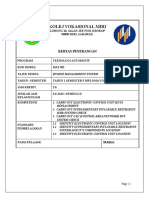

Professional Documents

Culture Documents

FujiTrax-ComCell App SDS V1.0.0

Uploaded by

Charlie Nevarez WittCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FujiTrax-ComCell App SDS V1.0.0

Uploaded by

Charlie Nevarez WittCopyright:

Available Formats

Communication protocol for FujiTrax

MES ComCell Application

for FujiTrax

Software Design Specification

Change record

Date Name Version Comments

02/26/2008 Stefan Rosskopf 1.0.0 Initial version

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 1 from 29

Communication protocol for FujiTrax

Index

1 ABBREVIATIONS & DEFINITIONS..............................................................................

DEFINITIONS..............................................................................4

4

2 REFERENCES...............................................................................................................

REFERENCES...............................................................................................................4

4

3 INTRODUCTION............................................................................................................

INTRODUCTION............................................................................................................4

4

3.1 Purpose...............................................................................................................................................

Purpose............................................................................................................................................... 4

3.2 Scope...................................................................................................................................................

Scope................................................................................................................................................... 4

4 GENERAL DESCRIPTION.............................................................................................

DESCRIPTION.............................................................................................5

5

4.1 NXT Machine.......................................................................................................................................

Machine....................................................................................................................................... 5

4.2 Kitting Station.....................................................................................................................................

Station..................................................................................................................................... 6

4.3 Software Components Overview.......................................................................................................

Overview....................................................................................................... 7

4.4 MES LineControl.................................................................................................................................

LineControl................................................................................................................................. 8

4.5 Communication mechanisms............................................................................................................

mechanisms............................................................................................................ 9

4.5.1 Fujitrax to MES ComCell interface................................................................................................

interface................................................................................................ 9

4.5.2 Initial Process................................................................................................................................

Process................................................................................................................................ 9

4.5.3 Sequence IDs................................................................................................................................

IDs................................................................................................................................ 9

4.6 Multiboard Handling.........................................................................................................................

Handling......................................................................................................................... 10

4.7 Error Handling and Indication.........................................................................................................

Indication......................................................................................................... 12

5 CONFIGURATION.......................................................................................................

CONFIGURATION.......................................................................................................13

13

5.1 FraMES.cfg Configuration...............................................................................................................

Configuration............................................................................................................... 13

5.1.1 Equipment type...........................................................................................................................

type........................................................................................................................... 13

5.1.2 Fujitrax machine and line name...................................................................................................

name................................................................................................... 13

5.1.3 Feeder Carrier in CarMa..............................................................................................................

CarMa.............................................................................................................. 13

5.2 LineControl Settings........................................................................................................................

Settings........................................................................................................................ 13

6 INTERACTION WITH THE LINECONTROL SERVER...............................................

SERVER...............................................13

13

6.1 Initialisation and Setup OK..............................................................................................................

OK.............................................................................................................. 13

6.2 Configuration....................................................................................................................................

Configuration.................................................................................................................................... 13

7 COMCELL EVENT FUNCTIONS.................................................................................

FUNCTIONS.................................................................................14

14

7.1 event_load.........................................................................................................................................

event_load......................................................................................................................................... 14

7.2 event_unload....................................................................................................................................

event_unload.................................................................................................................................... 14

7.3 event_start........................................................................................................................................

event_start........................................................................................................................................ 14

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 2 from 29

Communication protocol for FujiTrax

7.4 event_stop.........................................................................................................................................

event_stop......................................................................................................................................... 14

8 COMCELL MESSAGE FUNCTIONS...........................................................................

FUNCTIONS...........................................................................14

14

8.1 msg_setev_ack.................................................................................................................................

msg_setev_ack................................................................................................................................. 15

8.2 msg_startev_ack..............................................................................................................................

msg_startev_ack.............................................................................................................................. 15

8.3 msg_keepalive..................................................................................................................................

msg_keepalive.................................................................................................................................. 15

8.4 msg_pcbcheckin..............................................................................................................................

msg_pcbcheckin.............................................................................................................................. 15

8.5 msg_pcbcheckout............................................................................................................................

msg_pcbcheckout............................................................................................................................ 17

8.6 msg_loadcomp.................................................................................................................................

msg_loadcomp................................................................................................................................. 19

8.7 msg_unloadcomp.............................................................................................................................

msg_unloadcomp............................................................................................................................. 21

8.8 msg_changecomp............................................................................................................................

msg_changecomp............................................................................................................................ 23

8.9 msg_loadkitting................................................................................................................................

msg_loadkitting................................................................................................................................ 23

9 SAMPLE EVENT SEQUENCES..................................................................................

SEQUENCES..................................................................................25

25

9.1 xxxCOMP Events..............................................................................................................................

Events.............................................................................................................................. 26

10 OTHER CONSIDERATIONS....................................................................................

CONSIDERATIONS....................................................................................27

27

10.1 Configurable items.......................................................................................................................

items....................................................................................................................... 27

10.2 Minimizing impact on Equipment Cycle time...................................................................................27

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 3 from 29

Communication protocol for FujiTrax

1 Abbreviations & Definitions

The following terms are used along of this document. Here is the meaning:

ComCell. MES TCP/IP server application to listen TCP/IP messages

Commands. Used as a synonym of Message

Equipment Controller. Used as synonym of F&K Delvotec machine controller

MES. Manufacturer Execution System

Message Set. List of ASCII messages supported by agreement of MES and Equipment Controller

Run. Test a unit in a given Process station

Test Run. Result of measurements or Process result for a Run

Unit History. Set of entries which describe the station registration and processing in a time line for a

given unit.

WIP. Working in Process

2 References

“MES. Equipment Generic Setup & Machine Cycle Interaction V1.0.0.ppt”

Shows to Equipment supplier how to talk with MES across TCP/IP messages

"FujitraxHostSystemInterfaceSpecificationV1.0.0_Update.pdf"

Interface specification provided by Fuji.

"HostSystemInterface_Update.pdf"

Addon update of interface specification provided by Fuji.

"Specification LineControl.doc.pdf Version 1.2"

Specification of MES LineControl Server and Client module.

3 Introduction

3.1 Purpose

This document provides a detailed design specification to develop a ComCell filter dll for connection a Fuji

NXT machine to the Conti electronic plants MES.

3.2 Scope

This document provides the basic specification for writing the FraMES ComCell application for the Fujitrax.

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 4 from 29

Communication protocol for FujiTrax

4 General Description

The ComCell filter dll, together with ComCell framwork provides the communication interface between the

FujiTrax event base messages for Conti MES and the MES FraMES api. It als includes the process specific

part of the business logic which is not covered by MES.

The filter dll can be used to connect to a Fujitrax Central Server for one Fuji NXT machine a also to a

Fujitrax Kitting Station. This can be set in the ComCell configuration for the filter dll.

Here an overview ot the functions with a short description covered by the filter dll:

4.1 NXT Machine

NXT machine

event message id equipment action MES action

Component load LOADCOMP One or several feeders Components are set to batch

with reels are loaded on positions of the MES station.

the NXT machine. The components are not

assigned to a WIP

order/operation at this time.

Component unload UNLOADCOMP One or several feeders Components are released from

with reels are unloaded batch positions of the MES

from the NXT machine or station.

the reels run out of

components

Component change CHANGECOMP One or several reels are Components are set to batch

changed due to splicing positions of the MES station.

transitions The components are not

assigned to a WIP

order/operation at this time.

Checkin PCB PCBCHECKIN A PCB goes into the the Validate the WIP unit for the

first module of the NXT MES station and load the

associated WIP definitions into a

WIPMaMa slot

Checkout PCB PCBCHECKOUT A PCB comes out from Find the corresponding

the last module of the WIPMaMa slot and assign all

NXT provided components to that

slot, if they are not assigned

(use). Release all not provided

components from that slot.

(unuse)

Record quantities of used

components in WIPMaMa.

Process the WIP unit.

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 5 from 29

Communication protocol for FujiTrax

4.2 Kitting Station

Kitting Station

event message id equipment action MES action

Prepare kitting LOADKITTING A feeder is set at a The component reel is assigned

Fujitrax Kitting Station to a feeder carrier in CarMa

(Kitting Stand)

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 6 from 29

Communication protocol for FujiTrax

4.3 Software Components Overview

For the MES ComCell - Fujitrax approach, these components are required.

- MES Server

- MES ComCell Application supporting specified equipment interface protocol.

- Fujitrax Software and hardware including the Central Server Clients and Kitting Station supporting

specified equipment interface protocol.

MES Server

CAPS DLB CAPS DLB CAPS DLB

MES ComCell MES ComCell MES ComCell

Application Application Application

for Fujitrax for Fujitrax for Fujitrax

Fujitrax

Central Server

Verifier/Profiler EPI EPI EPI

Fujitrax Fujitrax

Fujitrax

Central Server Central Server

Kitting Station

Client Client

EPI: Equipment Interface Protocol

CAPS DLB: Camline Application Server Interface

For each NXT machine one connection to a MES ComCell Application is required. Target is to install the

MES ComCell Application at the same computer as the “Fujitrax Central Server Client”. In that case no

network commication for the EPI are needed. Therefore one Fujitrax Central Server Client is needed for

each NXT machine.

For the “Kitting Station” an additional instance of the MES ComCell application for Fujitrax is used.

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 7 from 29

Communication protocol for FujiTrax

4.4 MES LineControl

To provide additional dynamic configuration parameters assigned to the SMD line, the involving of a MES

LineControl Server is required.

MES Server

CAPS DLB

CAPS DLB CAPS DLB CAPS DLB

MES LineControl EPI

LineControl

Server

FraMES FraMES FraMES ComCell

Application Application Application

for Labeling or

Lasermarking

for Solder Paste Printer for Fujitrax

EPI: Equipment Interface Protocol

CAPS DLB: Camline Application Server Interface

One LineControl Server is used for one SMD Line. It is used to select the material that has to be produced.

It also can be configured to additionally select the MES order. When the material has been selected, a

LineControl configuration Testplan is loaded from the EVAPROD database. This testplan provides several

common LineControl configuration parameters:

- Identification type for the PCB multiboard panel

- Identification type for the PCB single board

- PCB Multiboard handling

Additional to that SMD dedicated configuration parameter can be configured.

The MES ComCell Application for Fujitrax communicates to the LineControl Server by using the LineControl

EPI.

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 8 from 29

Communication protocol for FujiTrax

4.5 Communication mechanisms

4.5.1 Fujitrax to MES ComCell interface

MES ComCell communicates with the Fujitrax through a set of messages.

Communication will be initiated by ComCell as ComCell is acting in active mode. Fujitrax is the TCP/IP

server and ComCell is the TCP/IP client. As soon as the connection is established and Fujitrax has got the

event list and the start event, Fujitrax starts sending events.

4.5.2 Initial Process

The initial process is needed to start the comunication between Fujitrac and MES ComCell. ComCell has to

send a SETEV message with the configured machine name and a list of all required events. Depending on

the configuration the events are for the NXT machine or only on event for the Kitting Station.

After that ComCell sends a STARTEV message to Fujitrax to start with the comunication. This procedure

has to be implemented by using the standard "event_start" function and the message functions "msg_..."

event_start

SETEV

Fujitrac

SETEV_ACK

STARTEV

msg_

setev_ack

STARTEV_ACK

msg_

startev_ack

4.5.3 Sequence IDs

As Fujitrax sends a sequence id (SeqID) for each message, the MES ComCell application has to reply the

same sequence id when sending the reply message.

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 9 from 29

Communication protocol for FujiTrax

4.6 Multiboard Handling

The ComCell application is able to process two differen types of multiboard handling.

If the hole multiboard is treated as on WIP unit with quantity ≥ 1 the WIP transactions (checkin and finish)

are done for the panel identification sent by Fujitrax. (MLTB2='P' - see FraMES LineControl specification)

If single units of a multiboard are treated as WIP units (quantity always 1) the WIP transactions (checkin and

finish) are done for the each single unit. The unit identifications are retrieved from the CarMa multiboard

carrier data set by panel identification sent by Fujitrax. (MLTB2='S' - see FraMES LineControl specification)

The type of the multiboard handling are selected by the LineControl setting. To keep the flowcharts readable

only MLTB2='P' are drawn for the message function msg_pcbcheckin and msg_pcbcheckout.

Flowchart multiboard handling entry:

MLTB entry

lnc_GetParameter(“MLTB2")

multiboard

S car_GetCarrierPositions

handling?

P

wpm_GetSlotForUnit

wpm_GetSlotForUnit

no,

slot returned ? no wpm_GetUnitLoss next

position

slot returned ? no

reply message NOK reply message NOK no loss?

no

same

material ?

same

no

material ?

yes

checkin checkin

wpm_UnitCheckin wpm_UnitCheckin

required ? required ?

last MLTB

position?

MLTB entry

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 10 from 29

Communication protocol for FujiTrax

Flowchart multiboard handling exit:

MLTB exit

lnc_GetParameter(“MLTB2")

multiboard

S car_GetCarrierPositions

handling?

P

wpm_GetSlotForUnit

wpm_GetSlotForUnit

slot returned ? no,

no wpm_GetUnitLoss

next

slot returned ? no position

reply message NOK reply message NOK no loss?

yes

wpm_UnitCheckin wpm_UnitFinish

last MLTB

position?

MLTB exit

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 11 from 29

Communication protocol for FujiTrax

4.7 Error Handling and Indication

All errors are handled within the ComCell application, and all errors are displayed at the GUI of the

ComCell.

Additional to that NOK results are sent back to Fujitrax.

Example error messages displayed at the ComCell GUI

Event Possible Errors

LOADCOMP Component (reel id) can not be created as batch unit in MES MaMa

UNLOADCOMP

Receipt for reel id not in MES MaMa

CHANGECOMP

PCBCHECKIN Unit not found in WIP

Unit not allowed to process at this station

Unit is scrap

PCBCHECKOUT Unit not found in WIP

Unit not allowed to process at this station

Unit is scrap

Component (reel id) can not be created as batch unit in MES MaMa

Receipt for reel id not in MES MaMa

(Component not part of MES partlist)

LOADKITTING Component (reel id) can not be created as batch unit in MES MaMa

Receipt for reel id not in MES MaMa

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 12 from 29

Communication protocol for FujiTrax

5 Configuration

There are two types of configurations for the ComCell application. One is done by entries in the FraMES.cfg

file. The other one is done via the settings of the LineControl server.

5.1 FraMES.cfg Configuration

The ComCell Fujitrax specific configuration is done in the FraMES.cfg file in a separate section [COMCELL]

5.1.1 Equipment type

EQUIPMENT_TYPE=NXT or

EQUIPMENT_TYPE=KITTING

The parameter defines the events set that have to be send to Fujitrax at the initial process with the SETEV

message.

5.1.2 Fujitrax machine and line name

The parameters define the machine name and the line name. The machine name is used during the initial

process. Both names are used to check if the Fujitrax messages fit to the ComCell instance.

MACHINE_NAME= name of machine defined in Fujittrax system

LINE_NAME= name of the line defined in Fujitrax system

5.1.3 Feeder Carrier in CarMa

The feeders are treated as carriers in CarMa if the kitting station is used. This parameter defines the CarMa

carrier type for the feeder.

FEEDER_CARRIER=carrier type

This parameter is only needed for the kitting station.

5.2 LineControl Settings

These settings are done after the LineControl testplan is loaded into the LineControl server. All configuration

parameters are retrieved from the LineControl server.

6 Interaction with the LineControl server

6.1 Initialisation and Setup OK

The ComCell application connects to a LineControl Server. Therefore it has to initialize the communication

and has to send a setup OK message if it is ready to listen from Fujitrax messages. The interaction with the

LineControl Server is implemented in the ComCell Event Functions: event_start and event_stop.

6.2 Configuration

All configuration parameters which are stored in the LineControl testplan are retrieved from the LineControl

Server. These are:

“MLTB2” Type of multiboard handling ‘P’ or ‘S’

“Material Number” Selected WIP material number

IDTP1 Idtype for PCB single unit number

IDTP2 Idtype for PCB multiboard panel number

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 13 from 29

Communication protocol for FujiTrax

7 ComCell Event Functions

ComCell event functions are triggered by the ComCell framework without a message from the connected

equipment. There are 4 event functions. Load and unload the filter dll. Start and stop the filter dll.

7.1 event_load

Load the ComCell Fujitrax configuration from the FraMES.cfg.

Load application specific GUI and place it in a tab of the WPPanel.

7.2 event_unload

Relase application specific GUI.

7.3 event_start

Create and send the SETEV message to Fujitrax. The message depends on the configuration:

EQUIPMENT_TYPE=NXT:

SETEV<TAB>SeqID<TAB>MachineName<TAB>NumList<CR>

LOADCOMP<TAB>Ack<CR>

UNLOADCOMP<TAB>Ack<CR>

CHANGECOMP<TAB>Ack<CR>

PCBCHECKIN<TAB>Ack<CR>

PCBCHECKOUT<TAB>Ack<CR>

LineControl message:

<STX>TS_INI:WRS:machine name<ETX>

Parameters to send

SeqID 1

MachineName configured parameter: MACHINE_NAME

NumList 5

Ack 1

EQUIPMENT_TYPE=KITTING:

SETEV<TAB>SeqID <TAB>MachineName<TAB> NumList <CR>

LOADKITTING<TAB>1<CR>

Parameters to send

SeqID 1

MachineName configured parameter: MACHINE_NAME

NumList 1

Ack 1

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 14 from 29

Communication protocol for FujiTrax

The answer for the message will be send to the ComCell message function msg_setev_ack. The sequence

id is set to 1 and can be checked by the msg_setev_ack.

7.4 event_stop

8 ComCell Message Functions

The following Message sets have to be supported.

8.1 msg_setev_ack

This function is called after the function "event_start" has sent an "SETEV" to the Fujitrax and Fujitrax

replies a "SETEV_ACK" message to the ComCell. There for a global variable is used to check the sequence

id set by the event_start function.

Additional to that, the machine name and the result (0=OK 1=NOK) is checked.

Usage of received parameters

SeqID Not used

MachineName Check agains configured parameter:

MACHINE_NAME

If all checks are OK, the STARTEV message is sent to Fujitrax:

STARTEV<TAB>SeqId<TAB>MachineName

Parameters to send

SeqID 2

MachineName configured parameter: MACHINE_NAME

The sequence id is set to 2, as this is the second message of the communication.

8.2 msg_startev_ack

This function is called after the function "msg_setev_ack" has sent a "STARTEV" message to the Fujitrax

and Fujitrax replied a "STARTEV_ACK" to the ComCell. The function doesn't have to reply a message to

Fujitrax.

Usage of received parameters

SeqID Not Used

MachineName Check with configured parameter:

MACHINE_NAME

After that, the LineControl gets a message, that the setup for the station is OK.

LineControl message: <STX>TS_INI:SOK<ETX>

Now the ComCell is waiting for events sent by Fujitrax (Central Server or Kitting Station)

8.3 msg_keepalive

This function provides the ComCell application part of the "Keep Alive" mechanism. This function always

sends back an "KEEPALIVE_ACK" message to notice that the application is still runnning.

Reply message:

KEEPALIVE_ACK<TAB>SeqID

Parameters to send

SeqID received SeqID

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 15 from 29

Communication protocol for FujiTrax

8.4 msg_pcbcheckin

This function is called wenn a PCB goes into the first module of the NXT machine. MES ComCell has to

validate if the unit is OK for that process step and sends back result=0 for ok or result=1 for not OK.

Tasks:

- Check the "Machine Name"

- Check if the unit is valid with the function wpm_GetSlotForUnit

- Check the ProgramName, if it fits to the material number of the unit

- Check if the material number is the same as the selected material number in the LineControl configuration

lnc_GetWIPMaterial

- Check if the critical msl remaining time is long enough lnc_GetParameter

Flowchart:

msg_pcbcheckin

MLTB entry

msg_pcbcheckin

The flow “MLTB entry” is displayed in the section “Multi Board Handling” of the “General Description”-

LineControl messages:

<STX>TS_GET:MAT<ETX> Get Materialnumber from LCS

<STX>TS_GET:SID<ETX> Get panel identification type

<STX>TS_GET:PID<ETX> Get single identification type

<STX>TS_PAR:MLTB:2<ETX> Get LineControl tesplan parameter for type ofmultiboard

handling

Usage of received parameters

SeqID Send SeqID

MachineName Check with configured parameter:

MACHINE_NAME

Time Not used

LineName Check with configured line name

LaneNo Not used

ProgramName Check with material number of the PCB in MES

PanelID Use to validate WIP unit PanelID

CriticalMslRemainingTime Optional to check with configured parameter in

LineControl testplan

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 16 from 29

Communication protocol for FujiTrax

If all checks are OK, this message is sent to Fujitrax:

PCBCHECKIN_ACK<TAB>SeqID<TAB>Result<TAB>MachineName<TAB>LaneNo<TAB>ProgramNa

me<TAB>PanelID

Parameters to send

SeqID received SeqID

Result 0 for OK / 1 for not OK

MachineName received and checked MachineName

LaneNo received LaneNo

ProgramName received and checked ProgramName

PanelID received and validated PanelID

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 17 from 29

Communication protocol for FujiTrax

8.5 msg_pcbcheckout

This function is called when a PCB goes out of the last module of the NXT machine. MES ComCell has to

validate if the unit and if its component traceability information is OK for that process step, stores the

traceability information in MES and sends back result=0 for OK or result=1 for not OK.

Although the feeder positions are controlled by the events “LOADCOMP”, “UNLOADCOMP” and

“CHANGECOMP”, the usage of the position for the slot in WIPMaMa are managed in the function

msg_pcbcheckout.

Tasks:

- Check the "Machine Name"

- Check if the unit is valid with the function wpm_GetSlotForUnit

- Check if the material number is the same as the selected material number in the LineControl configuration

wpm_GetSlotInfo lnc_GetWIPMaterial

- Get partlist setup for this slot to check if component us or unuse is required wpm_GetPartlistSetup

- For each component:

- check if position is already set with that component

- unuse position if needed wpm_UnusePosition

- if needed create batch unit in MaMa using the function wpm_CreateBachtUnit

- if needed set position in WIPMaMa by using the function wpm_SetPosition

- use position for current slot wpm_UsePosition

- use quantity for current slot and position with function wpm_UseQtyPosition

- reduce quantity for position with function wpm_DecQtyPosition

- Unuse all positions not in the list provided by the message "PCBCHECKOUT" wpm_UnusePosition

- Finish the PCB unit by calling the function wpm_UnitFinish.

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 18 from 29

Communication protocol for FujiTrax

Flowchart:

msg_pcbcheckout

MLTB entry

wpm_GetPartlistSetup

compare partlist setup

and component list

positione not used

wpm_UnusePosition yes

anymore

position used but

yes

different component

wpm_ReleasePosition

no

position not used

yes

before ?

(wpm_CreateBatchUnit)

wpm_SetPosition

wpm_UsePosition

wpm_UseQtyPosition

wpm_DecQtyPosition

all components

checked ?

wpm_UnitFinish

Error

yes

apeared?

no

reply message NOK reply message OK

msg_pcbcheckout

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 19 from 29

Communication protocol for FujiTrax

Usage of received parameters

SeqID Send SeqID

Time Not used

LineName Check with configured line name

MachineName Check with configured parameter:

MACHINE_NAME

LaneNo Not used

ProgramName Check with material number of the PCB in MES

PanelID Use to validate WIP unit PanelID

CriticalMslRemainingTime Optional to check with configured parameter in

LineControl testplan

NumList Number of used components

Components

StageNo Not Used

SlotNo Used for WIPMaMa batch Positions

PartNo Material number of the batch unti in WIPMaMa

ReelId Batch unit id in WIPMaMa

FeederId Feeder Carrier id (not used here)

PickupCount Used components for WIPMaMa

ErrorParts

RejectParts

DislodgedParts

NoPickup Not used

If everything is done this message is sent to Fujitrax:

PCBCHECKOUT_ACK<TAB>SeqID<TAB>Result<TAB>MachineName<TAB>LaneNo<TAB>ProgramN

ame<TAB>PanelID

Parameters to send

SeqID received SeqID

Result 0 for OK / 1 for not OK

MachineName received and checked MachineName

LaneNo received and checked LaneNo

ProgramName received and checked ProgramName

PanelID received and checked PanelID

8.6 msg_loadcomp

This event occurs when feeders with components are put to a module of the NXT machine., or when a reel

id is scanned during splicing.

Tasks:

- Check the "Machine Name"

- For each component:

- Check if ReelId is a batch unit in MaMa, if not create batch unit: wpm_CreateBatchUnit

- Check if FeederID is a carrier in CarMa. If not, create the carrier. car_CreateCarrier

- Check if ReelId belongs to FeederID. If not use CarMa to assign ReelID to FeederID

car_CarrierUsePosition

- Check if position is set. If not, set position with ReelID: wmp_SetPosition

- Id needed, adjust batch unit quantity wpm_DecQtyPosition

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 20 from 29

Communication protocol for FujiTrax

Flow:

msg_loadcomp

msg_changecomp

For each component of

provided list

wpm_GetBatchUnitInfo

MaMa batch units no

wpm_CreateBatchUnit OK?

exists ?

car_GetCarrierPosition

(car_CreateCarrier)

reel on that feeder

(car_CarrierReleasePosition) OK? no

carrier

car_CarrierUsePosition

No,

next

component

wpm_GetPosition

Position already

no wpm_SetPosition OK? no

set?

yes

reply message OK for reply message NOK for

this component this component

last component?

yes

reply message OK

msg_loadcomp

msg_changecomp

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 21 from 29

Communication protocol for FujiTrax

Usage of received parameters

SeqID Send SeqID

Time Not used

LineName Check with configured line name

MachineName Check with configured parameter:

MACHINE_NAME

ModuleNo Not used

NumList Number of loaded components

Components

StageNo Not Used

SlotNo Used for WIPMaMa batch Positions

PartNo Material number of the batch unti in WIPMaMa

FeederId Feeder Carrier id (not used here)

ReelId Batch unit id in WIPMaMa

Quantity Create or adjust quantity of batch unit in MaMa

Parameters to send

LOADCOMP_ACK Message name

SeqID Received SeqID

MachineName Received machine name

ModuleNo Received module no

NumList Received number of loaded components

Components

StageNo Received stage no

SlotNo Received slot no

Result 0: OK 1: NOK

PartNo Received part no

FeederId Received feeder id

ReelId Received reel id

Remaining Time MSL remaining time from MES MaMa

8.7 msg_unloadcomp

This event occurs when feeders with components are taken from a module of a NXT machine or when the

component is not longer available because the splice position is reached.

Tasks:

- Check the "Machine Name"

- For each component:

- Check if FeederID is a carrier in CarMa. If not, create the carrier. car_CreateCarrier

- Check if ReelId belongs to FeederID. If not use CarMa to assign ReelID to FeederID

car_CarrierUsePosition

- Id needed, adjust batch unit quantity wpm_DecQtyPosition

- Check if position is set. If yes release position: wmp_ReleasePosition

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 22 from 29

Communication protocol for FujiTrax

Flow:

msg_unloadcomp

For each component of

provided list

wpm_ReleasePosition

No,

next reply message NOK for

component OK? no

this component

reply message OK for

this component

last component?

yes

reply message

msg_unloadcomp

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 23 from 29

Communication protocol for FujiTrax

Usage of received parameters

SeqID Send SeqID

Time Not used

LineName Check with configured line name

MachineName Check with configured parameter:

MACHINE_NAME

ModuleNo Not used

NumList Number of unloaded components

Components

StageNo Not Used

SlotNo Used for WIPMaMa batch Positions

PartNo Material number of the batch unti in WIPMaMa

FeederId Feeder Carrier id (not used here)

ReelId Batch unit id in WIPMaMa

Quantity Adjust quantity of batch unit in MaMa

RemainingTime Optional: remaining time in MaMa

Parameters to send

UNLOADCOMP_ACK Message name

SeqID Received SeqID

MachineName Received machine name

ModuleNo Received module no

NumList Received number of loaded components

Components

StageNo Received stage no

SlotNo Received slot no

Result 0: OK 1: NOK

PartNo Received part no

FeederId Received feeder id

ReelId Received reel id

Remaining Time MSL remaining time from MES MaMa

8.8 msg_changecomp

This event occurs when the new reel id is valid because the splice position is reached. The FraMES

application can handle that like the "LOADCOMP" event.

The event “CHANGECOMP” is treated as the event “LOADCOMP”.

Usage of received parameters

SeqID Send SeqID

Time Not used

LineName Check with configured line name

MachineName Check with configured parameter:

MACHINE_NAME

ModuleNo Not used

NumList Number of unloaded components

Components

StageNo Not Used

SlotNo Used for WIPMaMa batch Positions

PartNo Material number of the batch unti in WIPMaMa

FeederId Feeder Carrier id (not used here)

ReelId Batch unit id in WIPMaMa

Quantity Adjust quantity of batch unit in MaMa

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 24 from 29

Communication protocol for FujiTrax

Parameters to send

CHANGECOMP_ACK Message name

SeqID Received SeqID

MachineName Received machine name

ModuleNo Received module no

NumList Received number of loaded components

Components

StageNo Received stage no

SlotNo Received slot no

Result 0: OK 1: NOK

PartNo Received part no

FeederId Received feeder id

ReelId Received reel id

Remaining Time MSL remaining time from MES MaMa

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 25 from 29

Communication protocol for FujiTrax

8.9 msg_loadkitting

This event occurs when a a feeder is set at the Kitting Station.

- Check the "Kitting Name"

- Check if FeederID is a carrier in CarMa. If not, create the carrier. wpm_CreateCarrier

- Check if ReelId belongs to FeederID. If not use CarMa to assign ReelID to FeederID

wpm_UseCarrierPosition

- If ReelID is not set by the Kitting Station, release position in CarMa. wpm_ReleaseCarrierPosition

Flow:

msg_loadkitting

wpm_GetBatchUnitInfo

MaMa batch units

wpm_CreateBatchUnit OK?

exists ?

yes

car_GetCarrierPosition

car_CreateCarrier

reel on that feeder

no car_CarrierReleasePosition OK?

carrier

car_CarrierUsePosition

yes

no

reply message NOK for

reply message OK

this component

msg_loadkitting

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 26 from 29

Communication protocol for FujiTrax

9 Sample Event Sequences

NXT Machine

Seq. Number of

MES ComCell

No. Comment events Fujitrax Central Server

Connect TCP/IP server

1 Socket Connection 1

Accept Client Connection

SETEV

2 Send a list of all required events 1

SETEV_ACK

STARTEV

3 Send start signal start with events 1

STARTEV_ACK

Central Server sends a load LOADCOMP

4 component for each module with a list 1..32

of all feeder positions for each module LOADCOMP_ACK

Central Server sends a change CHANGECOMP

component for each module with a list

5 of all feeder positions for each module 1..32

to identify that the components are CHANGECOMP_ACK

used from now on

First PCBs go into the machine. Event PCBCHECKIN

6 pcb checkin is sent several times 1..10

PCBCHECKIN_ACK

First PCB goes out of the machine. PCBCHECKOUT

7 Event pcb checkout is sent 1

PCB_CHECKOUT_ACK

PCBCHECKIN

Next PCB goes into the machine

PCBCHECKIN_ACK

8 1..n

PCBCHECKOUT

Next PCB goes out of the machine

PCB_CHECKOUT_ACK

PCBCHECKIN

Next PCB goes into the machine

PCBCHECKIN_ACK

New Feeder is set on the machine or LOADCOMP

new reel is scanned after splicing LOADCOMP_ACK

Splice position is reached, or new UNLOADCOMP

9 feeder is used the first time, therfore 1..n 0..32

old reel is unloaded UNLOADCOMP_ACK

Splice position is reached, or new CHANGECOMP

feeder is used the first time, therfore

old reel is used from now on CHANGECOMP_ACK

PCBCHECKOUT

Next PCB goes out of the machine

PCB_CHECKOUT_ACK

Kitting Station

Seq. Number of

MES ComCell

No. Comment events Fujitrax Kitting Station

Connect TCP/IP server

1 Socket Connection 1

Accept Client Connection

SETEV

2 Send a list of all required events 1

SETEV_ACK

STARTEV

3 Send start signal start with events 1

STARTEV_ACK

Kitting station sends load kitting LOADKITTING

4 events 1..n

LOADKITTING_ACK

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 27 from 29

Communication protocol for FujiTrax

9.1 xxxCOMP Events

Event sequence with splicing:

Feeder

Event Feeder Pos Reel Id Comment

LOADCOMP feeder1 pos1 reel1 verify reel, create batch unit in MaMa

change feeder carrier

set batch position

LOADCOMP feeder1 pos1 reel2 verify reel, create batch unit in MaMa

change feeder carrier

UNLOADCOMP feeder1 pos1 reel1 release WIPMaMa batch position

CHANGECOMP feeder1 pos1 reel2 set WIPMaMa batch position

LOADCOMP feeder1 pos1 reel3 verify reel, create batch unit in MaMa

change feeder carrier

UNLOADCOMP feeder1 pos1 reel2 release WIPMaMa batch position

CHANGECOMP feeder1 pos1 reel3 set WIPMaMa batch position

Event sequence without splicing:

Feeder

Event Feeder Pos Reel Id Comment

LOADCOMP feeder1 pos1 reel1 verify reel, create batch unit in MaMa

change feeder carrier

set batch position

UNLOADCOMP feeder1 pos1 reel1 ReleasePosition

LOADCOMP feeder1 pos1 reel2 verify reel, create batch unit in MaMa

change feeder carrier

set batch position

UNLOADCOMP feeder1 pos1 reel2 ReleasePosition

LOADCOMP feeder1 pos1 reel3 verify reel, create batch unit in MaMa

change feeder carrier

set batch position

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 28 from 29

Communication protocol for FujiTrax

10 Other considerations

10.1 Configurable items

Connection and message parameters that are constant should be stored in configuration files or be made

accessible via utilities on the equipment’s user interface. The configurable items include:

MES ComCell server host name or IP

TCP port through which communications to MES will take place

The equipment identifier (machine_id or kitting_station_id in message sets) that will identify the

equipment to MES

The number of seconds the equipment should wait for a reply from MES before concluding that is a

communication error and display the error to the operator

Destination folder for Logging Result files. It will be a local or network path location.

The MES application that talks to the equipment keeps a log for all message activity between itself and the

equipment, including the whole message send/received. As each log file reaches a certain size, it is named

according with the date it was closed and a new file is opened. Logging of messages activity by the

equipment software that talk with MES is also necessary. This could be implemented in two different ways:

1) A log file method as MES uses

2) A scrollable FIFO window of messages activity that does not log to disk.

Either or both methods will greatly aid in troubleshooting any problem between equipment and MES. To

prevent excessive disk usage for first option, a schema may be implemented where only the last X number

of files are kept and older files are deleted. In this case, it may be desirable to include the number of files to

keep and the maximum size of each file as configurable item discussed above. If both methods are used, a

means to “turn off” disk logging should be implemented.

10.2 Minimizing impact on Equipment Cycle time

Communication with MES should be implemented in such a way as to minimize the effect on the

equipment’s processing cycle time. In other words, the equipment should not spend time communicating

with MES or waiting for response when it could be processing product that is eligible for processing. This

doesn’t imply that product should be moved or processed before MES has replied to a message for that

particular product. Instead, mechanisms such as input and output queues may needed to allow pre or post-

process messaging to occur for one or more parts while another is in the process cycle (see Reference

section for PPT file)

The component tracking on MES side has to handled to minimize the impact of the cycle time at the

"PCBCHECKOUT" event. Therefore, all compontens provided by the event have to be cashed onFraMES

level and only if setup changes are recognised, these changes are stored in the "t_wip_partlist" table of the

WIP server.

END OF THIS DOCUMENT

/conversion/tmp/activity_task_scratch/539923821.doc Sheet 29 from 29

You might also like

- Supplier Quality ToolkitDocument5 pagesSupplier Quality ToolkitJosué PérezNo ratings yet

- CNT NXTIII - IIIc M3IIIs 11E00NXTIIIIIIcM3IIIsMachineSpecificationsDocument103 pagesCNT NXTIII - IIIc M3IIIs 11E00NXTIIIIIIcM3IIIsMachineSpecificationsEng Hady AliNo ratings yet

- H300 400 SplicerDocument127 pagesH300 400 SplicerMismail EgypacNo ratings yet

- 7本 DL1101A Pneumatic Trainer ManualDocument59 pages7本 DL1101A Pneumatic Trainer ManualNaoufel FaresNo ratings yet

- 1757 Um007 - en P PDFDocument160 pages1757 Um007 - en P PDFfitasmounirNo ratings yet

- LENZE DC Drive System Manual 342 PagesDocument342 pagesLENZE DC Drive System Manual 342 PagesShriram V. Date100% (1)

- MCAMX4 Installation GuideDocument16 pagesMCAMX4 Installation Guidehclraj406No ratings yet

- DX200 Options Instructions For Cc-Link Communications FunctionDocument49 pagesDX200 Options Instructions For Cc-Link Communications Functioninyong baik100% (1)

- SecuriFire 500 1000 2000 3000 PC2018 F001en DDocument118 pagesSecuriFire 500 1000 2000 3000 PC2018 F001en DLorand BartaNo ratings yet

- Programming of SimensDocument404 pagesProgramming of SimensHimanshuBhardwajNo ratings yet

- FactoryTalk View Site Edition Tips and Best Practices TOCDocument7 pagesFactoryTalk View Site Edition Tips and Best Practices TOCKevin PeñaNo ratings yet

- ESATAN 94 User GuideDocument560 pagesESATAN 94 User Guideknulp74No ratings yet

- DatasheetDocument61 pagesDatasheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- Ultra 3000 Integration ManualDocument180 pagesUltra 3000 Integration ManualdjtremorzNo ratings yet

- Comunicatii IndustrialeDocument468 pagesComunicatii Industrialepedro_luna_43No ratings yet

- Carsim Educational User Refence ManualDocument233 pagesCarsim Educational User Refence Manualmikael bezerra cotias dos santosNo ratings yet

- 5092@feedmax BS6@ENDocument40 pages5092@feedmax BS6@ENALFONSO TORRESNo ratings yet

- Manual KCM LLL KtronDocument116 pagesManual KCM LLL KtronRodrigo FogaçaNo ratings yet

- DriveTop Project Configuration GuideDocument91 pagesDriveTop Project Configuration GuideAlexander RussellNo ratings yet

- FAGOR 8035 CNC Ordering HandbookDocument1 pageFAGOR 8035 CNC Ordering HandbooksandrogoularteNo ratings yet

- Open Sim Tutorial 2Document8 pagesOpen Sim Tutorial 2Mohd Khairul Ikhwan AhmadNo ratings yet

- Technical Descriptions of Functions Introduction 1MRS750528 MUMDocument35 pagesTechnical Descriptions of Functions Introduction 1MRS750528 MUMmedNo ratings yet

- Magnum Prothru The Arm Robotic TorchDocument29 pagesMagnum Prothru The Arm Robotic TorchAnton KiryakovNo ratings yet

- 802SCDocument16 pages802SCNguyen Minh HieuNo ratings yet

- Et200sp Im 155 6 PN ST Manual en-US en-USDocument62 pagesEt200sp Im 155 6 PN ST Manual en-US en-USPhilNo ratings yet

- SEC1012010 - YV100XT Service - EDocument147 pagesSEC1012010 - YV100XT Service - EKien Phan100% (1)

- BVH2062GBDocument220 pagesBVH2062GBVladimir VojinovicNo ratings yet

- GX Works3 Operating ManualDocument540 pagesGX Works3 Operating Manualjafet riosNo ratings yet

- (Matrikon) OPC Server For Modbus Devices User's Ma (B-Ok - Xyz)Document69 pages(Matrikon) OPC Server For Modbus Devices User's Ma (B-Ok - Xyz)esutjiadiNo ratings yet

- Harris PlatinumDocument346 pagesHarris PlatinumAlmeida FábioNo ratings yet

- WMM Specification v1.1 PDFDocument36 pagesWMM Specification v1.1 PDFSorin GoldenbergNo ratings yet

- ADV200 Catalog System & AccessoriesDocument18 pagesADV200 Catalog System & AccessoriesMr. Tung PTCVietNamNo ratings yet

- Modbus V2 04 RTU 001Document123 pagesModbus V2 04 RTU 001Brian Domecq80% (5)

- Tcfen-154-001 CFD Startup PDFDocument88 pagesTcfen-154-001 CFD Startup PDFPhasin Chitutsaha100% (1)

- SCE en 030-020 R1209 Timers and CountersDocument41 pagesSCE en 030-020 R1209 Timers and CountersYoga AdiNo ratings yet

- Catalog Suruburi Cu Bile SKFDocument52 pagesCatalog Suruburi Cu Bile SKFjo_rz_57No ratings yet

- SJ-20120306200658-007-ZXUN uMAC (V4.11.20) GNGP SGSN GeneraDocument111 pagesSJ-20120306200658-007-ZXUN uMAC (V4.11.20) GNGP SGSN Generasyrish2622No ratings yet

- User's Manual For TL-30x Laser Engraving and Cutting Control SystemDocument103 pagesUser's Manual For TL-30x Laser Engraving and Cutting Control SystemGPrado100% (1)

- FestoDocument138 pagesFestoEmmanuel MelendezNo ratings yet

- 3070 Board Test Systems: System Installation Manual (MS Windows Version) June 2003Document116 pages3070 Board Test Systems: System Installation Manual (MS Windows Version) June 2003Miqueas PachecoNo ratings yet

- Kinetix 5700 Servo Drives: User ManualDocument466 pagesKinetix 5700 Servo Drives: User ManualNelsonNo ratings yet

- Isapi - AnprDocument116 pagesIsapi - AnprArmandoNo ratings yet

- ScriptDocument4 pagesScriptMhrNo ratings yet

- PCF 310 and Motor AssemblyDocument77 pagesPCF 310 and Motor AssemblyVasantha AbeygoonaratneNo ratings yet

- Iqclampcontrol Info EN PDFDocument8 pagesIqclampcontrol Info EN PDFMarius VaidaNo ratings yet

- Hart Driver ManualDocument119 pagesHart Driver ManualAntonio VerneNo ratings yet

- KIMA MillMaster TechnicalDocument6 pagesKIMA MillMaster TechnicalСергейNo ratings yet

- A02-Injection Machine Robot Control System Operation Manual V1.14Document133 pagesA02-Injection Machine Robot Control System Operation Manual V1.14jagoklurukNo ratings yet

- Catalogo RapplonDocument8 pagesCatalogo RapplonAlejandro Saco Herrera100% (1)

- Bend TrainingDocument4 pagesBend TrainingbdaneshvarNo ratings yet

- Instalatie Taiere Automatizata - CNC - Plasma ESAB EAGLE (En)Document4 pagesInstalatie Taiere Automatizata - CNC - Plasma ESAB EAGLE (En)Adnan KaraahmetovicNo ratings yet

- Open Modbus TCP For NCM - CP Redundant EnglishDocument71 pagesOpen Modbus TCP For NCM - CP Redundant EnglishJose LunaNo ratings yet

- ProjectingNotes USDocument99 pagesProjectingNotes USjose florNo ratings yet

- Bizhub C203 - C253 - C353 Replacing The Transfer Belt UnitDocument3 pagesBizhub C203 - C253 - C353 Replacing The Transfer Belt UnitaionicaNo ratings yet

- UCCNC UsersmanualDocument80 pagesUCCNC UsersmanualcristinaNo ratings yet

- Kertas Penerangan FullDocument50 pagesKertas Penerangan FullPAUL KENNY TSHONGNo ratings yet

- ArchestraObject Toolkit Reference Guide PDFDocument474 pagesArchestraObject Toolkit Reference Guide PDFdNichiNo ratings yet

- CTA Remote Interface ManualDocument217 pagesCTA Remote Interface ManualTomas RuizNo ratings yet

- FlexFactory Users Manual 29164188AADocument552 pagesFlexFactory Users Manual 29164188AAAshish GowandeNo ratings yet

- Banner Lights ControllerDocument76 pagesBanner Lights ControllerJuan Carlos SerranoNo ratings yet

- Cloud Computing Architecture and ManagementDocument4 pagesCloud Computing Architecture and ManagementSrikanth JannuNo ratings yet

- Slidex - Tips Vantagepoint Getting Results GuideDocument23 pagesSlidex - Tips Vantagepoint Getting Results GuideSACHINNo ratings yet

- Remote Access InstructionsDocument6 pagesRemote Access InstructionsRajiv KabadNo ratings yet

- Triconex DDE Server Quick GuideDocument11 pagesTriconex DDE Server Quick GuidejorisanNo ratings yet

- Arista ACP Thinmanager Ready Industrial Thin Client WhitepaperDocument8 pagesArista ACP Thinmanager Ready Industrial Thin Client Whitepaperali77sgNo ratings yet

- Advance Compliance Reporting: Setting Up (1J2)Document10 pagesAdvance Compliance Reporting: Setting Up (1J2)JimmyNo ratings yet

- SPIE APRS Tutorial Geowebservices HCKDocument23 pagesSPIE APRS Tutorial Geowebservices HCKGheorghe IonescuNo ratings yet

- Final Exam Review: 90% ScoreDocument25 pagesFinal Exam Review: 90% ScoreTon LazaroNo ratings yet

- Application SecurityDocument223 pagesApplication SecuritysatishkumarmaniNo ratings yet

- CS8791 BOOK MDocument68 pagesCS8791 BOOK Mmeenaklnce2022No ratings yet

- Whats NewDocument38 pagesWhats NewNguyễn Mạnh HùngNo ratings yet

- ENR-100 Series User Manual V4.04.36 20160129 PDFDocument54 pagesENR-100 Series User Manual V4.04.36 20160129 PDFJohn YbanezNo ratings yet

- WaterGEMS User's GuideDocument992 pagesWaterGEMS User's GuideIves_junio100% (2)

- 30-3001-835 Webclient Planning and Installation GuideDocument160 pages30-3001-835 Webclient Planning and Installation GuideRuben CuevasNo ratings yet

- Socket PresentationDocument13 pagesSocket PresentationYogananda PatnaikNo ratings yet

- Configurarea placii NodeMCU pentru scanarea rețelelor WiFi și funcționarea ca web serverDocument6 pagesConfigurarea placii NodeMCU pentru scanarea rețelelor WiFi și funcționarea ca web serverionNo ratings yet

- Amol Ghorpade CV PDFDocument6 pagesAmol Ghorpade CV PDFMakrandNo ratings yet

- A Software Architecture For GamesDocument9 pagesA Software Architecture For GamesTrần Thị Thúy An FX01502No ratings yet

- Vykon Alarm Service DatasheetDocument2 pagesVykon Alarm Service DatasheetvaldirNo ratings yet

- The No.1 in People Flow Monitoring: Take Off With The Market LeaderDocument8 pagesThe No.1 in People Flow Monitoring: Take Off With The Market LeaderRintheGreatNo ratings yet

- Classes of ComputersDocument7 pagesClasses of Computerspankaj sahuNo ratings yet

- MorphoManager Quick Install GuideDocument16 pagesMorphoManager Quick Install GuidebrandonNo ratings yet

- 7um62xx Manual Pixit A4 v047001 enDocument214 pages7um62xx Manual Pixit A4 v047001 enevonik123456No ratings yet

- Desigo Building Automation System 6.0 SPDocument416 pagesDesigo Building Automation System 6.0 SPnaveedfndNo ratings yet

- Chapter 1 Basic Distributed System ConceptsDocument45 pagesChapter 1 Basic Distributed System ConceptsMAFIA0% (1)

- Sap Spec v11Document51 pagesSap Spec v11AlfredoNo ratings yet

- Cloud Computing NotesDocument10 pagesCloud Computing NotesDikshant NaikNo ratings yet

- LogicDocument66 pagesLogicRoha CbcNo ratings yet

- Mobile Computing Unit 1Document175 pagesMobile Computing Unit 1bhupendra7kumawatNo ratings yet

- Keyence Ethernet ManualDocument39 pagesKeyence Ethernet Manualmgkso706No ratings yet