Professional Documents

Culture Documents

Appendix A-2 Monthly Checklist

Appendix A-2 Monthly Checklist

Uploaded by

Fakhreddine Ezzahi0 ratings0% found this document useful (0 votes)

2 views2 pagesOriginal Title

Appendix a-2 Monthly Checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views2 pagesAppendix A-2 Monthly Checklist

Appendix A-2 Monthly Checklist

Uploaded by

Fakhreddine EzzahiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

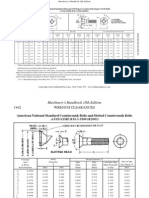

APPENDIX A-2: SAMPLE FORM FOR MONTHLY UNDERGROUND STORAGE SYSTEM INSPECTION CHECKLIST – Page 1

Go to www.pei.org/RP900 for an electronic version of this form.

MONTHLY UST SYSTEM INSPECTION CHECKLIST

Facility ID# Facility Name/Address Level II Qualified Person Signature Date

If any problem is found, contact: Contact information:

Category Description PEI/RP900 N/A Tank 1 Tank 2 Tank 3 Tank 4

Operator Training Review site training documents 7.4

Complete daily checklist and compare to previously completed daily

Daily Inspections 7.5.1

checklists

Leak Detection Circle method of tank leak detection: ATG, CIM, SIR, IC, GWM, SVM, MIMT

7.6

Recordkeeping Circle method of piping leak detection: CIM, MPLT, SIR, GWM, SVM, MIMP

Automatic Tank Gauge (ATG) Passing tank test report printed and properly filed 7.6.1.1

Continuous Interstitial Monitoring

Sensor status report printed and properly filed 7.6.2.1

(CIM)

Monthly Piping Leak Test (MPLT) Passing piping leak test report printed/documented and properly filed 7.6.3.1

Statistical Inventory

Last month’s SIR results passed and available for inspection 7.6.4.1

Reconciliation (SIR)

Inventory Control (IC) Inventory reconciled and within the company or regulatory standard 7.6.5.1

Manual Groundwater Monitoring

Groundwater bailer in good condition 7.6.6.1

(GWM)

Manual Groundwater (GWM) or

Wells sampled and results pass 7.6.6.2

Soil Vapor Monitoring (SVM)

Steel tank: interstitial space checked and found dry 7.6.7.1

Fiberglass tank: interstitial space checked and found dry 7.6.7.2

Manual Interstitial Monitoring

for Tanks (MIMT) Fiberglass tank: level of monitoring fluid within normal range 7.6.7.3

For steel and fiberglass tanks, vacuum level is within tolerances

7.6.7.4

Tnk 1 vac: Tnk 2 vac: Tnk 3 vac: Tnk 4 vac:

Manual Interstitial Monitoring Containment sump (STP and/or remote fill sump) inspected and no liquid

7.6.8.1

for Piping (MIMP) found

All Tanks 7.7

Spill Kit All components of the spill kit are present and in good condition 7.7.1

Grade-Level Covers All covers present, in good condition, seated firmly on the correct tank 7.7.2.1

Drain valve in spill containment manhole in good condition 7.7.3.1

Spill Containment Manhole

Interstitial space of double-walled containment manhole is dry 7.7.3.2

APPENDIX A-2: SAMPLE FORM FOR MONTHLY UNDERGROUND STORAGE SYSTEM INSPECTION CHECKLIST – Page 2

Go to www.pei.org/RP900 for an electronic version of this form.

Category Description PEI/RP900 N/A Tank 1 Tank 2 Tank 3 Tank 4

Standard drop tube smooth, no ragged edges, in good condition 7.7.4.1

Drop Tube Top edge of coaxial drop tube smooth, round, slightly below the top edge

7.7.4.2

of the fill pipe

Tank Gauge Stick Tank gauge stick can be clearly read, is not warped or broken 7.7.5.1

Check for Water No water present in the tank 7.7.6.1

Tank Vents Vent cap present, vent pipe solidly supported and vertical 7.7.7.1

Stage I Vapor Recovery 7.8

Cover present, colored orange, seated firmly at grade, not broken,

7.8.1.1

cracked or chipped

If spill containment manhole is present, no dirt, trash, water or product 7.8.1.2

Two-Point (Dual-Point)

Vapor Recovery If spill containment manhole is present, no cracks, bulges or holes 7.8.1.3

Vapor recovery cap in good condition, seals tightly 7.8.1.4

Poppet of vapor recovery adaptor seals tightly 7.8.1.5

Observation and Monitoring Wells 7.9

Observation well cover is properly identified and secured 7.9.1.1

Corrosion Protection 7.10

Record volt and amp readings, readings consistent with previous months 7.10.1.1

Impressed-Current

Cathodic Protection Record hour meter reading (if present); Reading increases by about 700 7.10.1.2

hours each month

Unmonitored Dispensers and Submersible Turbine Pumps (STPs) 7.11

Unmonitored Dispensers All dispenser components are clean and dry 7.11.1

Unmonitored STPs No fuel detected in STP access manhole 7.11.2

DESCRIBE ANY DEFICIENCIES HERE:

Instructions: Mark each tank where no problem is observed with a checkmark: √ If certain equipment is not required and / or not present, mark checklist in the N/A

column. If a defect is found, mark the checklist with an “X,” describe the problem in the “DEFICIENCIES” section, and notify the appropriate person. Refer to the

section listed in the “PEI/RP900” column for additional information. Refer to PEI RP500, Recommended Practices for Inspection and Maintenance of Motor Fuel

Dispensing Equipment, for inspection procedures that apply to fuel dispensing equipment.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fortive Corp CCPA Public Facing Privacy NoticeDocument9 pagesFortive Corp CCPA Public Facing Privacy NoticeFakhreddine EzzahiNo ratings yet

- 577013-727 - PLLD - WPLLD Alarm Quick HelpDocument20 pages577013-727 - PLLD - WPLLD Alarm Quick HelpFakhreddine EzzahiNo ratings yet

- VAPT7.E37780 - Solenoids For Use in Hazardous Locations Certified For Canada - UL Product IqDocument2 pagesVAPT7.E37780 - Solenoids For Use in Hazardous Locations Certified For Canada - UL Product IqFakhreddine EzzahiNo ratings yet

- Useful Information On Pump Shaft SealsDocument9 pagesUseful Information On Pump Shaft SealsFakhreddine EzzahiNo ratings yet

- 4.7 IELTS Task 1 TipsDocument3 pages4.7 IELTS Task 1 TipsFakhreddine EzzahiNo ratings yet

- Sr. Cost Code Boq No. Unit Description of Materials As Per Drawings Spec. Material AKZ QTY As Per IFC QTY As Per RFI Response 31/10/2020Document5 pagesSr. Cost Code Boq No. Unit Description of Materials As Per Drawings Spec. Material AKZ QTY As Per IFC QTY As Per RFI Response 31/10/2020Fakhreddine EzzahiNo ratings yet

- Wire Bending MachineDocument6 pagesWire Bending MachineFakher AlrashidNo ratings yet

- 'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTDocument150 pages'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTraul carvajal rozasNo ratings yet

- 9bf1l5c0 Bomba Goulds 3656s Bronze FittedDocument3 pages9bf1l5c0 Bomba Goulds 3656s Bronze FittedElmer RafaelNo ratings yet

- 3-1/2", 12.95#, S135, PH6, R2: Tubing Specification SheetDocument1 page3-1/2", 12.95#, S135, PH6, R2: Tubing Specification SheetMuhammad ImranNo ratings yet

- Crib InstructionsDocument7 pagesCrib InstructionsLynne GomesNo ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- 19 Screw CompressorDocument12 pages19 Screw CompressorNhân NgọcNo ratings yet

- Pure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)Document2 pagesPure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)sandeep sehrawatNo ratings yet

- Honda Bf50dDocument167 pagesHonda Bf50dAbd OuNo ratings yet

- Pneumatic Zig Zag LiftDocument2 pagesPneumatic Zig Zag Liftfahamith ahamedNo ratings yet

- Forces and Friction Investigation LabDocument11 pagesForces and Friction Investigation LabMichael Mohamed75% (4)

- Simple Machine: Mechanical AdvantageDocument4 pagesSimple Machine: Mechanical AdvantageTrisson HarteNo ratings yet

- Engineering Encyclopedia: Shell and Tube Process CalculationsDocument75 pagesEngineering Encyclopedia: Shell and Tube Process CalculationsLogeswaran AppaduraiNo ratings yet

- Du412i Specification EnglishDocument4 pagesDu412i Specification EnglishFelipeDeejayValenzuelaNo ratings yet

- Form 5 Phy MR Theva 25.05.2023Document29 pagesForm 5 Phy MR Theva 25.05.2023LittleDavieGNo ratings yet

- Ur110 (L5)Document70 pagesUr110 (L5)J CordovaNo ratings yet

- EN 2 1 Spec Withoutrail Rev16 2018 12 18Document10 pagesEN 2 1 Spec Withoutrail Rev16 2018 12 18deni jakaNo ratings yet

- A Guide To Practical Machine GuardingDocument31 pagesA Guide To Practical Machine GuardingKrishnarajNo ratings yet

- Worksheet Q2 Week 7Document3 pagesWorksheet Q2 Week 7Jaybie TejadaNo ratings yet

- Water - Dynamic and Kinematic ViscosityDocument14 pagesWater - Dynamic and Kinematic ViscosityNguyễn Văn MinhNo ratings yet

- Edexcel GCE: 6677 Mechanics M1 (New Syllabus) Advanced/Advanced SubsidiaryDocument7 pagesEdexcel GCE: 6677 Mechanics M1 (New Syllabus) Advanced/Advanced SubsidiaryLalith77No ratings yet

- Pernos Avellanados (Countersunk Bolt)Document9 pagesPernos Avellanados (Countersunk Bolt)Eric ToroNo ratings yet

- Determining Pollutants Accurately: Stack TestingDocument8 pagesDetermining Pollutants Accurately: Stack TestingsowabarNo ratings yet

- MAGLEVDocument9 pagesMAGLEVKaran DhawaleNo ratings yet

- EJMA-2008 - Standards of The Expansion Joint Manufacturers Association - 9th Edition PDFDocument238 pagesEJMA-2008 - Standards of The Expansion Joint Manufacturers Association - 9th Edition PDFJMNo ratings yet

- Hi Force CatalogDocument124 pagesHi Force Cataloganjangandak2932No ratings yet

- MAAE 2101 CD - Mock Final1Document14 pagesMAAE 2101 CD - Mock Final1Marc GoelNo ratings yet

- Technical AssessmentDocument22 pagesTechnical AssessmentdennisjuntakNo ratings yet

- Sunu 1Document16 pagesSunu 1Ayca Betul BingolNo ratings yet

- Multi Hull ThesisDocument174 pagesMulti Hull ThesisRafael Castelo Branco GoulartNo ratings yet