0% found this document useful (0 votes)

3K views1 pageSizing Guidelines for Hydraulic Decouplers

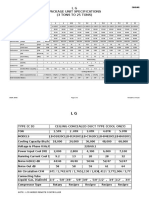

The document provides guidelines for sizing a hydraulic decoupler in a primary/secondary chilled water system. The decoupler acts to divide the circuit into a primary loop and secondary loop. It should be sized such that the friction loss is less than 1.5 ft and the length is 3 to 10 times the diameter. The decoupler diameter should match the main supply and return pipes. Flow through the decoupler should be 110-115% of the largest chiller's flow. The length cannot be too long or too short to avoid pressure drops or mixing issues.

Uploaded by

Waleed FathiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

3K views1 pageSizing Guidelines for Hydraulic Decouplers

The document provides guidelines for sizing a hydraulic decoupler in a primary/secondary chilled water system. The decoupler acts to divide the circuit into a primary loop and secondary loop. It should be sized such that the friction loss is less than 1.5 ft and the length is 3 to 10 times the diameter. The decoupler diameter should match the main supply and return pipes. Flow through the decoupler should be 110-115% of the largest chiller's flow. The length cannot be too long or too short to avoid pressure drops or mixing issues.

Uploaded by

Waleed FathiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- What is the Hydraulic Decoupler