Professional Documents

Culture Documents

Wafer Butterfly IOM

Uploaded by

tiagoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wafer Butterfly IOM

Uploaded by

tiagoCopyright:

Available Formats

2867 S.

Vail Avenue, Commerce, CA 90040

Phone: 323-890-4455

Fax: 323-890-4456

Butterfly Valve Installation Procedure - For Lug & Wafer Style Valves

Always position the connecting pipe flanges accurately in the line, allowing sufficient space between the flanges for the

valve. Make sure the pipe flange faces are clean of any foreign material such as scale, metal shavings or welding slag.

Valves should be installed with the disc in the closed position to prevent damage to sealing surfaces or the disc.

1. Carefully insert the valve between the pipe flanges. Do not apply any lubricants to the seat faces as this may damage them.

2. Line up, center and secure the valve between flanges using desired bolts or studs as listed in Table 2.

Do not tighten bolts at this time.

3. Carefully open the valve to assure free unobstructed disc movement. Disc interference may result when

valves are installed in pipelines having smaller than normal inside diameters, such as heavy wall pipe,

plastic-lined pipe, as-cast flanges or reducing flanges. Interference can also occur when connecting directly

to swing check or silent check valves. Suitable corrective measures must be taken to remove these

obstructions, such as taper boring the pipe or installing a spacer or spool piece.

4. After proper operation is verified, tighten the bolts to the minimum recommended

bolt torques listed in Table 1 below using a cross-over pattern.

5. Pressurize piping to valve and inspect for leakage. If leakage is observed, tighten bolts using cross-over pattern, increasing

torque until leak stops. DO NOT EXCEED MAXIMUM TORQUES LISTED IN TABLE 1.

6. Recommended torques are made without warranty. Installer must verify proper strength bolts for application. Bolts shall be

clean and un-lubricated.

Caution

1. Class 250 cast iron and Class 300 steel flanges can not be used on these valves.

2. Rubber faced or mechanical flanges are not recommended.

3. This valve is not recommended for steam service.

4. Valves should not be assembled to the flanges and then welded into the piping system.

5. Lever-lock handles are not recommended for use on 8" and larger valves.

6. Do not install EPDM liner in compressed air lines.

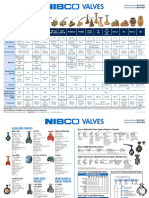

Table 1 Recommended Bolt Tightening Torque

Flange Bolt Minimum Bolt Maximum Bolt

Size Size Torque (ft.•lbs.) Torque (ft.•lbs.)

2"- 4" 5/8" 20 70

5"- 8" 3/4" 30 120

10" & 12" 7/8" 50 200

14" & 16" 1" 70 240

18" & 20" 1-1/8" 100 380

24" & 30" 1-1/4" 140 520

36"- 48" 1-1/2" 200 800

Page 2 January 28, 2014

Butterfly Valve Installation Procedure - For Lug & Wafer Style Valves

ANSI B16.47 (SERIES A)

ANSI B16.47 (SERIES B)

ANSI B16.47 (SERIES B)

CLASS 150 STEEL MSS

TOTAL QUANTITY CAP

CLASS 125 CAST IRON

RECOMMENDED CAP

FLANGE THICKNESS

FLANGE THICKNESS

FLANGE THICKNESS

FLANGE THICKNESS

FLANGE THICKNESS

MOUNT 2 FLANGES)

SCREWS/BOLTS (TO

(LUGGED VALVES)

CLASS 150 STEEL

CAP SCREW SIZE

(WAFER VALVES)

CLASS 150 STEEL

CLASS 150 STEEL

RECOMMENDED

SCREW LENGTH

DIMENSION "Y"

DIMENSION "X"

BOLT LENGTH

1000/2000/3000

BLIND STYLE

BODY WIDTH

TOTAL VALVE

SERIES ONLY

WELD NECK

VALVE SIZE

ANSI B16.1

ANSI B16.5

SP-44

0.63 — — — — 1.25 4.00 8/4

2" 1.69 — 0.75 — — — 1.50 4.00 8/4 5/8-11 UNC

0.69 — — — — 1.50 5.00 8/4

2 1/2" 1.81 — 0.88 — — — 1.75 5.00 8/4 5/8-11 UNC

0.75 — — — — 1.50 5.00 8/4

3" 1.81 — 0.94 — — — 1.75 5.00 8/4 5/8-11 UNC

4" 2.06 0.94 0.94 — — — 1.75 5.00 16/8 5/8-11 UNC

5" 2.19 0.94 0.94 — — — 1.75 5.00 16/8 3/4-10 UNC

6" 2.19 1.00 1.00 — — — 2.00 6.00 16/8 3/4-10 UNC

8" 2.38 1.12 1.12 — — — 2.25 6.00 16/8 3/4-10 UNC

10" 2.69 1.19 1.19 — — — 2.25 7.00 24/12 7/8-9 UNC

12" 3.00 1.25 1.25 — — — 2.50 7.00 24/12 7/8-9 UNC

14" 3.01 1.38 1.38 — — — 2.50 7.00 24/12 1-8 UNC

16" 3.38 1.44 1.44 — — — 3.00 8.00 32/16 1-8 UNC

18" 4.12 1.56 1.56 — — — 3.00 9.00 32/16 1 1/8-7 UNC

20" 5.14 1.69 1.69 — — — 3.50 10.00 40/20 1 1/8-7 UNC

24" 5.98 1.88 1.88 — — — 4.00 11.00 40/20 1 1/4-7 UNC

2.12 — — — — 3.50 — 56

— — — 1.75 — 3.00 — 56

30" 6.57 1 1/4-7 UNC

— — — — 2.00 3.50 — 56

— — 2.94 — — 4.25 — 56

2.38 — — — — 4.00 — 64

— — — 2.06 — 3.50 — 64

36" 8.00 1 1/2-6 UNC

— — — — 2.31 4.00 — 64

— — 3.56 — — 5.00 — 64

2.62 — — — — 4.50 — 72

— — — 2.31 — 4.00 — 72

42" 9.88 1 1/2-6 UNC

— — — — 2.69 4.50 — 72

— — 3.81 — — 5.50 — 72

2.75 — — — — 4.50 — 88

— — — 2.56 — 4.50 — 88

48" 10.87 1 1/2-6 UNC

— — — — 3.06 5.00 — 88

— — 4.25 — — 6.00 — 88

Table 2 Recommended Bolt Lengths

Suggested Bolting Methods

X Y

Care & Maintenance:

No regular maintenance is required on SCI butterfly valves, but it is advisable to “exercise” the valve

from full open to full closed and back to verify that the valve is functioning properly.

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- NV MedPress SMDocument8 pagesNV MedPress SMElinton SarmientoNo ratings yet

- Auto ClaveDocument464 pagesAuto ClavenokarajuNo ratings yet

- The Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeFrom EverandThe Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeDonald M. WallerRating: 4 out of 5 stars4/5 (1)

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Document370 pagesParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185No ratings yet

- Bobinas Sporlan: ESPECIFICACIONES ELECTRICAS - Bobinas Standard - MKC-1, OMKC-1, MKC-2 yDocument2 pagesBobinas Sporlan: ESPECIFICACIONES ELECTRICAS - Bobinas Standard - MKC-1, OMKC-1, MKC-2 yHenry Avilés ChongNo ratings yet

- Sae 6000 Psi PDFDocument41 pagesSae 6000 Psi PDFcardozoedmNo ratings yet

- FluidComponentsFullCatalog PDFDocument502 pagesFluidComponentsFullCatalog PDFPablo MNo ratings yet

- Catalogo DlineDocument5 pagesCatalogo DlinejojojoyNo ratings yet

- Zavero Ball Valves CatalogueDocument12 pagesZavero Ball Valves CatalogueKadri HelmiNo ratings yet

- sv2 sv3 Series CPC Cryolab Seal Off Valve v03 OperatorDocument2 pagessv2 sv3 Series CPC Cryolab Seal Off Valve v03 Operatoroscar garciaNo ratings yet

- VW-BV 80R (80 Series-RB) - v2021Document4 pagesVW-BV 80R (80 Series-RB) - v2021Mazwan Che MansorNo ratings yet

- Type T-40' (Formerly H-U') : Tubing SpidersDocument9 pagesType T-40' (Formerly H-U') : Tubing SpidersCamilo CajiaoNo ratings yet

- Et-200 P-48Document1 pageEt-200 P-48neivaprojetosNo ratings yet

- Sch. SAE 3000 PsiDocument19 pagesSch. SAE 3000 PsiWilson JustinoNo ratings yet

- Autoclave Full CatalogDocument481 pagesAutoclave Full CatalogGabriel Jamariqueli BueresNo ratings yet

- Nibco ValvesDocument2 pagesNibco ValvesD.No ratings yet

- Detroit Fluid PowerDocument5 pagesDetroit Fluid PowerAlenaNo ratings yet

- Plug Valve CatalogeDocument20 pagesPlug Valve CatalogenguyenmainamNo ratings yet

- VM 20130430 01Document4 pagesVM 20130430 01a0960539335No ratings yet

- Hydrant Post Connection: Pump House DiagramDocument1 pageHydrant Post Connection: Pump House Diagrampujan77No ratings yet

- Check and Relief ValvesDocument16 pagesCheck and Relief ValvesAdriana Herrera FloresNo ratings yet

- Mini-Size Flow Switches: Monitor Flow in 1/2 To 2 Pipe, Explosion-ProofDocument2 pagesMini-Size Flow Switches: Monitor Flow in 1/2 To 2 Pipe, Explosion-Proofjp3863887No ratings yet

- WC 1Document2 pagesWC 1Roberto VargasNo ratings yet

- Av2 SeriesDocument2 pagesAv2 SeriesAsa ReidNo ratings yet

- Centrifugal End Suction Firepump NFPA 20Document5 pagesCentrifugal End Suction Firepump NFPA 20huseeeNo ratings yet

- Deluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVDocument5 pagesDeluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVmuthuvelaaNo ratings yet

- Swing Check Valve Submittal Sheet Series 1106Document4 pagesSwing Check Valve Submittal Sheet Series 1106Imtiyaz KhanNo ratings yet

- Av3 SeriesDocument2 pagesAv3 SeriesAsa ReidNo ratings yet

- Cast Gate Globe Check Valve ShortDocument36 pagesCast Gate Globe Check Valve ShortAngga ErlanggaNo ratings yet

- Sae 1000 PsiDocument6 pagesSae 1000 PsiAnonymous uL3JlWfhNo ratings yet

- 110 01 Glass Trac Specification Guide Rev 1Document14 pages110 01 Glass Trac Specification Guide Rev 1vilegual1No ratings yet

- AFIL ENG Product Guide Ver212122008 HighDocument1 pageAFIL ENG Product Guide Ver212122008 HighWael ChouchaniNo ratings yet

- Bolts DimensionsDocument59 pagesBolts Dimensionsaravind100% (1)

- Piping Design Reference InfoDocument254 pagesPiping Design Reference InfoDr. M. Praveen Sandeep100% (1)

- Glass Trac Specification GuideDocument14 pagesGlass Trac Specification Guidemehdi HKNo ratings yet

- 22CC0214-plan - Construction of MPB (Ph1), Lolomboy Elem SCH 40M - 2Document5 pages22CC0214-plan - Construction of MPB (Ph1), Lolomboy Elem SCH 40M - 2Rodenjade CadungogNo ratings yet

- K-Tepf D1 94Document1 pageK-Tepf D1 94Mamadou BossNo ratings yet

- Flowcon General IndustryDocument12 pagesFlowcon General IndustryMelianaWuNo ratings yet

- Pump DetailDocument1 pagePump Detailjohn raymund tanugaNo ratings yet

- Air Manifolds: A.S.M.E. CertifiedDocument2 pagesAir Manifolds: A.S.M.E. CertifiedOceanexNo ratings yet

- Quick Release Couplings: AG-Series Agricultural InterchangeDocument2 pagesQuick Release Couplings: AG-Series Agricultural InterchangerweidlingNo ratings yet

- SAE 3000 PsiDocument27 pagesSAE 3000 PsiWilson JustinoNo ratings yet

- PB Eu ChangeovervalvesDocument6 pagesPB Eu ChangeovervalvesYour AngelNo ratings yet

- 095.en BDocument8 pages095.en BlesonspkNo ratings yet

- LMC Air Receiver M-5Document1 pageLMC Air Receiver M-5hilarionsayson5No ratings yet

- Flotect Mini-Size Flow Switches: Monitor Flow in 1/2 To 2 (12.70 To 50.80 MM) Pipe, Explosion-Proof, CompactDocument2 pagesFlotect Mini-Size Flow Switches: Monitor Flow in 1/2 To 2 (12.70 To 50.80 MM) Pipe, Explosion-Proof, CompactCarlos RojasNo ratings yet

- Injection Quill Instruction Sheet: Instructions For UseDocument1 pageInjection Quill Instruction Sheet: Instructions For UsesalcedopozasNo ratings yet

- Bridge Crossing Plan Cross Section DetailDocument1 pageBridge Crossing Plan Cross Section DetailVWSSI Technical TeamNo ratings yet

- 0602 - 2 - 222 Conexiones de Escaleras de Mano A Las Plataformas 450mmDocument3 pages0602 - 2 - 222 Conexiones de Escaleras de Mano A Las Plataformas 450mmJavier BastardoNo ratings yet

- Catalog PDFDocument72 pagesCatalog PDFVIVEK UPADHYAYNo ratings yet

- Co2 Cylinder Master Assembly: Data SheetDocument19 pagesCo2 Cylinder Master Assembly: Data SheetLaxmanDungraniNo ratings yet

- Genset Shelter Roof AdjustmentDocument1 pageGenset Shelter Roof AdjustmentpogingmalupitNo ratings yet

- K-Tepf D1 21Document1 pageK-Tepf D1 21Mamadou BossNo ratings yet

- PRV C 101 Data SheetDocument1 pagePRV C 101 Data SheetDevit FitriyantoNo ratings yet

- Rrvb-Svx01a-En - Rupture GuardDocument26 pagesRrvb-Svx01a-En - Rupture GuardEmerson PenaforteNo ratings yet

- Flange CalculationDocument48 pagesFlange CalculationAndi SuntoroNo ratings yet

- Yamaha Yz85 Parts CatalogueDocument50 pagesYamaha Yz85 Parts CatalogueJose Antonio Rodriguez FernandezNo ratings yet

- Chilled Water Buffer Tanks: SpecificationDocument2 pagesChilled Water Buffer Tanks: SpecificationRan NNo ratings yet

- Shell and Tube Heat Exchanger Specification Sheet: (Inlet) Shell Side (Outlet) (Inlet) Tube Side (Outlet)Document5 pagesShell and Tube Heat Exchanger Specification Sheet: (Inlet) Shell Side (Outlet) (Inlet) Tube Side (Outlet)John BenderNo ratings yet

- 343GF Data Sheet US MetricDocument2 pages343GF Data Sheet US Metricviktor_gligorovNo ratings yet

- Piping Class - GD30Document3 pagesPiping Class - GD30Dmitriy RybakovNo ratings yet

- Atlas Copco Boomer MD Spare Parts Catalogue Part-2Document680 pagesAtlas Copco Boomer MD Spare Parts Catalogue Part-2EFREN SANCHEZ ROBLESNo ratings yet

- Service Manual: Hammermaster RockbreakersDocument423 pagesService Manual: Hammermaster RockbreakersredNo ratings yet

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoDocument54 pagesChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiNo ratings yet

- Sumitec CatalogDocument90 pagesSumitec CatalogIfan JSENo ratings yet

- Awwa Flanges: General SpecificationsDocument3 pagesAwwa Flanges: General SpecificationsEHT pipeNo ratings yet

- Tour & Andersson Circuit Balancing Valves and Koil-Kit ComponentsDocument1 pageTour & Andersson Circuit Balancing Valves and Koil-Kit ComponentslesnikimagesNo ratings yet

- Felkercatalog071406-Web UnlockedDocument58 pagesFelkercatalog071406-Web UnlockedMohamed RaafatNo ratings yet

- CF Catalog PDFDocument15 pagesCF Catalog PDFHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Catalogo Valvulas de SeguridadDocument66 pagesCatalogo Valvulas de Seguridadhogsp1No ratings yet

- DIN 16963-05 GeneralDocument9 pagesDIN 16963-05 GeneralFelipe BarrientosNo ratings yet

- Sportsman 400Document60 pagesSportsman 400m_paul2121No ratings yet

- B-Flenzen2018 Vlakkelas Flens enDocument6 pagesB-Flenzen2018 Vlakkelas Flens enRoberta RamosNo ratings yet

- High Pressure Gear Pump W300: Concentric ABDocument8 pagesHigh Pressure Gear Pump W300: Concentric ABMarin GarazNo ratings yet

- Engineering Your Projects To SuccessDocument12 pagesEngineering Your Projects To SuccessshrikantbelekarNo ratings yet

- Mark 57 Series: Externally Piloted Back Pressure RegulatorsDocument4 pagesMark 57 Series: Externally Piloted Back Pressure Regulatorsbenzerga karimNo ratings yet

- Product Summary-3Z Corporation CatalogDocument73 pagesProduct Summary-3Z Corporation Catalogchem_taNo ratings yet

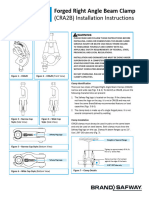

- Orn471 BSL Forged Right Angle Beam Clamp Installation InstructionsDocument4 pagesOrn471 BSL Forged Right Angle Beam Clamp Installation InstructionsNizam ShahNo ratings yet

- Powell Gate ValvesDocument3 pagesPowell Gate Valveszguy360No ratings yet

- Portable Machine MM2000iDocument3 pagesPortable Machine MM2000ijromero_rpgNo ratings yet

- AYVAZ Axial Exp. Joint PDFDocument92 pagesAYVAZ Axial Exp. Joint PDFAgung Eko WibowoNo ratings yet

- Dorot Hidr.300Document24 pagesDorot Hidr.300Pra YugoNo ratings yet

- Asme b31.8 Comp Iso 13623Document7 pagesAsme b31.8 Comp Iso 13623tss13723100% (2)