Professional Documents

Culture Documents

What Is Wear?: Written By: Steffen D. Nyman, Education Coordinator, C.C.JENSEN A/S

Uploaded by

sadeghiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Wear?: Written By: Steffen D. Nyman, Education Coordinator, C.C.JENSEN A/S

Uploaded by

sadeghiCopyright:

Available Formats

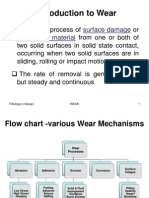

What is Wear?

Written by: Steffen D. Nyman, Education Coordinator, C.C.JENSEN A/S

It is generally recognized that contamination of lubricating and hydraulic oils are the primary cause of wear

and component failures – some say 70-80 percent of all failures. The purpose of the oil is to ensure that

component surfaces are kept clean, sufficiently cooled and to avoid metal-to-metal contact between

surfaces. However, contaminants can prevent the oil from doing what it is designed to do. Wear debris or

intruding particles and water can initiate a chain reaction of wear.

Even though a component surface might seem smooth, it actually has many tiny asperities and “high spots”.

The load applied to the surfaces will be transferred through these “high spots”, causing very high local

pressure forces, thus increasing the risk of metal-to-metal contact. Furthermore, the “high spots” and

“valleys” in the surfaces can hold particles, which will result in intense wear.

The hardness and finish of the surfaces are very important factors for the ability to withstand wear, but other

factors like load, speed, temperature and, of course, the oil film strength and oil cleanliness play equally

important roles.

In the following you will find descriptions of destructive wear modes that correspond to approx. 70 percent of

why a typical component fails. This can result in wear rates accelerating 10,000 times more than intended by

the machine designer.

On page 6 you will also find a list of typical dynamic oil film thickness in different machine components.

Abrasive wear

Abrasive wear occurs in sliding contact and is also known as grinding, because the wear mechanism is

basically the same as the machining, grinding, polishing or lapping used for the shaping of materials.

Two-body abrasive wear occurs when one surface (usually harder than the other) cuts material away from

the other surface, although this mechanism very often changes to three-body abrasion as the wear debris in

turn act as abrasive particles between the two surfaces. A similar situation occurs when a particle (e.g. silica

dust) enters a clearance between two component surfaces, when the clearance is equal to the particle size.

Abrasive particles such as silica dust can come from the oil system’s environment (airborne); or particles can

be generated within the oil system through wear, “high spots” breaking off, corrosion etc. The abrasive

particles can have a grinding effect when sticking to one of the surfaces - or a lapping effect where the

particle tumbles over the surfaces producing a series of notches and cavities as opposed to a scratch.

A particle can break into smaller particles, which in turn become harder due to the processes of work-

hardening (similar to hammering or rolling steel). These small and numerous particles are even more

dangerous, as they can enter even finer clearances, or get squeezed, accelerating further abrasive wear.

Abrasive wear is often seen both in hydraulic oil systems in servo valves, proportional valves, cylinders and

pumps - and in lubrication systems in bearings, bushings, pistons/liners etc.

Influencing factors:

- particles in the oil; the concentration, size and hardness of them

- oil film thickness (depending on load, oil viscosity and component speed/rpm)

- surface hardness

- component alignment

Description of wear, SDN, March 22, 2007 1

Photos show abrasive wear on gear tooth and on rolling element bearing

Adhesive wear

Adhesive wear is also known as scuffing or galling, and may occur under boundary lubrication conditions,

when two surfaces get ”bonded” locally during a sliding movement (metal-to-metal contact). Excessive load,

low velocity movements or reduced oil film/viscosity are the typical causes of adhesion.

This metal-to-metal contact may result in material transfer between the surfaces, similar to that of spot

welding. When the two surfaces separate, the bonded spot breaks off and removes material from the

surfaces, causing fractures, cavities and tiny abrasive particles which are released.

Due to the cold welding process, the released particles are harder than the surfaces from which they

originate and can thus cause great damage and speed up abrasive and erosive wear. For adhesive wear to

occur it is necessary for the two surfaces to come in close, solid contact with each other, i.e. without any

carrying oil film in between. Consequently, a clean lubricating oil film is the best way to avoid or reduce the

risk of adhesion to occur.

Usually, particle contamination in the oil will not cause adhesive wear, but insufficient oil viscosity and water

in the oil will. Oil has an ability to turn “solid” in local pressure points, e.g. in rolling element bearings, thus

protecting the moving surfaces. This momentarily pressure induced viscosity increase is called elasto-

hydrodynamic lubrication. Water does not have this ability, which results in the carrying film braking and the

moving surfaces getting into contact with each other, leading to adhesive wear, i.e. “spot welding”.

This can be seen in lubrication systems with rolling element bearings, between pistons/liners or in heavy

loaded gears. Adhesive wear is seldom seen in hydraulic systems.

The influencing factors are:

- oil film thickness and viscosity

- high loads, slow speed

- gear tooth size

- surface roughness

- improper use of anti-scuff

and AW/EP additives

Photo shows adhesive wear (scuffing) on gear teeth

Description of wear, SDN, March 22, 2007 2

Corrosive wear

Corrosive wear occur when there is a combination of a wear situation (abrasive or adhesive) and a

corrosive environment.

Most lubricants get acidic over time due to the degradation/oxidation processes (catalysed by heat, water,

metal particles etc.). Water or moisture reacts with the acid in the oil to increase the corrosive potential and

further stimulate the attack on the metal surfaces. The corrosive wear results in a removal of metal, mostly in

the form of ferrous oxides, also known as rust particles. The rust particles are hard and abrasive and in

combination with other wear particles, they can expose fresh metal to further corrosion - speeding up the

process of abrasive wear.

The rate of material loss can be very high, many times more than what would result from the individual

processes of wear or corrosion alone. This is because loose corrosion particles are easily removed by wear

to continually reveal fresh metal beneath, which can corrode quickly. Likewise, stable oxide films that would

normally limit corrosion (in the absence of wear) are instantly worn away.

Typically the corrosion rate (rust) doubles for every 10 °C increase in temperature.

Corrosive wear is seen in both hydraulic and lubrication systems where moisture/water is present either due

to condensation or ingress (leaking seals, cooler etc.).

Applications prone to corrosive wear are: steam turbines, steel mills, paper mills, marine applications, water

cooled oil systems etc.

Techniques to reduce corrosion:

- oil contamination control (remove water and acid)

- use oil with corrosion inhibitors and alkalinity reserve

- choose the correct metallurgy

- use protective cathodic plating (e.g. Zinc)

Description of wear, SDN, March 22, 2007 3

Fatigue wear

Fatigue wear on components in oil systems is usually initiated by cracks and notches, which are the result

of particles being trapped and squeezed in the clearance between two surfaces (abrasive wear).

Operation of the components being lubricated with oil will cause metal stress and may lead to cracks

spreading under the surface, due to repeating load and pressure. The result is metal fatigue, meaning that

the surface will eventually fail and the structure collapse, releasing lots of particles into the oil. In this state of

fatigue wear large craters or spalls across the surface can be seen with the naked eye (see photo below).

The release of wear particles starts a chain reaction, accelerating other wear processes. Again, the most

dangerous particles are those with roughly the same size as the dynamic clearance, because they get

trapped and instigate the formation of cracks.

Fatigue wear is mostly seen in oil systems with rolling element/ball bearings, cams, rollers and gears

exposed to cyclic stress variations e.g. at pitch line of a heavy loaded wind turbine gear.

Fatigue wear can also be caused by extreme material stressing (tiredness), caused by many contractions

and expansions, e.g. due to thermal changes, but this is not typically seen on components in hydraulic and

lubricating oil systems. If the load is doubled the gear or bearing life is cut to one tenth of the design lifetime.

In order to control surface fatigue the following can be done:

- increase oil film strength (viscosity)

- reduce surface roughness

- maximize surface hardness

- avoid particle contamination

- avoid moisture/water in the oil

The photo below shows fatigue wear on wind turbine gear (severe surface pitting/grinding temper).

Description of wear, SDN, March 22, 2007 4

Erosive wear

Erosion means that the surface gets deteriorated and porous, and it is often found in oil systems with high

oil pressure and high flow velocities. The flow carries particles which impinge the component surface or

edge, causing a “sand blasting” effect. Erosion can also be caused by chemical attacks, e.g. by acids.

In the process of erosion, material is blown and washed away from the surface, leaving it very open and

fragile, as well as introducing many particles to the oil. Erosive wear most commonly occurs in hydraulic

systems with servo and proportional valves, because the fine clearances in these valves result in high oil

velocity and pressure.

The effects of erosion can be seen in lubrication and hydraulic oil systems as component leakage, lower

efficiencies and as high particle counts in the oil.

Cavitation Erosion: Cavitation can also cause erosion, when water is present in the oil (as vapour). The

pressure increase causes the vapour/bubbles to collapse - they implode. This releases very large forces (like

a microjet), which blows particles off the surface, causing surface porosity and erosion.

Machine components typically affected by erosion:

- control valves

- pumps

- actuators

- sometimes also seen on journal bearings and rolling element bearings

Erosion wear on control valve

Description of wear, SDN, March 22, 2007 5

Dynamic oil film thickness

The following shows typical dynamic oil film thickness when components are operating. It is the

contaminating particles which have the same size as the clearance or slightly bigger that are the most

dangerous ones. We should limit the ingress of these and remove as much as possible by filtration.

Oil film thickness:

Rolling element bearings / ball bearings: 0.1 – 3 microns

Journal, slide and sleeve bearings: 0.5 – 100 microns

Engines, ring/cylinder: 0.3 – 7 microns

Gears: 0.1 – 1 micron

Servo and proportional valves: 1 – 3 microns

Gear pumps: 0.5 – 5 microns

Piston pumps: 0.5 – 5 microns

Hydraulic cylinders: 5 – 50 microns

Dynamic seals: 0.05 – 0.5 micron

Description of wear, SDN, March 22, 2007 6

You might also like

- Basic Wear ModesDocument6 pagesBasic Wear ModesolguinrfNo ratings yet

- Basic Wear Modes in Lubricated SystemDocument8 pagesBasic Wear Modes in Lubricated SystemTino_No ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Gear Oil: Function of A Gear LubricantDocument2 pagesGear Oil: Function of A Gear LubricantMedha Jog KatdareNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- How Water Causes Bearing FailureDocument3 pagesHow Water Causes Bearing Failuredaniel adamNo ratings yet

- Shell Bearing Failure GuidelineDocument10 pagesShell Bearing Failure GuidelineMadhana GopalNo ratings yet

- Detect equipment issues before costly repairs with oil analysisDocument5 pagesDetect equipment issues before costly repairs with oil analysisBhushan VermaNo ratings yet

- Six Wear Modes of Hydraulic ComponentsDocument3 pagesSix Wear Modes of Hydraulic ComponentsSamNo ratings yet

- DANA Bearing DamageDocument10 pagesDANA Bearing DamageAntonio da LuzNo ratings yet

- Sleeve or Plain Bearing LubricationDocument3 pagesSleeve or Plain Bearing LubricationVolety_Sarma_1703100% (1)

- Lubrication Regimes ExplainedDocument9 pagesLubrication Regimes ExplainedSounak SasmalNo ratings yet

- Timken Conspect OmDocument4 pagesTimken Conspect OmBogdan MocanuNo ratings yet

- Bogale GearTribologyDocument6 pagesBogale GearTribologyrohithishereNo ratings yet

- STLE - Basic of WearDocument17 pagesSTLE - Basic of WearGerson NevesNo ratings yet

- MOISTURE - The Second Most Destructive Lubricant Contaminate, and Its Effects On Bearing LifeDocument4 pagesMOISTURE - The Second Most Destructive Lubricant Contaminate, and Its Effects On Bearing LifeAnonymous F2TxS3YoaNo ratings yet

- Ques - AnsDocument9 pagesQues - Ansahmed titoNo ratings yet

- Chapter 7Document6 pagesChapter 7Tamirat NemomsaNo ratings yet

- Wear Debris AnalysisDocument28 pagesWear Debris AnalysisAjmal EsNo ratings yet

- Dickson and Benson 560 Assignment TwoDocument7 pagesDickson and Benson 560 Assignment TwoDICKSON SIMUTAMINo ratings yet

- Bearing FailureDocument5 pagesBearing Failuremechmaster4uNo ratings yet

- Tribological Properties of Tin-Based Bearing Materials in Dry Sliding ConditionsDocument7 pagesTribological Properties of Tin-Based Bearing Materials in Dry Sliding ConditionsMuhammed Mohsin KhanNo ratings yet

- Failure of Rolling Contact BearingsDocument21 pagesFailure of Rolling Contact BearingsLuis NunesNo ratings yet

- 03 Lubricants PDFDocument21 pages03 Lubricants PDFrenz pepaNo ratings yet

- Mechanical Seal Failure Modes Causes and PreventionDocument9 pagesMechanical Seal Failure Modes Causes and Preventionpmdongre100% (2)

- Mechanical Seal Failure ModesDocument9 pagesMechanical Seal Failure ModesMostafa MahmoudNo ratings yet

- A Critical Review On Different Types of Wear of MaterialsDocument7 pagesA Critical Review On Different Types of Wear of MaterialsIAEME PublicationNo ratings yet

- Unit 3 - Chemistry - WWW - Rgpvnotes.inDocument16 pagesUnit 3 - Chemistry - WWW - Rgpvnotes.inN S PatidarNo ratings yet

- ENGINEERING CHEMISTRY NOTES ON LUBRICANTS AND LUBRICATIONDocument14 pagesENGINEERING CHEMISTRY NOTES ON LUBRICANTS AND LUBRICATIONMufaddal HamidNo ratings yet

- False brinelling vs fretting corrosionDocument4 pagesFalse brinelling vs fretting corrosionfalconesas100% (1)

- NITA Chemistry Department Lubricants NotesDocument11 pagesNITA Chemistry Department Lubricants Notesnikunj chauhanNo ratings yet

- Hardfacing For Valves - Materials and ProcessesDocument3 pagesHardfacing For Valves - Materials and ProcessesiJordanScribdNo ratings yet

- Maintenance AssignmentDocument11 pagesMaintenance AssignmentEliyas AdamuNo ratings yet

- Tilting Pad TroubleshootingDocument7 pagesTilting Pad Troubleshootinghamedia83No ratings yet

- Manager, Turbomachinery, Generation Group Electric Power Research Institute Palo Alto, CaliforniaDocument20 pagesManager, Turbomachinery, Generation Group Electric Power Research Institute Palo Alto, CaliforniaAhtsham Ahmad100% (1)

- Wear Debris AnalysisDocument28 pagesWear Debris AnalysisAman Kumar SaranNo ratings yet

- SEMM3622 Mat. Tech. Group 5Document13 pagesSEMM3622 Mat. Tech. Group 5Ahmed AbdelhalimNo ratings yet

- Failure MechanismsDocument14 pagesFailure Mechanismsho-faNo ratings yet

- 02 WearDocument10 pages02 WearArulselvi chockalingamNo ratings yet

- Erosive Wear Mechanisms and FactorsDocument7 pagesErosive Wear Mechanisms and FactorsTamirat NemomsaNo ratings yet

- Module 3 (1)Document22 pagesModule 3 (1)sandhrarosechackochan.b20me1136No ratings yet

- Clean Oil GuideDocument44 pagesClean Oil GuidePrashant Tripathi100% (1)

- Gas Turbine Failure Modes: A PrimerDocument8 pagesGas Turbine Failure Modes: A PrimerAditya Shiva AppallaNo ratings yet

- Adhesion Wear and AbrasiveDocument28 pagesAdhesion Wear and AbrasiveSanjay Shelar100% (1)

- Mechanical Seal Troubleshooting GuideDocument10 pagesMechanical Seal Troubleshooting Guideempswook100% (2)

- Lu Bri CtionDocument5 pagesLu Bri Ctionme1901932No ratings yet

- Industrial Safety Engineering Module 3Document11 pagesIndustrial Safety Engineering Module 3rv4930976No ratings yet

- Oil OxidationDocument36 pagesOil OxidationdaudiNo ratings yet

- Marine TribologyDocument79 pagesMarine TribologyRam GovindasamyNo ratings yet

- G Damage ChainsDocument17 pagesG Damage ChainsLicitatie CitatiebNo ratings yet

- Automatic and Manual GreasingDocument10 pagesAutomatic and Manual GreasingAhmed SalahNo ratings yet

- ReviewofWearandGallingCharacteristicsofStainlessSteel 9006Document0 pagesReviewofWearandGallingCharacteristicsofStainlessSteel 9006fahreezNo ratings yet

- Module 3Document27 pagesModule 3Aditya ranjan BubunNo ratings yet

- Engine Bearing Failures and How To Avoid Them PDFDocument8 pagesEngine Bearing Failures and How To Avoid Them PDFCarlos RamirezNo ratings yet

- Engineering Tribology: Prof. Dr. Tamer S. MahmoudDocument44 pagesEngineering Tribology: Prof. Dr. Tamer S. MahmoudbassemNo ratings yet

- Introduction To Wear: Surface Damage Removal of MaterialDocument33 pagesIntroduction To Wear: Surface Damage Removal of MaterialSelvamuthu KumaranNo ratings yet

- Equip PDFDocument1 pageEquip PDFanujNo ratings yet

- Corrosion-Surface DamageDocument29 pagesCorrosion-Surface DamageGcwalisile DlaminiNo ratings yet

- How Gears Fail: Types of Gear FailuresDocument4 pagesHow Gears Fail: Types of Gear FailuressadeghiNo ratings yet

- Pergamon: Engineering Failure Analysis, Vol. 3, No. 3, Pp. 219-225, 1996Document7 pagesPergamon: Engineering Failure Analysis, Vol. 3, No. 3, Pp. 219-225, 1996sadeghiNo ratings yet

- Adhesive Wear PDFDocument23 pagesAdhesive Wear PDFGhaith MohmdNo ratings yet

- Bending Fatigue Failure in Gear Tooth IJERTV2IS60387 PDFDocument8 pagesBending Fatigue Failure in Gear Tooth IJERTV2IS60387 PDFsabaris ksNo ratings yet

- What Is Wear?: Written By: Steffen D. Nyman, Education Coordinator, C.C.JENSEN A/SDocument6 pagesWhat Is Wear?: Written By: Steffen D. Nyman, Education Coordinator, C.C.JENSEN A/SsadeghiNo ratings yet

- The Influence of Contact Stress Distribution and SDocument11 pagesThe Influence of Contact Stress Distribution and SsadeghiNo ratings yet

- How Gears Fail: Types of Gear FailuresDocument4 pagesHow Gears Fail: Types of Gear FailuressadeghiNo ratings yet

- Journal of Materials Processing TechnologyDocument12 pagesJournal of Materials Processing TechnologysadeghiNo ratings yet

- Pergamon: Engineering Failure Analysis, Vol. 3, No. 3, Pp. 219-225, 1996Document7 pagesPergamon: Engineering Failure Analysis, Vol. 3, No. 3, Pp. 219-225, 1996sadeghiNo ratings yet

- Systematic Analysis of Gear Failures PDFDocument241 pagesSystematic Analysis of Gear Failures PDFtheerapat patkaew100% (1)

- Adhesive Wear PDFDocument23 pagesAdhesive Wear PDFGhaith MohmdNo ratings yet

- Bending Fatigue Failure in Gear Tooth IJERTV2IS60387 PDFDocument8 pagesBending Fatigue Failure in Gear Tooth IJERTV2IS60387 PDFsabaris ksNo ratings yet

- Bending Fatigue Failure in Gear Tooth IJERTV2IS60387 PDFDocument8 pagesBending Fatigue Failure in Gear Tooth IJERTV2IS60387 PDFsabaris ksNo ratings yet

- PAPD Cable glands for hazardous areasDocument2 pagesPAPD Cable glands for hazardous areasGulf Trans PowerNo ratings yet

- CW18 PDFDocument2 pagesCW18 PDFjbsb2No ratings yet

- NEM Report - IntroDocument11 pagesNEM Report - IntroRoshni PatelNo ratings yet

- TCS L6 ActsDocument7 pagesTCS L6 ActsBhebz Erin MaeNo ratings yet

- I. VHF CommunicationsDocument12 pagesI. VHF CommunicationsSamuel OyelowoNo ratings yet

- Basavarajeshwari Group of Institutions: Self Balancing UnicycleDocument15 pagesBasavarajeshwari Group of Institutions: Self Balancing UnicycleJeerigi DeepikaNo ratings yet

- LMV Tyre SafetyDocument19 pagesLMV Tyre SafetykarvadNo ratings yet

- 2016 Annual Report - Printer-ReadyDocument35 pages2016 Annual Report - Printer-ReadyDonna BrodberNo ratings yet

- Eriopon R LiqDocument4 pagesEriopon R LiqsaskoNo ratings yet

- Owner'S Manual: Dell Poweredge T110 Ii SystemsDocument130 pagesOwner'S Manual: Dell Poweredge T110 Ii SystemsDonNo ratings yet

- Recommended Immunization - Canadian Immunization Guide - Seventh Edition - 2006Document2 pagesRecommended Immunization - Canadian Immunization Guide - Seventh Edition - 2006Maja MudriNo ratings yet

- Michigan English TestDocument22 pagesMichigan English TestLuisFelipeMartínezHerediaNo ratings yet

- Republic OF THE Philippines Department OF Budget AND Manageme 589 May 25, 2022Document14 pagesRepublic OF THE Philippines Department OF Budget AND Manageme 589 May 25, 2022Juvy BustamanteNo ratings yet

- Boutique HotelsDocument61 pagesBoutique Hotelsnour alkhateeb100% (1)

- JuliadatascienceDocument214 pagesJuliadatascienceFulvio JoséNo ratings yet

- Ritual and Religion Course at University of EdinburghDocument10 pagesRitual and Religion Course at University of EdinburghRenata DC MenezesNo ratings yet

- Importance of Plants in Our LivesDocument47 pagesImportance of Plants in Our LivesAlanie Grace Beron TrigoNo ratings yet

- LabVIEW Based EIT System TKBera IIScDocument6 pagesLabVIEW Based EIT System TKBera IISclatecNo ratings yet

- Program Pakan Budidaya Lele: Farm Pond Code AREA (m2) Stocking Date Stocking Amount DensityDocument6 pagesProgram Pakan Budidaya Lele: Farm Pond Code AREA (m2) Stocking Date Stocking Amount DensityChevienrenaldy SamsuNo ratings yet

- Google Book Search project makes public domain texts discoverable onlineDocument456 pagesGoogle Book Search project makes public domain texts discoverable onlineVladoMihojevićNo ratings yet

- Holes Human Anatomy and Physiology 12Th Edition Shier Test Bank Full Chapter PDFDocument53 pagesHoles Human Anatomy and Physiology 12Th Edition Shier Test Bank Full Chapter PDFJakeOwensbnpm100% (9)

- Lesson 1 G8Document11 pagesLesson 1 G8Malorie Dela CruzNo ratings yet

- MTA powerVAL Technical Data Sheet v00Document1 pageMTA powerVAL Technical Data Sheet v00muhammetNo ratings yet

- Week 1-12 strength and conditioning programDocument6 pagesWeek 1-12 strength and conditioning programBrian Michael CarrollNo ratings yet

- Class of 2016 Graduate ListsDocument16 pagesClass of 2016 Graduate ListscallertimesNo ratings yet

- Early strength predicts long-term performance of asphalt cold mixesDocument7 pagesEarly strength predicts long-term performance of asphalt cold mixesMonu GhadwalNo ratings yet

- 2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Document96 pages2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Aroob YaseenNo ratings yet

- 202-Nido 2024Document27 pages202-Nido 2024tabhonor69No ratings yet

- AMS 2750 E Heat Treatment Standards ComplianceDocument3 pagesAMS 2750 E Heat Treatment Standards ComplianceQualidadeTFNo ratings yet

- Coding deCoding class insightsDocument18 pagesCoding deCoding class insightsShalabh Vikram SahuNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)