Professional Documents

Culture Documents

Training Report On: Flow Assurance: Challenges & Solutions For Mature Oilfields

Training Report On: Flow Assurance: Challenges & Solutions For Mature Oilfields

Uploaded by

Arpita DeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training Report On: Flow Assurance: Challenges & Solutions For Mature Oilfields

Training Report On: Flow Assurance: Challenges & Solutions For Mature Oilfields

Uploaded by

Arpita DeyCopyright:

Available Formats

TRAINING REPORT ON

FLOW ASSURANCE: CHALLENGES & SOLUTIONS FOR MATURE OILFIELDS

CONTENT

S.NO

1. SUMMARY of 18th NOVEMBER 2019

1.1Introduction to Flow Assurance by Dr.Ashish Nagar

1.2 Flow Assurance Problems, their production chemistry, chemical intervention of flow

problems by Dr.Ashish Nagar

1.3 Gas Hydrates by Dr.Ashish Nagar

1.4 Case Study by Dr.Ashish Nagar

1.5 Oilfeild Production segments by Dr. A.K. Saxena

1.6 Chemistry of waxes,Asphaltenes and heavier deposition mechanism, emulsions and their roles by Dr. A.K.

Saxena.

2.

SUMMARY of 19th NOVEMBER 2019

2.1 Chemical Intervention of flow problems,choice of chemicals by Dr.Ashish Nagar

2.2 Case Study by Dr.Ashish Nagar

2.3Production enhancement through flow assurance, chemicals for flow assurance by Dr.

A.K. Saxena

2.4 Case Study by Dr. A.K. Saxena

3. Self-Learning

Prepared By Ms. Arpita Dey

Designation Officer-Technical

Department Mining & Refinery

Employee Code 9180

Location Patancheru

Training Duration 18-19 November 2019

Organizer

Course Co-ordnator Dr.Anil Bharadwaj:Ex-Group General

Manager(Chemistry),ONGC

TRAINING REPORT ON

FLOW ASSURANCE: CHALLENGES & SOLUTIONS FOR MATURE OILFIELDS

1.SUMMARY of 18th NOVEMBER 2019

Presentation By Dr.Ashish Nagar

Discussion Topic Brief Description

1.1 INTRODUCTION to Flow Flow Assurance-ensuring the fluid flows as intended in a pipe or a well.

Assurance The term was coined in 1990 by PETROBRASS. Crude oil production from

the matured oil fields often gets constrained due to high flow line pressures

which reduces the total through put of the line and causes decline in the

productivity of the concerned well.

1.2 Flow Assurance Problems, their High Flow line pressure may be due to ;

production chemistry, chemical Rheological properties of crude oil-Pour Point, Gel

intervention of flow problems Strength, Viscosity.

Properties of crude oil and/or crude oil emulsions-

WAT,WDT, Wax content, SARA Analysis

Temp. profile and shear rate condition in the pipeline-

Thermal history of oil can be determined by HTGC

Water cut/flow rate of well-Avg.water cut in oilfield is

70-75%.

Types of deposit-Asphaltenes,paraffins

Surface conditions in the pipelines.

Wax Deposition control

Mechanical-Scrappers,cutters,pigs,etc.

Thermal-Steaming,Bottom hole heaters,circulation of hot oil/water

Chemical(most efficient & economical)-solvent (Xylene,Solwax-

Xylene,toluene,Npthalene),Wax crystal growth inhibitors

1.3 Gas Hydrates Exploitation of gases like methane from gas hydrates because of their

potential as energy source.Gas.They cause plugging of pipelines Hydrate

inhibitors :

Thermal Hydrate inhibitors like alcohols & glycols.

Kinetic Hydrate Inhibitors like amine & carboxylic group.

1.4 Case Study Pipeline cleaning by Exothermic reaction with NaNo2 & NH4NO3,: Temp.

obtained 125-140 deg.C at pH 5.4 after 45 min. of reaction.

Prepared By Ms. Arpita Dey

Designation Officer-Technical

Department Mining & Refinery

Employee Code 9180

Location Patancheru

Training Duration 18-19 November 2019

Organizer

Course Co-ordnator Dr.Anil Bharadwaj:Ex-Group General

Manager(Chemistry),ONGC

TRAINING REPORT ON

FLOW ASSURANCE: CHALLENGES & SOLUTIONS FOR MATURE OILFIELDS

Presentation By Dr.A.K. Saxena

Discussion Topic Brief Description

1.5 Oilfield Production Segments Near Wellbore, Wellhead,Flowline , Group Gathering Station/Central tank form,

Trunk line.

Waxes are high molecular weight paraffins that crystallize from crude oil due to

1.6 Chemistry of waxes,Asphaltenes and decrease in fluid temperature .Wax in crude oil can be categorized into two

heavier deposition mechanism,emulsions broad classes :

and their roles Macrocrystalline wax-less complex network,low melting point,Can be

inhibited/removed by chemical,thermal or mechanical means

Microcrystalline wax-Complex network,high melting point,Diffficult to

inhibit/remove.

Crude oil emulsions are formed as oil is in contact with formation water which

is saline to varying degrees and oil/water have various other minor substances in

their composition which act as natural emulsifiers and fluid flow conditions

bring about thorough mixing and dispersal of one phase in another.

Oil must be demulsified as water causes problems such as :

Corrosion,coke deposition,foaming,increased power

consumption.

Dehydration treatment of Crude oil :

Gravity Separation-Stoke’s Law

Temperature effect:Heating of incoming oil/water stream

Chemical destabilization/Demulsification : Attraction to oil/water

interface,flocculation,coalescence,solid wetting.

Prepared By Ms. Arpita Dey

Designation Officer-Technical

Department Mining & Refinery

Employee Code 9180

Location Patancheru

Training Duration 18-19 November 2019

Organizer

Course Co-ordnator Dr.Anil Bharadwaj:Ex-Group General

Manager(Chemistry),ONGC

TRAINING REPORT ON

FLOW ASSURANCE: CHALLENGES & SOLUTIONS FOR MATURE OILFIELDS

2.SUMMARY of 19th NOVEMBER 2019

2. 1.Presentation By Dr.Ashish Nagar

Discussion Topic Brief Description

2.1 Chemical Intervention of flow Oilfield scales typically consist of one or more types of inorganic deposit

problems,choice of chemicals. along with other debris. Common types of scales and their chemistry and

treatment was discussed.

2.2 Case study Wax deposition removal with sol-wax :

Diesel/Light oil/condensate : 68%

Xylene :10%

Toluene :20%

Napthelene : 2%

PPD : 1Barrel

Asphaltene deposition removal with sol-asph :

Diesel/Light oil/condensate : 40%

Xylene :30%

Toluene :20%

Napthelene : 10%

Prepared By Ms. Arpita Dey

Designation Officer-Technical

Department Mining & Refinery

Employee Code 9180

Location Patancheru

Training Duration 18-19 November 2019

Organizer

Course Co-ordnator Dr.Anil Bharadwaj:Ex-Group General

Manager(Chemistry),ONGC

TRAINING REPORT ON

FLOW ASSURANCE: CHALLENGES & SOLUTIONS FOR MATURE OILFIELDS

2.2Presentation By Dr.A.K. Saxena

Discussion Topic Brief Description

2.3 Production enhancement Asphaltenes are complex molecules defined to be soluble in benzene and

through flow assurance, insoluble in n-alkanes with no definite melting point.Asphaltene exist in oil

chemicals for flow assurance. as a colloidal suspension and stabilized by resins adsorbed on their surface.

Asphaltene deposition control :

Mechanical : Scrapping

Chemical Cleaning : Organic Solvents

Asphaltene dispersants : Polymeric molecules increase asphaltene

stabilization in the crude oil.

Liquid PPDs are PPD s which remain liquid at room temperature are

used for improving the flow of oil and reducing the pour point.

Chemistry: acrylate ester,methacrylate ester, ethylene vinyl acetate

copolymer,maleic olefin alkyl half ester,etc.

Mechanism : Co-crystallize with paraffin crystalsand keeps paraffin

crystals in dispersed state in oil.

Different types of chemicals used in offshore operations were discussed.

2.4 Case study Performance of Liquid PPD on DS3 Crude Oil

HTGC study of Crude oil characterstics

Physico-Chemical characterstics study of Crude oil from:

Cold finger test in Assam Crude oil

Prepared By Ms. Arpita Dey

Designation Officer-Technical

Department Mining & Refinery

Employee Code 9180

Location Patancheru

Training Duration 18-19 November 2019

Organizer

Course Co-ordnator Dr.Anil Bharadwaj:Ex-Group General

Manager(Chemistry),ONGC

TRAINING REPORT ON

FLOW ASSURANCE: CHALLENGES & SOLUTIONS FOR MATURE OILFIELDS

3.Self-Learning

Challenges faced in oilfield due to flow assurance was discussed and understood

in detail.

Wax Chemistry and wax deposition problems and control mechanism was

discussed and understood.

Asphaltene Chemistry a nd asphaltene deposition control mechanism was

discussed and understood.

Scale formation and scale inhibition technique was discussed and understood.

Gas hydrates and their current exploration techniques were discussed and

understood.

Emulsion formation in oilfield, their problems and demulsification techniques

were discussed and understood.

Different chemical treatment required in offshore were discussed and

understood in brief.

Role and chemistry of PPDs, surfactants, dispersants, Corossion inhibit ors,

demulsifiers were discussed and understood in brief.

Prepared By Ms. Arpita Dey

Designation Officer-Technical

Department Mining & Refinery

Employee Code 9180

Location Patancheru

Training Duration 18-19 November 2019

Organizer

Course Co-ordnator Dr.Anil Bharadwaj:Ex-Group General

Manager(Chemistry),ONGC

You might also like

- Investor User ManualDocument38 pagesInvestor User ManualArpita DeyNo ratings yet

- Lecture 52 WEEK 11Document30 pagesLecture 52 WEEK 11Arpita DeyNo ratings yet

- Lecture 10_week2Document10 pagesLecture 10_week2Arpita DeyNo ratings yet

- Lecture 31_week 7Document16 pagesLecture 31_week 7Arpita DeyNo ratings yet

- Lecture 59 - Week12Document45 pagesLecture 59 - Week12Arpita DeyNo ratings yet

- Lecture 9 - Week 2Document9 pagesLecture 9 - Week 2Arpita DeyNo ratings yet

- Lecture 33Document19 pagesLecture 33Arpita DeyNo ratings yet

- Lecture 51 - WEEK 11Document22 pagesLecture 51 - WEEK 11Arpita DeyNo ratings yet

- Lecture 29 - Week 6Document11 pagesLecture 29 - Week 6Arpita DeyNo ratings yet

- Lecture 24 - Week5Document13 pagesLecture 24 - Week5Arpita DeyNo ratings yet

- Material Safety Data Sheet: 1 IdentificationDocument6 pagesMaterial Safety Data Sheet: 1 IdentificationArpita DeyNo ratings yet

- ICD ISO 45001-2018 (Valid Upto 19-06-2023)Document1 pageICD ISO 45001-2018 (Valid Upto 19-06-2023)Arpita DeyNo ratings yet

- Standard 1500Document1 pageStandard 1500Arpita DeyNo ratings yet

- Lecture 50Document27 pagesLecture 50Arpita DeyNo ratings yet

- Water Resource Management: by Arpita DeyDocument10 pagesWater Resource Management: by Arpita DeyArpita DeyNo ratings yet

- Lecture 49Document28 pagesLecture 49Arpita DeyNo ratings yet

- Lecture 01 - Week1Document13 pagesLecture 01 - Week1Arpita DeyNo ratings yet

- Lecture 34Document22 pagesLecture 34Arpita DeyNo ratings yet

- Lecture 60 - Week12Document26 pagesLecture 60 - Week12Arpita DeyNo ratings yet

- Lecture 05 - Week1Document7 pagesLecture 05 - Week1Arpita DeyNo ratings yet

- Lecture 35Document28 pagesLecture 35Arpita DeyNo ratings yet

- Lecture 02 - Week1Document14 pagesLecture 02 - Week1Arpita DeyNo ratings yet

- Lecture 03 - Week1Document8 pagesLecture 03 - Week1Arpita DeyNo ratings yet

- 150 To 250 Kg/cm2G Is Employed.: Acted Materials, To Cause The Urea Solution To ContactDocument5 pages150 To 250 Kg/cm2G Is Employed.: Acted Materials, To Cause The Urea Solution To ContactArpita DeyNo ratings yet

- Lecture 04 - Week1Document9 pagesLecture 04 - Week1Arpita DeyNo ratings yet

- Material Safety Data Sheet: INDFOAM 2346Document3 pagesMaterial Safety Data Sheet: INDFOAM 2346Arpita DeyNo ratings yet

- IOGCA 2021 Virtual Conference BrochureDocument8 pagesIOGCA 2021 Virtual Conference BrochureArpita DeyNo ratings yet

- Instrument For Corrosion Inhibitor Application Instrument For Kinematic Viscosity Analysis. Instrument For Flash Point AnalysisDocument2 pagesInstrument For Corrosion Inhibitor Application Instrument For Kinematic Viscosity Analysis. Instrument For Flash Point AnalysisArpita DeyNo ratings yet

- HandlerDocument772 pagesHandlerArpita DeyNo ratings yet

- Wet Breaking Length (In Meters)Document5 pagesWet Breaking Length (In Meters)Arpita DeyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tos Grade 10 ScienceDocument1 pageTos Grade 10 ScienceJesselyn Dacdac Llantada-Bautista100% (2)

- DuctilityDocument4 pagesDuctilitycelsolcruzNo ratings yet

- Evaluation of Compressed Air Adsorption Dryer WithDocument27 pagesEvaluation of Compressed Air Adsorption Dryer WithKarthikeyan VisvakNo ratings yet

- Honors ChemistryDocument3 pagesHonors ChemistryKelly TheisNo ratings yet

- C8 Book AnswersDocument10 pagesC8 Book AnswersMo KhNo ratings yet

- Bree DiagramDocument22 pagesBree DiagrampajadhavNo ratings yet

- Section A-Multiple Choice (10 Marks) 1 A B C D 2: Pearson Science New South Wales 9 Chapter 4 TestDocument9 pagesSection A-Multiple Choice (10 Marks) 1 A B C D 2: Pearson Science New South Wales 9 Chapter 4 TestAbigail ScottNo ratings yet

- Study Guide 001 (Both) For TST271ZDocument332 pagesStudy Guide 001 (Both) For TST271Zstevens50% (2)

- Sir - Tds.siropol 8340-PLV-180.v03.202012.no 1Document3 pagesSir - Tds.siropol 8340-PLV-180.v03.202012.no 1Yousef LotfyNo ratings yet

- Chapter 4 - Steam Generators (Boilers)Document55 pagesChapter 4 - Steam Generators (Boilers)rrhoshackNo ratings yet

- Biomedical Magnetic Resonance:: Proceedings of The International WorkshopDocument475 pagesBiomedical Magnetic Resonance:: Proceedings of The International Workshopsalah subbah0% (1)

- 42 Pbab 399Document3 pages42 Pbab 399false mailNo ratings yet

- Valve/ Actuator Torque Sizing Analysis Chart For Trunnion Ball ValvesDocument1 pageValve/ Actuator Torque Sizing Analysis Chart For Trunnion Ball ValvesagrovadoNo ratings yet

- 0305 Olevsky - Theory of SinteringDocument64 pages0305 Olevsky - Theory of SinteringKhadijah FaridNo ratings yet

- Flexural Strength of ConcreteDocument4 pagesFlexural Strength of ConcreteAicet Guru0% (1)

- Pad Footing CalculationDocument14 pagesPad Footing CalculationazwanNo ratings yet

- Consciousness Vorticity and DipolesDocument16 pagesConsciousness Vorticity and DipolesEraslan Şevki YilmazNo ratings yet

- Chapter - 4 Highway IIDocument32 pagesChapter - 4 Highway IIAssfachew BeleteNo ratings yet

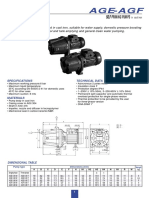

- Age-Agf: Self Priming PumpsDocument2 pagesAge-Agf: Self Priming PumpsNguyen Doan HuongNo ratings yet

- Per 1 CH 3 Sec 1Document18 pagesPer 1 CH 3 Sec 1api-312765846No ratings yet

- 2023 - Kadam - Review On Nanoparticles - SocioeconomicalDocument9 pages2023 - Kadam - Review On Nanoparticles - Socioeconomicaldba1992No ratings yet

- Stud Welding ProcedureDocument4 pagesStud Welding ProcedureREDDY SRCNo ratings yet

- Why Is Solar Cell Efficiency Low - GreentumbleDocument15 pagesWhy Is Solar Cell Efficiency Low - Greentumblevihan shahNo ratings yet

- Bbet+tre-2018-C-Xi (Paper-2) PCMDocument22 pagesBbet+tre-2018-C-Xi (Paper-2) PCMPankaj DhankerNo ratings yet

- Bataan Heroes College Balanga, Bataan: 97534.0409 BTU/hr 8.1278 TOR 3801.9336 CFM 67.8 Sq. MDocument55 pagesBataan Heroes College Balanga, Bataan: 97534.0409 BTU/hr 8.1278 TOR 3801.9336 CFM 67.8 Sq. MRalph Bernard Dela RosaNo ratings yet

- Tolerances, Limits, Fits and Surface FinishDocument6 pagesTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- FTIR Crystal Referance GuideDocument11 pagesFTIR Crystal Referance GuideberkahNo ratings yet

- Affinity Laws - HVAC Pumps and FansDocument16 pagesAffinity Laws - HVAC Pumps and Fanssumair uddinNo ratings yet

- Formative Assessment of Electricity: Short Answer Based QuestionsDocument4 pagesFormative Assessment of Electricity: Short Answer Based QuestionsMithleshNo ratings yet

- Dynamic Force Analysis of MechanismDocument21 pagesDynamic Force Analysis of MechanismAgare TubeNo ratings yet