Professional Documents

Culture Documents

Atmospheric Corrections in Dielectric Dry Test: June 2014

Uploaded by

Erhan KarabasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atmospheric Corrections in Dielectric Dry Test: June 2014

Uploaded by

Erhan KarabasCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/265465411

Atmospheric Corrections in Dielectric Dry Test

Conference Paper · June 2014

CITATIONS READS

0 429

1 author:

Muhammad Hanif

ABB Riyadh Saudi Arabia

1 PUBLICATION 0 CITATIONS

SEE PROFILE

All content following this page was uploaded by Muhammad Hanif on 09 September 2014.

The user has requested enhancement of the downloaded file.

Ü·»´»½¬®·½ Ì»¬·²¹

¾§

Muhammad Hanif

ßÞÍÌÎßÝÌ factor will apply. As per IEC 62271-1 [3], Table 1a, the

rated power frequency and impulse withstand voltages for

The disruptive discharge of external insulation depends

36 kV rated switchgear are:

upon the atmospheric conditions. The dielectric strength of

Rated power frequency withstand voltage (rms):

need to be taken into account when external insulation

- to ground and between phases: 70 kV at 60 Hz, 1 minute

is designed and tested. By applying correction factors,

- across isolating distance: 80 kV at 60 Hz, 1 minute

can be converted into the equivalent value under the

Rated impulse withstand voltage (peak):

test conditions. During dielectric dry tests where external

insulation in free air is of main concern, the atmospheric - to ground and between phases: 170 kV, 1.2/50 µs

correction factor shall be applied and test voltage shall be

corrected. This paper discusses application of atmospheric - across isolating distance: 195 kV, 1.2/50 µs

correction factor in dielectric dry tests as per relevant IEC The technical data of switchgear shows that pole

standards. distance for load break switch is 360 mm and creepage

×ÒÌÎÑÜËÝÌ×ÑÒ distance for the insulators used in the switchgear panel is

385 mm.

The dielectric stresses during service life of electrical

equipment are due to power frequency voltage, temporary The applicable IEC standards for dielectric dry tests on

overvoltage, switching overvoltage and lightning a switchgear panel under discussion are IEC 60265

overvoltage. For a given stress, the behavior of external [4], IEC 62271-1 [3], and 60060-1 [2]. According to

insulation is affected by the atmospheric conditions.

for appropriate insulation strength using the appropriate

considered by using correction factors. This allows tests voltage waveforms at standard reference atmosphere.

under different atmospheric conditions but with the same For a given phase under test, the required number of

external insulation stress to be performed. impulse voltage applications for each impulse polarity is

a sequence of 15 standard lightning impulses of positive

The standard atmospheric conditions for which the polarity as well as negative polarity. After successful

standardized test voltages apply are an air temperature impulse test, AC power frequency withstand voltage test

of to = 20 oC, an absolute pressure of po = 1013 hPa shall be performed. The power frequency testing requires

(1013 mbar) and an absolute humidity of ho = 11 g/m3 each situation should be tested so that line to ground; line

according to IEC 60071-1 [1] and IEC 60060-1 [2]. The to line and open switching devices are tested.

actual pressure, temperature and humidity at the instant of

measurement are denoted by p, t and h. The atmospheric Ì»¬·²¹ Í»¬«°

correction factor Kt has two parts, the air density correction Figures 1 and 2 show the test setup and connections for

factor k1 and the humidity correction factor k2. impulse voltage and power frequency voltage test on a 36

When test voltages are applied without considering kV rated switchgear panel.

atmospheric conditions during dielectric dry tests,

insulation systems may be subjected to excessive stress

or understress. If insulation systems are overstressed then

probability of failure of dielectric dry tests will increase

which may also cause aging and generate defects in the

internal insulation. On the other hand, if insulation systems

are understressed then it will not be tested fully.

ßÌÓÑÍÐØÛÎ×Ý ÝÑÎÎÛÝÌ×ÑÒÍ ÚßÝÌÑÎÍ

at reference atmospheric conditions, atmospheric

correction factor shall be applied. As an example, for a

36 kV, 60 Hz, 3 phase load break switch panel for a Basic

Impulse Level (BIL) of 170 kV, atmospheric correction Ú·¹«®» ïæ Ì»¬ »¬«° º±® ·³°«´» ¿²¼ °±©»®

º®»¯«»²½§ ª±´¬¿¹» ¬»¬ ±² ©·¬½¸¹»¿® °¿²»´

50 ×ÛÐóÍßÝ Ö±«®²¿´ îðïîóïí ©©©ò·»°ó¿ò±®¹

Ü·»´»½¬®·½ Ì»¬·²¹

relative air density factor (

= (p / p0) x [(273 + t0) / (273 + t)] (4)

In general, an increase in relative air density causes

an increase in breakdown voltage. The correction is

considered reliable for 0.8 < k1 < 1.05.

parameters such as the ionization and the attachment

humidity (h), which is usually expressed as the weight

Ú·¹«®» îæ Ì»¬ ½±²²»½¬·±² ±² ©·¬½¸¹»¿® °¿²»´ of water molecules present per unit of air volume (g/m3).

Generally the breakdown voltage increases with h over

ݱ®®»½¬·±² Ú¿½¬±® kï ¿²¼ kî 3

. The humidity

correction factor may be expressed by the equation:

The disruptive discharge of external insulation depends

upon the atmospheric conditions. Usually, the disruptive k2 = k w (5)

discharge voltage for a given path in air is increased by an

increase in either air density or humidity. However, when Where w is an exponent obtained from Table 1 and k is

the relative humidity exceeds about 80 %, the disruptive a parameter that depends on the type of test voltage and

discharge voltage becomes irregular, especially when the may be obtained as a function of the ratio of absolute

disruptive discharge occurs over an insulating surface. humidity, h, to the relative air density, , using the following

equation:

By applying correction factors, a disruptive discharge

voltage measured in given test conditions (t, p, h) may be AC: k = 1 + 0.012(h/

converted to the value, which would have been obtained for 1 g/m3 < h/ < 15 g/m3 (6)

under the standard reference atmospheric conditions

(t0, p0, h0 Impulse: k = 1 + 0.010(h/

reference conditions can be converted into the equivalent for 1 g/m3 < h/ < 20 g/m3 (7)

value under the test atmospheric conditions. 2

DC: k = 1 + 0.012(h/ ) (h/

The disruptive discharge voltage is proportional to the for 1 g/m3 < h/ < 15 g/m3 (8)

atmospheric correction factor Kt, which results from the

product of two correction factors; the air density correction Exponents m and w

factor k1 and the humidity correction factor k2. It is As the correction factors depend on the type of pre-

expressed by the following equation: discharges, this fact can be taken into account by

Kt = k1 k2 (1) considering the parameter g as given below.

The voltage U to be applied during a test on external g = (U50 / 500) L k (9)

Where U50 is the 50 % disruptive-discharge voltage

voltage U0 by Kt as per the following equation: (measured or estimated) at the actual atmospheric

U = U0 Kt (2) conditions, in kilovolt peak, L is the minimum discharge

path in meter at the actual relative air density and k is

The test report shall always contain the actual atmospheric the dimensionless parameter. In the case of a withstand

conditions during the test and the correction factor applied. test where an estimate of the 50 % disruptive-discharge

ݱ®®»½¬·±² Ú¿½¬±® ݱ³°±²»²¬ voltage is not available, U50 can be assumed to be 1.1

times the test voltage, U0.

The atmospheric correction factor components are air

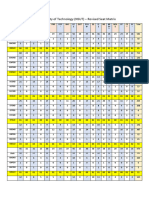

density correction factor k1 and Humidity correction factor The exponents, m and w, are obtained from Table 1 or

k2. g.

The air density correction factor k1 depends on the relative g m w

air density and can be generally expressed by the

ä ðòî ð ð

following equation:

ðòî ¬± ïòð gøgóðòî÷ñðòè gøgóðòî÷ñðòè

m

k1 = (3) ïò𠬱 ïòî ïòð ïòð

ïòî ¬± îòð ïòð øîòîóg÷øîòðóg÷ñðòè

Where mis an exponent obtained from Table 1. Atmospheric

âîòð ïòð ð

parameters such as temperature, pressure and humidity Ì¿¾´» ïæ Ê¿´«» ±º »¨°±²»²¬ô m º±® ¿·® ¼»²·¬§ ½±®®»½¬·±² ¿²¼ w º±®

¸«³·¼·¬§ ½±®®»½¬·±²ô ¿ ¿ º«²½¬·±² ±º ¬¸» °¿®¿³»¬»® g

an increase in the absolute temperature which causes an

increase in the average distance between molecules has

the same effect as a decrease in pressure and vice versa.

×ÛÐóÍßÝ Ö±«®²¿´ îðïîóïí ©©©ò·»°ó¿ò±®¹ 51

Ü·»´»½¬®·½ Ì»¬·²¹

Figure 3: Values of m versus g Figure 4: Values of w versus g

As per guidelines of IEC 62271-1, clause 6.2.1, for considered 0.95 will be as follows:

switchgear and controlgear of rated voltage of 52 kV and

below, it can be assumed that: The impulse voltage (peak) will be 161.5 kV for ground

and between phases and 185.2 kV across isolating

m = 1 and w = 0 when the absolute humidity is higher distance. The power frequency rms voltage will be 66.5 kV

than that of the reference atmosphere, i.e. when h > 11 for ground and between phases and 76 kV across isolating

g/m3; distance.

m = 1 and w = 1 when the absolute humidity is lower ÝÑÒÝÔËÍ×ÑÒÍ

than that of the reference atmosphere, i.e. when h < 11

g/m3. The withstand capability of external insulation is affected

by the atmospheric pressure, temperature and humidity.

For switchgear and controlgear having external and Withstand values given in IEC 62271-1 Table 1 and 2

internal insulation, the correction factor Kt shall be applied [3] are valid for standard atmospheric conditions. The

if its value is between 0.95 and 1.05. However, in order to atmospheric conditions at the testing place may deviate

avoid overstressing of internal insulation, the application from the standard reference condition and it is necessary

of the correction factor Kt may be omitted where the that correction factors may be applied for pressure,

satisfactory performance of external insulation has been temperature, and humidity. The voltage applied during a test

established. When the correction factor is outside the on external insulation is then determined by multiplying the

range of 0.95 and 1.05, details of dielectric tests shall be

subject to agreement between manufacturer and user. The application of atmospheric correction factor ensures

insulation systems are tested at correct voltages at normal

If Kt is above 1.0 then to fully test the external insulation stress. Therefore, risks of failure of dielectric tests and

system the internal insulation will be overstressed and

insulation aging are reduced if it would be overstressed as

steps may be necessary to prevent overstressing the well as risks of un-identifying the defects in the insulation

internal insulation systems. If Kt is below 1.0 then to test are minimized if it would be under stressed.

the internal insulation system fully, the external insulation

will be overstressed and steps may be necessary to ÎÛÚÛÎÛÒÝÛÍ

prevent overstressing the external insulation systems.

[1] IEC 60060-1: High-voltage test techniques - Part 1:

rd

The atmospheric correction factor shall be applied for Ed, 2010.

each type of test voltage. The impulse test voltage will be

“rated impulse voltage multiplied by the correction factor” [2] IEC 60071-1: Insulation co-ordination – Part 1:

th

and power frequency test voltage will be “rated power Ed, 2006.

frequency voltage multiplied by the correction factor” [3] IEC62271-1: High-voltage switchgear and controlgear

calculated from measured values of p, t and h. st

Ed, 2007.

Ý¿´½«´¿¬·±² ±º ݱ®®»½¬·±² Ú¿½¬±® ¿²¼ ß°°´·»¼ Ì»¬ [4] IEC 60265-1: High-voltage switches – Part 1:

ʱ´¬¿¹» Switches for rated voltages above 1 kV and less than 52

In the view of above discussion the correction factor and kV, 3rd Ed., 1998.

applied test voltages for lightning impulse and power Engr Muhammad Hanif Muhammad (hanif.muhammad101@

hanif.muhammad101@

voltage are calculated as under: yahoo.com) received his BEng degree in Electronics

yahoo.com

in 1983 from NED University of Engineering &

The assumed values of p, t and h for calculation purpose

Technology, Karachi, and PGD in Total Quality

during the test on the switchgear panel are 950.1 hPa,

Management from the University of Punjab. He

26 oC and 8.3 g/m3 respectively. The k1, k2 and Kt are

has worked in various public and private sector

calculated which are 0.919, 0.976, and 0.897 respectively.

organizations in Pakistan and presently works for

The correction factor Kt is 0.897 which is below than 0.95,

ABB Electrical Industries, Riyadh, in PPMV Business

therefore, this value may be taken if mutually agreed

Unit as the Quality Control Manager. Insulation testing, power

between manufacturer and user, otherwise 0.95 may be

transformer, instrument transformer, on-load tap-changer and

taken for calculation. The applied test voltages when Kt is

statistical quality control are his subjects of interests.

52 ×ÛÐóÍßÝ Ö±«®²¿´ îðïîóïí ©©©ò·»°ó¿ò±®¹

View publication stats

You might also like

- Altitude Corrections For External Insulation Design Iec Standards and Engineering Applications 92 PaperDocument8 pagesAltitude Corrections For External Insulation Design Iec Standards and Engineering Applications 92 PaperDrakhoNo ratings yet

- High Voltage Unit 5Document18 pagesHigh Voltage Unit 5smrutishree swainNo ratings yet

- Unit 5: High Voltage Testing & Insulation CoordinationDocument17 pagesUnit 5: High Voltage Testing & Insulation CoordinationarunjiboseNo ratings yet

- Unit 5: High Voltage Testing & Insulation Coordination: Important Definitions: Disruptive Discharge VoltageDocument18 pagesUnit 5: High Voltage Testing & Insulation Coordination: Important Definitions: Disruptive Discharge VoltageANAND POZHATHNo ratings yet

- Altitude Factos Ok - Divide by Factorguidelines - For - Altitude - Correction - For - PDocument9 pagesAltitude Factos Ok - Divide by Factorguidelines - For - Altitude - Correction - For - PnarinderNo ratings yet

- Altitude Correction FactorsDocument6 pagesAltitude Correction FactorsMayank YadavNo ratings yet

- Temperature Correction Factors - Power Grid IndiaDocument6 pagesTemperature Correction Factors - Power Grid IndiaAMIT BISWASNo ratings yet

- Techncial Paper Environmental Impact On TX Performance2Document12 pagesTechncial Paper Environmental Impact On TX Performance2Vishal MahireNo ratings yet

- IEC 60060-1 CorrectionsDocument6 pagesIEC 60060-1 CorrectionsmemohsNo ratings yet

- Power Frequency Withstand Test Iec PDFDocument6 pagesPower Frequency Withstand Test Iec PDFTravis WoodNo ratings yet

- AcfDocument23 pagesAcfManish RajNo ratings yet

- Two Mark Questions and Answers For Industrial Instrumentation (Ei 1301)Document8 pagesTwo Mark Questions and Answers For Industrial Instrumentation (Ei 1301)Rujuta KadamNo ratings yet

- Altitude Correction FactorsDocument6 pagesAltitude Correction Factorscarlos.calderonNo ratings yet

- 0f1c142a Partyka Mechanical Strength ofDocument10 pages0f1c142a Partyka Mechanical Strength ofKannan ViswanathanNo ratings yet

- High Voltage Testing & Insulation CoordinationDocument60 pagesHigh Voltage Testing & Insulation CoordinationAnish John Paul MNo ratings yet

- High Voltage TestingDocument60 pagesHigh Voltage TestingAnish John Paul M100% (1)

- Dielectric Withstand: Design RulesDocument3 pagesDielectric Withstand: Design RulesargenNo ratings yet

- Gaps (First Revision) : Indian StandardDocument33 pagesGaps (First Revision) : Indian StandardNag AKbnms100% (1)

- High Voltage Testing of Electrical ApparatusDocument29 pagesHigh Voltage Testing of Electrical ApparatusNRCM EEENo ratings yet

- High Voltage Testing of Electrical ApparatusDocument29 pagesHigh Voltage Testing of Electrical ApparatusNRCM EEENo ratings yet

- Diagnostic Tests and Condition Monitoring of Electrical MachinesDocument3 pagesDiagnostic Tests and Condition Monitoring of Electrical Machineslbk50No ratings yet

- Koch Raetzke Krueger IEEE 2010Document6 pagesKoch Raetzke Krueger IEEE 2010PCIngMec SyselNo ratings yet

- Atmospheric Correction Factor For Impulse Breakdown Voltage: P. Ortéga, R.T.Waters, A.Haddad, R.Hameed, A.J.DaviesDocument4 pagesAtmospheric Correction Factor For Impulse Breakdown Voltage: P. Ortéga, R.T.Waters, A.Haddad, R.Hameed, A.J.DaviesSriramulu KolliparaNo ratings yet

- Experiment Number - 7 AimDocument2 pagesExperiment Number - 7 AimPurukapoorNo ratings yet

- Bushing Insulation Diagnostics Based On Dielectric Response - 110326Document9 pagesBushing Insulation Diagnostics Based On Dielectric Response - 110326Carlos MontoyaNo ratings yet

- High Alitude InsulatorDocument6 pagesHigh Alitude Insulator정상진No ratings yet

- MpcFinal 2014 SolutionDocument4 pagesMpcFinal 2014 SolutionMohammed BelkheiriNo ratings yet

- Calculation of Electrical Maximum DemandDocument4 pagesCalculation of Electrical Maximum Demandguna698650% (6)

- 10 11648 J Epes 20180705 12 PDFDocument6 pages10 11648 J Epes 20180705 12 PDFbelayneh ayichewNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- String EfficiencyDocument5 pagesString EfficiencyManish KumawatNo ratings yet

- Electrical and Chemical Diagnostics of Transformer Insulation Abstrac1Document36 pagesElectrical and Chemical Diagnostics of Transformer Insulation Abstrac1GoliBharggavNo ratings yet

- Entendiendo Las Mediciones de Resistencia de AislamientoDocument5 pagesEntendiendo Las Mediciones de Resistencia de AislamientoMarco VelvelNo ratings yet

- NPTEL Tranmission Tower Design Facotr - 220305 - 104039Document70 pagesNPTEL Tranmission Tower Design Facotr - 220305 - 104039Dipanku GoswamiNo ratings yet

- Breakdown Characteristics of Air GapsDocument9 pagesBreakdown Characteristics of Air GapsSupun Amarasinghe100% (6)

- Converter Transformer Bushing External Insulation DesignDocument4 pagesConverter Transformer Bushing External Insulation Designbtd2011No ratings yet

- An Experimental Study of Air Breakdown Voltage - J. Electrical SystemsDocument9 pagesAn Experimental Study of Air Breakdown Voltage - J. Electrical Systemsdineshsoni29685100% (1)

- STD Data IEC62271Document4 pagesSTD Data IEC62271Theresa WestNo ratings yet

- Dry Transformer TestDocument6 pagesDry Transformer Testpopera93100% (2)

- Dielectric Analysis of High Voltage Power TransformersDocument13 pagesDielectric Analysis of High Voltage Power Transformersykh92167No ratings yet

- Electrical and Chemical Diagnostics of Transformer InsulationDocument33 pagesElectrical and Chemical Diagnostics of Transformer InsulationVikas Vooturi100% (1)

- 1HSM 9543 41-02en Installation of Instrument Transformers at High Altitu...Document8 pages1HSM 9543 41-02en Installation of Instrument Transformers at High Altitu...alisolmazNo ratings yet

- High Voltage Measurement and Testing: Chapter-7Document46 pagesHigh Voltage Measurement and Testing: Chapter-7prakashNo ratings yet

- Insulation CoordinationDocument44 pagesInsulation CoordinationDrakhoNo ratings yet

- High Voltage Lab Report 1Document5 pagesHigh Voltage Lab Report 1testNo ratings yet

- Lecture 9 - CE 433Document21 pagesLecture 9 - CE 433SEEMA NIHALANINo ratings yet

- High Voltage Assignment by HirenDocument7 pagesHigh Voltage Assignment by HirenSumit HarwaniNo ratings yet

- Vortrag Denis DenisovDocument10 pagesVortrag Denis DenisovMarioNo ratings yet

- Rosemary Ainslie. Quantum October 2002Document5 pagesRosemary Ainslie. Quantum October 2002MANNAJANELAGUNANo ratings yet

- Fluid Mechanics ProjectDocument12 pagesFluid Mechanics ProjectDouglas Felix0% (1)

- NWsp08 - BishopDocument3 pagesNWsp08 - Bishopsethi_nitishNo ratings yet

- Pitot Static System UlDocument41 pagesPitot Static System UlMd. Naquibul Islam0% (1)

- Dimensioning of Electrical Clearance of OHL Using Correlation Between Weather Condition and Lightning Strike ProbabilityDocument10 pagesDimensioning of Electrical Clearance of OHL Using Correlation Between Weather Condition and Lightning Strike ProbabilityluisrearteNo ratings yet

- Dielectric Analysis of Power TransformersDocument13 pagesDielectric Analysis of Power TransformersK Vijay Bhaskar ReddyNo ratings yet

- Experimental Study of Factors Affecting Capacitance of High-Voltage Compressed-Gas CapacitorsDocument5 pagesExperimental Study of Factors Affecting Capacitance of High-Voltage Compressed-Gas CapacitorsdaskhagoNo ratings yet

- Design Considerations Form Pools and Spas NatatoriDocument5 pagesDesign Considerations Form Pools and Spas NatatoriService TechniqueNo ratings yet

- Piezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesFrom EverandPiezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 4: Electromagnetic CompatibilityFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 4: Electromagnetic CompatibilityNo ratings yet

- Asymmetry During Load-Loss Measurement of Three-Phase Three-Limb TransformersDocument10 pagesAsymmetry During Load-Loss Measurement of Three-Phase Three-Limb TransformersErhan KarabasNo ratings yet

- Product Range: Sensor and Automation Solutions For Your SuccessDocument36 pagesProduct Range: Sensor and Automation Solutions For Your SuccessErhan KarabasNo ratings yet

- CDAX 605: High-Precision Capacitance and Dissipation Factor Measurement InstrumentDocument3 pagesCDAX 605: High-Precision Capacitance and Dissipation Factor Measurement InstrumentErhan KarabasNo ratings yet

- OLTC ScanDocument3 pagesOLTC Scanwilliam damanikNo ratings yet

- Push-In RTD Temperature Probe With Connecting Cable: Technical DataDocument6 pagesPush-In RTD Temperature Probe With Connecting Cable: Technical DataVeryco BudiantoNo ratings yet

- Energies 11 01908Document14 pagesEnergies 11 01908robinknit2009No ratings yet

- Transformers Stray LossDocument34 pagesTransformers Stray LossPop GabrielNo ratings yet

- Transformer StudyDocument256 pagesTransformer StudysulemankhalidNo ratings yet

- Yaacob2014 Article ReviewOnPartialDischargeDetectDocument13 pagesYaacob2014 Article ReviewOnPartialDischargeDetectErhan KarabasNo ratings yet

- Chapter-6 Generator Transformer and Insulation CoordinationDocument46 pagesChapter-6 Generator Transformer and Insulation CoordinationyaoNo ratings yet

- IEC 60076-3 ED 3.0 2013-07 Clause 5Document2 pagesIEC 60076-3 ED 3.0 2013-07 Clause 5Erhan KarabasNo ratings yet

- IEC 60076-3 ED 3.0 2013-07 Clause 5Document2 pagesIEC 60076-3 ED 3.0 2013-07 Clause 5Erhan KarabasNo ratings yet

- TEİAŞ-MYD-2004-003.2 Technical Specification For Power Transformer (400 KV-MV, 154 KV-MV) PDFDocument1 pageTEİAŞ-MYD-2004-003.2 Technical Specification For Power Transformer (400 KV-MV, 154 KV-MV) PDFErhan KarabasNo ratings yet

- 1zba004509-001 AdvanceddiagnosticsDocument6 pages1zba004509-001 AdvanceddiagnosticsIoana Adriana HirschNo ratings yet

- Designing For Worldwide PowerDocument6 pagesDesigning For Worldwide PowerlemehmetNo ratings yet

- Transformer Inrush Is Over: An Experience With A 100MVA, 230/138 KV Three-Phase Transformer Controlled EnergizingDocument6 pagesTransformer Inrush Is Over: An Experience With A 100MVA, 230/138 KV Three-Phase Transformer Controlled EnergizingErhan KarabasNo ratings yet

- Department of Energy: Thursday November 12, 1998Document14 pagesDepartment of Energy: Thursday November 12, 1998harmlesdragonNo ratings yet

- Dalessandro Self-Capacitance HV TransformersDocument12 pagesDalessandro Self-Capacitance HV TransformersErhan KarabasNo ratings yet

- Rezgui-An Overview of Optical FibersDocument8 pagesRezgui-An Overview of Optical FibersMarciano SantamariaNo ratings yet

- NSUT Revised Seat MatrixDocument3 pagesNSUT Revised Seat Matrixrohit kumar rajNo ratings yet

- Approved+vendors +upto+29.05.2019 PDFDocument29 pagesApproved+vendors +upto+29.05.2019 PDFRAJESH SHARMANo ratings yet

- Nexpring NP10M Specification enDocument3 pagesNexpring NP10M Specification enblue 1234100% (2)

- 2N5294 2N5296 2N5298 NPN Silicon Transistor DescriptionDocument4 pages2N5294 2N5296 2N5298 NPN Silicon Transistor DescriptionVenu Gopal Rao AggressNo ratings yet

- 30° Directional AntennaDocument2 pages30° Directional AntennaLuis Diaz ArroyoNo ratings yet

- Servo User Manual LITE en PDFDocument76 pagesServo User Manual LITE en PDFleon3388No ratings yet

- V, V, K U C W/L, V I, I, G, R: Unless Given SpecificallyDocument2 pagesV, V, K U C W/L, V I, I, G, R: Unless Given SpecificallyraghavbhatiaNo ratings yet

- RANGER 7600 Downloadable Control Communicator Installation ManualDocument38 pagesRANGER 7600 Downloadable Control Communicator Installation ManualviorenNo ratings yet

- Comfort-Aire CMA1412SG-0 Specification SheetDocument4 pagesComfort-Aire CMA1412SG-0 Specification SheetRudieNo ratings yet

- ECE WorkShopDocument268 pagesECE WorkShopRaghava RaghuNo ratings yet

- Uni Line Top 4921240130 UkDocument6 pagesUni Line Top 4921240130 UkLUATNo ratings yet

- Fabrication of Solar Powered Portable - HBRP PublicationDocument7 pagesFabrication of Solar Powered Portable - HBRP PublicationPrince DasNo ratings yet

- Tutorial III Root Locus DesignDocument25 pagesTutorial III Root Locus DesignNur DalilaNo ratings yet

- Encoders and Decoders, Multiplexer, Tri-State InverterDocument25 pagesEncoders and Decoders, Multiplexer, Tri-State InverterRohit SainiNo ratings yet

- ModiconM218 CatalogueDocument84 pagesModiconM218 CatalogueSagar JadhavNo ratings yet

- TPS7A4700EVM-094 Evaluation Module: User's GuideDocument14 pagesTPS7A4700EVM-094 Evaluation Module: User's GuideJaroslav BiresNo ratings yet

- R 42043042015Document4 pagesR 42043042015Sridhar MiriyalaNo ratings yet

- Time Delay SystemsDocument25 pagesTime Delay SystemsSamarendu BaulNo ratings yet

- Robot Monitoring of Power SystemsDocument23 pagesRobot Monitoring of Power SystemsJashuva Kiran86% (14)

- Electrical DetailsDocument4 pagesElectrical Detailsdppl.mepNo ratings yet

- ServiceManuals LG TV PLASMA 50PJ350 50PJ350 Service ManualDocument33 pagesServiceManuals LG TV PLASMA 50PJ350 50PJ350 Service ManualDan Prewitt63% (8)

- KT-502H en Tcd210202ab 20211221 Manual WDocument3 pagesKT-502H en Tcd210202ab 20211221 Manual WGopal HegdeNo ratings yet

- Function Generator XR2206Document8 pagesFunction Generator XR2206and roidNo ratings yet

- Lenovo-IBM CORONADO-5 INT SOVP (COR5I-7) 43Y6956 REV 4.06 (3.09) - IBM LENOVO THINKPAD T500 W500Document101 pagesLenovo-IBM CORONADO-5 INT SOVP (COR5I-7) 43Y6956 REV 4.06 (3.09) - IBM LENOVO THINKPAD T500 W500yousef abozerNo ratings yet

- Solution For Designing A Transition Mode PFC Preregulator With The L6562ADocument36 pagesSolution For Designing A Transition Mode PFC Preregulator With The L6562AZhenhua GaoNo ratings yet

- 1112 Ehv+xlpe+cable (0229)Document42 pages1112 Ehv+xlpe+cable (0229)Chikirin Grønlund100% (2)

- EKM HOT SPWM 075 Water Meter Spec SheetDocument2 pagesEKM HOT SPWM 075 Water Meter Spec SheetAdam BrouwerNo ratings yet

- Lecture1 IntroDocument35 pagesLecture1 Introapi-3834272No ratings yet

- Layout Variations On LNADocument4 pagesLayout Variations On LNArichbuggerNo ratings yet