Professional Documents

Culture Documents

Piping Class - DD20

Uploaded by

Дмитрий РыбаковOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Class - DD20

Uploaded by

Дмитрий РыбаковCopyright:

Available Formats

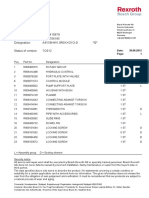

Title : Piping and Valves Doc. No.

L-001 Annex: B Class DD20

Project : NORSOK Company : Rev.Date : 20.09.99 Rev. : 3

Max Design Pressure at Temperature Rating CL 600

Pressure (Barg) 103.4 103.4 102.5 98.4 91.6 85.4 80.3 Branch Table NBR3

Temperature (Deg. C) -46 38 50 100 150 200 250 Service Code N-D200

Design Code ASME B31.3

Corr. Allow. 0.0

Wall Thickness Under <=16"=12.5%, >16"=0.3mm, SEE NOTE 2

Tolerance

Longitudinal Weld Efficiency 1

ND (inch) 0.50 0.75 1.00 1.50 2.00 3.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00 20.00 24.00 30.00 36.00

OD (mm) 21.3 26.7 33.4 48.3 60.3 88.9 114.3 168.3 219.1 273.1 323.9 355.6 406.4 457.0 508.0 610.0 762.0 914.0

THK (mm) 2.77 2.87 3.38 3.68 3.91 5.49 6.02 7.11 8.18 9.27 9.53 11.13 12.70 12.70 12.70 17.48 20.00 25.00

SCH 40S 40S 40S 40S 40S 40S 40S 40S 40S 40S 40S 40 40 30 40

WEIGHT XS XS XS

END

RANGE GEOMETRIC EDS/ MATERIAL

ITEM TYPE FROM TO STANDARD VDS CONN DESCR. MDS RATING SCHD. NOTES

#1 #2

A790 S31803

PIPE 0.50 12.00 ASME B36.19M PE PE D41

SMLS

A928 S31803 CL1

PIPE 4.00 12.00 ASME B36.19M PE PE D42

OR 3

A790 S31803

PIPE 14.00 16.00 ASME B36.10M PE PE D41

SMLS

PIPE 14.00 16.00 ASME B36.10M PE PE A928 S31803 CL1 D42

OR 3

PIPE 18.00 20.00 ASME B36.19M PE PE A928 S31803 CL1 D42

OR 3

PIPE 24.00 24.00 ASME B36.10M PE PE A928 S31803 CL1 D42

OR 3

PIPE 30.00 36.00 ISO 4200 PE PE A928 S31803 CL1 D42

OR 3

PIPE NIPPLE 100MM LONG 0.50 1.00 ASME B36.19M TE PE A790 S31803 D41 80S

SMLS

BENDING 0.50 36.00 MADE FROM PIPE NBE1

CAP 0.50 16.00 ASME B16.9 BE A815 S31803 S D43

CAP 18.00 36.00 MSS SP-75 BE A815 S31803 S D43

CONCENTRIC REDUCER 0.75 24.00 ASME B16.9 BE BE A815 S31803 D43

S/WX

CONCENTRIC REDUCER 30.00 36.00 MSS SP-75 BE BE A815 S31803 D43

S/WX

ECCENTRIC REDUCER 0.75 24.00 ASME B16.9 BE BE A815 S31803 D43

S/WX

ECCENTRIC REDUCER 30.00 36.00 MSS SP-75 BE BE A815 S31803 D43

S/WX

ELBOW LONG RADIUS 45 DEG 0.50 24.00 ASME B16.9 BE BE A815 S31803 D43

S/WX

ELBOW LONG RADIUS 45 DEG 30.00 36.00 MSS SP-75 BE BE A815 S31803 D43

S/WX

ELBOW LONG RADIUS 90 DEG 0.50 24.00 ASME B16.9 BE BE A815 S31803 D43

S/WX

ELBOW LONG RADIUS 90 DEG 30.00 36.00 MSS SP-75 BE BE A815 S31803 D43

S/WX

STRAIGHT TEE 0.50 24.00 ASME B16.9 BE BE A815 S31803 D43

S/WX

STRAIGHT TEE 30.00 36.00 MSS SP-75 BE BE A815 S31803 D43

S/WX

REDUCING TEE 0.75 24.00 ASME B16.9 BE BE A815 S31803 D43

S/WX

A815 S31803

REDUCING TEE 30.00 36.00 MSS SP-75 BE BE D43

S/WX

WELDOLET 2.00 36.00 NORSOK EDS NOL1 BE BE A182 F51 D44

REINFORCED NIPOFLANGE 2.00 36.00 NORSOK EDS NOL1 BE RJ A182 F51 D44

BLIND FLANGE 0.50 24.00 ASME B16.5 RJ A182 F51 D44

BLIND FLANGE 0.50 24.00 ASME B16.5 RJ A240 S31803 D45

BLIND FLANGE 30.00 36.00 MSS SP-44 RJ A182 F51 D44

BLIND FLANGE 30.00 36.00 MSS SP-44 RJ A240 S31803 D45

WELDNECK FLANGE 0.50 24.00 ASME B16.5 NAF1 RJ BE A182 F51 D44

WELDNECK FLANGE 30.00 36.00 MSS SP-44 NAF1 RJ BE A182 F51 D44

WELDNECK ORIFICE FLANGE 1.00 20.00 ASME B16.36 NAF1 RJ BE A182 F51 D44

SPECTACLE BLIND 0.50 10.00 NORSOK EDS NLB1 RJ RJ A182 F51 D44

SPECTACLE BLIND 0.50 10.00 NORSOK EDS NLB1 RJ RJ A240 S31803 D45

SPADE 12.00 36.00 NORSOK EDS NLB1 RJ RJ A182 F51 D44

SPADE 12.00 36.00 NORSOK EDS NLB1 RJ RJ A240 S31803 D45

SPACER 12.00 36.00 NORSOK EDS NLB1 RJ RJ A182 F51 D44

SPACER 12.00 36.00 NORSOK EDS NLB1 RJ RJ A240 S31803 D45

GASKET OCTAGONAL RING 0.50 36.00 ASME B16.20 AISI 316

HEX HEAD PLUG 0.50 1.00 ASME B16.11 MT A182 F51 D44 6000

LBS

STUD BOLT C/W NUTS 0.50 36.00 ASME B16.5 NBO1 A193 B7/A194 2H

BALL VALVE FULL BORE 2.00 36.00 BLDD40J RJ RJ CL 600 075

BALL VALVE METAL SEAT FULL BORE 2.00 36.00 BLDD60J RJ RJ CL 600 076

BALL VALVE METAL SEAT REDUCED BORE 3.00 36.00 BLDD50J RJ RJ CL 600 076

BALL VALVE NON CONTACT 2.00 24.00 BLDD80J RJ RJ CL 600

BALL VALVE REDUCED BORE 3.00 36.00 BLDD30J RJ RJ CL 600 075

GATE VALVE THROUGH CONDUIT DOUBLE

2.00 36.00 GTDD70J RJ RJ CL 600 069

EXPANDING

GATE VALVE THROUGH CONDUIT SLAB 2.00 36.00 GTDD40J RJ RJ CL 600 069

GATE VALVE WEDGE 0.50 1.00 GTRD00D BE FT CL 800

GATE VALVE WEDGE 0.50 1.50 GTDD00J RJ RJ CL 600

GATE VALVE WEDGE 0.50 1.50 GTRD00B BE BE CL 800

GATE VALVE WEDGE 2.00 36.00 GTDD10J RJ RJ CL 600

GLOBE VALVE SWIVELLING 0.50 1.50 GBDD00B BE BE CL 600

GLOBE VALVE SWIVELLING 0.50 1.50 GBDD00J RJ RJ CL 600

GLOBE VALVE SWIVELLING 2.00 6.00 GBDD10J RJ RJ CL 600

CHECK VALVE DUAL WAFER 2.00 36.00 CHDD50J RJ RJ CL 600

CHECK VALVE PISTON 0.50 1.50 CHDD00B BE BE CL 600

CHECK VALVE PISTON 0.50 1.50 CHDD00J RJ RJ CL 600

PLUG VALVE 2.00 24.00 PGDD40J RJ RJ CL 600

DOUBLE BLOCK AND BLEED 1.00 3.00 CBDD10J RJ RJ CL 600 075

Notes :

001 REF. SECTION 6 FOR SERVICES REQUIRING NACE MR0175.

002 THE WALL THICKNESS TOLERANCE IS USED FOR DESIGN AND IS NOT PART OF THE PURCHASE SPECIFICATION WHEN DEVIATING FROM THE

INDIVIUAL PIPING ITEMS.

007 IF THE OPERATIONAL TEMP. IS ABOVE 110 DEG C, SPECIAL CARE SHALL BE TAKEN TO AVOID CHLORIDE STRESS CORROSION CRACKING.

069 FOR GAS SERVICE IS SEAT SKIRT NOT NECESSARY.

075 MAX. 150 DEG C.

076 MAX. 200 DEG C.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Piping Class - GD20Document3 pagesPiping Class - GD20Dmitriy RybakovNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Piping Class - GR20Document3 pagesPiping Class - GR20Dmitriy RybakovNo ratings yet

- Piping Class - GD30Document3 pagesPiping Class - GD30Dmitriy RybakovNo ratings yet

- Piping Class - DS20Document2 pagesPiping Class - DS20Дмитрий РыбаковNo ratings yet

- Piping Class - GS20Document3 pagesPiping Class - GS20Dmitriy RybakovNo ratings yet

- Piping Class - AD20Document2 pagesPiping Class - AD20Дмитрий РыбаковNo ratings yet

- Piping Class - AR71Document2 pagesPiping Class - AR71Дмитрий РыбаковNo ratings yet

- Piping Class - AR75Document2 pagesPiping Class - AR75Дмитрий РыбаковNo ratings yet

- Piping Class - AD30Document2 pagesPiping Class - AD30Дмитрий РыбаковNo ratings yet

- Piping Class - BS20Document2 pagesPiping Class - BS20Дмитрий РыбаковNo ratings yet

- Piping Class - DC11Document2 pagesPiping Class - DC11Дмитрий РыбаковNo ratings yet

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковNo ratings yet

- Piping Class - AC11Document2 pagesPiping Class - AC11Дмитрий РыбаковNo ratings yet

- Piping Class - EC11Document2 pagesPiping Class - EC11Дмитрий РыбаковNo ratings yet

- Piping Class - BC21Document2 pagesPiping Class - BC21Дмитрий РыбаковNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- Piping Class - AR20Document2 pagesPiping Class - AR20Дмитрий РыбаковNo ratings yet

- Piping Class - GC11Document3 pagesPiping Class - GC11Dmitriy RybakovNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - AG70Document2 pagesPiping Class - AG70Дмитрий Рыбаков100% (1)

- Piping Class - DC21Document2 pagesPiping Class - DC21Дмитрий РыбаковNo ratings yet

- Piping Class - AC21Document2 pagesPiping Class - AC21Дмитрий РыбаковNo ratings yet

- Li-5005-731-04-7502 - 1 Pipe Material List-For Installation RFQ OnlyDocument39 pagesLi-5005-731-04-7502 - 1 Pipe Material List-For Installation RFQ OnlyClaudio Fica RamirezNo ratings yet

- Ms Trading Pipefittingcatalogue Dec2016 ElectronicDocument44 pagesMs Trading Pipefittingcatalogue Dec2016 ElectronicANV100% (1)

- Spec Report - 20150922Document1,507 pagesSpec Report - 20150922Midhun K ChandraboseNo ratings yet

- 1.02.E.DT42S Thermodynamic Steam Traps DN15-25Document2 pages1.02.E.DT42S Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- MD 512 1a51 Iso WRW XXXX XXX 01 PDFDocument1 pageMD 512 1a51 Iso WRW XXXX XXX 01 PDFsarsan nedumkuzhiNo ratings yet

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Piping Class - KX70Document2 pagesPiping Class - KX70Дмитрий РыбаковNo ratings yet

- Po31510 Fres30x24 SF48410Document1 pagePo31510 Fres30x24 SF48410Keshia Murillo PinnockNo ratings yet

- Class 150# (18,4 Bar) Duplex (S 31803)Document2 pagesClass 150# (18,4 Bar) Duplex (S 31803)Veeramani krishnamoorthyNo ratings yet

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- 09 Design of A Tema ShellDocument20 pages09 Design of A Tema ShellJoan CordovaNo ratings yet

- Template MTODocument8 pagesTemplate MTOAmruta ShirtikarNo ratings yet

- Astm A325m PDFDocument8 pagesAstm A325m PDFDastaggir KarimiNo ratings yet

- Petromat PI - 43 - 2022-23Document4 pagesPetromat PI - 43 - 2022-23Dolon DasNo ratings yet

- Types & Sizes of Pipes For HRSG Piping-Block-2 - Muara Tawar ProjectDocument1 pageTypes & Sizes of Pipes For HRSG Piping-Block-2 - Muara Tawar ProjectSyach FirmNo ratings yet

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Document11 pages4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Piping Material Specification: Pipe DataDocument3 pagesPiping Material Specification: Pipe DataBhaumik BhuvaNo ratings yet

- GroomingDocument1 pageGroomingIkbal AlanisNo ratings yet

- PMS Conoco PhilipsDocument2 pagesPMS Conoco PhilipsManjunatha VNo ratings yet

- Heat Exchanger Tubes From T LDocument2 pagesHeat Exchanger Tubes From T LFaizan KhanNo ratings yet

- ASTM - A325M-bolts, NutsDocument7 pagesASTM - A325M-bolts, NutsNed VasicNo ratings yet

- Data Sheet ASME B31.3 s901 - PipeDocument21 pagesData Sheet ASME B31.3 s901 - PipeDaniel Alcantara CNo ratings yet

- Ft-Valvula Compuerta Roscada Imox 316Document1 pageFt-Valvula Compuerta Roscada Imox 316Galindo FivigaorNo ratings yet

- Butterfly Valves Gd-381: SpecificationDocument2 pagesButterfly Valves Gd-381: SpecificationJOSE GABRIELNo ratings yet

- Piping Class - AC71Document2 pagesPiping Class - AC71Дмитрий РыбаковNo ratings yet

- Piping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014Document12 pagesPiping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014azilahnazriNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0fayyazdnvNo ratings yet

- Piping SpecificationDocument3 pagesPiping SpecificationArun KumarNo ratings yet

- Idoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318Document9 pagesIdoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318GEMSL MONo ratings yet

- Tata Consulting Engineers Limited: Piping Material SpecificationDocument3 pagesTata Consulting Engineers Limited: Piping Material SpecificationkasvikrajNo ratings yet

- 4WPI-CWAC004 PdfFile 4 1 1Document7 pages4WPI-CWAC004 PdfFile 4 1 1Fred AksoNo ratings yet

- Piping Class Spec. - 1C23 (Lurgi)Document5 pagesPiping Class Spec. - 1C23 (Lurgi)otezgidenNo ratings yet

- 1707 DD Pi 3 Cal 3001 - Tinh Toan Be Day Thanh OngDocument3 pages1707 DD Pi 3 Cal 3001 - Tinh Toan Be Day Thanh OngNguyễn DuyNo ratings yet

- PART NO. Description Material Specification Options: DN Dimensions (Inch) L H1 (Close) H2 (Open) D D1 C n-ΦL Item NoDocument1 pagePART NO. Description Material Specification Options: DN Dimensions (Inch) L H1 (Close) H2 (Open) D D1 C n-ΦL Item NoRodolfo Antonio Cardenas FernandezNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0vajithaNo ratings yet

- 4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Document6 pages4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Piping Class - JS80Document1 pagePiping Class - JS80Дмитрий РыбаковNo ratings yet

- Piping Class - KX70Document2 pagesPiping Class - KX70Дмитрий РыбаковNo ratings yet

- Piping Class - KD80Document1 pagePiping Class - KD80Дмитрий РыбаковNo ratings yet

- Piping Class - IS70Document1 pagePiping Class - IS70Дмитрий РыбаковNo ratings yet

- Piping Class - IS80Document1 pagePiping Class - IS80Дмитрий РыбаковNo ratings yet

- Piping Class - EC11Document2 pagesPiping Class - EC11Дмитрий РыбаковNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- Piping Class - AR71Document2 pagesPiping Class - AR71Дмитрий РыбаковNo ratings yet

- Piping Class - DC21Document2 pagesPiping Class - DC21Дмитрий РыбаковNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- Piping Class - DC11Document2 pagesPiping Class - DC11Дмитрий РыбаковNo ratings yet

- Piping Class - BS20Document2 pagesPiping Class - BS20Дмитрий РыбаковNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - AG70Document2 pagesPiping Class - AG70Дмитрий Рыбаков100% (1)

- Piping Class - BC21Document2 pagesPiping Class - BC21Дмитрий РыбаковNo ratings yet

- Piping Class - BS20Document2 pagesPiping Class - BS20Дмитрий РыбаковNo ratings yet

- Piping Class - AP03Document2 pagesPiping Class - AP03Дмитрий РыбаковNo ratings yet

- Piping Class - BC11Document2 pagesPiping Class - BC11Дмитрий РыбаковNo ratings yet

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- Piping Class - AR75Document2 pagesPiping Class - AR75Дмитрий РыбаковNo ratings yet

- Piping Class - AR20Document2 pagesPiping Class - AR20Дмитрий РыбаковNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- Guidelines For The Oral Presentation Bands Singers e MusicDocument2 pagesGuidelines For The Oral Presentation Bands Singers e Musicjuliusdelazare100% (1)

- FAUDI Aviation Diesel - Company Profile-ENDocument6 pagesFAUDI Aviation Diesel - Company Profile-ENAttila HontváriNo ratings yet

- Intelligent Building FacadeDocument32 pagesIntelligent Building FacadeVeè Vêk JåyswãlNo ratings yet

- Full Cutoff LightingDocument3 pagesFull Cutoff LightingFatma IbrahimNo ratings yet

- Florian1995, Mental HealthDocument9 pagesFlorian1995, Mental Healthade ubaidahNo ratings yet

- Title DefenseDocument3 pagesTitle DefenseLiezl Sabado100% (1)

- 02.03.05.06.01 - Manage Sales Rebate AgreementDocument11 pages02.03.05.06.01 - Manage Sales Rebate AgreementVinoth100% (1)

- RWB 60-856 Inst - Op. Mantto.Document52 pagesRWB 60-856 Inst - Op. Mantto.Daniel Dennis Escobar Subirana100% (1)

- Excel Tips Tricks e-BookV1.1 PDFDocument20 pagesExcel Tips Tricks e-BookV1.1 PDFSulabhNo ratings yet

- Inventory Counting in Inventory ManagementDocument15 pagesInventory Counting in Inventory ManagementDinesh GuptaNo ratings yet

- C PM 71.v2016-12-11 PDFDocument31 pagesC PM 71.v2016-12-11 PDFbobi2201No ratings yet

- Planmeca Promax 3D Max CBVT Product PresentationDocument36 pagesPlanmeca Promax 3D Max CBVT Product PresentationAD TwentyOne DentalNo ratings yet

- GeoDocument6 pagesGeoKanadeTachibana75% (4)

- SAP2000 Analysis - Computers and Structures, IncDocument6 pagesSAP2000 Analysis - Computers and Structures, IncshadabghazaliNo ratings yet

- Section A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentDocument22 pagesSection A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentThanh PhongNo ratings yet

- Intermolecular Force Worksheet KeyDocument3 pagesIntermolecular Force Worksheet KeyBill alfonsoNo ratings yet

- Lac CultureDocument7 pagesLac CultureDhruboNo ratings yet

- Pests and Diseases Identification in MangoDocument4 pagesPests and Diseases Identification in MangoBaino Olpugad Gerald100% (1)

- AI Coming For LawyersDocument4 pagesAI Coming For LawyersbashiNo ratings yet

- A4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Document25 pagesA4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Alonso TabordaNo ratings yet

- Excavation and Trenching Implementation PlanDocument29 pagesExcavation and Trenching Implementation Planracing.phreakNo ratings yet

- JSEA - Hydro Test - 2833Document13 pagesJSEA - Hydro Test - 2833Amit Sharma100% (1)

- Problem Set 1Document2 pagesProblem Set 1Lovedeep SinghNo ratings yet

- Transco Summary Gudinace For Work Method Statements R 0 300912Document12 pagesTransco Summary Gudinace For Work Method Statements R 0 300912kla_alk100% (2)

- Oo All MethodDocument35 pagesOo All Methodmeeraselvam19761970No ratings yet

- Stas 500-2-80 RDocument4 pagesStas 500-2-80 RSzabolcs KovacsNo ratings yet

- I O OrganizationDocument26 pagesI O Organization08-Avinash SNo ratings yet

- TOS 5 Unit 2b Design of Continuous One Way SlabDocument9 pagesTOS 5 Unit 2b Design of Continuous One Way SlabKshitija100% (1)

- Frequency Spectrum On XXX OperatorsDocument4 pagesFrequency Spectrum On XXX OperatorsPeng Yuan FengNo ratings yet

- What's New: Contemporary Quiz#5Document2 pagesWhat's New: Contemporary Quiz#5Christian Castañeda100% (1)