Professional Documents

Culture Documents

Baker ZTX Brochure PUB CM-P2 13872 en

Baker ZTX Brochure PUB CM-P2 13872 en

Uploaded by

Pablo Marcelo Garnica TejerinaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baker ZTX Brochure PUB CM-P2 13872 en

Baker ZTX Brochure PUB CM-P2 13872 en

Uploaded by

Pablo Marcelo Garnica TejerinaCopyright:

Available Formats

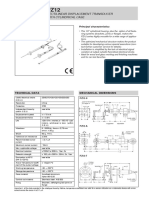

SKF Static Motor Analyzer

Accessory – Baker ZTX

Extend the functionality of Baker DX and Baker AWA-IV

analyzers to tests of low-impedance DC windings or coils

Introduction spurs sometimes produced by under-cuts in

Low-impedance coils typical of DC arma- the manufacturing process. Probe and clip

tures, coils or interpoles can make it difficult fixtures provide easy access through inspec-

to detect insulation weaknesses. Due to the tion plates on assembled motors, which

low inductance characteristics of armature makes it easier to perform tests on field

windings, high test currents are necessary pieces or interpoles.

to achieve the minimum voltage require-

ments required to accurately detect insula- Easy, accurate analysis

tion weaknesses in DC motors. The Baker When coupled with the appropriate 6- or

ZTX provides the necessary current at low 12-kV SKF static motor analyzer, the Baker

test voltages to find insulation problems or ZTX allows motor manufacturing and repair

faults in DC armatures, coils or interpoles shop personnel to perform a comprehensive

when using SKF static motor analyzers. array of tests on coils of a DC armature.

The accessory applies a surge pulse to

Key benefits two adjacent bars on the armature to pro-

The Baker ZTX is designed with a proprie- duce a reference wave form, which is saved

tary impedance transformer that enables on the host analyzer. Successive bars are

6 kV and 12 kV SKF static motor analyzers then tested with automatic comparisons to

to accurately detect DC motor problems, the reference wave form. A bar graph of er-

including: ror-area ratio (EAR) values can be created

• weak or damaged winding insulation for easy comparison and analysis. The pre-

• turn-to-turn (winding) shorts cise mathematical analysis of the EAR algo-

rithm minimizes the inaccurate analysis that

• turn-to-turn (winding) opens often occurs with mere visual comparisons

• coil imbalances of the waveforms.

• connection problems

• commutator bar insulation problems

The device also helps locate commutator

Specifications

Test inductance

Maximum: 20 µH

Minimum: 0,4 µH

Physical characteristics

Weight: 7 kg (15 lb)

Dimensions: 235 mm wide

300 mm deep

150 mm tall

(9 in x 12 in x 6 in)

Improve service QC Compatible analyzers insulation test techniques. The span test

With any inspection of a used armature, or Baker DX (6 kV/6 k HO, 12 kV/12 kV HO) method enables comparisons of spans

when quality control efforts are performed Baker AWA-IV (6 kV, 12 kV/12 kV HO) across several rotor bars, but is limited at

on new or rebuilt armatures, turn-to-turn low currents. The SKF bar-to-bar method

insulation needs to be free of any scratches, enables tests of turn-to-turn insulation at

pinholes or damage of any kind. The Baker readings. The test waveform is displayed lower voltages, but at a current high enough

ZTX reduces the possibility of overlooking on the host analyzer (e.g., a Baker DX or to simulate what a motor experiences in

such damage before the motor is cleared for Baker AWA-IV). actual service.

service use. The accessory also comes with a foots- SKF’s bar-to-bar test approach over-

witch, which helps reduce the time it takes comes the limitations of span testing with

Safety and convenience to perform repetitive tests on armatures. the right application of sufficient current to

The Baker ZTX includes a hand-held safety- provide a controlled, lower voltage test to

grounded armature contact device to make Bar-to-bar vs. span tests each individual bar. This method also over-

it as easy and safe as possible to perform Manufacturers and rebuilders of industrial comes the problems associated with low

surge tests on DC commutators. This device DC motors prefer the use of bar-to-bar impedances that equalizer windings can

measures the surge voltage wave at the tests over span tests to improve quality con- create during armature tests.

commutator via a separate shielded cable, trol. The bar-to-bar test method is more

which reduces errors in the test voltage comprehensive than span or other DC motor

Baker Instrument Company, an SKF Group Company

4812 McMurry Avenue, Fort Collins, CO 80525 USA

T: +1 970-282-1200 – +1 800-752-8272 F: +1 970-282-1010

® SKF is a registered trademark of the SKF Group.

™ Baker is a trademark of the SKF Group.

© SKF Group 2013

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permis-

sion is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

PUB CM/P2 13872 EN · June 2013

skf.com bakerinst.com

You might also like

- B22,25,30,35X-7 Sb4451e00Document439 pagesB22,25,30,35X-7 Sb4451e00Ricardo VieiraNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Areva WIADocument52 pagesAreva WIAAnonymous N13Jdn100% (1)

- Baker ZTX Low-Impedance Coil Test AccessoryDocument2 pagesBaker ZTX Low-Impedance Coil Test AccessoryWilmar LEON PEÑANo ratings yet

- Baker DX-15A Brochure PUB CM-P2 13773 enDocument4 pagesBaker DX-15A Brochure PUB CM-P2 13773 enPablo Marcelo Garnica TejerinaNo ratings yet

- Baker AT101-ZTX: Expands Testing Capabilities To Include DC Motors and Other Low Impedance CoilsDocument2 pagesBaker AT101-ZTX: Expands Testing Capabilities To Include DC Motors and Other Low Impedance CoilsSergio PereiraNo ratings yet

- Baker WinAST Brochure A4 en v1.0 Online-MinDocument8 pagesBaker WinAST Brochure A4 en v1.0 Online-MinJulio De la RosaNo ratings yet

- 35kv Loadbreak Products by HJ PDFDocument4 pages35kv Loadbreak Products by HJ PDFJH_ProjectNo ratings yet

- Bluthunder PDFDocument2 pagesBluthunder PDFsachdarNo ratings yet

- Series 26NMDocument2 pagesSeries 26NMHassen LazharNo ratings yet

- Blue-Thunder Serie: The Power of BlueDocument2 pagesBlue-Thunder Serie: The Power of BlueBenjamin Musa ダNo ratings yet

- Back-to-Back Accelerometer CalibrationDocument3 pagesBack-to-Back Accelerometer CalibrationAekDzLaiNo ratings yet

- 35TB600 062123-1Document5 pages35TB600 062123-1Jorge Mtz ZapataNo ratings yet

- Subarc AC/DC Series: The Power of BlueDocument8 pagesSubarc AC/DC Series: The Power of Bluemiguel angelNo ratings yet

- PUB CM P2 13104 en Baker DX BrochureDocument4 pagesPUB CM P2 13104 en Baker DX BrochurefernandogobetteNo ratings yet

- CM-P8 12200 EN SKF Static Motor Analyzer Baker DX Data Sheet PDFDocument4 pagesCM-P8 12200 EN SKF Static Motor Analyzer Baker DX Data Sheet PDFFelix AcebeyNo ratings yet

- Elastimold Underground Cable Accessories MV HV CatalogueDocument60 pagesElastimold Underground Cable Accessories MV HV Cataloguejmrs7322No ratings yet

- Automatic Circuit Reclosers/ Sectionalisers: Switchgear SolutionsDocument8 pagesAutomatic Circuit Reclosers/ Sectionalisers: Switchgear SolutionsJHAMES MAYCON JACO TORREJONNo ratings yet

- BR280001EN - Recloser NOVA TypeDocument2 pagesBR280001EN - Recloser NOVA Typejose alberto garcia santosNo ratings yet

- Catalogue MitsubishiDocument71 pagesCatalogue MitsubishiMinhchau NguyenNo ratings yet

- 200 A LoadbreakDocument6 pages200 A Loadbreakmreza84No ratings yet

- DS - Calatogue PDFDocument8 pagesDS - Calatogue PDFPritam SinghNo ratings yet

- Solid Dielectric, Three Phase ReclosersDocument8 pagesSolid Dielectric, Three Phase ReclosersAdib Darul QuthniNo ratings yet

- Catalogo CSHDocument5 pagesCatalogo CSHismael perezNo ratings yet

- Electrical Test & Measurement Power Product Catalog: Next Generation of Testing TechnologyDocument19 pagesElectrical Test & Measurement Power Product Catalog: Next Generation of Testing TechnologyWilliam RaicoNo ratings yet

- Baker-St 112eDocument2 pagesBaker-St 112eDenis MoreschiNo ratings yet

- NA-5 Control and Heads: Flux-Cored, Submerged Arc K356-2Document4 pagesNA-5 Control and Heads: Flux-Cored, Submerged Arc K356-2edwinNo ratings yet

- Loadbreak Products: Experience & ReliabilityDocument8 pagesLoadbreak Products: Experience & ReliabilityCbdtxd PcbtrNo ratings yet

- Baker DX Series Static Motor AnalyzersDocument8 pagesBaker DX Series Static Motor AnalyzersjuanmalegreNo ratings yet

- Baker ST112A-ST106A-ST103A DatasheetDocument2 pagesBaker ST112A-ST106A-ST103A DatasheetJose LiraNo ratings yet

- Switchgear Type 8DJH Compact For Secondary Distribution Systems Up To 24 KV, Gas-InsulatedDocument2 pagesSwitchgear Type 8DJH Compact For Secondary Distribution Systems Up To 24 KV, Gas-InsulatedHukic77No ratings yet

- Portable Shaker Table: Vibration Field TestingDocument2 pagesPortable Shaker Table: Vibration Field TestingvikryaNo ratings yet

- Fluke Clamp Meter Lowest Price in BD CatalogDocument8 pagesFluke Clamp Meter Lowest Price in BD CatalogFluke BangladeshNo ratings yet

- CET Datasheet Enclosure Systems 48Vdc-120VacDocument5 pagesCET Datasheet Enclosure Systems 48Vdc-120VacAlejandro Garcia MNo ratings yet

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Te S Raychem Screened Elbow/Straight Separable Connectors Rses/RsssDocument2 pagesTe S Raychem Screened Elbow/Straight Separable Connectors Rses/RsssIrfan Pv50% (2)

- GVR Recloser: For Pole Mounting and Substation ApplicationsDocument2 pagesGVR Recloser: For Pole Mounting and Substation ApplicationsOscar MorenoNo ratings yet

- Omicron TetranoDocument16 pagesOmicron Tetranoykh92167No ratings yet

- Testrano 600: Three-Phase Test System For Comprehensive Power and Distribution Transformer TestingDocument16 pagesTestrano 600: Three-Phase Test System For Comprehensive Power and Distribution Transformer TestingimranNo ratings yet

- Cooper ArresterDocument8 pagesCooper ArresterHongNo ratings yet

- Analog Power Meter 90deg WQDocument4 pagesAnalog Power Meter 90deg WQMichael Dela CruzNo ratings yet

- Cooper Surge Arrestors - 23587Document16 pagesCooper Surge Arrestors - 23587Matthew CooneyNo ratings yet

- OVR LeafletDocument2 pagesOVR Leafletbatzorig valyaNo ratings yet

- Service Lif Evaluations of Low Voltage Power Circuit Breakers and Molded Case Circuit Breakers PDFDocument9 pagesService Lif Evaluations of Low Voltage Power Circuit Breakers and Molded Case Circuit Breakers PDFzacharioudakisNo ratings yet

- Switchgears: Tested Power... Trusted SolutionDocument2 pagesSwitchgears: Tested Power... Trusted SolutionNimish TaterhNo ratings yet

- DJ635A4BDocument4 pagesDJ635A4BluchorcrluisNo ratings yet

- (Susol VCB) Catalog en 202006Document256 pages(Susol VCB) Catalog en 202006mas zak danielNo ratings yet

- WelderDocument2 pagesWelderpilionNo ratings yet

- Catalogo Pararrayos PolimDocument8 pagesCatalogo Pararrayos PolimTomas VelasquezNo ratings yet

- How To Test An RF Coaxial Cable Using A VNADocument5 pagesHow To Test An RF Coaxial Cable Using A VNAStefanvnvNo ratings yet

- DTS PZ12 08-2021 EngDocument2 pagesDTS PZ12 08-2021 EngOmar BarcenasNo ratings yet

- 1VAL2601-TG-en - OVRDocument20 pages1VAL2601-TG-en - OVRKurt WyleNo ratings yet

- 15-35kv Hubbel PararrayosDocument4 pages15-35kv Hubbel PararrayosSig DuranNo ratings yet

- 600a 15 25kv Class Bol T Deadbreak Connector Catalog Ca650003enDocument8 pages600a 15 25kv Class Bol T Deadbreak Connector Catalog Ca650003enJalal AlbadriNo ratings yet

- neoGEN CS459I1905A1Document2 pagesneoGEN CS459I1905A1Filipe BrandaoNo ratings yet

- 600A - 15 and 25kV Deadbreak-Bushing-CA800025ENDocument4 pages600A - 15 and 25kV Deadbreak-Bushing-CA800025ENAldo MolinariNo ratings yet

- DC 25 Ub 25Document4 pagesDC 25 Ub 25nameNo ratings yet

- 15LJ200 MinDocument4 pages15LJ200 Mincristopher bravo rodriguezNo ratings yet

- AVC63-4, AVC63-4D, Voltage Regulator: Eatures EnefitsDocument2 pagesAVC63-4, AVC63-4D, Voltage Regulator: Eatures EnefitsalexisNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- MRF5007 2RSDocument1 pageMRF5007 2RSPablo Marcelo Garnica TejerinaNo ratings yet

- L12022 Laser Cutter Flyer SinglesDocument4 pagesL12022 Laser Cutter Flyer SinglesPablo Marcelo Garnica TejerinaNo ratings yet

- Forestry ChainDocument14 pagesForestry ChainPablo Marcelo Garnica TejerinaNo ratings yet

- SSlv-OffhighwayDocument40 pagesSSlv-OffhighwayPablo Marcelo Garnica TejerinaNo ratings yet

- HeatsetFolder - 3RZ V FinalDocument4 pagesHeatsetFolder - 3RZ V FinalPablo Marcelo Garnica TejerinaNo ratings yet

- Static Products Sizing ChartDocument1 pageStatic Products Sizing ChartPablo Marcelo Garnica TejerinaNo ratings yet

- Baker Product MatrixDocument1 pageBaker Product MatrixPablo Marcelo Garnica TejerinaNo ratings yet

- Ric Test On DXDocument1 pageRic Test On DXPablo Marcelo Garnica TejerinaNo ratings yet

- Application Guide Belt DriveDocument1 pageApplication Guide Belt DrivePablo Marcelo Garnica TejerinaNo ratings yet

- Application Guide Easy Splice2Document1 pageApplication Guide Easy Splice2Pablo Marcelo Garnica TejerinaNo ratings yet

- Baker PP30, PP40, PP85: The Effective Solution For Testing High Voltage WindingsDocument2 pagesBaker PP30, PP40, PP85: The Effective Solution For Testing High Voltage WindingsPablo Marcelo Garnica TejerinaNo ratings yet

- Cylinderform PDFDocument1 pageCylinderform PDFPablo Marcelo Garnica TejerinaNo ratings yet

- Transfer Matrix Method To Vibration Analysis of Rotors With Coupler OffsetsDocument13 pagesTransfer Matrix Method To Vibration Analysis of Rotors With Coupler OffsetsPablo Marcelo Garnica TejerinaNo ratings yet

- 8V1640.001-2 en V1.8Document14 pages8V1640.001-2 en V1.8JlavieraNo ratings yet

- 7FBR English PDFDocument16 pages7FBR English PDFVadivelNo ratings yet

- Placa de Caracteristicas Motor IngDocument25 pagesPlaca de Caracteristicas Motor IngJorge ContrerasNo ratings yet

- JMag Noise VibrationDocument7 pagesJMag Noise VibrationhonghieutrNo ratings yet

- Sliding Mode Controller SMC Governed Speed Control of DC MotorDocument6 pagesSliding Mode Controller SMC Governed Speed Control of DC Motorraghav4life8724No ratings yet

- MCQ ElectDocument68 pagesMCQ ElectAviation WorldNo ratings yet

- SK 24 SigmaDocument5 pagesSK 24 SigmaDedi KartiwaNo ratings yet

- Agricultural 2012 Licensure Examination Answer KeyDocument3 pagesAgricultural 2012 Licensure Examination Answer KeyMayseee06No ratings yet

- Lesson 9 - Electric Drives-DC Series MotorsDocument10 pagesLesson 9 - Electric Drives-DC Series MotorsHafsa AlhaddabiNo ratings yet

- Science10 - Q2how A Simple Electric MotorDocument25 pagesScience10 - Q2how A Simple Electric MotorSean LituañasNo ratings yet

- An Off Line Technique For Prediction of Performance Characteristics of Three Phase Induction Motor IJERTV2IS1417Document6 pagesAn Off Line Technique For Prediction of Performance Characteristics of Three Phase Induction Motor IJERTV2IS1417Rayhana KararNo ratings yet

- Electrical Engineering Objective Type QuestionsDocument117 pagesElectrical Engineering Objective Type QuestionsSuresh ThallapelliNo ratings yet

- An Review of Power Factor Correction in SRM DrivesDocument6 pagesAn Review of Power Factor Correction in SRM Drivesdavid bennyNo ratings yet

- DIY Self Balancing One Wheel Vehicle PDFDocument15 pagesDIY Self Balancing One Wheel Vehicle PDFjyotesh namdeoNo ratings yet

- Heavy Industrial-Duty Gear-Reduced Hoist Operator: Logic 3.0 TechnologyDocument2 pagesHeavy Industrial-Duty Gear-Reduced Hoist Operator: Logic 3.0 TechnologyAhmed Mohamed FarahatNo ratings yet

- Xylem FLYGT Model Mixed FlowDocument12 pagesXylem FLYGT Model Mixed FlowEdilberto AlegatoNo ratings yet

- 950G Series II, 962G Series II, and Electrical System IT62G Series II Wheel LoaderDocument4 pages950G Series II, 962G Series II, and Electrical System IT62G Series II Wheel LoaderElie Abisaad100% (1)

- AXERA 6-226: Technical Specification 6-9650-B 2004-07-02Document4 pagesAXERA 6-226: Technical Specification 6-9650-B 2004-07-02cristianNo ratings yet

- EE8005 Special Electrical MachinesDocument3 pagesEE8005 Special Electrical MachinesKumar RajNo ratings yet

- Texas AM PDFDocument43 pagesTexas AM PDFJorgito AriasNo ratings yet

- KWPK080 065 0200Document2 pagesKWPK080 065 0200andreasjayatriaskNo ratings yet

- Manitou 578 3Document142 pagesManitou 578 3António FreireNo ratings yet

- Single Phase Inductive LoadDocument40 pagesSingle Phase Inductive LoadJULIET MOKWUGWONo ratings yet

- Portable Electric Tiller Machine: IjarsctDocument4 pagesPortable Electric Tiller Machine: Ijarsctnagaraju b 334No ratings yet

- Commissioning Variable Speed DrivesDocument5 pagesCommissioning Variable Speed DrivesAleksandar Lazić100% (2)

- GC5 iSMA-B-FCU Application Manual EN V1.1Document47 pagesGC5 iSMA-B-FCU Application Manual EN V1.1Bruno AlcaideNo ratings yet

- Your Driving Force: Submersible Water EngineeringDocument2 pagesYour Driving Force: Submersible Water EngineeringChrist Rodney MAKANANo ratings yet

- mrj2sb SeriesDocument225 pagesmrj2sb Seriesnestor gonzalez de leonNo ratings yet

- Current Harmonic Suppression For Dual Three-Phase PDFDocument11 pagesCurrent Harmonic Suppression For Dual Three-Phase PDFMoyasserengAlattarNo ratings yet