Professional Documents

Culture Documents

Overhead Transmission Line Coductors:: Power Transmission Lab Manual Lab # 01

Uploaded by

Awais SarfrazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhead Transmission Line Coductors:: Power Transmission Lab Manual Lab # 01

Uploaded by

Awais SarfrazCopyright:

Available Formats

Power Transmission Lab Manual Lab # 01

OVERHEAD TRANSMISSION LINE CODUCTORS:

Most famous types of Materials used for the overhead line Conductors are:

Copper conductor:

Copper is the most famous Material used for Overhead Transmission Line

Conductor.

It is Hard Material.

It is low resistance.

There is no Coating required.

Conductivity is very high.

Mechanical or Tensile Strength is very high so very suitable for Long Span.

Its cost is very high.

Aluminum conductor:

Aluminum is the second best Conductor.

Its conductivity is less as compared to Copper.

It is not hard, so a soft type Material it is.

Its Cost is very low as compared to Copper.

Mechanical or Tensile Strength is very low because of Softness so it is not

suitable for Long Span.

Steel:

Steel has a very low Conductivity.

It is not used as a transmission line conductor.

It is used to increase the Tensile Strength of Aluminum.

It can get rusted. So its toughness reduces as the time passes on.

It is used to strengthen the Aluminum Conductor. To provide hardness to

Aluminum Conductor so that it will be suitable for Long Span.

Aluminum alloy conductor:

It is an alloy of Aluminum and steel.

Steel can get rusted with time.

Alumo weld conductor (AW):

The Alumoweld process consists of a continuous application of a pure atomized

aluminum powder to a high strength steel rod, without changing original

proportions of aluminum and steel.

When compared to solid aluminum wire, Alumoweld offers tremendous savings

because it has the toughness of steel and conductivity of Aluminum.

Hafiz Muhammad Awais 12-EE-67 Section – C1

Power Transmission Lab Manual Lab # 01

Alumoweld wire has excellent corrosion resistance. Its strength and conductivity

remain unchanged in any atmosphere.

Its Strength is Comparable to Steel.

Copper weld conductor (CW):

Copper weld wire and strand combines the electrical characteristics of copper

with the mechanical properties of high strength and extra high strength steel.

The combination of conductivity, corrosion resistance and high strength are the

foundation of this protection.

Types According to Construction:

Conductors can also be classified according to the type of their Construction:

Solid conductors:

They are not actually used for overhead transmission lines.

The physical reason is the its Manufacturing, Holding, Transportation, Installation

Is very difficult and highly expensive.

The technical Reason is that because of the skin effect, effective resistance

increase due to flow of current only on the surface. But in DC system it is not a

problem.

Hollow conductors:

As their name suggests, they are hallow from inside.

They are very used very less.

They are suitable at high frequency.

Generally they have air inside them or often water flows inside.

Stranded conductors:

The group of conductors having small diameter with respective solid conductors

are known as stranded conductors.

Al has the property of conductivity so outside layer is made of it and steel has the

property of high tensile strength so it is at inside layer.

Disadvantages of Solid Conductor are benefits of Stranded Conductors.

Stranded and reinforced Conductors:

Aluminum conductor steel-reinforced (ACSR) is a specific type of high-capacity,

high-strength stranded conductor typically used in overhead power lines.

The outer strands are high-purity aluminum alloy, chosen for its excellent

conductivity, low weight and low cost. The center strands are of steel for the

Hafiz Muhammad Awais 12-EE-67 Section – C1

Power Transmission Lab Manual Lab # 01

strength required to support the weight without stretching the aluminum due to

its ductility.

It has three more types:

Aluminum conductor steel reinforced (ACSR)

ACSR/AW

Aluminum Alloy conductor steel reinforced (AACSR)

Homogenous Conductors:

Homogenous Conductors are those in which individual material cannot be seen. There are three

types of Homogenous Conductors. There are odd number of strands used in these.

Hard Drawn Copper:

These are the conductors with Pure Copper. There is no mixing in them.

All Aluminum Conductors:

There is no mixing of steel in these.

Aluminum Alloy Conductors :

There are odd number of strands used in these.

Number of Strands are multiples of increased by multiples of six.

Number of strand sequence is 1,7,19,……

All Strand’s Diameter is same.

Non – Homogenous Conductors:

Homogenous Conductors are those in which individual material can be seen easily. There are

three types of Homogenous Conductors.

There are even number of Strands used. Because central strand is missing due to aluminum

Layer outside. The Steel is at the center.

ACSR:

Diameter of Strands of Aluminum and steel may be same or may be different.

Like in Table Horse has same Diameter but Dog has different.

ACSR/AW:

ACSR/CW:

TABLES:

Hafiz Muhammad Awais 12-EE-67 Section – C1

Power Transmission Lab Manual Lab # 01

All Aluminum conductors:-

(BS 215:part1)

Code Area Dia. Of Over all Weight Resistance Current

(mm 2) wires(No./mm) Dia.(mm) (Kg/Km) (Ω/Km) Rating(A)

Ant 50 7/3.10 9.30 145 0.5419 175

Fly 60 7/3.40 10.20 174 0.4505 196

Cockroach 250 19/4.22 21.0 731 0.1083 471

Ant 300 19/4.65 23.25 888 0.08916 530

ACSR

Code No. of wires Al. Steel Weight At 200 C Current

(No./mm) (Area) Area (Kg/km) (Ω/Km) Ratting

Al Cu (mm 2) (mm 2) (A)

Rabbit 6/3.35 1/3.35 52.88 8.82 214 0.5426 178

Horse 12/2.79 7/2.79 73.77 42.83 538 0.3936 225

Dog 6/4.72 7/1.51 105 13.5 394 0.2733 271

Zebra 54/3.13 7/3.18 428.9 55.6 1621 0.0674 636

Comparison of conductor material:-

Description Annealed Hard Drawn Hard Drawn Al. Alloy

Copper Copper (Al)

Conductivity 100 97 61 53.5

(%)

Resistance at 200 C(Ω-m 17.241 17.71 28.264 32.2

m 2/km)

Ρ at 200 C (Gram/cm3) 8.89 8.89 2.703 2.703

Weight(Kg/cm3) 11562 11562 3516 3516

Ultimate Tensile 225 420 165 300

Strength

Hafiz Muhammad Awais 12-EE-67 Section – C1

You might also like

- Types of Overhead Line ConductorDocument7 pagesTypes of Overhead Line ConductorMuhammad MudassarNo ratings yet

- FPSC Assistant Executive Engineer (Electrical) Test PreparationDocument12 pagesFPSC Assistant Executive Engineer (Electrical) Test PreparationMustafa ShaykhNo ratings yet

- Design of crash barrier with reinforced concreteDocument1 pageDesign of crash barrier with reinforced concreteAnkush SharmaNo ratings yet

- Seismic Design of Retaining WallsDocument23 pagesSeismic Design of Retaining WallsRutvik ShethNo ratings yet

- BG2 2010 Commissioning Water SystemsDocument87 pagesBG2 2010 Commissioning Water SystemsFinlayNo ratings yet

- IEEE TP&C Winter Meeting Albuquerque, NM: Bare Overhead Transmission Conductors, Selection and ApplicationDocument25 pagesIEEE TP&C Winter Meeting Albuquerque, NM: Bare Overhead Transmission Conductors, Selection and Applicationsiva0108100% (1)

- NSW Annual Seminar - Metals for BusbarsDocument19 pagesNSW Annual Seminar - Metals for BusbarsYuttapong SupattaravongNo ratings yet

- JNC Cables PDFDocument30 pagesJNC Cables PDFVasudev AgrawalNo ratings yet

- UK ATEX IECEx Sensor CatalogueDocument26 pagesUK ATEX IECEx Sensor Cataloguedj22500No ratings yet

- Transpowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-StrandedDocument18 pagesTranspowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-Strandedravi474No ratings yet

- Overhead ConductorsDocument46 pagesOverhead Conductorsمحمد كهرباءNo ratings yet

- RR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction OrificeDocument16 pagesRR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction Orificemohsen ranjbar100% (1)

- Conductor Design & BehaviourDocument93 pagesConductor Design & BehaviourSubodh SontakkeNo ratings yet

- Moose - Camel - Elk - Zebra - Deer - Jaguar Bare ACSR Conductor - China Acsr, Moose Acsr ConductorDocument4 pagesMoose - Camel - Elk - Zebra - Deer - Jaguar Bare ACSR Conductor - China Acsr, Moose Acsr ConductorumamaheshwarraoNo ratings yet

- Composite Overhead ConductorsDocument21 pagesComposite Overhead ConductorsEnrique Garcia100% (1)

- Dosya554386 310656Document46 pagesDosya554386 310656gvsbabu63No ratings yet

- Mechanical Design of Overhead Lines PDFDocument70 pagesMechanical Design of Overhead Lines PDFEng-Ahmad Abo-AledousNo ratings yet

- Southwire Transmission ConductorsDocument11 pagesSouthwire Transmission Conductorsanon_446006458No ratings yet

- HTLS (HPC) IEEMA Seminar BrianWareingDocument69 pagesHTLS (HPC) IEEMA Seminar BrianWareingJose ValdiviesoNo ratings yet

- Merits and Demerits of Various ConductorDocument13 pagesMerits and Demerits of Various ConductorSumit100% (6)

- Aluminium Uses in Electrical EngineeringDocument7 pagesAluminium Uses in Electrical EngineeringTigrilloNo ratings yet

- Roof TrussesDocument20 pagesRoof Trussesalexmihai00100% (1)

- AAAC Advantages Over ACSRDocument2 pagesAAAC Advantages Over ACSRVivek KumarNo ratings yet

- How Hot Water Heater WorksDocument71 pagesHow Hot Water Heater Worksjunlab0807100% (1)

- Aluminum Copper Cable CompareDocument4 pagesAluminum Copper Cable Comparesaronnolu100% (1)

- Unit-I Transmission Line Parameters: Conductor MaterialsDocument53 pagesUnit-I Transmission Line Parameters: Conductor Materialsirshad224No ratings yet

- AluminumPresentationIEEE (CompatibilityMode)Document31 pagesAluminumPresentationIEEE (CompatibilityMode)A. HassanNo ratings yet

- Acsr Astm B Aluminium Conductor Steel Reinforced PDFDocument10 pagesAcsr Astm B Aluminium Conductor Steel Reinforced PDFyetignrNo ratings yet

- Acsr SpecsDocument1 pageAcsr SpecsPanda NoirNo ratings yet

- Electric Utility Overhead Conductors TransPowr® ACSR Bare Overhead Conductor (Canada)Document9 pagesElectric Utility Overhead Conductors TransPowr® ACSR Bare Overhead Conductor (Canada)asirprakashNo ratings yet

- Messenger: S2 Covered ConductorsDocument1 pageMessenger: S2 Covered Conductorsjorge_moralesmNo ratings yet

- Types of Conductors Used in Overhead Power Lines: Conductor MaterialsDocument4 pagesTypes of Conductors Used in Overhead Power Lines: Conductor MaterialsrameshNo ratings yet

- ConductorsDocument18 pagesConductorsCBNo ratings yet

- Motion-Resistant Conductor: ApplicationsDocument2 pagesMotion-Resistant Conductor: ApplicationsZdravko VidakovicNo ratings yet

- History: Why Aluminium?Document5 pagesHistory: Why Aluminium?electrical zuhairNo ratings yet

- TS PHIIR Part4Document104 pagesTS PHIIR Part4purechemcabledeptNo ratings yet

- EEE Types of Transmission Line Conductors and InsulatorsDocument20 pagesEEE Types of Transmission Line Conductors and Insulatorssk.karimeeeNo ratings yet

- Transmission Line ConductorsDocument18 pagesTransmission Line ConductorsSukhwinder SinghNo ratings yet

- Aluminium ConductorsDocument2 pagesAluminium ConductorsNgô Tiến PhúNo ratings yet

- TransPowr® ACSS-TW Bare Overhead Conductor (US)Document5 pagesTransPowr® ACSS-TW Bare Overhead Conductor (US)JOGmzNo ratings yet

- Transmission Line ConstantsDocument10 pagesTransmission Line ConstantsSiddhantSolankiNo ratings yet

- ZMS Cable CatalogDocument28 pagesZMS Cable Catalogenghassanain6486No ratings yet

- SEC4 Overhead Conductors PDFDocument106 pagesSEC4 Overhead Conductors PDFKy TaNo ratings yet

- What Are Aluminium Conductors Used For?Document2 pagesWhat Are Aluminium Conductors Used For?yogacruiseNo ratings yet

- ConductoresDocument14 pagesConductoresRobinsonavenNo ratings yet

- ACSS/AW Aluminum Conductor Specs and ApplicationsDocument3 pagesACSS/AW Aluminum Conductor Specs and Applicationsharoldc4No ratings yet

- Acss TWDocument5 pagesAcss TWharoldc4No ratings yet

- 29 File 20201104-111337 Bare-Conductor PDFDocument31 pages29 File 20201104-111337 Bare-Conductor PDFAfrizal RivaNo ratings yet

- Copper vs. Aluminum ConductorDocument2 pagesCopper vs. Aluminum ConductorQatadaNo ratings yet

- Technical Specification of 55Sqmm 100Sqmm AAACDocument14 pagesTechnical Specification of 55Sqmm 100Sqmm AAACMurtuzaNo ratings yet

- Gci AcssDocument12 pagesGci AcssMohit Chowdary NNo ratings yet

- Substation Industrial VisitDocument20 pagesSubstation Industrial VisitSsrk ScientistNo ratings yet

- Over-Head Conductors IN Transmission LineDocument33 pagesOver-Head Conductors IN Transmission LineSubhashree SahuNo ratings yet

- HCC PDFDocument24 pagesHCC PDFmark mywordNo ratings yet

- Mechanical Design of Overhead Lines Lec 01Document5 pagesMechanical Design of Overhead Lines Lec 01Samdany HossainNo ratings yet

- TL ConductorsDocument15 pagesTL Conductorsj3oNo ratings yet

- What Is Acsr Cable? Ans:: Why Aluminium Is Used To Make Overhead Power Cables? AnsDocument2 pagesWhat Is Acsr Cable? Ans:: Why Aluminium Is Used To Make Overhead Power Cables? AnsMehran Ud DinNo ratings yet

- Report 3: Name: Zeina Mohamed ID: 1170273Document6 pagesReport 3: Name: Zeina Mohamed ID: 1170273Zeina El RamelyNo ratings yet

- Power Cables & Wires Technical ManualDocument163 pagesPower Cables & Wires Technical Manualbharatsehgal00@gmail.comNo ratings yet

- BEEE304L - PSE - Module - 5 - L1 - Line Supports and ConductorsDocument15 pagesBEEE304L - PSE - Module - 5 - L1 - Line Supports and ConductorsRahul ganthNo ratings yet

- TRACO ReportDocument11 pagesTRACO ReportKinginiKingini100% (1)

- Aluminum Vs COPPERDocument4 pagesAluminum Vs COPPERTapi SkNo ratings yet

- Aerial Catalog 2 - 8 Alumoweld PDFDocument1 pageAerial Catalog 2 - 8 Alumoweld PDFsb_al20No ratings yet

- Southwire Bare Acsr AwDocument3 pagesSouthwire Bare Acsr Awgari_monsantoNo ratings yet

- ConductorsDocument2 pagesConductorsBalaji NaikNo ratings yet

- Conductors Used For Transmitting Electric PowerDocument52 pagesConductors Used For Transmitting Electric PowerNaresh GollapalliNo ratings yet

- Series-Parallel CircuitsDocument3 pagesSeries-Parallel CircuitsAwais SarfrazNo ratings yet

- Transistor Tuned AmplifiersDocument2 pagesTransistor Tuned AmplifiersAwais SarfrazNo ratings yet

- Passive FiltersDocument3 pagesPassive FiltersAwais SarfrazNo ratings yet

- Passive FiltersDocument3 pagesPassive FiltersAwais SarfrazNo ratings yet

- Transistor Tuned AmplifiersDocument2 pagesTransistor Tuned AmplifiersAwais SarfrazNo ratings yet

- NTDCL Test 2018Document12 pagesNTDCL Test 2018Engr Saeed Khan100% (1)

- Electrical Machines (Induction Motor)Document5 pagesElectrical Machines (Induction Motor)Faizan MateenNo ratings yet

- Lab Title: Apparatus:: Testing of Power Cables SampleDocument8 pagesLab Title: Apparatus:: Testing of Power Cables SampleAwais SarfrazNo ratings yet

- Course Objectives:: Power Transmission Lab Manual Lab # 01Document2 pagesCourse Objectives:: Power Transmission Lab Manual Lab # 01Awais SarfrazNo ratings yet

- Item 346 Block Valve - 3 SectionsDocument2 pagesItem 346 Block Valve - 3 SectionsAlexDorNo ratings yet

- ADVANCEDBeam ManualCompositeDocument28 pagesADVANCEDBeam ManualCompositeAmir ShaikNo ratings yet

- York Rooftop PDFDocument124 pagesYork Rooftop PDFitovarsilva100% (1)

- Ficha SprinkersDocument4 pagesFicha SprinkersMaestrycous KairosNo ratings yet

- PAC-IF013B-E Installation Operation Manual RG79F030H04Document24 pagesPAC-IF013B-E Installation Operation Manual RG79F030H04S KNo ratings yet

- Investigation of Seismic Behavior of Steel Coupling Beams in Hybrid Coupled StructuresDocument9 pagesInvestigation of Seismic Behavior of Steel Coupling Beams in Hybrid Coupled StructuresSinem Kocabaş ŞirikçiNo ratings yet

- Article Floating Roof Design Volume Emissions MaintenanceDocument3 pagesArticle Floating Roof Design Volume Emissions MaintenanceSara NunesNo ratings yet

- TenCate Polyfelt TS TechnicalData en 502644 Tcm28-36720Document2 pagesTenCate Polyfelt TS TechnicalData en 502644 Tcm28-36720james_frankNo ratings yet

- DBB BNCPP B M v29 0015 Revb IfaDocument6 pagesDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990No ratings yet

- Chapter 8 - Interior FinishesDocument6 pagesChapter 8 - Interior FinishesPODNo ratings yet

- Nycolube 127 TDSDocument1 pageNycolube 127 TDSpokleNo ratings yet

- Shore D Hardness Test (Durometer Scale) - Hardness of Plastic MaterialsDocument3 pagesShore D Hardness Test (Durometer Scale) - Hardness of Plastic MaterialsValentin0% (1)

- Building Services Piping: ASME B31.9-2020Document5 pagesBuilding Services Piping: ASME B31.9-2020ammarashraf91No ratings yet

- Optimizing PVC Pipes Using Mixture DesignDocument8 pagesOptimizing PVC Pipes Using Mixture DesignKaleem UllahNo ratings yet

- DEVELOPMENT OF PERFORMANCE GRADED BINDER SELECTION METHOD FOR AIRPORT PAVEMENTSDocument17 pagesDEVELOPMENT OF PERFORMANCE GRADED BINDER SELECTION METHOD FOR AIRPORT PAVEMENTSprathabvNo ratings yet

- 3.SS Braided Epdm HoseDocument2 pages3.SS Braided Epdm HoseKhaled Al AkhdarNo ratings yet

- Ball Valves KH ParkerDocument7 pagesBall Valves KH Parkerkocho79No ratings yet

- JJ - Assessment of Some Physical and Mechanical Properties of Different Flexible Packaging Films For Packaging of Tamarind (Tamarindus Indica L.) Pulp BriquettesDocument5 pagesJJ - Assessment of Some Physical and Mechanical Properties of Different Flexible Packaging Films For Packaging of Tamarind (Tamarindus Indica L.) Pulp BriquettesArif RahmadhiNo ratings yet

- Materials 13 04110Document23 pagesMaterials 13 04110Boy AlfredoNo ratings yet

- Cable TrunkingDocument5 pagesCable TrunkingLeo GeeNo ratings yet

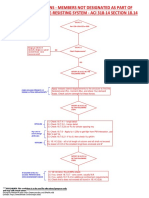

- Concrete Columns - Members Not Designated As Part of The Seismic-Force-Resisting System - Aci 318-14 Section 18.14Document2 pagesConcrete Columns - Members Not Designated As Part of The Seismic-Force-Resisting System - Aci 318-14 Section 18.14stephanie madridNo ratings yet

- Budget Household Elect WiringDocument1 pageBudget Household Elect WiringFroilan MatutinoNo ratings yet

- Repair of Pile Cap Foundations Using Strut and Tie ModelsDocument8 pagesRepair of Pile Cap Foundations Using Strut and Tie ModelsMyat NoeNo ratings yet