Professional Documents

Culture Documents

Toaz - Info 1963 Paris P Erdogana Critical Analysis of Crack Propagation Laws PR

Uploaded by

Ryann MengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toaz - Info 1963 Paris P Erdogana Critical Analysis of Crack Propagation Laws PR

Uploaded by

Ryann MengCopyright:

Available Formats

P.

PARIS 1

Associate Professor of Mechanics and

Assistant Director of the Institute of Research,

A Critical Analysis of Crack Propagation Laws

Lehigh University, Bethlehem, Pa,

The practice of attempting validation of crack-propagation laws (i.e., the laws of Head,

Frost and Dugdale, McEvily and Illg, Liu, and Paris) with a small amount of data,

F. ERDOGAN such as a few single specimen test results, is questioned. It is shown that all the laws,

Professor of Mechanical though they are mutually contradictory, can be in agreement with the same small sample

Engineering, Lehigh University, of data. It is suggested that agreement with a wide selection of data from many speci-

Bethlehem, Pa. Mem. ASME

mens and over many orders of magnitudes of crack-extension rates may be necessary to

validate crack-propagation laius. For such a wide comparison of data a new simple

empirical law is given which fits the broad trend of the data.

Introduction da

= / ( f , a, Ci) (1)

dN

sIEVEHAL

* crack-propagation laws have been pre-

sented in the past few years, which claim to be verified b y the Therefore this format will be employed in the discussion to

experimental data analyzed in their respective papers. They follow.

are specifically the work of Head [l], a Frost and Dugdale [2], Chronologically the first crack-propagation law which drew

McEvilj' and Illg [3 ], Liu [4, 5 ], and Paris, Gomez, and Anderson wide attention was that of Head [1] in 1953. He employed a

[6,7,8]. mechanical model which considered rigid-plastic work-hardening

This paper will attempt to show that basing validation of a elements ahead of a crack tip and elastic elements over the re-

crack-propagation theory on a limited amount of data is a poor mainder of the infinite sheet. The model required extensive

test of any theory. Moreover, a wide range of test data is now calculations and deductions to obtain a law which may be

available in a convenient form [9] which may be employed to written as

analyze critically these several crack propagation laws.

Therefore the paper will consist of three parts which will in- da C^a'*

(Head's law) (2)

clude: dN (C 2 - 0>„'/'

1 A review and comparison of existing crack-propagation

where Ci depends upon the strain-hardening modulus, the modu-

laws.

lus of elasticity, the yield stress and the fracture stress of the

2 The erroneous results obtained by comparing each law with

material, and Ci is the yield strength of the material. Head de-

a limited range of test data.

fined Wo as the size of the plastic zone near the crack tip and pre-

3 The results of comparing crack-propagation laws with a sumed it was constant during crack propagation. However,

wide range of data. Frost [2] noticed that the plastic-zone size increased in direct

proportion to the crack length in his tests. Moreover, Irwin [10]

has recently pointed out from analytical considerations that

A Review of Existing Crack-Propagation Laws

Crack-propagation laws given in the literature take many Wo (3)

forms. In general they treat cracks in infinite sheets subjected

for the configuration treated here which is in agreement with

to a uniform stress perpendicular to the crack (or can be applied

Frost's conclusions. Therefore, though Head adopted equation

to that configuration) and they relate the crack length, 2a, to the

(2) with w0 considered constant as his crack-propagation law, we

number of cycles of load applied, N , with the stress range cr, and

are forced here to introduce equation (3) into equation (2) to

material constants C,-.' The single form in which all crack-

obtain a modified or corrected form of Head's crack-propagation

propagation laws may be written is

law; i.e.,

da C3o~2a

1Also Consultant to the Boeing Company, Transport Division, (Head's corrected law) (4)

dN = (C 2 - o)

Renton, Wash.

2 Numbers in brackets designate References at end of paper.

3 In this discussion a will imply the stress-fluctuation range and Ci Frost and Dugdale [2] in 1958 presented a new approach to

will vary slightly with mean stress in a general interpretation. crack-propagation laws. They observed as was introduced in

Contributed by the Metals Engineering Division and presented at equation (4), that Head's law should be corrected for the varia-

the Winter Annual Meeting, New York, N. Y., November 25-30, tion of plastic-zone size with crack length. They deduced that

1962, of THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS.

Manuscript received at ASME Headquarters, April 11, 1962. Paper the corrected result, equation (4), depends linearly on the crack

No. 62—WA-234. length a. However, they also argued b y dimensional analysis

•Nomenclature-

a = half crack length F{ } = a function of da

Qo = initial half crack length G{ } = a function of — = crack extension per cycle of

B = a function of stress range (and k = stress-intensity factor (range)

d N load

mean stress) IClW = stress-concentration factor Ak = stress-intensity-factor range

C = a numerical constant m = a numerical exponent p, pi = crack-tip radius

C; — constants (which vary slightly M = a material constant cr = applied stress (range)

with mean stress) n = a numerical exponent UQ = stress at a crack tip (with

Ds = constants which depend on N = cycle number finite radius p)

stress level Aro, Nj, — initial and final cycle number, crnot = net section stress

/ ( ) = a function of respectively w0 = plastic-zone size

528 / DECEMBER 1963 Transactions of the AS M E

Copyright © 1963 by ASME

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/15/2013 Terms of Use: http://asme.org/terms

that the incremental increase in crack length da, for an incremen- following arguments: Irwin's [12] stress-intensity-factor k re-

tal number of cycles dN, should be directly proportional to the flects the effect of external load and configuration on the in-

crack length a. Hence they concluded that (independent of tensity of the whole stress field around a crack tip. Moreover,

Head's model) for various configurations the crack-tip stress field always has the

same form (i.e., distribution). Therefore it was reasoned that

da

Ba (5) the intensity of the crack-tip stress field as represented by k

dN should control the rate of crack extension. 4 That is to say:

where B is a function of the applied stresses. Then they ob-

served that in order to fit their experimental data: = (?{fc} (15)

dN

B = (6) In treating the special configuration of interest in this discussion,

C; it should first be observed that (11)

Combining equations (5) and (6) they obtained the law: k = < r a ( 1 6 )

da cr3a whereupon equation (15) may be specialized to read:

— = — (Frost and Dugdale's law) (7)

dN Ci

da

"A! (17)

About the same time McEvily and Illg [3] modified a method dN =

of analysis of static strength of plates with cracks used at N A S A

to obtain a theory of crack propagation. Their arguments were Somewhat later, Liu [4] restated Frost and Dugdale's [2] di-

as follows: Presuming that a crack tip in a material has a charac- mensional analysis in a much more elegant form and argued that

teristic (fictitious) radius pi, which allows computation of the the crack-growth rate should depend linearly on the crack

stress (To, in the element at the crack tip using elastic stress- length; i.e.,

concentration factor concepts, the stress a 0 is da

— = Ba (Liu's law) (18)

dN

(To = Kn(T net (8)

where K N is the stress-concentration factor and <rnet is the net which is the same result as equation (5). Liu then presumed

area stress at the cracked section. For the configuration used that B was in general a function of stress range a (and mean

stress); i.e.,

here, i.e., an infinite plate with uniform stress a

B = B(o-) (19)

ICN = 1 + 2 ( a / p , ) ' A (9)

In a subsequent work, Liu [5] notes that mean stress is of

which is based on the elastic solution for an elliptical hole of secondary influence and, using a model of crack extension em-

semimajor axis a and end radius pi. ploying an idealized elastic-plastic stress-strain diagram and a

concept of total hysteresis energy absorption to failure, reasons

<Tnet = <J (10)

that

and substituting equations (9) and (10) into (8) gives

B{<T) = C6o-2 (20)

tr„ = <r[l + 2 ( a / p , ) ' ^ ] (11)

which combined with equation (18) gives

Based on considerations that under cyclic loading work-hardening

at the crack tip will raise the local stress to a fracture stress, they da

— = C5o"'a (Liu's modified law) (21)

concluded that the crack-extension rate will be a function of <ra or dN

da

- = F{tr„} = F{KN<rnei\ (12) The Equivalence of K N to k

dN

Hardrath [14] observed that KNanet for the special configura-

tion employed here, from equations (8) and (10),

(McEvily and Illg's law)

Therefore for the special configuration of interest here, i.e., in-

K N <r net = u [ l + 2(a/p,)'/«] (22)

troducing equations (8), (9), (10), and (11) into (12), we have is similar to the stress-intensity factor, equation (16),

S - ' K - O T <u> k = <sah

if pi is small compared to a. For aluminum alloys (2024T3 and

7075T6) his colleagues McEvily and Illg [3] had already observed

(23)

which is the desired form in this discussion upon considering pi to

that pi is less than 0.005 in. so that the condition pi <K a is in fact

be a material constant, in likeness to the Cs.

present for cracks of a readily observable length in crack-propaga-

McEvily and Illg go on in an empirical manner to obtain the

tion tests. Thus Kj/O'net and k are known to concur for this

form of the function F { } , and suggest

special configuration and in addition a proof that they are

34 equivalent in general will be offered here.

logi 00509 ffiVcrnel - 5.472 - (14)

KNane, - 34 Irwin [12] observed that the equations for the stress field sur-

rounding the tip of a sharp crack contains the factor fc/(2r)1/,J

(McEvily and Illg's law empirically extended)

which implies a singularity of stress at the crack tip. Now, if a

It should be noted b y the reader that McEvily and Illg's laws, hole of radius p is drilled at the crack tip, the maximum stress on

equations (12) and (14), are not restricted to the special configura- the periphery of the hole will be proportional to k/(2p)1^ or

tion here, as was the case for the laws of Head, and Frost and

<r„ = CT/(2p)'A (24)

Dugdale. The applicability to other configurations and an addi-

tional similarity to Paris' work [6, 7, 8 ] will warrant later com- which applies for any p which is small compared to other planar

ments.

4 At about this same time Martin and Sinclair [13] attempted un-

Independent of McEvily and Illg, Paris [11] proposed a crack- successfully to correlate crack-extension rates using a similar parame-

propagation theory at about the same time. It is based on the ter but did not observe a correlation which does in fact occur.

Journal of Basic Engineering DECEMBER 19 6 3 / 5 2 9

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/15/2013 Terms of Use: http://asme.org/terms

dimensions of any configuration considered, and C is a constant

independent of the configuration. Finally, cr0 in equation (24) may

be interpreted to be the same as KN<TNET, from equation (8) and

its accompanying discussion, if p is taken equal to pi. Then

Ck

K N anet = ffo (25)

(2 p , ) ' A

In order to evaluate C, the results for the special configuration

considered herein may be employed, i.e., substituting equations

(22) and (23) into (25) and noting equivalence for small pi gives

C = lim

= lim

pi—>-0

a 1 +2

[_ (tO a ] (2p,)I/! = 2 (26)

Putting this result into equation (25) and rearranging, 200000 eio o o o 220 000 2 3 0 OOO

, N0.I5

575 0 0 0 600 000 625 0 0 0

Kn 1

<r net p i / ' NO. 10 ,

k •• lim (27) 102 0 0 0 103000

pi-t-0

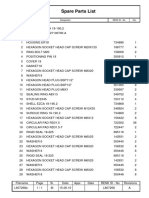

Fig. 1 Typical data from Martin and Sinclair on Head's suggested plot

which implies the general equivalence of /fA.<Jnet and k.

Similarities Between Crack-Propagation Laws

;

The result of the foregoing discussion, equation (27), implies TESTS BY M A R T I N 8 SINCLAIR [.13} !

the direct similarity of McEvily and Illg's law, equation (12), and SYMBOL SPECIMEN STRESS

Paris' result, equation (15). A choice between the two is strictly • MO. 10 2 7 0 2 7 PSI

dependent on a matter of convenience and clarity of accompanying • NO. 14 2 3 760 •

concepts in employing one or the other.6 O NO. 15 21978 •

The laws of Head, equation (4), Frost and Dugdale, equation

(7), and Liu, equations (18) and (21), can all be approximated by

the form

// '

da <T"a'n

= (28)

dN

for the special configuration which is treated. N o w , it is evident

that Paris' result for this configuration, equation (17), implies:

n

(29)

~2

NO 13 ,

575 0 0 0 600 0 0 0 6250 0 0

which can also be derived from McEvily and Illg's result, equa- NO. 14

tion (13), for pi small compared to a. 200 0 0 0 2 JO 0 0 0 220 000 230000

, NO. 10

The laws of Head, and Frost and Dugdale do not quite [02000 105000 110 0 0 0 115000

agree with applying equation (29) to equation (28), however, N (eyelo)

Fig. 2 The same data from Martin and Sinclair on Frost's or Liu's sug-

Liu's law does concur with the specified form.

gested plot

It is pertinent to now show that determining m and n from a

limited quantity of data is a doubtful practice. That is to say

that plotting data from single test specimens on a logarithmic or

semilogarithmic graph on which laws such as Head's, Frost's, and

Liu's predict straight line relationships is not a reasonable test TESTS BY MARTIN 8 SINCLAIR [|3J

of the validity of a crack propagation law. SYMBOL SPECIMEN STRESS

Erroneous Evaluation of Data From Single Tests

A typical crack-propagation test consists of a wide plate with a

central crack of length 2a, subjected to uniform tension <r, re-

peatedly applied. During a single test then tr is a constant and

data consisting of crack lengths and corresponding cycle numbers

are obtained. Let the problem of examining each of the previous

crack-propagation laws for a particular test be formulated.

In a constant maximum repeated stress-level test Head's law,

equation (2), is reduced to

^da = „ a A,,

(30)

6 For very small cracks there is a difference between the two

Fig. 3 Again the same data from Martin and Sinclair on McEvily's or

theories which is left unresolved. Paris' suggested plot

530 / DECEMBER 1963 Transactions of the A S M E

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/15/2013 Terms of Use: http://asme.org/terms

where D\ is a constant for a given stress range a. Integrating this not fall on the straight-line portions of Figs. 1 and 2 seem to be

expression gives perfectly acceptable here. Since the data were differentiated

to obtain da/dN, an additional amount of scatter is introduced.

rr = DiN + const (31) Therefore the data also imply verification of these two laws as

n ' 2

well.

Hence, all of the laws agree with the data and, since these laws

Therefore Head suggested plotting l/a^ versus N and, observing

are not identical, the method of verification of crack-propagation

equation (31), implied that obtaining a straight line for each

theories from a limited amount of test data is evidently in error.

specimen whose data are plotted this way indicates verification of

An alternative approach employing a wider range of test data

his law.

must be employed.

The data of Martin and Sinclair [13] are employed here as an

unbiased source. From their data specimens nos. 10, 14, and 15

were chosen since those specimens were run at medium stress Comparison of Crack-Propagation Laws With a Wide

levels and the greatest number of data points per specimen was Range of Test Data

recorded for them. Fig. 1 shows the type of plot suggested by In previous work [6, 8] it was observed that data from several

Head and it is noticed that portions of the data do form straight sources [3, 9, 13] may be plotted in the form of Fig. 3 (semi-

lines. Does this mean that Head's theory is verified? The logarithmic) to obtain a single curve on a range of stress-in-

reader is warned that this might be a hasty conclusion. tensity factor, Ak (corresponding to stress range) versus log

First, consider the corrected law of Head, Frost and Dugdale's (da/dN) diagram, where da/dN covers as many as 6 log cycles.

law, and Liu's law, equations (4), (7), (18), and (19), respec- However, replotting these data on a log Ak versus log (da/dN)

tively. For a constant stress-range test all these laws reduce graph reveals some pertinent results. The data are replotted in

to the form Fig. 4 and the three specimens from Martin and Sinclair's work

used in the foregoing for the purpose of illustration are shown to

da

(32) indicate their concurrence with the general trend.

dN = D*a

The authors are hesitant but cannot resist the temptation to

draw the straight line of slope 'A through the data in Fig. 4. The

Integrating this result gives:

equation of this line is observed to be

log a = D2N + const (33)

da (Aky

(35)

Therefore plotting log a versus N and obtaining straight lines has dN M

been accepted as verifying these theories. Fig. 2 is this type of

plot employing the very same test data point by point of Martin Equation (35) fits the data almost as well as McEvily and Illg's

and Sinclair shown in Fig. 1. Again, the test data have straight- extended law, equation (14), and is considerably simpler in form.

line portions. Therefore it now seems to verify both Head's law The advantage of this form is clarified by considering its ap-

equation (30) and the other laws with the form of equation (32). plication to the configuration employed earlier, in which case it

But the theories represented by equations (30) and (32) are becomes

not the same! da

Now let the laws of McEvily and Illg, and Paris, equations (36)

dN M

(12) and (15), be examined in the light of these same data. Re-

calling equation (27) these two laws are equivalently expressed The laws of Head, Frost and Dugdale, and Liu depend on a in a

by manner other than a2. Clearly, their laws are at variance with

the data trend in Fig. 4; i.e., Head predicts the slope of l /z and

(34)

Frost and Dugdale as well as Liu would predict '/* as indicated

in the figure.

for a given material. T o test these theories, data from several Moreover, if one might be so bold as to attempt to integrate

specimens should be plotted on a k versus da/dN (or log da/dN) equation (36) it becomes

graph and these laws predict that the data of several specimens

will form a single curve. Again the same data of Martin and J_

«o (N - N„) (37)

Sinclair are plotted in Fig. 3. Notice that the points which do M

10

O NASA

AK

• LIU

A MARTIN a SINCLAIR SLOPE • 1/2

X BOEING

• LIU

I04 '

- O - O - o j S ^ V

10

_L_

-7 -6 d(2o) •UL -3

10 10 eye. 10 10

10 dN 10

Fig. 4 Broad trend of crack-growth data on 2024-T3 aluminum alloy

Journal of Basic Engineering DECEMBER 19 6 3 / 5 3 1

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/15/2013 Terms of Use: http://asme.org/terms

where a« and No are the initial crack size and cycle number, re- tion (40) and hence weakens any arguments based on dimensional

spectively. For final failure of a specimen, the number of cycles analyses which do not include further considerations. Therefore

may be equated to N r , as a approaches infinity whereupon equa- the crack propagation laws of Head, Frost and Dugdale, and Liu

tion (37)reduces to must be considered as unclarified, if not totally in error.

Moreover, Fig. 6 is a graph, similar in form to Fig. 4, but for a

M

N P = (38) different material; i.e., 7075T6 aluminum alloy. The data shown

cr'on are from two independent sources [3 and 9] and in addition

wedge-force test data from tests employing configuration of Fig. 5

which does in fact resemble an S-N diagram. The authors do not

are also plotted. N o further comment seems necessary.

wish to imply that equation (38) is directly useful, but derive it

here to show that such considerations do not immediately lead to

the conclusion that equations (35) or (36) are in error. Conclusion

The results here indicate that the practice of using data from

Data From Wedge-Force Tests single test specimens is not a sensitive evaluation of a crack-

propagation law's validity. Randomly chosen data from single

The results of wedge-force tests of the configuration shown in

specimens analyzed here leads to an apparent agreement of

Fig. 5 are useful in critically examining the dimensional analyses

several contradictory laws to the same test data.

of Frost and Dugdale, and Liu in deriving their crack-propagation

laws. If the sheet is infinite, the only characteristic dimension For that reason the authors suggest that laws which correlate

of the problem is a. As the crack grows, strictly dimensional a wide range of test data from many specimens are perhaps the

arguments imply that for different crack lengths oi and a? the "correct" laws. The results at least indicate that hasty conclu-

incremental rates of crack extension are sions have been drawn in many earlier works which should be re-

examined before any given crack-propagation law is accepted as

valid.

dN Oi dN a.2

which might be thought valid for all crack lengths or Acknowledgment

5 = Sa <40>

This work was supported by the Boeing Company, Transport

Division, Renton, Wash. Their encouragement, as well as

dN financial aid, is gratefully acknowledged.

This result is the basis of equations (5) and (18).

In wedge-force tests Donaldson and Anderson [9] observe that References

the crack grows slower as it gets larger. This is contrary to equa-

1 A. K. Head, "The Growth of Fatigue Cracks," The Philo-

sophical Magazine, vol. 44, series 7, 1953, p. 925.

2 N. E. Frost and D. S. Dugdale, " T h e Propagation of Fatigue

Cracks in Sheet Specimens," Journal of the Mechanics and Physics of

Solids, vol. 6, no. 2, 1958, p. 92.

3 A. J. McEvily and W. Illg, "The Rate of Crack Propagation in

Two Aluminum Alloys," NACA Technical Note 4394, September,

1958.

4 H. W. Liu, "Crack Propagation in Thin Metal Sheets Under

Repeated Loading," T H E JOURNAL OF BASIC ENGINEERING, TRANS.

ASME, Series D, vol. 83, 1961, p. 23.

5 H. W. Liu, "Fatigue Crack Propagation and Applied Stress

Range—An Energy Approach," JOURNAL OF BASIC ENGINEERING,

TRANS. A S M E , S e r i e s D , v o l . 8 5 , 1 9 6 3 , p . 1 1 6 .

6 P. C. Paris, M. P. Gomez, and W. E. Anderson, " A Rational

Analytic Theory of Fatigue," The Trend in Engineering, vol. 13, no. 1,

January, 1961, p. 9.

7 W. E. Anderson and P. C. Paris, "Evaluation of Aircraft Ma-

terial by Fracture," Metals Engineering Quarterly, vol. 1, no. 2, Mav,

1961, p. 33.

8 P. C. Paris, "Crack Propagation Caused by Fluctuating

Fig. 5 W e d g e - f o r c e lest configuration Loads," ASME Paper No. 62—Met-3.

10

O NASA

& K

A BOEING

* BOEING,WEDGE FORCE TESTS

> OjQ

-jO-O

4 -

10

r r o ' f r *

,-iSxrV

-6 -5 d ( 2 a) -4 in, "3 -2

10 10 dN 10 eye. 10 10

Fig. 6 Broad trend of c r a c k - g r o w t h d a t a on 7 0 7 5 - T 6 a l u m i n u m a l l o y including w e d g e - f o r c e tests

532 / DECEMBER 1963 Transactions of the A S M E

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/15/2013 Terms of Use: http://asme.org/terms

P. PARIS 1

Associate Professor of Mechanics and

Assistant Director of the Institute of Research,

A Critical Analysis of Crack Propagation Laws

Lehigh University, Bethlehem, Pa,

The practice of attempting validation of crack-propagation laws (i.e., the laws of Head,

Frost and Dugdale, McEvily and Illg, Liu, and Paris) with a small amount of data,

F. ERDOGAN such as a few single specimen test results, is questioned. It is shown that all the laws,

Professor of Mechanical though they are mutually contradictory, can be in agreement with the same small sample

Engineering, Lehigh University, of data. It is suggested that agreement with a wide selection of data from many speci-

Bethlehem, Pa. Mem. ASME

mens and over many orders of magnitudes of crack-extension rates may be necessary to

validate crack-propagation laius. For such a wide comparison of data a new simple

empirical law is given which fits the broad trend of the data.

Introduction da

= / ( f , a, Ci) (1)

dN

sIEVEHAL

* crack-propagation laws have been pre-

sented in the past few years, which claim to be verified b y the Therefore this format will be employed in the discussion to

experimental data analyzed in their respective papers. They follow.

are specifically the work of Head [l], a Frost and Dugdale [2], Chronologically the first crack-propagation law which drew

McEvilj' and Illg [3 ], Liu [4, 5 ], and Paris, Gomez, and Anderson wide attention was that of Head [1] in 1953. He employed a

[6,7,8]. mechanical model which considered rigid-plastic work-hardening

This paper will attempt to show that basing validation of a elements ahead of a crack tip and elastic elements over the re-

crack-propagation theory on a limited amount of data is a poor mainder of the infinite sheet. The model required extensive

test of any theory. Moreover, a wide range of test data is now calculations and deductions to obtain a law which may be

available in a convenient form [9] which may be employed to written as

analyze critically these several crack propagation laws.

Therefore the paper will consist of three parts which will in- da C^a'*

(Head's law) (2)

clude: dN (C 2 - 0>„'/'

1 A review and comparison of existing crack-propagation

where Ci depends upon the strain-hardening modulus, the modu-

laws.

lus of elasticity, the yield stress and the fracture stress of the

2 The erroneous results obtained by comparing each law with

material, and Ci is the yield strength of the material. Head de-

a limited range of test data.

fined Wo as the size of the plastic zone near the crack tip and pre-

3 The results of comparing crack-propagation laws with a sumed it was constant during crack propagation. However,

wide range of data. Frost [2] noticed that the plastic-zone size increased in direct

proportion to the crack length in his tests. Moreover, Irwin [10]

has recently pointed out from analytical considerations that

A Review of Existing Crack-Propagation Laws

Crack-propagation laws given in the literature take many Wo (3)

forms. In general they treat cracks in infinite sheets subjected

for the configuration treated here which is in agreement with

to a uniform stress perpendicular to the crack (or can be applied

Frost's conclusions. Therefore, though Head adopted equation

to that configuration) and they relate the crack length, 2a, to the

(2) with w0 considered constant as his crack-propagation law, we

number of cycles of load applied, N , with the stress range cr, and

are forced here to introduce equation (3) into equation (2) to

material constants C,-.' The single form in which all crack-

obtain a modified or corrected form of Head's crack-propagation

propagation laws may be written is

law; i.e.,

da C3o~2a

1Also Consultant to the Boeing Company, Transport Division, (Head's corrected law) (4)

dN = (C 2 - o)

Renton, Wash.

2 Numbers in brackets designate References at end of paper.

3 In this discussion a will imply the stress-fluctuation range and Ci Frost and Dugdale [2] in 1958 presented a new approach to

will vary slightly with mean stress in a general interpretation. crack-propagation laws. They observed as was introduced in

Contributed by the Metals Engineering Division and presented at equation (4), that Head's law should be corrected for the varia-

the Winter Annual Meeting, New York, N. Y., November 25-30, tion of plastic-zone size with crack length. They deduced that

1962, of THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS.

Manuscript received at ASME Headquarters, April 11, 1962. Paper the corrected result, equation (4), depends linearly on the crack

No. 62—WA-234. length a. However, they also argued b y dimensional analysis

•Nomenclature-

a = half crack length F{ } = a function of da

Qo = initial half crack length G{ } = a function of — = crack extension per cycle of

B = a function of stress range (and k = stress-intensity factor (range)

d N load

mean stress) IClW = stress-concentration factor Ak = stress-intensity-factor range

C = a numerical constant m = a numerical exponent p, pi = crack-tip radius

C; — constants (which vary slightly M = a material constant cr = applied stress (range)

with mean stress) n = a numerical exponent UQ = stress at a crack tip (with

Ds = constants which depend on N = cycle number finite radius p)

stress level Aro, Nj, — initial and final cycle number, crnot = net section stress

/ ( ) = a function of respectively w0 = plastic-zone size

528 / DECEMBER 1963 Transactions of the AS M E

Copyright © 1963 by ASME

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/15/2013 Terms of Use: http://asme.org/terms

You might also like

- Procedure To Destroy Occultic or Cursed ObjectsDocument5 pagesProcedure To Destroy Occultic or Cursed ObjectsJuan Jaylou Ante100% (1)

- Passenger Elevator Operation ManualDocument24 pagesPassenger Elevator Operation ManualJahn Ray B. Lanozo100% (1)

- 1963-Paris, P. ErdoganA Critical Analysis of Crack Propagation LawsDocument6 pages1963-Paris, P. ErdoganA Critical Analysis of Crack Propagation LawsAna Isabel Aguilar ReyesNo ratings yet

- 1998 - The Measurement and Control of Blast Induced Damage of Final Pit Walls in Open Pit Mining - W. Adamson, C.Scherpenisse - ISEE-1998Document18 pages1998 - The Measurement and Control of Blast Induced Damage of Final Pit Walls in Open Pit Mining - W. Adamson, C.Scherpenisse - ISEE-1998Elías Bravo CortésNo ratings yet

- Karta Ronjenje en 163341Document2 pagesKarta Ronjenje en 163341mulalic_dNo ratings yet

- A Code of Practice For The Determination of Cyclic Stress-StrainDocument22 pagesA Code of Practice For The Determination of Cyclic Stress-StrainDeivyson AugustoNo ratings yet

- PC-1 FORM Revised 2005 Government of Pakistan Planning Commission Pc-1 Form (Social SECTORS)Document18 pagesPC-1 FORM Revised 2005 Government of Pakistan Planning Commission Pc-1 Form (Social SECTORS)Muhammad IlyasNo ratings yet

- Foundation Failure Case Histories Reexamined Using Modern GeomechDocument14 pagesFoundation Failure Case Histories Reexamined Using Modern GeomechMayra Vaca100% (1)

- Physical Storage: Data ONTAP 8.0 7-Mode AdministrationDocument71 pagesPhysical Storage: Data ONTAP 8.0 7-Mode AdministrationkurtenweiserNo ratings yet

- ABLSDocument86 pagesABLSRenée Alejandra100% (2)

- 1 s2.0 S0009250914002358 MainDocument16 pages1 s2.0 S0009250914002358 Mainyunfei2023uwaNo ratings yet

- Crack Propagation by Finite Element Method: Luiz Carlos H. RicardoDocument22 pagesCrack Propagation by Finite Element Method: Luiz Carlos H. RicardoMikhailNo ratings yet

- Contribution of The Cyclic Loading PortiDocument7 pagesContribution of The Cyclic Loading PortiAdrien MartinazzoNo ratings yet

- Journal of The Mechanics and Physics of Solids: Ryan S. Ginder, William D. Nix, George M. PharrDocument11 pagesJournal of The Mechanics and Physics of Solids: Ryan S. Ginder, William D. Nix, George M. PharrRaj Jung MahatNo ratings yet

- 1 s2.0 S0734743X23001355 MainDocument19 pages1 s2.0 S0734743X23001355 Mainhuangyifan350No ratings yet

- Heliyon: Zeinab Noorpoor, Saeed Tavangar, Hosein Soury, Seyed Ghorban HosseiniDocument11 pagesHeliyon: Zeinab Noorpoor, Saeed Tavangar, Hosein Soury, Seyed Ghorban HosseinilfgmarcantoniNo ratings yet

- Bài Báo 3-1Document17 pagesBài Báo 3-1Lê Văn HòaNo ratings yet

- Fast Inverse Estimation of 9 Poroelastic MaterialDocument7 pagesFast Inverse Estimation of 9 Poroelastic Material林宇宣No ratings yet

- Theoretical Model Drop Bubble Breakup in Turbulent DispersionsDocument9 pagesTheoretical Model Drop Bubble Breakup in Turbulent DispersionsrajuvadlakondaNo ratings yet

- Thermal Stress in Bonded JointsDocument10 pagesThermal Stress in Bonded JointsprabhunirikshanNo ratings yet

- Just 2021 0136Document8 pagesJust 2021 0136Houria BessaNo ratings yet

- tmp975F TMPDocument7 pagestmp975F TMPFrontiersNo ratings yet

- Scratch Testing of Metals and PolymersDocument8 pagesScratch Testing of Metals and PolymersPratap Singh GangwarNo ratings yet

- Song 2016Document13 pagesSong 2016Arunachalam BjNo ratings yet

- 1 s2.0 S0307904X11005622 MainDocument9 pages1 s2.0 S0307904X11005622 MainCesar RosalesNo ratings yet

- Quantitative Investigations of AggregateDocument7 pagesQuantitative Investigations of AggregateMILON KUMAR HORENo ratings yet

- 10 1016@j Ces 2019 06 046Document15 pages10 1016@j Ces 2019 06 046Мила ГетоваNo ratings yet

- The Effect of Residual Stresses On Stress-Strain Curves Obtained Via Profilometry Based Inverse Finite Element Method Indentation PlastometryDocument12 pagesThe Effect of Residual Stresses On Stress-Strain Curves Obtained Via Profilometry Based Inverse Finite Element Method Indentation PlastometryRaúl AponteNo ratings yet

- C-P12 An Energy Criterion To Predict Delayed Failure of Multi-Directional Polymer Matrix Composites Based On A Non-Linear Viscoelastic ModelDocument13 pagesC-P12 An Energy Criterion To Predict Delayed Failure of Multi-Directional Polymer Matrix Composites Based On A Non-Linear Viscoelastic Modelzane.spotify.a1No ratings yet

- Using Large Eddy Simulation For Understanding Vented Gas Explosions in The Presence of ObstaclesDocument8 pagesUsing Large Eddy Simulation For Understanding Vented Gas Explosions in The Presence of ObstaclesaliNo ratings yet

- Turbo Expo 2013 Conference Paper 2Document9 pagesTurbo Expo 2013 Conference Paper 2Yashika MalhotraNo ratings yet

- Battelle Memorial Institute, Pacific Northwest Laboratory, Richland, Washington, USADocument10 pagesBattelle Memorial Institute, Pacific Northwest Laboratory, Richland, Washington, USAaliNo ratings yet

- Predicting The Resilient Modulus of Unbound Granular Materials by Neural NetworksDocument9 pagesPredicting The Resilient Modulus of Unbound Granular Materials by Neural NetworksĐức Trung TrầnNo ratings yet

- Uri Keshet, Ofir Arad, and Yuri Lyubarski (Dated: October 21, 2019)Document11 pagesUri Keshet, Ofir Arad, and Yuri Lyubarski (Dated: October 21, 2019)Carlos FazNo ratings yet

- Measurement: C. Ararat-Ibarguen, R.A. Pérez, M. IribarrenDocument10 pagesMeasurement: C. Ararat-Ibarguen, R.A. Pérez, M. IribarrenALEJANDRA FONTALVO STUDENTNo ratings yet

- A Continuum-Based Reaction Growth Model For The Shock Initiation of ExplosivesDocument11 pagesA Continuum-Based Reaction Growth Model For The Shock Initiation of ExplosivesWahid AziziNo ratings yet

- Safe Separation Distances From Natural Gas PipelinesDocument19 pagesSafe Separation Distances From Natural Gas PipelinesBensmatNo ratings yet

- A Model For Creep Based On Microstructural Length Scale EvolutionDocument9 pagesA Model For Creep Based On Microstructural Length Scale Evolutionhassan ghorbaniNo ratings yet

- Lattice Theory of Threedimensional Cracks: 129.97.21.43 On: Tue, 03 Feb 2015 18:48:53Document9 pagesLattice Theory of Threedimensional Cracks: 129.97.21.43 On: Tue, 03 Feb 2015 18:48:53Jasmine RaiNo ratings yet

- Floc Rupture and Turbulence: A Framework For Analysis: D.H. BacheDocument14 pagesFloc Rupture and Turbulence: A Framework For Analysis: D.H. BacheMatias Jeldres ValenzuelaNo ratings yet

- J4 BahanDocument13 pagesJ4 Bahanmr mustofaNo ratings yet

- Herp, Nadini - Bayesian State Prediction of Wind Turbine Bearing FailureDocument10 pagesHerp, Nadini - Bayesian State Prediction of Wind Turbine Bearing FailureLeonardo TerraNo ratings yet

- 10.1016 J.crme.2017.02.005 Fatigue Crack Growth Simulation in Coated Materials Using X FEMDocument10 pages10.1016 J.crme.2017.02.005 Fatigue Crack Growth Simulation in Coated Materials Using X FEMhamid rezaNo ratings yet

- (3 - 4) A General Analytical Model Based On Elastic Foundation Beam TheoryDocument14 pages(3 - 4) A General Analytical Model Based On Elastic Foundation Beam Theoryshahbazbegian.uniNo ratings yet

- European Journal of Mechanics A/SolidsDocument12 pagesEuropean Journal of Mechanics A/Solidshamid rezaNo ratings yet

- Approaching Detonation Dynamics As An Ensemble of Interacting WavesDocument14 pagesApproaching Detonation Dynamics As An Ensemble of Interacting WavesPawan KumarNo ratings yet

- PhysRevD 107 074509Document20 pagesPhysRevD 107 074509ghostNo ratings yet

- Creep TestingDocument19 pagesCreep Testingاقْرَأْ وَرَبُّكَ الْأَكْرَمُNo ratings yet

- 2 AcceleratingFramesAndGravitational GerardoMunozDocument11 pages2 AcceleratingFramesAndGravitational GerardoMunozomid parsiaNo ratings yet

- 1 s2.0 S0009250906004908 MainDocument15 pages1 s2.0 S0009250906004908 MainPrashant GuptaNo ratings yet

- A LES-based Eulerian-Lagrangian Approach To Predict The DynamicsDocument10 pagesA LES-based Eulerian-Lagrangian Approach To Predict The DynamicsStephany CamacaroNo ratings yet

- Restlife AssessmentDocument12 pagesRestlife AssessmentsachzenNo ratings yet

- Monte Carlo Determination of The Frequrncy of Lightning Strokes and Shielding Failures On Transmission LinesDocument8 pagesMonte Carlo Determination of The Frequrncy of Lightning Strokes and Shielding Failures On Transmission LinesMansoor AsifNo ratings yet

- BCGDMDocument9 pagesBCGDMNora al-anssariNo ratings yet

- Shaik Tomin Voskov 2018Document17 pagesShaik Tomin Voskov 2018Israel Arias GonzálezNo ratings yet

- Chemical Engineering Science: Q.J. Zheng, A.B. YuDocument9 pagesChemical Engineering Science: Q.J. Zheng, A.B. Yumaior64No ratings yet

- Fire Load Survey Data Recent Standards ADocument14 pagesFire Load Survey Data Recent Standards AEmerenziano PalmieriNo ratings yet

- 10.1016 J.ijsolstr.2017.01.035 Dynamic Fracture Analysis by Explicit Solid Dynamics and Implicit Crack PropagationDocument37 pages10.1016 J.ijsolstr.2017.01.035 Dynamic Fracture Analysis by Explicit Solid Dynamics and Implicit Crack Propagationhamid rezaNo ratings yet

- Hansen Et Al 2023Document12 pagesHansen Et Al 2023pusht123No ratings yet

- Statistical Size Effects On Compressive StrengthDocument6 pagesStatistical Size Effects On Compressive StrengthPetro JikkenNo ratings yet

- Application of Digital Image Correlation (DIC) To The Measurement of Strain Concentration of A PVA Dual-Crosslink Hydrogel Under Large DeformationDocument12 pagesApplication of Digital Image Correlation (DIC) To The Measurement of Strain Concentration of A PVA Dual-Crosslink Hydrogel Under Large DeformationsravanthiNo ratings yet

- International Journal of Heat and Mass Transfer: J.B.R. Loureiro, A.P. Silva FreireDocument10 pagesInternational Journal of Heat and Mass Transfer: J.B.R. Loureiro, A.P. Silva FreireAbhijeet YeljaleNo ratings yet

- Context-Aware Drift DetectionDocument25 pagesContext-Aware Drift DetectionsibanandarmsNo ratings yet

- Asimplifiedstatistic BasedprocedureforgasDocument17 pagesAsimplifiedstatistic BasedprocedureforgasRaghava KarthikNo ratings yet

- Calculational Methods for Interacting Arrays of Fissile Material: International Series of Monographs in Nuclear EnergyFrom EverandCalculational Methods for Interacting Arrays of Fissile Material: International Series of Monographs in Nuclear EnergyNo ratings yet

- International Journal of Fatigue: SciencedirectDocument8 pagesInternational Journal of Fatigue: SciencedirectRyann MengNo ratings yet

- International Journal of Fatigue: Ankit Agrawal, Alok ChoudharyDocument12 pagesInternational Journal of Fatigue: Ankit Agrawal, Alok ChoudharyRyann MengNo ratings yet

- Engineering Fracture Mechanics: SciencedirectDocument14 pagesEngineering Fracture Mechanics: SciencedirectRyann MengNo ratings yet

- Low Cycle Fatigue and Creep-Fatigue Interaction Behavior of 316L (N) Stainless Steel and Life Prediction by Artificial Neural Network ApproachDocument12 pagesLow Cycle Fatigue and Creep-Fatigue Interaction Behavior of 316L (N) Stainless Steel and Life Prediction by Artificial Neural Network ApproachRyann MengNo ratings yet

- Cement and Concrete CompositesDocument17 pagesCement and Concrete CompositesRyann MengNo ratings yet

- Applied Soft Computing: Deepayan Gope, Prakash Chandra Gope, Aruna Thakur, Abhishek YadavDocument15 pagesApplied Soft Computing: Deepayan Gope, Prakash Chandra Gope, Aruna Thakur, Abhishek YadavRyann MengNo ratings yet

- Renewable and Sustainable Energy Reviews: ArticleinfoDocument10 pagesRenewable and Sustainable Energy Reviews: ArticleinfoRyann MengNo ratings yet

- Analogy - 10 Page - 01 PDFDocument10 pagesAnalogy - 10 Page - 01 PDFrifathasan13No ratings yet

- L807268EDocument1 pageL807268EsjsshipNo ratings yet

- CAT LOGO ALPINESTARS OFF-ROAD 2021Document73 pagesCAT LOGO ALPINESTARS OFF-ROAD 2021Carla ArcosNo ratings yet

- 1.1.DeFacto Academy enDocument7 pages1.1.DeFacto Academy enYahya AçafNo ratings yet

- Ernst Bloch Principle of Hope PDFDocument2 pagesErnst Bloch Principle of Hope PDFAdamNo ratings yet

- Bihar-Board-Intermediate-Mathematics-Protect KeyDocument37 pagesBihar-Board-Intermediate-Mathematics-Protect Keyapi-335786032No ratings yet

- Assignment 3: Course Title: ECO101Document4 pagesAssignment 3: Course Title: ECO101Rashik AhmedNo ratings yet

- 6.1 Mean Median Mode and RangeDocument21 pages6.1 Mean Median Mode and RangeGilbert Guzman TurarayNo ratings yet

- 900 MCQs Ancient IndiaDocument189 pages900 MCQs Ancient IndiaZahaab AlimNo ratings yet

- RK20 Power Flow SparseDocument33 pagesRK20 Power Flow Sparsejohn smithNo ratings yet

- Momentum - Action High Intensity 2022Document24 pagesMomentum - Action High Intensity 2022GabrielNo ratings yet

- Group1 App 005 Mini PTDocument8 pagesGroup1 App 005 Mini PTAngelito Montajes AroyNo ratings yet

- Riddlesdown Collegiate HomeworkDocument7 pagesRiddlesdown Collegiate Homeworkgepuz0gohew2100% (1)

- Economics Key WordsDocument30 pagesEconomics Key WordsJanetNo ratings yet

- 344W11MidTermExamI Solution PDFDocument22 pages344W11MidTermExamI Solution PDFTrường TùngNo ratings yet

- Abrar AwolDocument153 pagesAbrar AwolErmias Assaminew AlmazNo ratings yet

- Penjelasan IMRAD StructureDocument2 pagesPenjelasan IMRAD Structureaji bondesNo ratings yet

- Product Sheet: AutoclaveDocument2 pagesProduct Sheet: AutoclaveISHA ARORANo ratings yet

- CV TemplateDocument1 pageCV TemplateHimanshu RaghuwanshiNo ratings yet

- Kitimat JRP SummaryDocument17 pagesKitimat JRP SummaryNorthwest InstituteNo ratings yet

- Civic Ass JolaxDocument3 pagesCivic Ass JolaxEyob TeferaNo ratings yet

- Cybersecurity in Operational Technology: Special ReportDocument15 pagesCybersecurity in Operational Technology: Special ReportAdrian ReyesNo ratings yet

- Smart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Document1 pageSmart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Eeman AkbarNo ratings yet