Professional Documents

Culture Documents

Porta Guarderas

Uploaded by

Mary Huaylla ACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Porta Guarderas

Uploaded by

Mary Huaylla ACopyright:

Available Formats

FLEX-SEAL™ Skirting System

Material Containment Products Conveyor Skirt Clamps

Solves Spillage and Dust

Control Problems

Flex-Seal™ Skirting System is a dynamic containment

unit that fully seals the loading zone. It stops material

spillage leaks, controls dust emissions and eliminates

other resulting problems such as belt damage and

mistracking. Conventional skirt clamps and systems may

contain spillage of materials, but maintenance is typically

difficult and time-consuming. And more importantly, the

damage done to the conveyor belt is costly. Flex-Seal

is expressly designed to guard against belt damage.

The skirt rubber is automatically angled to make a low-

pressure, parallel seal with belt. And it adjusts to belt A “No Hassle” Skirting System

movement to maintain a consistent seal. No belt grooving

Flex-Seal is user-friendly. It has few parts and comes complete

or excessive cover wear means longer belt life. The

with step-by-step instructions. Each 4' (1.2 M) module includes

Flex-Seal Skirting System is simple to install. Its modular

two clamp pins, two clamp plates and a clamp bar. Each

design allows the system to be built to any length on the

module is easy to handle and multiple modules can be used

conveyor. Skirt rubber adjustment can be done in minutes

for a skirting system of any length. For installation, simply bolt

by one person and any maintenance can be done safely

the clamp pins to the plate angle and then stitch weld the plate

from the catwalk. Flex-Seal is cost-effective for your

to the conveyor skirtboard. There are convenient cut-outs in

operation and affordable.

the plate so all of the welding can be done safely from the

side of the conveyor. The clamp plates and the clamp bar then

interlock over the clamp pins. Once the skirt rubber is put in

place, the clamp bar can be tack welded to the clamp plates

for a one-piece unit. Simple, affordable yet effective. Flex-Seal

stops material loss, eliminates safety hazards and reduces

wear and premature failure of conveyor components.

Benefits for Your Beltline

• Reduces material clean-up and related costs.

• Improves dust control.

• Reduces belt mistracking.

• Minimizes belt top-cover wear.

• One-person adjustment of skirt rubber.

• Easy to maintain. No corrosion of nuts and bolts or clamp handles.

• Economical. Low cost unit, and reduces material waste due to spillage.

• Safety. All work is done from the sides of the conveyor.

• Versatile. 4-foot lengths can be used to create any length systems.

• Parts can be easily replaced when necessary.

For more information on this product, visit www.flexco.com

FLEX-SEAL™ Skirting System

Material Containment Products Conveyor Skirt Clamps

Quick Adjustment Easy on the Belt

Other skirt clamp systems can create a seal to the belt; but many times it is at the

expense of belt damages such as grooves along the belt’s edges or excessive

belt cover wear. Flex-Seal’s angle plate positions the skirt rubber to the belt with a

gentle angle so that the internal spring-back tension in the rubber creates the seal

but without the damage. The low contact pressure on the belt means negligible top

cover wear and absolutely no grooving.

Flex-Seal™ angles the skirt

rubber to the belt so it seals with

low contact pressure. A seal

A unique locking wedge on the clamp without potential of belt damage.

pin makes Flex-Seal quick and easy

to adjust worn skirt rubber. Simply tap

loose the locking wedges on the clamp

pins, reposition the skirt rubber and Skirt clamp systems that call for

hammering down the skirt rubber

relock the pins. A one-person job, and

may leak material as the belt sags

done in minutes. This captive wedge

between idlers. And typically this style

feature allows the wedge to be locked is a major cause of belt grooves that

in any position 360° around the pin, so result when the user over-pounds on

it can be installed in the best position the skirt rubber to get a good seal.

for easy access. And there are no parts

to drop or lose. The rest of the parts

interlock so when the pins are unlocked, Some skirt clamps position the skirt rubber to lay on the belt past

they remain in place supporting the skirt the skirt board for a more effective seal. The hard bend at the belt

rubber while maintenance is completed. and the extended skirt rubber on the belt typically cause excessive

top-cover wear on the belt. Material can also get caught under the

skirt rubber causing small grooves; and material lying on the skirt

rubber can add to the belt wear, and in some cases the added

weight will pull the rubber out of the clamp.

Specifications

(Skirt rubber not included)

Skirt Rubber Width and Thickness Range

Width Required 6" (150 mm)

Thickness Range 5/16" - 3/4" (8 - 19 mm)

Ordering Information

Flex-Seal Skirting System

Description Item Code Ordering Number

Flex-Seal Skirting System 76558 RMC2-FS-1

Replacement Parts Item Code Ordering Number

FS Angle Plate Kit 76559 FS-APK

2525 Wisconsin Avenue Bolt-On Clamp Pin 76414 RMC1-BCP

Downers Grove, IL 60515-4200 U.S.A.

Telephone: (630)-971-0150 Clamp Plate 75821 RMC1-PL

Fax: (630)-971-1180 Clamp Bar 75820 RMC1-CB

BCP Help Line: 1-800-253-8132

E-mail: info@flexco.com

www.flexco.com

Australia: 61-2-9680-3322 • England: 44-1274-600-942 • Germany: 49-7428-9406-0 • Mexico: 52-55-5674-5326 • Republic of South Africa: 27-11-608-4180

©2007 Flexible Steel Lacing Company. Flex-Seal™ is a trademark of Flexible Steel Lacing Company. Released 10/07 For Reorder: Item Code X1571

You might also like

- FABM2121 Fundamentals of Accountancy Q2 Written Work 1Document4 pagesFABM2121 Fundamentals of Accountancy Q2 Written Work 1Christian Tero100% (2)

- International Trade and AgreementDocument119 pagesInternational Trade and AgreementAirah Golingay100% (1)

- Pac Seal Brochure Fsd132 Eng FDocument32 pagesPac Seal Brochure Fsd132 Eng FIR fanNo ratings yet

- Safety Wedge Lock WasherDocument2 pagesSafety Wedge Lock WasherVijay BhureNo ratings yet

- IGCSE Economics Self Assessment Chapter 24 AnswersDocument2 pagesIGCSE Economics Self Assessment Chapter 24 AnswersDesreNo ratings yet

- Knots: An Illustrated Practical Guide to the Essential Knot Types and their UsesFrom EverandKnots: An Illustrated Practical Guide to the Essential Knot Types and their UsesNo ratings yet

- Chapter 6: Setting and Implementing: Prices Revenue ManagementDocument29 pagesChapter 6: Setting and Implementing: Prices Revenue ManagementQuế Phương NguyễnNo ratings yet

- Pulley Alignment ProceduDocument9 pagesPulley Alignment ProceduJosh Watts100% (2)

- J940305 PDFDocument4 pagesJ940305 PDFratheeshNo ratings yet

- A MateriauDocument29 pagesA MateriaubeforeRGNo ratings yet

- Camlock Safety How Not Have A SpillDocument5 pagesCamlock Safety How Not Have A SpillHamdi RafiekNo ratings yet

- Other Trade Exporters DatabaseDocument126 pagesOther Trade Exporters DatabaseKunwar SaigalNo ratings yet

- Working Principle: Contact Free Conveyor Belt SkirtingDocument4 pagesWorking Principle: Contact Free Conveyor Belt Skirtingdedison_rNo ratings yet

- Belt Slippage SPWP1178ENPR-01Document2 pagesBelt Slippage SPWP1178ENPR-01JrbritoNo ratings yet

- Pt. Magdatama - Wabo Modular JointDocument8 pagesPt. Magdatama - Wabo Modular JointMangisi Haryanto ParapatNo ratings yet

- Tool For Belt SplicingDocument12 pagesTool For Belt SplicingYudhi Nur ArifiantoNo ratings yet

- Gates Belt GuideDocument12 pagesGates Belt GuideAriel QuezadaNo ratings yet

- LG Lock-Grip Pullers Brochure en-GBDocument8 pagesLG Lock-Grip Pullers Brochure en-GBPLANNER REBHNo ratings yet

- Mac Gregor Sealing DevicesDocument8 pagesMac Gregor Sealing DevicesFernando Raúl LADINONo ratings yet

- Conveyor SpecsDocument8 pagesConveyor SpecsPrashant TankNo ratings yet

- XOMOXDocument16 pagesXOMOXjkpothabathula4581No ratings yet

- Back To Basics: Mechanical Seals: Sealing SenseDocument4 pagesBack To Basics: Mechanical Seals: Sealing SensemusaNo ratings yet

- W412 EnUS 412 SelectFstrINS 110716Document2 pagesW412 EnUS 412 SelectFstrINS 110716Mary Antoinette C. MadoloraNo ratings yet

- Farbprospekt DOMINO-Flachschieber (GB) - 2018-09Document12 pagesFarbprospekt DOMINO-Flachschieber (GB) - 2018-09cvfNo ratings yet

- Tufline SPV WeldEnd 329723 12-04Document16 pagesTufline SPV WeldEnd 329723 12-04Marcio NegraoNo ratings yet

- Trouble-Shooting Five Common Belt Conveyor Buildup ProblemsDocument2 pagesTrouble-Shooting Five Common Belt Conveyor Buildup ProblemsTamal Tanu RoyNo ratings yet

- Nexgen One Step Shrink Wrap SystemsDocument1 pageNexgen One Step Shrink Wrap SystemsshrinkfilmNo ratings yet

- Ergonomics For Scaffold ErectionDocument2 pagesErgonomics For Scaffold ErectionTTYY08No ratings yet

- AVK Service Connection System BrochureDocument20 pagesAVK Service Connection System BrochureAhlan kpNo ratings yet

- Agrar Ohne PreiseDocument55 pagesAgrar Ohne PreiseBaiuliang BaiuliangNo ratings yet

- MKT Apac Tds Fleximesh Feb 2022 enDocument2 pagesMKT Apac Tds Fleximesh Feb 2022 enIvanRomanovićNo ratings yet

- LiftAll - EslingasDocument19 pagesLiftAll - EslingasJoaquín IgoaNo ratings yet

- Multitool ManualDocument2 pagesMultitool ManualJA C FNo ratings yet

- Chain InspectionDocument4 pagesChain Inspectionadhi nrNo ratings yet

- 2012 RF Insamcor LW Catalogue - EnglishDocument7 pages2012 RF Insamcor LW Catalogue - EnglishNay Win MaungNo ratings yet

- Belt Splicing SPWP1179ENPR-01Document2 pagesBelt Splicing SPWP1179ENPR-01JrbritoNo ratings yet

- Offer Advantages: Faster. EasierDocument2 pagesOffer Advantages: Faster. EasierÁlvaro Sebastián QuintanaNo ratings yet

- Endless Fin Sheet RevDocument1 pageEndless Fin Sheet Revcw.aehdNo ratings yet

- BSF42-5 Brochure 2021 inDocument6 pagesBSF42-5 Brochure 2021 inShubham SinghNo ratings yet

- E 45 GP 005 - Installation of Belts On ConveyorsDocument11 pagesE 45 GP 005 - Installation of Belts On Conveyorsthiru_jsrNo ratings yet

- BSF - CT 4281-8 in - 36-5 PDFDocument6 pagesBSF - CT 4281-8 in - 36-5 PDFHugh O'Brien GwazeNo ratings yet

- Consider in Razor Slitting: Four Factors ToDocument2 pagesConsider in Razor Slitting: Four Factors ToAli AliNo ratings yet

- Conveyor SurveyDocument4 pagesConveyor SurveycarlosgulfoNo ratings yet

- Technical Information: Fiber Optic Pulling and Support GripsDocument9 pagesTechnical Information: Fiber Optic Pulling and Support GripssoayNo ratings yet

- Arlon Installation Guide SLX PlusDocument5 pagesArlon Installation Guide SLX PlusMarek KamenickyNo ratings yet

- Triptico Técnico Quickbelts - IngDocument10 pagesTriptico Técnico Quickbelts - IngElbin Antonio EspinalNo ratings yet

- Built Tough, Worn in Comfort: The Newly-Designed Delta™ Comfort Harnesses Are As Tough As Those Who Wear ThemDocument6 pagesBuilt Tough, Worn in Comfort: The Newly-Designed Delta™ Comfort Harnesses Are As Tough As Those Who Wear ThemAlmeidaAmandioNo ratings yet

- FE500 - Section Fijadores Silla RuedasDocument4 pagesFE500 - Section Fijadores Silla RuedasJorge nunezNo ratings yet

- VCS VCFS BrochureDocument5 pagesVCS VCFS Brochurepayam.ghafooriNo ratings yet

- Mechanical Fasteners Boost Uptime in Light-Duty Conveyor Applications 10/8/2007Document6 pagesMechanical Fasteners Boost Uptime in Light-Duty Conveyor Applications 10/8/2007Kondala RaoNo ratings yet

- AVK Wastewater Treatment BrochureDocument24 pagesAVK Wastewater Treatment Brochureفاعل الخيرNo ratings yet

- Pump Reliability Through Bearing IsolatorsDocument2 pagesPump Reliability Through Bearing IsolatorsduhaimNo ratings yet

- PIRMH Chain Inspection PIDocument4 pagesPIRMH Chain Inspection PIRicardoNo ratings yet

- Around The MX Injection Molding Machine: Impressive TourDocument3 pagesAround The MX Injection Molding Machine: Impressive TourShreeraj ModiNo ratings yet

- Tech Tips Via FerrataDocument2 pagesTech Tips Via FerrataRamirez Rpo JorgeNo ratings yet

- AlgaFlex TXDocument12 pagesAlgaFlex TXpedroppaulo77No ratings yet

- BDocument2 pagesBharshNo ratings yet

- Quicke Implement Leaflet NEWDocument16 pagesQuicke Implement Leaflet NEWinfo4826No ratings yet

- Rubber DamDocument27 pagesRubber DamApeksha JadhavNo ratings yet

- Flexible Machine ElementsDocument53 pagesFlexible Machine ElementsALAN ANDRE FAUSTO REYESNo ratings yet

- Mueller Fire HydrantDocument6 pagesMueller Fire Hydrantfarshan296015No ratings yet

- EslingasDocument118 pagesEslingasVictor GañaNo ratings yet

- Katalog Heben 2017 EN Rev3Document61 pagesKatalog Heben 2017 EN Rev3M. saeed TorabiNo ratings yet

- Conveyor Belt Edge Types: Technical Information BulletinDocument2 pagesConveyor Belt Edge Types: Technical Information BulletinRestuNo ratings yet

- Gemini Twin Line ParalelaDocument1 pageGemini Twin Line ParalelaMary Huaylla ANo ratings yet

- HORIZON 200 y 300Document2 pagesHORIZON 200 y 300Mary Huaylla ANo ratings yet

- Food Washdown: Sani-Wash 300Document1 pageFood Washdown: Sani-Wash 300Mary Huaylla ANo ratings yet

- Catalogo EliminatorDocument4 pagesCatalogo EliminatorMary Huaylla ANo ratings yet

- Heavy-Duty Secondary Standard-Duty Secondary Special SecondaryDocument2 pagesHeavy-Duty Secondary Standard-Duty Secondary Special SecondaryMary Huaylla ANo ratings yet

- Massive, Rugged, Ready To Work.: HD Cartridge PrecleanerDocument2 pagesMassive, Rugged, Ready To Work.: HD Cartridge PrecleanerMary Huaylla ANo ratings yet

- Limpiador Secundario Con CatridgeDocument2 pagesLimpiador Secundario Con CatridgeMary Huaylla ANo ratings yet

- Mineline MSP Sell SheetDocument2 pagesMineline MSP Sell SheetMary Huaylla ANo ratings yet

- Catalogo Flexco InglesDocument13 pagesCatalogo Flexco InglesMary Huaylla ANo ratings yet

- Torque Team V-Belt: Installation GuideDocument2 pagesTorque Team V-Belt: Installation GuideMary Huaylla ANo ratings yet

- API SI - POV.NAHC DS2 en Excel v2 10081287Document37 pagesAPI SI - POV.NAHC DS2 en Excel v2 10081287mommysharkNo ratings yet

- Summarize: The Variable Effectiveness of Hedging StrategiesDocument3 pagesSummarize: The Variable Effectiveness of Hedging Strategieshakseng lyNo ratings yet

- Market StructuresDocument8 pagesMarket StructuresJojie De RamosNo ratings yet

- Department of Education: Project Proposal IDocument6 pagesDepartment of Education: Project Proposal IIt's AlfredNo ratings yet

- AG Nutrition Business Concept2 PDFDocument34 pagesAG Nutrition Business Concept2 PDFBtsibanda100% (2)

- Business Economics Most Important MCQ by AkashDocument59 pagesBusiness Economics Most Important MCQ by AkashAkash YadavNo ratings yet

- Reaction Paper To Financial Literacy LectureDocument1 pageReaction Paper To Financial Literacy LecturePatricia Bianca ArceoNo ratings yet

- The Company CAUDocument2 pagesThe Company CAUayoubbagdadkhNo ratings yet

- IE255 Tables BookletDocument107 pagesIE255 Tables BookletMuhammad AdilNo ratings yet

- DB GP Report Q2FY2023-24 17-January-2024Document34 pagesDB GP Report Q2FY2023-24 17-January-2024GP ITNo ratings yet

- GK and Current Affairs Worksheet - 5 (Block - D)Document3 pagesGK and Current Affairs Worksheet - 5 (Block - D)Bla BlaNo ratings yet

- MCQ Far 1Document7 pagesMCQ Far 1syaaNo ratings yet

- Mid Test HVNHDocument8 pagesMid Test HVNHDương ĐặngNo ratings yet

- Measuring Monetary Policy1998Quarterly Journal of EconomicsDocument34 pagesMeasuring Monetary Policy1998Quarterly Journal of EconomicsMaxim ShelkovNo ratings yet

- 1 Liquidity RiskDocument8 pages1 Liquidity RiskShreyanko GhosalNo ratings yet

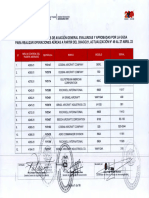

- Relacion de Aeronaves Aprobadas Por Ggsa N Al 23 de AbrilDocument16 pagesRelacion de Aeronaves Aprobadas Por Ggsa N Al 23 de Abrilpedrazaalejandro099No ratings yet

- Truck Europe Q1 2023 JPMorgan 280423Document10 pagesTruck Europe Q1 2023 JPMorgan 280423keshav.mundhraNo ratings yet

- On The Road Toward A More Adequate Understanding of The StateDocument20 pagesOn The Road Toward A More Adequate Understanding of The StateCan XuNo ratings yet

- Ifrs 1 First Time AdoptionDocument27 pagesIfrs 1 First Time AdoptionSabaa ifNo ratings yet

- CYQBDocument19 pagesCYQBGFNo ratings yet

- Sustainable Development EssaysDocument5 pagesSustainable Development Essayslpuaduwhd100% (2)

- Cox & KingsDocument407 pagesCox & KingsadhavvikasNo ratings yet

- TSPSC Group-I 2024 Mains Test SeriesDocument6 pagesTSPSC Group-I 2024 Mains Test SeriesVinod KumarNo ratings yet

- Sweat Equity SharesDocument8 pagesSweat Equity SharesPratik RankaNo ratings yet