Professional Documents

Culture Documents

Annealing of Polymer Membranes

Uploaded by

Ayyaz Butt0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

Vona2014_ReferenceWorkEntry_AnnealingOfPolymerMembranes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesAnnealing of Polymer Membranes

Uploaded by

Ayyaz ButtCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

A

Annealing of Polymer Membranes (b) To reduce or cancel deformations previously

provoked at higher temperature which

Maria Luisa Di Vona remain as frozen (permanent) deformations

Dip. Di Scienze Technologie Chimiche, when the material is cooled to room

University of Rome Tor Vergata, Rome, Italy temperature

(c) To increase crystallization

(d) To decrease the free volume between poly-

Annealing can be defined as a process where a meric chains thus inducing a mechanical sta-

material undergoes a heat treatment to a certain bilization of polymeric materials

temperature, is kept there for a definite time, and

is then cooled to room temperature in order to Annealing of liquid crystalline polymers

alter the material properties. The annealing pro- between the glass transition temperature and the

cess is time and temperature dependent. melting temperature leads to an increased level of

Annealing of polymers is a heating of a poly- crystallinity and increased crystalline perfection

meric part to below its glass transition tempera- analogous to the behavior of conventional semi-

ture in order to relieve the internal stresses crystalline polymers. Annealing at or above the

introduced during its fabrication (molding, melting point also leads to enhanced crystallinity

cooling after molding, machining, welding, etc.). and crystalline perfection.

Annealing of conjugated polymers and poly- The annealing of semicrystalline polymers

mer blend films is a widely used process that may change the crystal structure, the degree of

achieves optimal film morphology and therefore crystallinity, the perfection of the crystals, the

improves material properties, such as electrical orientation of both crystalline and amorphous

mobility for photovoltaic devices and other appli- phases, their contiguous structural morphology,

cations. Annealing of ion-conducting polymers and the number of tie chains between the crystal-

reduces the excessive swelling observed in pres- lites. Morphological changes are also observed

ence of water. on annealing bulk-crystallized samples. Poly-

In particular, annealing is used (Young and morphism may result due to annealing crystalline

Lovell 1991): polymers as its one crystalline form transforms

into another. The concept that mechanical stabi-

(a) To increase the melting point of some poly- lization was due to a generic decrease of the free

mers because it facilitates the melting of volume between ionomer chains when thermally

small and irregular crystals in favor of larger treated was abandoned and replaced by the con-

and better formed ones sideration that the mechanical stabilization was

# Springer-Verlag Berlin Heidelberg 2014

E. Drioli, L. Giorno (eds.), Encyclopedia of Membranes,

DOI 10.1007/978-3-642-40872-4_627-1

2 Annealing of Polymer Membranes

induced by an increased crystallization of a molecular diffusion as the process is occurring

preexisting semicrystalline phase (Alberti in the solid state. Thermal treatments were

et al. 2013). believed to be more and more efficient as the

Thermal annealing is a simple route for stabi- temperature increases and therefore empirical

lizing glassy polymers via the densification of short treatments were performed at high temper-

their polymer chains and is accomplished through atures. Thus, the annealing temperature (Tann)

thermal treatment of the glassy thermoplastics. was connected with the crystallization tempera-

For amorphous polymers, the thermal treatment ture (Tc) and it became clear that the annealing

can play a very important role in changing the temperature cannot be higher than the melting

morphology. If the temperature is lower than the temperature (Tm) of the semicrystalline phase.

glass transition temperature Tg, the polymer

chains are mainly immobile, thereby maintaining

the existing morphology; however, if the

References

annealing temperature is greater than the Tg, the

polymer chains will relax. It has been found that Alberti G, Narducci R, Di Vona ML, Giancola S (2013)

the morphology can be modified upon annealing Annealing of Nafion 1100 in the presence of an

at a temperature higher than the Tg, thus changing annealing agent: a powerful method for increasing

ionomer working temperature in PEMFCs. Fuel Cells

the physical properties of the polymers.

13:42–47

A certain amount of molecular rearrangement Young RJ, Lovell PA (1991) Introduction to polymers,

must take place during crystallization but this 2nd edn. CRC Press, Boca Raton

rearrangement cannot arise through large-scale

You might also like

- S Announcement 5994Document20 pagesS Announcement 5994itokki otoyaNo ratings yet

- Modulus: Effect On The Elastic of High-Density Polyethylene Differing Thermal TreatmentsDocument4 pagesModulus: Effect On The Elastic of High-Density Polyethylene Differing Thermal Treatmentsapi-3733260No ratings yet

- Swolfs 2015Document11 pagesSwolfs 2015Ethan ZNo ratings yet

- Valeur Temps RelaxDocument14 pagesValeur Temps RelaxRomain LefèbvreNo ratings yet

- Glass Transition - Wikipedia PDFDocument69 pagesGlass Transition - Wikipedia PDFMumtahin Ul KousarNo ratings yet

- Annealing of Poly (Ethylene Terephthalate)Document8 pagesAnnealing of Poly (Ethylene Terephthalate)SSGKONSPECNo ratings yet

- Isothermal Crystallization of Isotactic Poly (Propylene) Studied by Superfast Calorimetry - 2007 - Macromolecular Rapid CommunicationsDocument7 pagesIsothermal Crystallization of Isotactic Poly (Propylene) Studied by Superfast Calorimetry - 2007 - Macromolecular Rapid CommunicationsLubomirBenicekNo ratings yet

- PJ 198044Document7 pagesPJ 198044Luis GalloNo ratings yet

- Acs JPCC 6b11845Document15 pagesAcs JPCC 6b11845Subhratanu BhattacharyaNo ratings yet

- High-Temperature Viscoelasticity and Heat-Setting of Poly (Ethylene Terephthalate)Document17 pagesHigh-Temperature Viscoelasticity and Heat-Setting of Poly (Ethylene Terephthalate)api-3733260No ratings yet

- Experimental Thermal and Fluid ScienceDocument8 pagesExperimental Thermal and Fluid Sciencemalika mudaliarNo ratings yet

- 2009 Fouling 2Document10 pages2009 Fouling 2mitsuboshi702No ratings yet

- Unit 5 Polymer TechDocument44 pagesUnit 5 Polymer TechShyam MarquezNo ratings yet

- Articulo 2Document3 pagesArticulo 2nathaloaNo ratings yet

- Molecular ArchitectureDocument8 pagesMolecular ArchitectureGolda MadhuNo ratings yet

- Molecular ArchitectureDocument6 pagesMolecular ArchitectureGolda MadhuNo ratings yet

- Shanthi R, Shanmuga Sundaram ANANDAN and Velraj RAMALINGAMDocument25 pagesShanthi R, Shanmuga Sundaram ANANDAN and Velraj RAMALINGAMVishal LabdeNo ratings yet

- Initiation of Caso Scale Formation On Heat Transfer Surfaces Under Pool Boiling ConditionsDocument8 pagesInitiation of Caso Scale Formation On Heat Transfer Surfaces Under Pool Boiling ConditionsDilipNo ratings yet

- Heat Treatment of Polymers: A ReviewDocument9 pagesHeat Treatment of Polymers: A ReviewApurv PaulNo ratings yet

- 1556 276X 6 334Document15 pages1556 276X 6 334Ghassan MousaNo ratings yet

- Glass Transition Temperature TGDocument9 pagesGlass Transition Temperature TGApoorva KNo ratings yet

- Chapter 7 SummaryDocument3 pagesChapter 7 SummaryMichelle BabantoNo ratings yet

- Polymers: Temperature-Modulated Scanning Calorimetry of Melting-Recrystallization of Poly (Butylene Terephthalate)Document9 pagesPolymers: Temperature-Modulated Scanning Calorimetry of Melting-Recrystallization of Poly (Butylene Terephthalate)Gonzalo BenavidesNo ratings yet

- J of Applied Polymer Sci - 1998 - Cook - Curing Kinetics and Thermal Properties of Vinyl Ester ResinsDocument13 pagesJ of Applied Polymer Sci - 1998 - Cook - Curing Kinetics and Thermal Properties of Vinyl Ester Resinsasaad biqaiNo ratings yet

- Roghayeh Lotfi 2012Document4 pagesRoghayeh Lotfi 2012GiovanniRoblesZarateNo ratings yet

- Thermal and Chemical Properties of Diopside-Wollastonite Glass Ceramics in The SiO2-CaO-MgO System From Raw MaterialsDocument5 pagesThermal and Chemical Properties of Diopside-Wollastonite Glass Ceramics in The SiO2-CaO-MgO System From Raw MaterialsBintang IndrantoNo ratings yet

- Processes: Heat Transfer and Rheological Behavior of Fumed Silica NanofluidsDocument16 pagesProcesses: Heat Transfer and Rheological Behavior of Fumed Silica NanofluidsSalahNo ratings yet

- International Journal of Heat and Mass Transfer: B. Zhang, T. Kim, T.J. LuDocument9 pagesInternational Journal of Heat and Mass Transfer: B. Zhang, T. Kim, T.J. LuHarikumar ANo ratings yet

- Procesos de Deshidratacion Del Cemento Pasta Expuesta Ambientes de Alta TemperaturaDocument10 pagesProcesos de Deshidratacion Del Cemento Pasta Expuesta Ambientes de Alta TemperaturaYoselin Medina FonsecaNo ratings yet

- ThermoplasticsDocument3 pagesThermoplasticsMadhuShakthiNo ratings yet

- Applications and Processing of PolymersDocument15 pagesApplications and Processing of PolymersRaymart Racoma MagdatoNo ratings yet

- Expedited Energy Charging of Water Using Natural Graphite Flake For Cool Thermal StorageDocument9 pagesExpedited Energy Charging of Water Using Natural Graphite Flake For Cool Thermal StorageIyyappan jNo ratings yet

- AluminiumDocument31 pagesAluminiumsamuelNo ratings yet

- Synthesis of Lanthanum Tungstate Interconnecting Nanoparticles Byhigh Voltage ElectrospinningDocument6 pagesSynthesis of Lanthanum Tungstate Interconnecting Nanoparticles Byhigh Voltage ElectrospinningYanee KeereetaNo ratings yet

- Construction and Building Materials: Dong Ho Yoo, in Kyu Jeon, Hong Gi Kim, Jun Suk Lee, Jae-Suk RyouDocument11 pagesConstruction and Building Materials: Dong Ho Yoo, in Kyu Jeon, Hong Gi Kim, Jun Suk Lee, Jae-Suk RyouTuğçe VuralNo ratings yet

- Thermomechnical Properties of Textile FiberDocument2 pagesThermomechnical Properties of Textile FiberEhtasham Javed100% (1)

- JOURNAL - 2015 - Design of A Spray Tower For The Granulation of MeltDocument7 pagesJOURNAL - 2015 - Design of A Spray Tower For The Granulation of Meltmita febri anitaNo ratings yet

- Ijser: Nano Fluids and Heat Transfer Enhancement A ReviewDocument7 pagesIjser: Nano Fluids and Heat Transfer Enhancement A ReviewSaiNo ratings yet

- Pool-Boiling Heat Transfer in Liquid Nitrogen : Muneo KIDA, Yoshihiro KIKUCHI:Osamu TAKAHASHIDocument13 pagesPool-Boiling Heat Transfer in Liquid Nitrogen : Muneo KIDA, Yoshihiro KIKUCHI:Osamu TAKAHASHInauman18No ratings yet

- c2Document145 pagesc2Prithviraj NetkeNo ratings yet

- Ceramic Processing Research: Natt Makul and Dinesh AgrawalDocument4 pagesCeramic Processing Research: Natt Makul and Dinesh AgrawalShivaram RamNo ratings yet

- Effect of Annealing On Thermal Properties and Crystalline Structure of Polyamides. Nylon 12 (Polylaurolactam)Document7 pagesEffect of Annealing On Thermal Properties and Crystalline Structure of Polyamides. Nylon 12 (Polylaurolactam)CFNo ratings yet

- Polymer Processing: Donald G. BairdDocument33 pagesPolymer Processing: Donald G. BairdRay CNo ratings yet

- Development and Characterization of Sulfonated Polysulfone Membranes For Direct Methanol Fuel CellsDocument3 pagesDevelopment and Characterization of Sulfonated Polysulfone Membranes For Direct Methanol Fuel CellsKaustubhNo ratings yet

- Nanofibrillar Cellulose AerogelsDocument5 pagesNanofibrillar Cellulose Aerogelsbrunorodrigoh1No ratings yet

- Pick 2006Document9 pagesPick 2006Adan Smith Arribasplata SeguinNo ratings yet

- Annealing-Induced Crystalline Structure and Mechanical Property Changes of Polypropylene Random CopolymerDocument10 pagesAnnealing-Induced Crystalline Structure and Mechanical Property Changes of Polypropylene Random CopolymerDuong DoanNo ratings yet

- J Ijthermalsci 2015 10 025Document10 pagesJ Ijthermalsci 2015 10 025QA LAB ISMNo ratings yet

- Velten Et Al-2002-Journal of Biomedical Materials ResearchDocument11 pagesVelten Et Al-2002-Journal of Biomedical Materials ResearchjeffreylopezNo ratings yet

- The Effect of Molecular Weight and Crystallinity On The Mechanical Properties of Injection Moulded Poly (Aryl-Ether-Ether-Ketone) ResinDocument7 pagesThe Effect of Molecular Weight and Crystallinity On The Mechanical Properties of Injection Moulded Poly (Aryl-Ether-Ether-Ketone) ResinSakhaviTVNo ratings yet

- Crystallization Behaviour of Poly (-Lactide) : Tadakazu Miyata and Toru MasukoDocument7 pagesCrystallization Behaviour of Poly (-Lactide) : Tadakazu Miyata and Toru MasukoJavier Vallejo MontesinosNo ratings yet

- BSCH Chemistry Semester VI Sec B Glass Transition TemperatureDocument5 pagesBSCH Chemistry Semester VI Sec B Glass Transition TemperatureIqbal HossainNo ratings yet

- Ultra Grain Reà Nement During The Simulated Thermomechanical-Processing of Low Carbon SteelDocument7 pagesUltra Grain Reà Nement During The Simulated Thermomechanical-Processing of Low Carbon Steelkayron limaNo ratings yet

- Elearnica - Ir 637241874011988823Document6 pagesElearnica - Ir 637241874011988823taghdirimNo ratings yet

- Octadecane (Al2o3 200nm, 2009)Document4 pagesOctadecane (Al2o3 200nm, 2009)EANESTJEBASINGHNo ratings yet

- Degradation of Sulfur-Containing Aromatic Polymers (II) : Change in Fluorescence Spectra of Polyphenylenesuifide (PPS) During AnnealingDocument6 pagesDegradation of Sulfur-Containing Aromatic Polymers (II) : Change in Fluorescence Spectra of Polyphenylenesuifide (PPS) During AnnealingBaraNo ratings yet

- Re Tten May Rint Mater Rev 2009Document17 pagesRe Tten May Rint Mater Rev 2009alirafiqNo ratings yet

- Al Abdulrazzak2002Document10 pagesAl Abdulrazzak2002Khang KhangNo ratings yet

- Mgo:tio 2Document17 pagesMgo:tio 2Seyedeh Maryam MousaviNo ratings yet

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975From EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovRating: 5 out of 5 stars5/5 (1)

- Yanagishita 1994Document10 pagesYanagishita 1994Ayyaz ButtNo ratings yet

- Maghsoud 2017Document10 pagesMaghsoud 2017Ayyaz ButtNo ratings yet

- (PAN) Wang2006Document9 pages(PAN) Wang2006Ayyaz ButtNo ratings yet

- Preparation of Asymmetric PEEKWC Flat Membranes With Different Microstructures by Wet Phase InversionDocument16 pagesPreparation of Asymmetric PEEKWC Flat Membranes With Different Microstructures by Wet Phase InversionAyyaz ButtNo ratings yet

- Preparation of Polyvinylchloride Membranes From Solvent Mixture by Immersion PrecipitationDocument8 pagesPreparation of Polyvinylchloride Membranes From Solvent Mixture by Immersion PrecipitationAyyaz ButtNo ratings yet

- (PAN) Kim2002Document10 pages(PAN) Kim2002Ayyaz ButtNo ratings yet

- Groundwater Treatment by Reverse Osmosis 2007 Belkacem Desalination 206Document8 pagesGroundwater Treatment by Reverse Osmosis 2007 Belkacem Desalination 206Ayyaz ButtNo ratings yet

- Lec 1Document28 pagesLec 1Ayyaz ButtNo ratings yet

- Lec 11Document24 pagesLec 11Ayyaz ButtNo ratings yet

- Lec 4Document57 pagesLec 4Ayyaz ButtNo ratings yet

- Lec 4Document57 pagesLec 4Ayyaz ButtNo ratings yet

- Lec 11Document24 pagesLec 11Ayyaz ButtNo ratings yet

- DSO Digital Storage Oscilloscope: ApplicationDocument2 pagesDSO Digital Storage Oscilloscope: ApplicationmsequipmentsNo ratings yet

- AWS Lecture NotesDocument4 pagesAWS Lecture NotesAsad Bin Ala Qatari0% (1)

- Planmeca Promax 3D Max CBVT Product PresentationDocument36 pagesPlanmeca Promax 3D Max CBVT Product PresentationAD TwentyOne DentalNo ratings yet

- Pests and Diseases Identification in MangoDocument4 pagesPests and Diseases Identification in MangoBaino Olpugad Gerald100% (1)

- Ball Valves PDFDocument34 pagesBall Valves PDFThomasFrenchNo ratings yet

- Criteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysDocument5 pagesCriteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysProduction DepartmentNo ratings yet

- I O OrganizationDocument26 pagesI O Organization08-Avinash SNo ratings yet

- Assessment Center GuideDocument4 pagesAssessment Center GuidebilloobuttNo ratings yet

- AEF0 - File 1,2,3Document3 pagesAEF0 - File 1,2,3Nayib Bucarin CarlNo ratings yet

- Creativity MCQDocument17 pagesCreativity MCQAmanVatsNo ratings yet

- 12auxiliary ViewsDocument22 pages12auxiliary Viewsmanishjangid9869No ratings yet

- Ruskin As A Social Reformer - Docx ADocument2 pagesRuskin As A Social Reformer - Docx AAtif Hayat50% (2)

- Jurnal: Ekonomi PembangunanDocument14 pagesJurnal: Ekonomi PembangunanAgus MelasNo ratings yet

- Vocabulary Placement TestDocument3 pagesVocabulary Placement TestMonica Vergara MejiaNo ratings yet

- Socio Economic Conditions of Migrant LabourDocument7 pagesSocio Economic Conditions of Migrant LabourDR SEKHARNo ratings yet

- Lecture Notes 10: Fading Channels ModelsDocument19 pagesLecture Notes 10: Fading Channels ModelsayushNo ratings yet

- 3.Space-Activity BookDocument21 pages3.Space-Activity BookRania FarranNo ratings yet

- S&S PDFDocument224 pagesS&S PDFMohammed MateenNo ratings yet

- Instructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Document6 pagesInstructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Princess DumlaoNo ratings yet

- Winning at New ProductsDocument24 pagesWinning at New Products劉緯文100% (1)

- 3 Master Star 1 Super Star: Forged Steel Ball ValvesDocument7 pages3 Master Star 1 Super Star: Forged Steel Ball ValvesAhmed IbrahimNo ratings yet

- Google - (Chrome) - Default NetworkDocument21 pagesGoogle - (Chrome) - Default Networkjohnnyalves93302No ratings yet

- Questionaire Abusive Supervision SurveyDocument2 pagesQuestionaire Abusive Supervision SurveyAabee SyedNo ratings yet

- High Low MethodDocument4 pagesHigh Low MethodSamreen LodhiNo ratings yet

- Always Treat The Computer Lab Equipment AND Your Teacher andDocument2 pagesAlways Treat The Computer Lab Equipment AND Your Teacher andKayanna EdwardsNo ratings yet

- Principles of MicroeconomicsDocument41 pagesPrinciples of MicroeconomicsHoàng LýNo ratings yet

- Thermal Stress AnalysisDocument11 pagesThermal Stress AnalysisFahad KhanNo ratings yet

- Intelligent Building FacadeDocument32 pagesIntelligent Building FacadeVeè Vêk JåyswãlNo ratings yet

- Hatton National Bank PLC: Instance Type and TransmissionDocument2 pagesHatton National Bank PLC: Instance Type and TransmissiontaraNo ratings yet

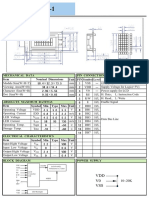

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocument1 pageV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriNo ratings yet