a part of BASF’s terms and conditions of sale. Further, the descriptions, designs, data and information furnished by BASF hereunder are given gratis and BASF assumes

no obligation or liability for the descriptions, designs, data or information given or results obtained, all such being given and accepted at the reader’s risk.

®

= registered trademark of BASF Group.

© 2019 BASF, Charlotte, NC 28273. All rights reserved. r08/19

You might also like

- EMC-MTP-01: Material Traceability ProcedureDocument9 pagesEMC-MTP-01: Material Traceability Procedurekingofpenetration100% (3)

- Exportlayers DWG BS1192Document4 pagesExportlayers DWG BS1192Arief Rahman100% (1)

- Plextol R 4152Document1 pagePlextol R 4152Phạm Việt DũngNo ratings yet

- RHOPLEX™ MC-1834P: Cement Mortar ModifierDocument6 pagesRHOPLEX™ MC-1834P: Cement Mortar Modifierhemantrulz100% (1)

- Primal™ SF-016 ErDocument8 pagesPrimal™ SF-016 ErAPEX SONNo ratings yet

- Producerea RasinilorDocument115 pagesProducerea RasinilorPaul Chende100% (2)

- AW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebDocument64 pagesAW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebLong An DoNo ratings yet

- Cellosize QP 100mhDocument2 pagesCellosize QP 100mhca_rl_4No ratings yet

- DIDE261 Products & Materials: Residential: Assignment 2: Case StudyDocument21 pagesDIDE261 Products & Materials: Residential: Assignment 2: Case StudyoxNo ratings yet

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Document4 pagesUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006No ratings yet

- Guozhong LU, Weixuan ZHAO and Dewei DAI: Study On Preparation of Cementitious Capillary Crystalline Waterproofing CoatingDocument6 pagesGuozhong LU, Weixuan ZHAO and Dewei DAI: Study On Preparation of Cementitious Capillary Crystalline Waterproofing CoatingLenard BadayosNo ratings yet

- TDS Celvolit 1326 (SG)Document2 pagesTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- 100% Acrylic Emulsion For Cement Modification: Primal™ Mc-330EfDocument4 pages100% Acrylic Emulsion For Cement Modification: Primal™ Mc-330EfLong An DoNo ratings yet

- BASF MasterGlenium 3889 - SuperplasticizerDocument2 pagesBASF MasterGlenium 3889 - SuperplasticizerHJ100% (2)

- 2K Solvent Free Waterproofing FormulationDocument2 pages2K Solvent Free Waterproofing FormulationM Idrees100% (2)

- Acronal S 400 Ap PDFDocument3 pagesAcronal S 400 Ap PDFRajuNSanaboinaNo ratings yet

- Acronal NX 3587: ConstructionDocument3 pagesAcronal NX 3587: ConstructionRajuNSanaboinaNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- 2016 Construction ProdCat 1-31-2017Document36 pages2016 Construction ProdCat 1-31-2017umar buttNo ratings yet

- Construction-Additives - 2019 FinalDocument8 pagesConstruction-Additives - 2019 FinalDtotecnico MorterosNo ratings yet

- Brand AQAGloss-Brochure - Product Overview Polymer Dispersions Architectural Coatings-EnglishDocument6 pagesBrand AQAGloss-Brochure - Product Overview Polymer Dispersions Architectural Coatings-Englishfrox123No ratings yet

- Acronal 7079 PI EDADocument3 pagesAcronal 7079 PI EDAGokul Basker100% (2)

- Opaque Polymer HIQUE - as white as the driven snowDocument12 pagesOpaque Polymer HIQUE - as white as the driven snowLong An ĐỗNo ratings yet

- 07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiDocument62 pages07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiForeverNo ratings yet

- How To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry PaintsDocument45 pagesHow To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry Paintssriatul2006No ratings yet

- Ucar Latex R-362 - Mielco PDFDocument3 pagesUcar Latex R-362 - Mielco PDFForever0% (1)

- Acronal - Plus - 7023 - Jan 2020Document3 pagesAcronal - Plus - 7023 - Jan 2020Nikhil GoyalNo ratings yet

- Road Surfacing: STP LimitedDocument8 pagesRoad Surfacing: STP LimitedRana MahatoNo ratings yet

- Adekanol Uh-420: Thickener Rheology ModifiersDocument6 pagesAdekanol Uh-420: Thickener Rheology ModifierszxcvxcvxzcvNo ratings yet

- Acronal IA 734 AP PIDocument3 pagesAcronal IA 734 AP PIkishanptlNo ratings yet

- Aquaflow TechnicalDocument11 pagesAquaflow TechnicalCeratita ClarkNo ratings yet

- FoamStar ST 2412 August 2018 R3 ED2Document2 pagesFoamStar ST 2412 August 2018 R3 ED2APEX SONNo ratings yet

- Defoamers. Dispersions & Pigments Division Formulation AdditivesDocument51 pagesDefoamers. Dispersions & Pigments Division Formulation AdditivesLong An DoNo ratings yet

- BASF Construction Additives BrochureDocument8 pagesBASF Construction Additives BrochureHarshal PatilNo ratings yet

- Acronal EDGE 4247 Premium Performance For Exterior Paint and Primer in OneDocument8 pagesAcronal EDGE 4247 Premium Performance For Exterior Paint and Primer in OneLong An DoNo ratings yet

- Cement, Concrete & Mortar: Product Characteristics Brand NameDocument2 pagesCement, Concrete & Mortar: Product Characteristics Brand NameAliaksandr PrybauNo ratings yet

- Finco GroutDocument2 pagesFinco GroutaselabollegalaNo ratings yet

- 01 - 2K PU SB Auto Refinish & Ind Systems 08-10Document67 pages01 - 2K PU SB Auto Refinish & Ind Systems 08-10محمد عزتNo ratings yet

- Comparitive of Waterproofing WorkDocument12 pagesComparitive of Waterproofing WorkReshik KannanNo ratings yet

- Optifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintDocument16 pagesOptifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintAPEX SONNo ratings yet

- Incozol 2 TDSDocument1 pageIncozol 2 TDSArmando Van BuurenNo ratings yet

- Coating Resins Technical Data SheetDocument2 pagesCoating Resins Technical Data SheetWALTER KLISSMANNo ratings yet

- Corrosion Inhibitor BS 6580: Data SheetDocument4 pagesCorrosion Inhibitor BS 6580: Data SheetNicko RizqienggalNo ratings yet

- Attagel 50: AttapulgiteDocument2 pagesAttagel 50: AttapulgiteAPEX SON100% (1)

- Horsepower, Blade Size, and Tank Configuration RulesDocument24 pagesHorsepower, Blade Size, and Tank Configuration RulesEugene PaiNo ratings yet

- Architectural EN-VINAVIL PDFDocument36 pagesArchitectural EN-VINAVIL PDFSeafar YachtingNo ratings yet

- S2300 PaintDocument40 pagesS2300 PaintArun KastwarNo ratings yet

- VISCOLAM 635 TDS 171027 enDocument2 pagesVISCOLAM 635 TDS 171027 enDuodo NguyenNo ratings yet

- VINNAPAS Construction 2011 2012Document56 pagesVINNAPAS Construction 2011 2012fahmyaziz67% (3)

- Technical Data Sheet TexanolDocument4 pagesTechnical Data Sheet TexanolRICHARD ODINDONo ratings yet

- 6226 en 1Document28 pages6226 en 1adelabdelaal100% (1)

- Nitoflor SL2050: Constructive SolutionsDocument4 pagesNitoflor SL2050: Constructive SolutionsNishant VasuNo ratings yet

- Economic Paint RedaDocument1 pageEconomic Paint RedaForeverNo ratings yet

- Expansion Joint Waterproofing Specs - SD Combiflex SG v2Document5 pagesExpansion Joint Waterproofing Specs - SD Combiflex SG v2VIJAYTECH CONSULTANTS PVT. LTD.No ratings yet

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 pagesFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireNo ratings yet

- Inter Penertrating Polymer Network CBRI Paper PDFDocument8 pagesInter Penertrating Polymer Network CBRI Paper PDFRadha KrishnanNo ratings yet

- ElementisDocument16 pagesElementispipaporn kanjanapipatkulNo ratings yet

- Dirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.DDocument31 pagesDirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.Dichsan hakimNo ratings yet

- Akfix Eng Technical Catalog 2022 Rev16Document211 pagesAkfix Eng Technical Catalog 2022 Rev16ahmed.serefNo ratings yet

- 2K PU SB Waterproofing Formulation LCDocument2 pages2K PU SB Waterproofing Formulation LCM IdreesNo ratings yet

- Dispersing Agents and Humectants For Pigment PreparationsDocument2 pagesDispersing Agents and Humectants For Pigment PreparationsNiko KraljNo ratings yet

- DefomerDocument37 pagesDefomerKassahun LeykunNo ratings yet

- WaterproofingDocument2 pagesWaterproofingKiran JoshiNo ratings yet

- CMCI Concrete Curing - KureNsealDocument2 pagesCMCI Concrete Curing - KureNsealPrabhakar SvNo ratings yet

- (Shima and Afshan, 3C) BMS Water-Proofing Market Survey (Group 4)Document17 pages(Shima and Afshan, 3C) BMS Water-Proofing Market Survey (Group 4)Shima SharafNo ratings yet

- Aw31902 - 10 - Sonnet User Manual en English UsDocument76 pagesAw31902 - 10 - Sonnet User Manual en English UsLong An DoNo ratings yet

- FUN2799 ISS2 OCT17 MAY17 CI Fact SheetDocument3 pagesFUN2799 ISS2 OCT17 MAY17 CI Fact SheetLong An DoNo ratings yet

- Van de Heyning 2021 Two Phase Survey On The Frequency oDocument9 pagesVan de Heyning 2021 Two Phase Survey On The Frequency oLong An DoNo ratings yet

- Summary of Safety and Effectiveness Data (Ssed) : I. General InformationDocument36 pagesSummary of Safety and Effectiveness Data (Ssed) : I. General InformationLong An DoNo ratings yet

- Mi1210 Synchrony ST: Surgical GuideDocument64 pagesMi1210 Synchrony ST: Surgical GuideLong An DoNo ratings yet

- MRI Safety: of Cochlear Implants, Middle Ear Implants, and Bone Conduction ImplantsDocument3 pagesMRI Safety: of Cochlear Implants, Middle Ear Implants, and Bone Conduction ImplantsLong An DoNo ratings yet

- Cochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesDocument9 pagesCochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesLong An DoNo ratings yet

- 6 Mertens Thursday July 11 1Document16 pages6 Mertens Thursday July 11 1Long An DoNo ratings yet

- Rondo 2: Quick GuideDocument32 pagesRondo 2: Quick GuideLong An DoNo ratings yet

- RONDO 2 Audio Processor: Product CatalogueDocument24 pagesRONDO 2 Audio Processor: Product CatalogueLong An DoNo ratings yet

- Aw31902 - 10 - Sonnet User Manual en English UsDocument76 pagesAw31902 - 10 - Sonnet User Manual en English UsLong An DoNo ratings yet

- 003244v3 FullDocument91 pages003244v3 FullLong An DoNo ratings yet

- 24315CE r4 1-synchronyImplantFS WEBDocument4 pages24315CE r4 1-synchronyImplantFS WEBLong An DoNo ratings yet

- Rondo 2: It's Never Been EasierDocument4 pagesRondo 2: It's Never Been EasierLong An DoNo ratings yet

- ANSD Guidelines V 2-2 0608131Document29 pagesANSD Guidelines V 2-2 0608131Long An DoNo ratings yet

- Catalogue Surfactants PDFDocument16 pagesCatalogue Surfactants PDFMukesh KumarNo ratings yet

- CG Op200Document1 pageCG Op200Long An DoNo ratings yet

- Lamberti Brochure Additives Constructions v4!1!2020 BQDocument8 pagesLamberti Brochure Additives Constructions v4!1!2020 BQLong An DoNo ratings yet

- Fibers 08 00048Document14 pagesFibers 08 00048Long An DoNo ratings yet

- Cancers 13 02731Document17 pagesCancers 13 02731Long An DoNo ratings yet

- 2016 BASF ArchitecturalCoatingsBrochure ELDocument64 pages2016 BASF ArchitecturalCoatingsBrochure ELLong An DoNo ratings yet

- Defoamers. Dispersions & Pigments Division Formulation AdditivesDocument51 pagesDefoamers. Dispersions & Pigments Division Formulation AdditivesLong An DoNo ratings yet

- Desmodur L 75 - en - 82358391 12978387 13422316Document3 pagesDesmodur L 75 - en - 82358391 12978387 13422316Long An DoNo ratings yet

- Cells 10 02400Document16 pagesCells 10 02400Long An DoNo ratings yet

- Materials 14 02736 v2Document12 pagesMaterials 14 02736 v2Long An DoNo ratings yet

- 407 3 Emmanuelleyvonx PTDocument46 pages407 3 Emmanuelleyvonx PTLong An DoNo ratings yet

- BASF Waterproofing Product Guide LRDocument4 pagesBASF Waterproofing Product Guide LRLong An DoNo ratings yet

- Painting Statue TutorialDocument15 pagesPainting Statue TutoriallaurentstravaNo ratings yet

- BOQ - KURIGRAM-ELECTRIC fITTINGDocument8 pagesBOQ - KURIGRAM-ELECTRIC fITTINGlse furnitureNo ratings yet

- Central Workshop Manual For Mechanical Workshop CourseDocument60 pagesCentral Workshop Manual For Mechanical Workshop Courseankitbugalia56No ratings yet

- High Strength GroutDocument2 pagesHigh Strength GroutAmira RamleeNo ratings yet

- OPSS - PROV 903 Apr16Document24 pagesOPSS - PROV 903 Apr16Mark PermaulNo ratings yet

- CSKJBFDocument17 pagesCSKJBFgsNo ratings yet

- Pricelist 2022 1St QuarterDocument7 pagesPricelist 2022 1St QuarterJefNo ratings yet

- CONSTRUCTION STANDARD FOR INSTALLING PRECAST CONCRETE MANHOLESDocument9 pagesCONSTRUCTION STANDARD FOR INSTALLING PRECAST CONCRETE MANHOLESgemotorresNo ratings yet

- Conservation of 17th century Jama MasjidDocument26 pagesConservation of 17th century Jama Masjidhaneena RiyazNo ratings yet

- TLE Grade 8 Ilas: Food Processing EntrepDocument5 pagesTLE Grade 8 Ilas: Food Processing EntrepJeah mae TauleNo ratings yet

- COMBINEDDocument7 pagesCOMBINEDApple AterradoNo ratings yet

- Architecture in The Industrial RevolutionDocument6 pagesArchitecture in The Industrial RevolutionMark Steven ElordeNo ratings yet

- Lucien Field Estates - Colonial ManorDocument2 pagesLucien Field Estates - Colonial ManorJhannon WellsNo ratings yet

- Week 11Document3 pagesWeek 11Florenell PacureNo ratings yet

- Lokfix Anchoring SolutionsDocument4 pagesLokfix Anchoring SolutionsJose ManjooranNo ratings yet

- Section Details of Staff Common RoomDocument1 pageSection Details of Staff Common RoomAshok DhengeNo ratings yet

- Detailed Estimate PNP HeadquarterDocument33 pagesDetailed Estimate PNP HeadquarterLizza AnnaNo ratings yet

- Maxifloor MFT 323 SL Epoxy CoatingDocument2 pagesMaxifloor MFT 323 SL Epoxy CoatinganggaNo ratings yet

- Manandhar 2019Document13 pagesManandhar 2019Danica Joy AlfarNo ratings yet

- Class 12 Investigatory Project - ChemistryDocument11 pagesClass 12 Investigatory Project - ChemistrySunil ShahNo ratings yet

- Architectural Design Assignment Adaptive ReuseDocument24 pagesArchitectural Design Assignment Adaptive ReuseSUPRIYA SINHANo ratings yet

- TLE Carpentry Grade 10 Module 2Document25 pagesTLE Carpentry Grade 10 Module 2Amelyn Goco Mañoso100% (4)

- The history of furniture design and decoration in the Byzantine middle agesDocument3 pagesThe history of furniture design and decoration in the Byzantine middle agesshivani kanaujiyaNo ratings yet

- Area A Reviewer CompilationDocument27 pagesArea A Reviewer CompilationCARLA PAULINE ROSCANo ratings yet

- Jopet Dela Cruz, Et 158 M1Document6 pagesJopet Dela Cruz, Et 158 M1Romnick Elgamo GalantoNo ratings yet

- Bridge Cost Estimate SheetDocument2 pagesBridge Cost Estimate SheetDimas PurnamaNo ratings yet