Professional Documents

Culture Documents

Grinding Process Within Vertical Roller Mills Experiment and Simulation

Grinding Process Within Vertical Roller Mills Experiment and Simulation

Uploaded by

Dirceu NascimentoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grinding Process Within Vertical Roller Mills Experiment and Simulation

Grinding Process Within Vertical Roller Mills Experiment and Simulation

Uploaded by

Dirceu NascimentoCopyright:

Available Formats

www.cementechnology.

ir

MINING

SCIENCE AND

TECHNOLOGY

Mining Science and Technology 19 (2009) 00970101

www.elsevier.com/locate/jcumt

Grinding process within vertical roller mills:

experiment and simulation

WANG Jian-huai1, CHEN Qing-ru1, KUANG Ya-li1, LYNCH A J2, ZHUO Jin-wu1

. ir

1

School of Chemical Engineering and Technology, China University of Mining & Technology, Xuzhou, Jiangsu , China

gy

2

Juius Kruttschnitt Mineral Research Centre, Queensland University, Brisbane, Australia

lo

Abstract: Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement

and a power plant, a simulation of the grinding process in vertical roller mills was carried out. The simulation calculation used a

breakage function, B. The results indicate that the breakage function, B, and the selection function, S, in the form of a matrix, can

no

be used to express the probability of the material breaking during the grinding process. This allows the size distribution of the

product to be numerically estimated. The simulation results also show that the simulated size distribution curves fit the actual ex-

perimental product curves quite well. The model provides a good starting point for simulation of the grinding process. Further re-

search is needed to determine the proper breakage function and the matrix value of the selection function.

ch

Keywords: vertical roller mill; grinding; simulation

te

1 Introduction fired power plants and cement plants used 6.16% of

all nationwide industrial power-consumption (see

en

Grinding is a highly energy consuming process. Table 1). Statistics also show that the grinding energy

Considerable coal, cement raw materials and clinkers, consumption in China was 50% higher than what

metal and non-metal minerals, and the like, are would be expected at the world class, advanced

level[12]. Therefore, optimizing grinding process pa-

em

crushed every year in China for power generation,

cement manufacturing, industrial combustion and rameters is a very important field of study related to

other industrial purposes. According to statistics, the energy-saving and the reduction of power consump-

energy consumption of the coal and cement grinding tion in China. It is estimated that power consumption

.c

processes in power and cement plants accounted for could be lowered by 30%50% after optimization of

7.26% of all nationwide industrial power consump- the grinding process.

tion in 2003. In 2004 grinding associated with coal-

w

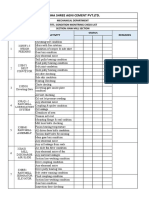

Table 1 Power-consumption Statistics

w

Amount of Power consumption Account for Possible power-saving

grinding (Gt) (109kWh) industrial power-consumption (109kWh)

w

2003 2004 2003 2004 2003 2004 2003 2004

Cement plant 0.82 1.0[35] 82.0 100.0 6.27 5.18 24.641.0 3050

Power plant 0.826[1] 0.9[1] 17.43 18.90 1.3 0.98 5.238.72 5.679.45

Total 99.43 118.90 7.57 6.16 29.8349.72 35.679.45

Note: not including other industries involving grinding.

Simulation of grinding processes started nearly a was also making progress. The approach by Lynch A

century ago. These early researchers found that the J was to use industrial scale experiments, which

grinding processes cost huge amounts of energy. studied not only power consumption but also the en-

Therefore, most of their studies were aimed at energy tire grinding process, and to investigate other factors

consumption of the mills. In the meantime the mod- affecting grinding such as the type of mills, the en-

eling of the hydrocyclone used in grinding circuits ergy costs, the property of the feed materials and the

Received 16 July 2008; accepted 30 October 2008

Project PBK2005022 supported by the Natural Science Foundation of Jiangsu Province

Corresponding author. Tel: +86-516-83883530; E-mail address: kylxjx@163.com

cement technology magazine: 021-22883306, 22861343

www.cementechnology.ir

98 Mining Science and Technology Vol.19 No.1

operating parameters[12]. Grinding process models Sampling and experiments were also carried out in

for a ball mill were established where a selection a power plant that has four ball-mill circuits used for

function and a breakage function were used to de- coal grinding so that different equipment could be

scribe the breaking rate and the particle size distribu- compared.

tion. Other models that have been developed can be

2.2 Sampling and experiments

used to optimize production flow design, process pa-

rameters, equipment performance, raw material and All the samples used in the lab experiments were

operating conditions for ball mills, classifying cy- taken from the production line of the plant. The feed,

clones, screen classifiers and other equipment intermediate materials, products of the limestone and

through on-line simulations. These results were pub- clinker systems and the coal feed were each sampled

lished early in the 1980s and were transformed into from conveyor belts or chutes. The ground coal and

the commercial software JKSIMMET, which has final cement products were sampled with a CY40

been used in Australia, Turkey and other countries[34]. automatic powder sampler. Each sample was taken

Current research abroad into the grinding process of over a period of at least two hours to ensure that a

ir

ball mills, rod mills, cone crushers and autogenous representative sample had been collected. Sampling

mills is comparatively mature. time intervals, and the weight of the subsamples,

.

gy

There have been some reports on the mathematical conformed to the national and coal industry

modeling of grinding equipment by Chinese re- regulations and standards.

searchers. For example: The study of general grinding Laboratory grindability tests, screening analyses

dynamic equations of ultra-critical speed mills[5];

lo

(for +0.5 mm particles), laser size analyses (for 0.5

multi-factor experiments to determine the variation of mm particles) and comminution rate testing were

grinding fineness and net energy consumption as a carried out using the samples obtained from the three

function of ball-mill rotation speed, grinding medium

filling-ratio, feed quantity, slurry concentration and

other processing variables[6]; and research on classi-

no types of mills and the four grinding circuits.

Sufficient reliable data was collected so that a

mathematical model for a vertical roller mill could be

ch

fier overflow control systems using a new prediction set up. Grindability tests were completed on a

control algorithm and computer simulation[7]. non-standard ball mill. Therefore, these results are

There are few studies both at home and abroad only indirectly comparable to the other data. The goal

te

concerning process simulation of recently developed of the experiments was to optimize the grinding

new equipment such as vertical roller mills and stir- process, to improve comminution efficiency and to

en

ring mills. In China almost no work has been done on reduce energy consumption.

the simulation of multi-factor industrial manufactur-

ing systems. 3 Results and discussion

em

This paper describes the simulation of the grinding

process in vertical roller mills. It is based on actual 3.1 Comparison of grinding results using differ-

experimental data obtained on a production line at the ent kinds of coals

plant and from lab experiments.

.c

The following data were obtained from the

experiments on the coal samples from both the

2 Experimental cement plant and the power plant (Table 3).

w

Table 3 Grinding results: different types of coals

2.1 Equipment

w

Grindability Power

>74 m

The main experimental equipment was a large- Coal sample factor Mill type consumption

yield (%)

(g/r) (kWh/t)

w

scale cement plant with a capacity of 4000 t/d. The

Power plant

plant is equipped with advanced technologies and has coal

20.8 0.74 Ball mills 21

different types of grinding mills. Four grinding Cement plant Vertical roller

6.0 0.45 12

circuits are used with different materials: vertical coal mills

mills (Loesche) for coal and cement feed; vertical

roller mills for cement clinkers; and ball mills for The experimental results in Table 3 show that the

cement products. Table 2 shows the main technical fractions of particles sized greater than 74 m are

parameters of the vertical roller mill (CKP) studied in 20.8% and 6.0% in the screening of the power plant

this paper. coal and the cement plant coal, respectively. The data

indicate that the product size from the vertical roller

Table 2 Main parameters of the vertical roller mill (CKP) mill in the cement plant is far smaller than that of the

Capacity

Rated Measured Roller Rotating table Rotation power plant. The grindability result is the grams of

power power diameter diameter speed

(t/h)

(kW) (kW) (mm) (mm) (r/min)

fine particles, which pass a 0.125 mm screen aperture

size, produced per revolution of the mill. A standard

99 950 745 600 1 700 39.8

procedure is used to determine this value. The lower

cement technology magazine: 021-22883306, 22861343

www.cementechnology.ir

WANG Jian-huai et al Grinding process within vertical roller mills: experiment and simulation 99

the value the harder the material is. The difference in Table 4 Screening data of samples

grindability between power and cement plant coal is Cyclone Cyclone

Clinker Clinker mill Ball mill

also quite notable. Moreover, the feed coal of the Size

mill feed product output

separation separation

(mm) coarse final

cement plant is coarser than that of the power plant yield (%) yield (%) yield (%)

yield (%) yield (%)

(Fig. 1).

25 0.8

13 14.6 2.4

6 16.5 5.9

3 18.6 10.2

1 21.2 13.9

0.5 12.2 11.6

(0.5) (16.1)

0.25 8.2 0.9

ir

0.125 6.6 1.9 2

0.074 6.5 7.1 11.6

.

Fig. 1 Cumulative size curves of the feed coal

gy

0.045 6.3 19.9 30.8 1.5

of the two plants

(0.045) 28.4 71.1 54.7 98.5

The above study shows that the hardness of the

lo

coal samples taken from the cement plant is greater 4 Modeling a vertical roller mill

than the hardness of power plant coal. The feed sizes

power plant, but the size of the product from the

no

are also larger in the cement plant, compared to the

vertical roller mill in the cement plant is smaller than

A mathematical model for the grinding process in

vertical roller mills has been made. The cement

plant's vertical roller mills (CKP) are used to crush

ch

the size of product from the power plant ball mill. It cement clinkers and prepare for the next step, which

can be concluded that the process of grinding coal are ball mills. The grinding mechanism of the CKP

into fine particles for cement or power plant imposes pressure on the particles instead of impact

te

consumption uses less energy when grinding is done forces. It has higher energy efficiency than do the ball

with a vertical roller mill rather than a ball mill. mills. Although more actual operational data are

Obviously, this conclusion is based on the crushing

en

required to set up an industrially practical

process only. The energy consumption of the fans mathematical model, the data obtained from the

used in the classification process has not been taken open-circuit vertical roller mills (CKP) are still

into account. The example shows that optimum

em

valuable.

selection of the equipment could reduce power

consumption enormously. 4.1 Breakage probability function

3.2 Analysis of the vertical roller mill Observation of the size range of the input and

.c

output materials indicates that a simple breakage

By analyzing the size distribution of the samples probability function might be a suitable starting step

(Table 4) it can be seen that some improvements are

w

for setting up the model, i.e.;

needed in the performance of the cement plant

equipment. The product size from the clinker mills is P = B f (1)

w

fine enough for the following tube mills: +6 mm where P and f are particle size distributions of the

accounts for only 8.3% (+13 mm/1.4%) and 97% of output and input materials, respectively, and B is a

w

that is recycled by the mills separator. So there are breakage function.

only a few coarse particles in the feed material going

to the ball mills. The diameter of the steel ball is 4.2 Breakage function

much too large and much energy is wasted lifting The breakage function, B, represents the

these large diameter balls rather than grinding probability that ith sized particles proceed to the size

efficiently. Therefore, the clinker grinding rate and fractions from (i+1) to (i+n). The function depends on

the overall production capacity of the ball mill circuit the property of the material and can be expressed as a

could be improved, without more energy matrix:

consumption, by adjusting the ratio of chamber

B11 0 ... 0 0

length to steel ball diameter in the following tube

mills. This example shows that grinding circuit ... ... ... ... ...

(2)

simulation can be used to analyze the production B ã Bi1 ... Bij ... ...

circuit, to optimize the operating parameters and to ... ... ... ... 0

reduce energy consumption. Bn1 ... Bnj ... Bnn

cement technology magazine: 021-22883306, 22861343

www.cementechnology.ir

100 Mining Science and Technology Vol.19 No.1

For vertical roller mills B is a pressure breakage 4.3 Selection function

function and is determined from test data. It is

All feed particles have certain breakage probabili-

different from an impact force breakage function

ties. These probabilities are affected by technical

appropriate for a jaw crusher, cone crusher or ball

conditions and will vary with particle size and the

mill. Fig. 2 shows equipment to obtain B. Pressure is

grinding stage. Call the breakage probability of size

applied to the hammer and the sizes of the resulting

fraction i, Si. This is the selection function, which can

particles allow a breakage function, in the form of

be expressed as a diagonal matrix:

Eq.(2), to be obtained. This is a thought experiment

and, therefore, it may not fully simulate vertical roller S = (S1, , Si , , Sn) (3)

mills. Experimental data and research experience of A The selection function, S, for the materials in

J Lynch has allowed the breakage function, B, for the question has been established as:

materials in question to be established (see Table 5). S = (0.3, 0.3, 0.3, 0.2, 0.2, , 0.2)

4.4 Results of simulation

ir

Table 6 shows how the breakage function P=Bf

.

can be used to model the grinding process. In this

gy

example all materials are comminuted according to

the breakage function, B, to gain the final products.

The size of the first grinding cycle product

lo

calculated from Eq.(1) is larger than that of the

experimental product. This is because the experimen-

Fig. 2 Experimental set for obtaining the breakage function

no tal materials are crushed repeatedly in the roller mill.

Therefore, multiple cycles must be taken into account

in the model. Suppose that the breakage probability

ch

of the second grinding cycle depends on the size of

Table 5 Breakage function obtained from experiments input material.

and experience The model of the second grinding cycle can be

te

B1 B2 B3 B4 B5 B6 B7 B8 B9 considered as an expansion of the first one. It is

0.227 0 0 0 0 0 0 0 0 expressed as:

en

0.213 0.227 0 0 0 0 0 0 0 P2 = (BS + I S) P1 (4)

0.180 0.213 0.227 0 0 0 0 0 0

where S is the selection function.

0.146 0.180 0.213 0.227 0 0 0 0 0

Table 6 shows the results of calculations using this

em

0.109 0.146 0.180 0.213 0.227 0 0 0 0

model function. The first and the second grinding

0.074 0.109 0.146 0.180 0.213 0.227 0 0 0

cycles have the same breakage function, B, because

0.046 0.074 0.109 0.146 0.180 0.213 0.227 0 0 they have the same breaking mechanism. The final

0.031 0.046 0.074 0.109 0.146 0.180 0.213 0.227 0 products are the sum of all broken and unbroken

.c

0.011 0.031 0.046 0.074 0.109 0.146 0.180 0.213 0.227 materials.

w

Table 6 Tabulation of actual and simulated products

Size Actual products Feed Simulated products Simulated products

SP1 P1SP1 BSP1

w

(mm) P F P1 BF P2= BSP1+P1SP1

13.000 2.4 15.40 3.50 1.05 2.45 0.48 2.93

w

6.000 5.9 16.50 7.03 2.11 4.92 1.16 6.08

3.000 10.2 18.60 10.51 3.15 7.36 1.69 9.04

1.000 13.9 21.20 13.99 2.80 11.19 1.99 13.18

0.500 11.6 12.20 11.33 2.27 9.07 2.10 11.16

0.250 8.2 1.78 9.22 1.84 7.38 2.04 9.42

0.125 6.6 1.32 7.38 1.48 5.91 1.88 7.78

0.074 6.5 2.44 5.83 1.17 4.66 1.71 6.37

0.045 6.3 2.39 5.83 1.17 4.66 2.44 7.10

0.045 28.4 8.17 25.40 5.08 20.31 0.00 26.93

Total 100.0 100.00 100.00 27.90 72.10 18.72 100.00

Four size distribution curves are given in Fig. 3 distribution of final products derived by calculation.

where F, P, P1, and P2 represent the feed to the mills, It can be seen in Fig. 3 that the two simulated

the actual products, the first and the second grinding product curves resemble each other and are similar to

cycle products, respectively. P2 is also the size the experimental product curve. The simulated curve

cement technology magazine: 021-22883306, 22861343

www.cementechnology.ir

WANG Jian-huai et al Grinding process within vertical roller mills: experiment and simulation 101

of the second cycle, P2, fits the actual product curve breaking cycles before becoming the final product

better. It indicates that the feed materials are broken this fact should be taken into account by the model.

more than once during the grinding process and that 3) A mathematical simulation of a vertical roller

the working state of vertical roller mills can be mill based on experimental data has been carried out.

simulated with a proper model. Further research is The simulation results show that simulated size dis-

needed to reduce simulation errors and to establish tribution curves fit the actual experimental product

more reliable breakage and selection functions. curves quite well. It is feasible to simulate the grind-

ing process of vertical roller mills by using a proper

mathematical model; further research is still needed.

References

[1] Lynch A J. Mineral Crushing and Grinding Circuits,

Their Simulation, Optimization, Design and Control.

ir

Amsterdam: Elsevier Scientific Publishing Co, 1977.

[2] Lynch A J, Oner M, Benzer H. Simulation of a closed

.

cement grinding circuit. Zement-Kalk-Gips, 2000, 53(10):

gy

560567.

[3] Benzer H, Ergun L, Oner M, Lynch A J. Simulation of

Fig. 3 Sizing curves of actual and simulated products open circuit clinker grinding. Minerals Engineering,

lo

2001, 14(7): 701710.

5 Conclusions [4] Benzer H, Ergun L, Lynch A J, Oner M. Modeling ce-

ment grinding circuit. Minerals Engineering, 2001, 14

no

1) Experimental results show that the coal grinding

process consumes less energy in vertical roller mills

than in ball mills: it is very important to select the

[5]

(11): 14691482.

Ye X D, Wen S M, Zhang W B. Grinding kinetics of

ultra-critical rotation speed mill. Nonferrous Metals,

ch

2004, 56(1): 8385. (In Chinese)

proper equipment to be used in the grinding process. [6] Zhai H X. Combination behavior of the process variables

2) A breakage function, B, and a selection function, affecting grinding in ball mill. Mining & Processing

S, in the form of a matrix, can be used to represent the Equipment, 2003(7): 810. (In Chinese)

te

breaking probability of the materials during the [7] Gu S F, Xu P. Application of prediction control algo-

rithm in grinding grade. Industry and Mine Automation,

grinding process. This allows an estimation of the 2003(5): 2123. (In Chinese)

en

size distribution after breaking. The approach

provides a good starting point for grinding simulation.

Since materials typically undergo more than two

em

.c

w

w

w

cement technology magazine: 021-22883306, 22861343

You might also like

- Influence of Quartz Particles On Wear in Vertical Roller Mills.Document9 pagesInfluence of Quartz Particles On Wear in Vertical Roller Mills.chienhamthepNo ratings yet

- Modelling and Simulation of Particle Breakage in Impact CrushersDocument8 pagesModelling and Simulation of Particle Breakage in Impact CrushersDirceu NascimentoNo ratings yet

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Document6 pagesRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiNo ratings yet

- Manual For Visual Inspection of HPGR Rollers: Top PictureDocument1 pageManual For Visual Inspection of HPGR Rollers: Top PictureRAVINo ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- 09.00 Daniel Strohmeyer, Loesche GMBHDocument16 pages09.00 Daniel Strohmeyer, Loesche GMBHMohd Ali100% (1)

- Mps MillDocument4 pagesMps MillRahul RoyNo ratings yet

- Grinding System and Circuit of VRM Process Data Plant DataDocument58 pagesGrinding System and Circuit of VRM Process Data Plant DataFasil Ayele60% (5)

- Pneumatic Conveying Design GuideDocument33 pagesPneumatic Conveying Design GuideVisnu Sankar100% (2)

- Uiw Bucket Elevator Ansi Bem0308 r21Document42 pagesUiw Bucket Elevator Ansi Bem0308 r21annccknarimeNo ratings yet

- Reverse Air Bag House PDFDocument4 pagesReverse Air Bag House PDFRanga VamshiNo ratings yet

- Zenith Grinding Mill Catalogue-EmailDocument26 pagesZenith Grinding Mill Catalogue-EmailalijandroNo ratings yet

- Raw Grinding System PDFDocument37 pagesRaw Grinding System PDFSiti Nurhidayati100% (1)

- Machines and Processes For The Cement IndustryDocument19 pagesMachines and Processes For The Cement IndustryAli Alshaqah100% (1)

- Roller Mill FundamentalsDocument11 pagesRoller Mill Fundamentalshidrastar123100% (1)

- Verticle Roller Mill: Presented By-Mahesh Kumar Nyati Get-MeDocument34 pagesVerticle Roller Mill: Presented By-Mahesh Kumar Nyati Get-Mevikas100% (1)

- Polytrack Clinker Cooler.: PolysiusDocument3 pagesPolytrack Clinker Cooler.: PolysiushathamphanNo ratings yet

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- 01 Raw Grinding Systems PDFDocument17 pages01 Raw Grinding Systems PDFSokreach DinNo ratings yet

- Kiln Shell SpecificationDocument20 pagesKiln Shell SpecificationAnonymous p4GdtQpNo ratings yet

- Pneumatic TransportDocument9 pagesPneumatic TransportMehmet CNo ratings yet

- Ball MillDocument9 pagesBall MillTaufik AchmadNo ratings yet

- Vertical Roller MillDocument2 pagesVertical Roller MillAhmed Younis0% (2)

- Vertical Roller MillDocument2 pagesVertical Roller MillAhmed Younis0% (2)

- Parts of Vertical Roller MillDocument1 pageParts of Vertical Roller Millcostea002867% (3)

- Parts of Vertical Roller MillDocument1 pageParts of Vertical Roller Millcostea002867% (3)

- 41 Vertical Mills - V2-0Document56 pages41 Vertical Mills - V2-0Sai Sricharan Reddy86% (14)

- Coal Mills PDFDocument16 pagesCoal Mills PDFvtbkNo ratings yet

- Grinding Process and OperationDocument30 pagesGrinding Process and Operationchibssa alemayehu100% (6)

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDocument56 pages1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguNo ratings yet

- 071 How To Maintain Hydraulic SystemDocument10 pages071 How To Maintain Hydraulic Systemhaziq100% (1)

- 01.0 - 22146.002E - Hydraulic SystemDocument126 pages01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- Performance Driven Maintenance Feb 52013Document25 pagesPerformance Driven Maintenance Feb 52013recaiNo ratings yet

- 132 Loesche Mills For Solid Fuels Coal Mill E 2016Document24 pages132 Loesche Mills For Solid Fuels Coal Mill E 2016Verananda Ariyanto100% (1)

- Ball Mill InspectionDocument9 pagesBall Mill InspectionmahantmtechNo ratings yet

- Quest - Vertical Roller Mill - KM (Rough)Document6 pagesQuest - Vertical Roller Mill - KM (Rough)Raji SuriNo ratings yet

- RMH & GrindingDocument132 pagesRMH & Grindingmkpq100% (1)

- One Kiln - 13,000 TPD: Cement & MineralsDocument52 pagesOne Kiln - 13,000 TPD: Cement & MineralsKristínaNo ratings yet

- Gebr. Pfeiffer Brochure Passion For Grinding enDocument28 pagesGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyNo ratings yet

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATrecaiNo ratings yet

- Blaz Jurko - GEBR. Pfeiffer - MPS Grinding Technology PDFDocument22 pagesBlaz Jurko - GEBR. Pfeiffer - MPS Grinding Technology PDFrpazbNo ratings yet

- 2 200901loeschetadipatri 120803014722 Phpapp01Document4 pages2 200901loeschetadipatri 120803014722 Phpapp01Sai Sricharan ReddyNo ratings yet

- Vertical Roller MillsDocument52 pagesVertical Roller MillsThibaut Leconte50% (2)

- Shock Load Roller MillDocument1 pageShock Load Roller MillrecaiNo ratings yet

- Tube MillsDocument44 pagesTube MillsISLAM I. Fekry100% (2)

- Gujarat Sidhee Cement Limited-SmitDocument26 pagesGujarat Sidhee Cement Limited-SmitHimadri MahatoNo ratings yet

- Mecawber DenseveyorDocument4 pagesMecawber DenseveyorkanthmekalaNo ratings yet

- Fons Technology PDFDocument28 pagesFons Technology PDFBulent BULUTNo ratings yet

- Proceedings Rev A English - Print ResDocument130 pagesProceedings Rev A English - Print ResRaúl Marcelo Veloz100% (1)

- Nelsonmachineryintl Equipmenthighlights2019 04 190415060844 PDFDocument64 pagesNelsonmachineryintl Equipmenthighlights2019 04 190415060844 PDFFederico BrigatoNo ratings yet

- VRM Daily Stoppage DetailsDocument7 pagesVRM Daily Stoppage DetailsValipireddy NagarjunNo ratings yet

- 06 Mill Body Upper HousingDocument15 pages06 Mill Body Upper HousingDavid Vilca MamaniNo ratings yet

- VRM PresentationDocument49 pagesVRM PresentationMKPashaPasha100% (4)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Dokumen - Tips - Atox Raw Mill 55844e0e63329Document13 pagesDokumen - Tips - Atox Raw Mill 55844e0e63329pipit agusNo ratings yet

- A4-P 1.0 enDocument21 pagesA4-P 1.0 enmkpqNo ratings yet

- 2006 Slag Grinding With MPS Vertical Roller MillsDocument4 pages2006 Slag Grinding With MPS Vertical Roller Millslijosh_rexy1983No ratings yet

- 04 Vertical Roller MillsDocument12 pages04 Vertical Roller MillsaktaserdincNo ratings yet

- FivesFCB Brochure Horomill GBDocument6 pagesFivesFCB Brochure Horomill GBpeymanNo ratings yet

- Vertical Mills 2008 - V2-0Document45 pagesVertical Mills 2008 - V2-0Mujahid BalochNo ratings yet

- EN21004243A Roller StationsDocument51 pagesEN21004243A Roller StationsbulentbulutNo ratings yet

- Collaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurDocument4 pagesCollaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurjmpbarrosNo ratings yet

- Vertical Roller MillDocument3 pagesVertical Roller MillChaitanya Chinta0% (1)

- MAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenDocument1 pageMAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenpeymanNo ratings yet

- Jaypee Cement Project ReportDocument29 pagesJaypee Cement Project ReportPurnendu MishraNo ratings yet

- Active Redundancy ConceptDocument9 pagesActive Redundancy ConceptRollerJonnyNo ratings yet

- 23 HaverDocument36 pages23 HaverkonstantasNo ratings yet

- MARCH 17, 2017: India's Biggest OK™ Mill - A Story of Reliable Operations and Smoother PerformanceDocument2 pagesMARCH 17, 2017: India's Biggest OK™ Mill - A Story of Reliable Operations and Smoother PerformanceRahul RoyNo ratings yet

- Cement Process Engineering Vade-Mecum: 4. MillingDocument21 pagesCement Process Engineering Vade-Mecum: 4. Millinganwar saeedNo ratings yet

- Coal NEW CHECKLIST Coal MillDocument9 pagesCoal NEW CHECKLIST Coal MillanilNo ratings yet

- Gebr Pfeiffer FICEM PLANTILLA CONGRESO T+ëCNICO 2016Document38 pagesGebr Pfeiffer FICEM PLANTILLA CONGRESO T+ëCNICO 2016Julio CarneiroNo ratings yet

- 3 3 Euragglo Komarek Roller Presses Presentation Pascal Hervieu PDFDocument55 pages3 3 Euragglo Komarek Roller Presses Presentation Pascal Hervieu PDFssmith2007100% (1)

- Raw Mill Check ListDocument2 pagesRaw Mill Check Listlaxman JoshiNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- ResumeDocument3 pagesResumeHari Prathap ReddyNo ratings yet

- Cement Mill Note BookDocument4 pagesCement Mill Note BookK.SRINIVAS RAONo ratings yet

- Grinding Process Within Vertical Roller Mills: Experiment and SimulationDocument5 pagesGrinding Process Within Vertical Roller Mills: Experiment and SimulationRendotian AnugrahNo ratings yet

- Log Y.ir: Grinding Process Within Vertical Roller Mills: Experiment and SimulationDocument5 pagesLog Y.ir: Grinding Process Within Vertical Roller Mills: Experiment and SimulationMohammed AbdoNo ratings yet

- Reducing Grinding Energy and Cost - Magnetite Iron Ore Design Case StudyDocument8 pagesReducing Grinding Energy and Cost - Magnetite Iron Ore Design Case StudyElwathig BakhietNo ratings yet

- Simulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantDocument13 pagesSimulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantW ZuoNo ratings yet

- Calculation Method and Its Application For Energy Consumption of Ball Mills in Ceramic Industry Based On Power Feature DeploymentDocument14 pagesCalculation Method and Its Application For Energy Consumption of Ball Mills in Ceramic Industry Based On Power Feature DeploymentKiran ShetNo ratings yet

- Modeling and Simulation For System Reliability Analysis: The RAMSAS MethodDocument7 pagesModeling and Simulation For System Reliability Analysis: The RAMSAS MethodDirceu NascimentoNo ratings yet

- The Modelling of Froth Zone Recovery in Batch and Continuously Operated Laboratory Flotation CellsDocument17 pagesThe Modelling of Froth Zone Recovery in Batch and Continuously Operated Laboratory Flotation CellsDirceu NascimentoNo ratings yet

- Crusher PBM TMDocument4 pagesCrusher PBM TMDirceu NascimentoNo ratings yet

- Gae Rtner 2000Document15 pagesGae Rtner 2000Dirceu NascimentoNo ratings yet

- State of The Art and Challenges in Mineral Processing ControlDocument11 pagesState of The Art and Challenges in Mineral Processing ControlDirceu NascimentoNo ratings yet

- A Compartment Model For The Mass Transfer Inside A Conventional F Lotation CellDocument15 pagesA Compartment Model For The Mass Transfer Inside A Conventional F Lotation CellDirceu NascimentoNo ratings yet

- 2015 WCSB7 Placer Gold SamplingDocument8 pages2015 WCSB7 Placer Gold SamplingDirceu NascimentoNo ratings yet

- 1994c Apcom Slovenie Opti MoinhoDocument10 pages1994c Apcom Slovenie Opti MoinhoDirceu NascimentoNo ratings yet

- 2006 Advances in ComminutionDocument21 pages2006 Advances in ComminutionDirceu NascimentoNo ratings yet

- 1993c Cim2 UP HydroDocument14 pages1993c Cim2 UP HydroDirceu NascimentoNo ratings yet

- A Mathematical Model of Recovery of Dense Medium Magnetics in The Wet Drum Magnetic SeparatorDocument17 pagesA Mathematical Model of Recovery of Dense Medium Magnetics in The Wet Drum Magnetic SeparatorDirceu NascimentoNo ratings yet

- 2013 Wcsb6 SB Sampling SDDocument12 pages2013 Wcsb6 SB Sampling SDDirceu NascimentoNo ratings yet

- Crusher Bond's Law: General DescriptionDocument3 pagesCrusher Bond's Law: General DescriptionDirceu NascimentoNo ratings yet

- 2014 Impc Paper112 HPGRDocument11 pages2014 Impc Paper112 HPGRDirceu NascimentoNo ratings yet

- A Model of Particle Sliding Time For Flotation Size BubblesDocument6 pagesA Model of Particle Sliding Time For Flotation Size BubblesDirceu NascimentoNo ratings yet

- 1995g Impc UP SupervisorDocument6 pages1995g Impc UP SupervisorDirceu NascimentoNo ratings yet

- 1996 Sag Up CVRD BrazilDocument9 pages1996 Sag Up CVRD BrazilDirceu NascimentoNo ratings yet

- I-1 Fi - , I J K L: Elsevier Sequoia S-A - , Lausanne - Printed in The NetherlandsDocument2 pagesI-1 Fi - , I J K L: Elsevier Sequoia S-A - , Lausanne - Printed in The NetherlandsDirceu NascimentoNo ratings yet

- Raw MillDocument6 pagesRaw MillRohmi SafitriNo ratings yet

- OK PRO Plus Brochure - FLSDocument4 pagesOK PRO Plus Brochure - FLSMuhammad SaputraNo ratings yet

- Sika Solutions For Cement IndustryDocument24 pagesSika Solutions For Cement IndustryMadanKarkiNo ratings yet

- Rolling Bearings in Vertical Mills Built by Gebr. Pfeiffer AG, GermanyDocument2 pagesRolling Bearings in Vertical Mills Built by Gebr. Pfeiffer AG, GermanyAnonymous H9Mu3yQNo ratings yet

- Rashmi Cement Expansion Plan-CEMENT PDFDocument69 pagesRashmi Cement Expansion Plan-CEMENT PDFSoumyakanti S. Samanta (Pgdm 09-11, Batch II)No ratings yet

- MARCH 17, 2017: India's Biggest OK™ Mill - A Story of Reliable Operations and Smoother PerformanceDocument2 pagesMARCH 17, 2017: India's Biggest OK™ Mill - A Story of Reliable Operations and Smoother PerformanceRahul RoyNo ratings yet

- Loesche America Inc: Loesche "The Solution For Cement Grinding" Sept 2012Document33 pagesLoesche America Inc: Loesche "The Solution For Cement Grinding" Sept 2012Aftab RafiqueNo ratings yet

- Vertical Roller Mill IntroductionDocument2 pagesVertical Roller Mill Introductionemad sabriNo ratings yet

- Test Report 10034-1 Raw Material Grasim Rawan IndiaDocument6 pagesTest Report 10034-1 Raw Material Grasim Rawan IndiaKenny RuizNo ratings yet