Professional Documents

Culture Documents

Evaluation of Comp Stength 3 of 4

Uploaded by

rameshkaa0 ratings0% found this document useful (0 votes)

5 views1 pageEvaluation of Comp Strength 4 of 4

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

5 views1 pageEvaluation of Comp Stength 3 of 4

Uploaded by

rameshkaaYou are on page 1of 1

Kabashi, et al.

(2015)

Concrete elements variability

Variations in concrete supply will be due to differences in

materials, batching, transport and handling techniques. These will

reflect the degree of control over production and will normally be

indicated by control and compliance test specimens in which other

factors are all standardized. In-situ measurement of these variations

is difficult because of the problem of isolating them from compaction

and curing effects. Typical relative strength variations for normal

concretes according to member type are illustrated in Figure 1.

In-situ strength relative to standard specimens

If the measured in-situ values are expressed as equivalent cube

strengths, it will usually be found that they are less than the strengths

of cubes made of concrete from the same mix which are compacted

and cured in a ‘standard’ way. In-situ compaction and curing will vary

widely, and other factors such as mixing, bleeding and susceptibility

to impurities are difficult to predict. Nevertheless a general trend

according to member type can be identified and the values given in

Table 1 [2,5].

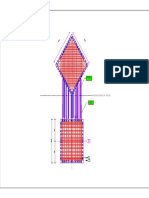

The relations between the Standard Samples and In-situ strength

is presented through the algorithm (Figure 2).

Design and specification are usually based on a 150mm cube, Figure 2: Typical in Situ equivalent 28 Days Cube Strength.

but the variation is depend of the Class of the concrete, presented in

Figure 3. hammer test we can using also the Methods of Core Samples taking in

Example of evaluation the compressive strength in- concrete elements of structures.

situ according to the EN 13791 According to the EN 13791 [8], the results will used for comparing

The reduction of the influence of several factors affecting rebound the methods and finally to evaluate the concrete strength in different

concrete elements. The data are presented in Table 2.

According to the number of samples we can used the Approach

B-EN 13791, with following expression:

fck,is = fm(n),is – k (1)

Or

fck,is = fis,lowest + 4 (2)

For the taking core samples with dimensions 100x100 mm, and

the expression using for indirect test using the EN 12504-04; rebound

number.

fck,is = fm(n),is − 1,48 × s (3)

Or

fck,is = fis,lowest + 4 (4)

Using the expression the calculation is presented in Figure 4.

Figure 1: Relative strength according to the member type. Conclusions

The aim of the in situ testing is to obtain an estimate of the

Table 1: Comparing the In Situ test and 28 Days Strength.

properties of concrete in the structure. Very often the desired property

Typical 28-days in-situ equilent wet cube strength as % of

Member type

'standard' cube strength.

is the cube compressive strength. To make a strength estimation

Average Likely range it is necessary to have a known relationship between the result of

Colum 65 55-75 the in-place test and the strength of the concrete for the particular

Wall 65 45-95 concrete mix concerned. The results presented in this paper are only

Beam 75 60-100 part of examinations of existing structures, and based on that we can

Slab 50 40-60 presented the main conclusions point:

Citation: Kabashi N, Krasniqi C, Dautaj A (2015) Evaluation the Compressive Strength in Concrete Structures Using the In-situ Test Methods. J Civ Eng

Environ Sci 1(2): 032-035.

034

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Precast Handbook 4 of 10Document1 pagePrecast Handbook 4 of 10rameshkaaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Precast Handbook 2 of 10Document1 pagePrecast Handbook 2 of 10rameshkaaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Evaluation of Comp Stength 4 of 4Document1 pageEvaluation of Comp Stength 4 of 4rameshkaaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Precast Handbook 3 of 10Document1 pagePrecast Handbook 3 of 10rameshkaaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Precast Handbook 5 of 10Document1 pagePrecast Handbook 5 of 10rameshkaaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Evaluation of Comp Stength 1 of 4Document1 pageEvaluation of Comp Stength 1 of 4rameshkaaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- TWF 7 of 13Document1 pageTWF 7 of 13rameshkaaNo ratings yet

- TWF 9 of 13Document1 pageTWF 9 of 13rameshkaaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Evaluation of Comp Stength 2 of 4Document1 pageEvaluation of Comp Stength 2 of 4rameshkaaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TWCTC TWCTC TWCTC TWCTC - Temporary Works Co Temporary Works Co Temporary Works Co Temporary Works Co - Ordinator Ordinator Ordinator OrdinatorDocument1 pageTWCTC TWCTC TWCTC TWCTC - Temporary Works Co Temporary Works Co Temporary Works Co Temporary Works Co - Ordinator Ordinator Ordinator OrdinatorrameshkaaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- TWF 10 of 13Document1 pageTWF 10 of 13rameshkaaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Temporary Works Procedures and Specialist FieldsDocument1 pageTemporary Works Procedures and Specialist FieldsrameshkaaNo ratings yet

- WR Ichptral: Tied Concrete Column, Without BeamsDocument1 pageWR Ichptral: Tied Concrete Column, Without BeamsrameshkaaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- TWCTC TWCTC TWCTC TWCTC TWSTC TWSTC TWSTC TWSTC Twgatc Twgatc Twgatc TwgatcDocument1 pageTWCTC TWCTC TWCTC TWCTC TWSTC TWSTC TWSTC TWSTC Twgatc Twgatc Twgatc TwgatcrameshkaaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- TWF 5 of 13Document1 pageTWF 5 of 13rameshkaaNo ratings yet

- TWF 4 of 13Document1 pageTWF 4 of 13rameshkaaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Figure 1111 - Temporary Works Training Selection AidDocument1 pageFigure 1111 - Temporary Works Training Selection AidrameshkaaNo ratings yet

- Lapping 2Document1 pageLapping 2rameshkaaNo ratings yet

- Temporary Works Training Information SheetDocument1 pageTemporary Works Training Information SheetrameshkaaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Design Considerations For One-Strut Failure According To TR26 - A Practical Approach For Practising EngineersDocument17 pagesDesign Considerations For One-Strut Failure According To TR26 - A Practical Approach For Practising EngineersrrprasathNo ratings yet

- TWF 5 of 13Document1 pageTWF 5 of 13rameshkaaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Analysis of Hollow-Core Slab Oors: January 2005Document14 pagesAnalysis of Hollow-Core Slab Oors: January 2005N TNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Temporary Works Training ScopeDocument1 pageTemporary Works Training ScoperameshkaaNo ratings yet

- Guideline For Good Practice of Fibre Reinforced Precast Segment - Vol. 2 Production Aspects201803 PDFDocument36 pagesGuideline For Good Practice of Fibre Reinforced Precast Segment - Vol. 2 Production Aspects201803 PDFZHIHENG ZHAI100% (1)

- Use of SBEDS For Blast Resistant Design in Accordance With UFC 3 340 02Document38 pagesUse of SBEDS For Blast Resistant Design in Accordance With UFC 3 340 02wokeoooNo ratings yet

- Single-Degree-of-Freedom Blast Effects Design Spreadsheet (SBEDS)Document1 pageSingle-Degree-of-Freedom Blast Effects Design Spreadsheet (SBEDS)rameshkaaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- WG6 Without annex-BD PDFDocument47 pagesWG6 Without annex-BD PDFTanvirH.ChowdhuryNo ratings yet

- Tunnelling Impacts on Critical Structures in Kuala LumpurDocument14 pagesTunnelling Impacts on Critical Structures in Kuala LumpurrameshkaaNo ratings yet

- Mechanical Properties of New Dry-Type Beam-Column Bolt Connection JointDocument14 pagesMechanical Properties of New Dry-Type Beam-Column Bolt Connection JointJanelle MichaelsonNo ratings yet

- Wiccan - The Basics of Herbs and Herbal Magic and Spells and MagickDocument5 pagesWiccan - The Basics of Herbs and Herbal Magic and Spells and Magickkhalilgib67% (3)

- LTC Bill Form-G.a.r. 14-cDocument10 pagesLTC Bill Form-G.a.r. 14-cpraveen reddyNo ratings yet

- Sante Worklist Server QSG 1Document25 pagesSante Worklist Server QSG 1adamas77No ratings yet

- Improve Asset Performance with Integrated Asset ManagementDocument12 pagesImprove Asset Performance with Integrated Asset ManagementArun KarthikeyanNo ratings yet

- Skylab 4 PAO Mission Commentary 16 of 32Document188 pagesSkylab 4 PAO Mission Commentary 16 of 32Bob Andrepont100% (1)

- The Amazing VFP2C32 LibraryDocument28 pagesThe Amazing VFP2C32 Libraryluis eduardo ostos febresNo ratings yet

- S Com ManualDocument64 pagesS Com ManualL. J.No ratings yet

- 9) - Stategy Formulation at Corporate LevelDocument34 pages9) - Stategy Formulation at Corporate Leveldulshan jeewanthaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- FINAL REPORT (L ND M)Document84 pagesFINAL REPORT (L ND M)MuzamilNo ratings yet

- Home Appliances Controlling Using Bluetooth On Android Mobile AbstractDocument2 pagesHome Appliances Controlling Using Bluetooth On Android Mobile AbstractramyaNo ratings yet

- Documentation ProcessDocument6 pagesDocumentation ProcessmuthuselvanNo ratings yet

- IBM Informix 4GL V7.50 - Quick Start GuideDocument2 pagesIBM Informix 4GL V7.50 - Quick Start GuideMohamed AfeilalNo ratings yet

- iC60L Circuit Breakers (Curve B, C, K, Z)Document1 pageiC60L Circuit Breakers (Curve B, C, K, Z)Diego PeñaNo ratings yet

- MXTX1012 GX PA00Document28 pagesMXTX1012 GX PA00200880956No ratings yet

- Lecture PLCDocument30 pagesLecture PLCProsenjit Chatterjee100% (1)

- Production Manager-43-4Document4 pagesProduction Manager-43-4Mohanram PandiNo ratings yet

- Arm Multiple ChoiceDocument4 pagesArm Multiple ChoiceStalin Sbr33% (9)

- Brochure Thermoformer Range enDocument52 pagesBrochure Thermoformer Range enJawad LOUHADINo ratings yet

- Logistics Supply Chain Multiple Choice QuestionsDocument183 pagesLogistics Supply Chain Multiple Choice QuestionsSanjay sadafule100% (1)

- CV of Reaz EHS EngineerDocument3 pagesCV of Reaz EHS EngineerReaz UddinNo ratings yet

- An 124Document4 pagesAn 124Ank Electro FuzzNo ratings yet

- Citibank'S Epay: Online Credit Card Payment. From Any BankDocument2 pagesCitibank'S Epay: Online Credit Card Payment. From Any BankHamsa KiranNo ratings yet

- Spawn Production of Common CarpDocument5 pagesSpawn Production of Common CarpGrowel Agrovet Private Limited.No ratings yet

- Introduction of Kissan Credit Card SchemeDocument4 pagesIntroduction of Kissan Credit Card SchemeRomen BuragohainNo ratings yet

- CAO 2018 T3 Question PaperDocument2 pagesCAO 2018 T3 Question Paperharsh guptaNo ratings yet

- Posteguillo The Semantic Structure of Computer Science Research ArticalsDocument22 pagesPosteguillo The Semantic Structure of Computer Science Research ArticalsRobin ThomasNo ratings yet

- Quick Start Guide: Before You BeginDocument13 pagesQuick Start Guide: Before You Beginfrinsa noroesteNo ratings yet

- Business Description: Executive SummaryDocument4 pagesBusiness Description: Executive SummaryYudhi SugataNo ratings yet

- Valencia v. Sandiganbayan DIGESTDocument2 pagesValencia v. Sandiganbayan DIGESTkathrynmaydevezaNo ratings yet

- BFN 111 - Week 1Document20 pagesBFN 111 - Week 1CHIDINMA ONUORAHNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet