Professional Documents

Culture Documents

2nd Class Motor Examination Questions

Uploaded by

my generalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2nd Class Motor Examination Questions

Uploaded by

my generalCopyright:

Available Formats

6/16/2020 December 2002 Question 8

2nd Class Motor Examination Questions

December 2002 Question 8.

With reference to air compressors and starting air systems:

a. state, with reasons, why compressor cylinder lubrication should be kept to a

minimum that is compatible with an acceptable cylinder wear rate; (4)

b. explain the effects of operating an air compressor with a leaking first stage

discharge valve; (4)

c. explain why compressor intercoolers should be kept as clean as possible and with

an adequate circulating water supply; (4)

d. explain why all air pipelines should be kept clear of oil deposits, indicating how this

may be achieved. (4)

a.

If the cylinder lubrication is excessive, oil will be carried over with the compressed air,

depositing on the discharge valves where, especially in the case of mineral oil, due to the

high temperatures it will form carbon deposits preventing the valve from closing properly.

Oil will also be carried over into the air receiver, where it will oxidise and cause corrosion.

excessive oil in the 2nd stage cylinder of an air compressor is dangerous should the

compressor overheat as there is a possibility of the oil vapour being ignited.

b.

The volumetric efficiency of the compressor will be reduced (vol of air drawn in/swept vol of

cylinder); this is because as the piston moves down the cylinder on the induction stroke, air

previously compressed will be drawn back into the cylinder. This will result in increased

running hours and overheating as the recompressed air is raised in temperature each time.

c.

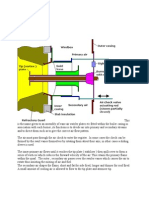

For the compressor to be as efficient as

possible compression of the air should be

as close to isothermal as possible. By

cooling the air between stages the actual

polytropic compression is bought as close

to the ideal isothermal line (see diagram).

Cooling the air between stages will also

prevent the air temperature rising during

compression to a level which would cause

overheating and burning of the cylinder oil,

leading to excessive wear and the danger of

explosion.

The compressor is designed so that equal

work is done by each stage. Inefficient

file:///E:/STUDY/MARINE ENGINEERING/Marine Books/UK NOTES/book 3/air comp..mht 1/2

6/16/2020 December 2002 Question 8

intercooling would prevent that, leading to

out of balance forces and increased wear.

d.

Oil in pipelines, especially air start pipelines is especially dangerous as an air start explosion

can result. This will happen when starting an engine during manoeuvring, if a cylinder air

start valve has been leaking, if fuel ignites in the cylinder during the start sequence, or, as is

thought, the compressed air rushing down the air start line acts like a piston compressing the

air and oil in the line, raising its temperature and causing ignition. In addition, the oil, as

previously mentioned, will oxidise causing pitting corrosion.

Prevention of oil deposits is achieved by not over lubricating the cylinders of the air

compressors, placing oil separators in the discharge line from the compressor, draining (oil

and water) from the air receivers regularly, and not introducing oil into the air start line

deliberately (lubrication of air start valves clearing of drains using hydraulic pump etc.).

Next Question Previous Question

file:///E:/STUDY/MARINE ENGINEERING/Marine Books/UK NOTES/book 3/air comp..mht 2/2

You might also like

- Intek.v Twin - GovernorDocument18 pagesIntek.v Twin - Governorjclarkjr67% (3)

- ActiveFaults 7cyl GeneralDocument8 pagesActiveFaults 7cyl GeneralCalin Silviu100% (1)

- Piaggio Fly 125 I.E - 150 I.E Leader MY 2011 (EN)Document231 pagesPiaggio Fly 125 I.E - 150 I.E Leader MY 2011 (EN)ManuallesNo ratings yet

- Piaggio Xevo 400ie (EN)Document376 pagesPiaggio Xevo 400ie (EN)Manualles100% (2)

- Vdocuments - MX Guangzhou GDF 8320Document203 pagesVdocuments - MX Guangzhou GDF 8320Bryan EndricoNo ratings yet

- DEUTZ Diesel Engine BF4/6M2012 Operation ManualDocument62 pagesDEUTZ Diesel Engine BF4/6M2012 Operation Manualnicoss69No ratings yet

- Tad572ve enDocument2 pagesTad572ve enPakito-sanNo ratings yet

- Hondata Tuning GuideDocument11 pagesHondata Tuning Guidejameel babooram0% (1)

- 2nd Class Motor Examination QuestionsDocument2 pages2nd Class Motor Examination Questionsmy generalNo ratings yet

- 1st Class Motor Examination QuestionsDocument2 pages1st Class Motor Examination Questionsmy generalNo ratings yet

- 1st Class Motor Examination QuestionsDocument2 pages1st Class Motor Examination Questionsmy generalNo ratings yet

- Chap 14Document14 pagesChap 14Khurram AliNo ratings yet

- Temp 1 PDFDocument15 pagesTemp 1 PDFmaddukuri jagadeesh babuNo ratings yet

- Compressed Air Drying PDFDocument29 pagesCompressed Air Drying PDFmaddukuri jagadeesh babu100% (2)

- Mam II, Answers To Question Bank, 20-4-11Document57 pagesMam II, Answers To Question Bank, 20-4-11Giri VenkatesanNo ratings yet

- Chap 3Document8 pagesChap 3Khurram AliNo ratings yet

- 1 Description of ICE-finalDocument12 pages1 Description of ICE-finalaliNo ratings yet

- Air CompsDocument26 pagesAir CompssameerNo ratings yet

- 2nd Class Motor Examination QuestionsDocument2 pages2nd Class Motor Examination Questionsmy generalNo ratings yet

- Modu 11 - Engine Cooling SystemReviewedDocument24 pagesModu 11 - Engine Cooling SystemReviewedHAFIDY RIZKY ILHAMSYAHNo ratings yet

- Air Compressors: Graph of Pressure Against Volume in A Reciprocating CompressorDocument14 pagesAir Compressors: Graph of Pressure Against Volume in A Reciprocating CompressorJAY PARIKHNo ratings yet

- Combustor: Flame Stabilized by CycloneDocument56 pagesCombustor: Flame Stabilized by CycloneChadwickajiNo ratings yet

- 9 Actual CyclesDocument27 pages9 Actual Cyclesxemovi7309No ratings yet

- Design and Analysis of Gas Turbine Combustion Chamber: P.Sravan Kumar, P.Punna RaoDocument5 pagesDesign and Analysis of Gas Turbine Combustion Chamber: P.Sravan Kumar, P.Punna RaoInternational Journal of computational Engineering research (IJCER)No ratings yet

- 03 Preparation of Compressed AirDocument3 pages03 Preparation of Compressed AirNatsuko KayamaNo ratings yet

- Module 5 CombustorDocument11 pagesModule 5 CombustorKevin MangroliyaNo ratings yet

- Chapter 6 Combustion ChambersDocument31 pagesChapter 6 Combustion Chambersmustafaxdar4No ratings yet

- Thermodynamics Tutorial 6 Air Compressors: © D.J.Dunn 1Document26 pagesThermodynamics Tutorial 6 Air Compressors: © D.J.Dunn 1Eddie SantillánNo ratings yet

- Materials Used For Construction: 1. Reciprocating CompressorDocument6 pagesMaterials Used For Construction: 1. Reciprocating CompressorEdemNo ratings yet

- An Evaluation of Encapsulated Oil Flooded Screw Compressor SystemsDocument7 pagesAn Evaluation of Encapsulated Oil Flooded Screw Compressor SystemsAkhli RahmatullohNo ratings yet

- Centrifugal Compressor Construction and TestingDocument10 pagesCentrifugal Compressor Construction and Testingmusaveer0% (1)

- Qip-Ice-09-Actual Cycles PDFDocument28 pagesQip-Ice-09-Actual Cycles PDFankit ghildiyalNo ratings yet

- 結冰Document14 pages結冰a0968973521No ratings yet

- Actual CyclesDocument6 pagesActual CycleskondusamyNo ratings yet

- Air CompressorDocument23 pagesAir CompressorsaadNo ratings yet

- I. Choose The Most Appropriate Answer From The Choices Given Below: - (15 Marks)Document4 pagesI. Choose The Most Appropriate Answer From The Choices Given Below: - (15 Marks)indusampathNo ratings yet

- Engineering Letter: FansandblowersforcombustionprocessDocument4 pagesEngineering Letter: Fansandblowersforcombustionprocessnedduc20No ratings yet

- AccumulatorsDocument5 pagesAccumulatorspaplus50% (2)

- 1.1.3 Four-Stroke-Cycle Compression-Ignition (Diesel) EngineDocument1 page1.1.3 Four-Stroke-Cycle Compression-Ignition (Diesel) EngineFuad AnwarNo ratings yet

- Fire Flooding Thermal EORDocument5 pagesFire Flooding Thermal EORPrakhar SarkarNo ratings yet

- Technical Information: Equipment Rental & Wholesale Industrial SuppliesDocument1 pageTechnical Information: Equipment Rental & Wholesale Industrial SuppliesRita Herwiyani PriandariNo ratings yet

- Mot03 03 1400Document8 pagesMot03 03 1400Mobin GhariNo ratings yet

- G02, Compressor FaultsDocument2 pagesG02, Compressor Faultsbyronblake80No ratings yet

- CompressorsDocument45 pagesCompressorssubscruNo ratings yet

- 21 254 Dehumidification For ElectronicsDocument12 pages21 254 Dehumidification For ElectronicsJose LopezNo ratings yet

- Screw CompressorDocument4 pagesScrew Compressordarksun2011100% (2)

- Prepared By: Hemanthkrishnan R Roll No 44 S5Ma NssceDocument22 pagesPrepared By: Hemanthkrishnan R Roll No 44 S5Ma NssceKingNo ratings yet

- Steam Turbine Preventing Corrosion Maintenance in Idle TurbinesDocument2 pagesSteam Turbine Preventing Corrosion Maintenance in Idle Turbinesparthibanemails5779No ratings yet

- Copeland Zr90 300Document21 pagesCopeland Zr90 300Wilson Javier CubaNo ratings yet

- Piston Vs Rotary Screw in Collision Market FINAL 08152013-tcm9-387791Document4 pagesPiston Vs Rotary Screw in Collision Market FINAL 08152013-tcm9-387791Anonymous 1XHScfCINo ratings yet

- Beant College of Engineering and Technology Gurdaspur: Seminar Report (TH-590)Document20 pagesBeant College of Engineering and Technology Gurdaspur: Seminar Report (TH-590)Ahmad Riaz KhanNo ratings yet

- The Importance of Oil and Particle Flow For Exhaust Valve Wear-Anforsberg14Document8 pagesThe Importance of Oil and Particle Flow For Exhaust Valve Wear-Anforsberg14enjpetNo ratings yet

- Locomotive: Service ManualDocument12 pagesLocomotive: Service ManualGabrielaNo ratings yet

- Compressed Air and Its Purifi Cation From Generation To ApplicationDocument7 pagesCompressed Air and Its Purifi Cation From Generation To ApplicationJayson AlvaNo ratings yet

- Registers: Air RegisterDocument2 pagesRegisters: Air RegisterTin Aung KyiNo ratings yet

- Engine Cooling System Notes 31-5-17Document26 pagesEngine Cooling System Notes 31-5-17collins arogoNo ratings yet

- Name: Umar Amin Reg No: 2018-CH-227 Section: A Subject:: Thermodynamics 2 LabDocument3 pagesName: Umar Amin Reg No: 2018-CH-227 Section: A Subject:: Thermodynamics 2 LabHussain AliNo ratings yet

- GTE Combustion ChamberDocument33 pagesGTE Combustion ChamberTAMILSELVAM NALLUSAMYNo ratings yet

- Compressors: Objective: Desired Learning OutcomesDocument17 pagesCompressors: Objective: Desired Learning OutcomesKhurram AliNo ratings yet

- Jet Engine DefinitionDocument9 pagesJet Engine DefinitionDan AglioneNo ratings yet

- Fallsem2016-17 2134 RM001 09-Aug-2016 Che2006 THDocument35 pagesFallsem2016-17 2134 RM001 09-Aug-2016 Che2006 THsinsnigNo ratings yet

- 1cylinder CombustionDocument23 pages1cylinder CombustionBharatiyulamNo ratings yet

- Compressor Design Mechanical and Electrical PDFDocument44 pagesCompressor Design Mechanical and Electrical PDF임학진No ratings yet

- Presence of Contaminants in Refrigerant and Their Effect On Refrigeration CycleDocument6 pagesPresence of Contaminants in Refrigerant and Their Effect On Refrigeration CycleHouse And LotNo ratings yet

- Air CompDocument15 pagesAir ComppaviliondmNo ratings yet

- Yuda Bungaran - Aircraft Cabin Environmental SystemDocument6 pagesYuda Bungaran - Aircraft Cabin Environmental SystemYuda Bungaran PadangsNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- 1st Class Motor Examination QuestionsDocument2 pages1st Class Motor Examination Questionsmy generalNo ratings yet

- 1st Class Motor Examination QuestionsDocument2 pages1st Class Motor Examination Questionsmy generalNo ratings yet

- 2nd Class Motor Examination QuestionsDocument2 pages2nd Class Motor Examination Questionsmy generalNo ratings yet

- Parts FailureDocument5 pagesParts Failuremy generalNo ratings yet

- Safety CertificateDocument292 pagesSafety Certificatemy generalNo ratings yet

- Pneumatic ManuoveringDocument5 pagesPneumatic Manuoveringmy generalNo ratings yet

- Marine Diesel EngineDocument5 pagesMarine Diesel Enginemy generalNo ratings yet

- Engine Parts MaterialsDocument4 pagesEngine Parts Materialsmy generalNo ratings yet

- Reciprocating Air CompressorDocument19 pagesReciprocating Air Compressorrajeesh4meNo ratings yet

- Honda Cm185 Workshop ManualDocument206 pagesHonda Cm185 Workshop ManualGerman HurtadoNo ratings yet

- FHI Develops A New-Generation Subaru Boxer EngineDocument2 pagesFHI Develops A New-Generation Subaru Boxer EngineVICTORMARCENo ratings yet

- KTA38 Letter PDFDocument2 pagesKTA38 Letter PDFSamir YehyaNo ratings yet

- Codigos Motor Navistar 466EDocument5 pagesCodigos Motor Navistar 466EJj Marquez Chacon75% (4)

- L27 - 38 - HFO Maintenance ProgramDocument2 pagesL27 - 38 - HFO Maintenance Programventa kevaraNo ratings yet

- Volvo Penta Inboard Diesel: Technical DataDocument2 pagesVolvo Penta Inboard Diesel: Technical DataAlexNo ratings yet

- lUBRICATION SYSTEMDocument22 pageslUBRICATION SYSTEMricrispim100% (2)

- Emission Control Systems: On-Board DiagnosticsDocument22 pagesEmission Control Systems: On-Board DiagnosticsPelis CloneNo ratings yet

- p2 5S-FE+ENGINE+REPAIR+MANUALDocument19 pagesp2 5S-FE+ENGINE+REPAIR+MANUALMuhammad SafdarNo ratings yet

- Clean The Throttle Body and RelocateDocument8 pagesClean The Throttle Body and RelocateJorge Luis DislaGonzalezNo ratings yet

- 5 KVA Engien Alternator-Ashok LeylandDocument7 pages5 KVA Engien Alternator-Ashok LeylandmohdrashidNo ratings yet

- Crankshafts Ski DooDocument8 pagesCrankshafts Ski Doocarlos roberto chan chinNo ratings yet

- Ge12ti Co Gen-GDocument2 pagesGe12ti Co Gen-GTilok DasNo ratings yet

- PERKINS (Trobuleshooting)Document224 pagesPERKINS (Trobuleshooting)Iordan Adrian100% (1)

- 7-8 Engine Bottom Enditransmission: Crankcase AssemblyDocument1 page7-8 Engine Bottom Enditransmission: Crankcase AssemblyPabloNo ratings yet

- ISM Codes: A Complete List of All Cummins Fault Codes For ISM Diesel EnginesDocument3 pagesISM Codes: A Complete List of All Cummins Fault Codes For ISM Diesel EnginesEduardo TorresNo ratings yet

- Lecture-Diesel Power PlantDocument32 pagesLecture-Diesel Power Plantvinmwale91430% (1)

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 13-02 - Oil PumpDocument5 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 13-02 - Oil PumpMANUALESNo ratings yet

- Variable Turbine GeometryDocument2 pagesVariable Turbine GeometryRowan CorneliusNo ratings yet

- Engine: QSB3.3-C99 Machine: AP240 Tier 3 Specification: Z07-620-2Document60 pagesEngine: QSB3.3-C99 Machine: AP240 Tier 3 Specification: Z07-620-2abelmonte_geotecnia67% (3)

- FM-FCL-06 Riwayat Perbaikan Sarana Prasarana - 2023-01Document106 pagesFM-FCL-06 Riwayat Perbaikan Sarana Prasarana - 2023-01allannassNo ratings yet