Professional Documents

Culture Documents

Installation Instructions MCD Modbus Module

Uploaded by

pirokiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions MCD Modbus Module

Uploaded by

pirokiCopyright:

Available Formats

MCD Modbus Module

MCD

INSTALLATION INSTRUCTIONS

MCD Modbus Module

MCD MODBUS MODULE

Modbus Module

Order Code: 175G9000

Remove the Modbus Module using the following

Introduction

procedure:

MCD 3000 and MCD 200 Series soft starters can be

1. Remove power from the module.

controlled and monitored across an RS485 serial

2. Remove control power and mains supply from

communication network using the Modbus RTU and

the soft starter.

AP ASCII protocols.

3. Push a small flat-bladed screwdriver into the

For users requiring simple control of an MCD 200 slots at the top and bottom of the module and

soft starter using Modbus RTU or AP ASCII, the depress the retaining clips.

instructions below describe the installation and 4. Pull the module away from the soft starter.

operation of the Modbus Module.

MCD 200 starters can also connect to the network

via a correctly configured Remote Operator - see

Appendix A for details.

MCD 3000 soft starters have AP ASCII protocol

support built in - see the MCD 3000 Operating

177HA378.10

Instructions for details of message formats. The

MCD 3000 supports Modbus RTU control when

used in conjunction with a Remote Operator.

This document describes Modbus messaging and

Appendix A describes how to connect the Remote

Operator. CAUTION

Remove control power and mains supply

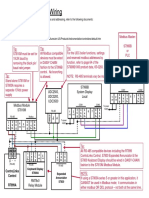

Installation from the soft starter before attaching or

Install the Modbus Module using the following removing accessories. Failure to do so may

procedure: damage the equipment.

1. Remove control power and mains supply from

the soft starter. Adjustment

2. Attach the Modbus Module to the starter as Network communication parameters must be set on

shown. the Modbus Module.

3. Apply control power to the soft starter. AP

ASCII RTU

Protocol

1 2 3 4 5 6

OFF ON

DIP SWITCH A

Example: Address = 24

+16 0 +16 0

+8 0 +8 0

Address +4 0 +4 0

+2 0 +2 0

ON

+1 0 +1 0

ON ON

4800 9600 19200 38400

1 2 3 4 5 6

Baud Rate OFF OFF ON ON

DIP SWITCH B

OFF ON OFF ON

177HA261.10

No Parity ODD EVEN 10 bit

Parity OFF OFF ON ON

OFF ON OFF ON

ON

No Time Out 10 s 60 s 100 s

Timeout OFF OFF ON ON

(seconds)

OFF ON OFF ON

177HA262.11

35 mm

(1.38 inches)

MG.17.F4.02 - VLT is a registered Danfoss trademark 1

MCD Modbus Module

MCD Modbus Module

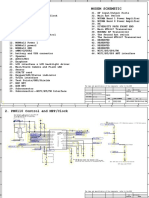

Connection Modbus Register

Register Type Description

177HA326.11

MCD 200

Address

A1

40002 Write 1 = Start

N2

Command 2 = Stop

MODBUS

MODULE 3 = Reset

RS485 4 = Quick stop

SERIAL PORT 5 = Forced communication trip

+ GND -

B8 B7 B6

40003 Read Bit Description

Starter 0 to 3 1 = Ready

status 2 = Starting

3 = Running

4 = Stopping

5 = Restart delay

6 = Tripped

7 = Programming mode

N.B.!: 4 1 = Forward phase rotation

For the Modbus Module to operate correctly, a 5 1 = Current exceeds FLC

link must be fitted across terminals A1-N2 on 6 0 = Uninitialised

the starter. 1 = Initialised (Bit 4 is only

valid if Bit 6 = 1)

7 0 = Remote Operator status

Network Status LED OK

1 = Remote Operator fault

40004 Read 255 = No trip

Trip code 0 = Shorted SCR

177HA263.10

1 = Excess start time

2 = Motor overload

3 = Motor thermistor

4 = Phase imbalance

5 = Supply frequency

6 = Phase rotation

7 = Instantaneous overcurrent

8 = Power circuit fault

LED

9 = Undercurrent

10 = Starter overtemperature

The Network Status LED indicates the state of the

11 = Motor connection error

communications link between the module and the

13 = FLC range error

network. LED operation is as follows:

15 = Communication failure between

Off On Flashing starter and module

No connection Network active Network inactive 16 = Communication failure between

module and network

33 = Bypass overload

N.B.!: 40005 Read

If the network is inactive, the soft starter may Current

trip if the Communications Timeout function has 40006 Read

been set on the module. When communication Temp-

is restored, the MCD 200 will require an erature

individual Reset.

40007 Read Bit Description

Product 0 to 2 Parameter list version

type and 3 to 7 1 = MCD 3000

version 4 = MCD 200

2 MG.17.F4.02 - VLT is a registered Danfoss trademark

MCD Modbus Module

MCD

40008 Read RS485 protocol version Download parameter from starter (MCD 3000 only) -

RS485 Read Parameter 3, Initial Current, 350%

MCD Modbus Module

Modbus Module

Protocol

Message

Function

Address

Address

Register

version

Starter

Code

CRC

Data

40009 to Multiple Upload or download parameters

40061 read or from the starter (see MCD 3000

Starter single Operating Instructions for details) In 20 03 40011 1 CRC1, CRC2

parameters write Out 20 03 2 350 CRC1, CRC2

1 to 53

Only available on MCD 202 and MCD 3000 units. Upload parameter to starter (MCD 3000 only) -

Only available on MCD 3000 units Write Parameter 17, Soft Stop Profile, set = 3

Only available on MCD 202 units.

Message

Function

Address

Address

Register

Starter

Code

Modbus Hex Functions

CRC

Data

MCD 3000 and MCD 200 Series soft starters

support two functions:

In 20 06 40025 3 CRC1, CRC2

• 03 (Multiple Read) Out 20 03 40025 3 CRC1, CRC2

• 06 (Single Write) Modbus Error Codes

MCD 3000 and MCD 200 Series soft starters do not

support broadcast functions. Code Description Example

01 Illegal function code

Function other than 03 or 06

N.B.!: 02 Illegal data addressNot in range 40002 to 40255

Command, Starter Status, Trip Code, Motor Current, 03 Not readable data Register not allowed for data

Motor Temperature, Product Type/Version, RS485 reading

Protocol Version and Parameter Upload must be 04 Not writable data Register not allowed for data

sent individually (i.e. one data word request at a writing

time). 05 Data boundary fault Multiple data transfer across

Least significant bit is transmitted first. data boundary, or data size

more than 127

Command: Start

06 Invalid command Writing "6" into 40002

Message

Function

code

Address

Address

Register

Starter

Code

07 Illegal parameter Invalid parameter number

CRC

Data

read

08 Illegal parameter Invalid parameter number,

In 20 06 40002 1 CRC1, CRC2

write read only, or hidden

Out 20 06 40002 1 CRC1, CRC2

parameter

09 Unsupported Writing parameter with starter

Starter Status: Running command running (not applicable for

Function

MCD 200 Series)

Address

Address

Register

Messag

Starter

Code

10 Local Communication error

CRC

Data

communication between Modbus slave and

e

error starter

In 20 03 40003 1 CRC1, CRC2

Out 20 03 2 xxxx0011 CRC1, CRC2

N.B.!:

Some of the above codes are different from those

Trip Code: Motor Overload

defined in the Modbus Application Protocol

Message

Specification available on www.modbus.org.

Function

Address

Address

Register

Starter

Code

CRC

Data

In 20 03 40004 1 CRC1, CRC2

Out 20 03 2 00000010 CRC1, CRC2

MG.17.F4.02 - VLT is a registered Danfoss trademark 3

MCD Modbus Module

MCD Modbus Module

Commands

AP ASCII Protocol Commands can be sent to the soft starter using the

This section describes AP ASCII communications

following format:

with MCD 200 soft starters. For details of AP ASCII

message formats for MCD 3000 soft starters, see Send Send

ACK ACK

the MCD 3000 Operating Instructions. Address Command

177HA311.10

The message fragments used in communicating with

Possible error responses NAK Invalid LRC

the MCD 200 are shown below. The message

fragments may be assembled into complete

messages as described in the sections that follow.

= Master = Slave (MCD)

Command ASCII Comment

N.B.!:

Data transmitted to and from the Modbus Start B10 Initiates a start

Module must be in 8 bit ASCII, no parity, 1 stop Stop B12 Initiates a stop

bit. Reset B14 Resets a trip state

Coast to stop B16 Initiates an immediate

Message ASCII Character String or removal of voltage from

Fragment Type (Hexadecimal Character String) the motor. Any soft stop

Send address EOT [nn] [lrc] ENQ or settings are ignored.

(04h [nn] [lrc] 05h) Forced B18 Causes a communications

Send command STX [ccc] [lrc] ETX or communication trip

Send request (02h [ccc] [lrc] 03h) trip

Receive data STX [dddd] [lrc] ETX or

(02h [dddd] [lrc] 03h) Status Retrieval

Receive status STX [ssss] [lrc] ETX or Soft starter status can be retrieved using the

following format:

(02h [ssss] [lrc] 03h)

ACK ACK or Send Send Receive

ACK

(acknowledge) (06h) Address Request Status

NAK (negative NAK or

acknowledge) (15h) Possible error responses NAK Invalid LRC

ERR (error) BEL or

177HA316.12

(07h)

= Master = Slave (MCD)

nn = two byte ASCII number representing the soft

starter address where each decimal digit is

represented by n. Request ASCII Receive Status (ssss)

lrc = two byte longitudinal redundancy check in Trip code C18 Requests the trip status of the

hexadecimal. starter.

ccc = three byte ASCII command number where 255 = No trip

each character is represented by c. 1 = Excess start time

dddd = four byte ASCII number representing the 2 = Motor overload

current or temperature data where each 3 = Motor thermistor

decimal digit is represented by d. 4 = Phase imbalance

ssss = four byte ASCII number. The first two bytes 5 = Supply frequency

are ASCII zero. The last two bytes represent 6 = Phase rotation

the nibbles of a single byte of status data in 8 = Power circuit fault

hexadecimal. 15 = Communication failure

between starter and module

16 = Communication failure

between module and network

33 = Bypass overload

4 MG.17.F4.02 - VLT is a registered Danfoss trademark

MCD Modbus Module

MCD

Starter C22 Bit Description

Calculating the Checksum (LRC)

status 0 to 3 0 = Not used

MCD Modbus Module

Each command string sent to and from the starter

Modbus Module

1 = Ready

includes a checksum. The form used is the

2 = Starting (including

longitudinal redundancy check (LRC) in ASCII hex.

Pre-start tests)

This is an 8-bit binary number represented and

3 = Running

transmitted as two ASCII hexadecimal characters.

4 = Stopping

6 = Tripped To calculate LRC:

4 1 = Forward phase 1. Sum all ASCII bytes

rotation 2. Mod 256

5 1 = Current exceeds the 3. 2's complement

FLC 4. ASCII convert

6 0 = Uninitialised

For example Command String (Start):

1 = Initialised (Bit 4 is

ASCII STX B 1 0

only valid if Bit 6 = 1)

or 02h 42h 31h 30h

7 0 = Remote Operator

ASCII Hex Binary

status OK

STX 02h 0000 0010

1 = Remote Operator

B 42h 0100 0010

fault

1 31h 0011 0001

= MCD 202 models only.

0 30h 0011 0000

A5h 1010 0101 SUM (1)

Data Retrieval A5h 1010 0101 MOD 256 (2)

Data can be retrieved from closed loop MCD 202 5Ah 0101 1010 1's COMPLEMENT

models using the following format: 01h 0000 0001 +1=

5Bh 0101 1011 2's COMPLEMENT (3)

ASCII 5 B ASCII CONVERT (4)

Send Send Receive

Address ACK Request Data or 35h 42h LRC CHECKSUM

The complete command string becomes:

177HA313.10

Possible error responses NAK Invalid LRC ASCII STX B 1 0 5 B ETX

or 02h 42h 31h 30h 35h 42h 03h

To verify a received message containing an LRC:

= Master = Slave (MCD)

1. Convert last two bytes of message from ASCII to binary

nd

2. Left shift 2 to last byte four bits

Request ASCII Receive Data (dddd)

3. Add to last byte to get binary LRC

Motor current D10 Requests motor current. The

4. Remove last two bytes from message

data is four byte decimal ASCII.

5. Add remaining bytes of message

Minimum value 0000 A,

maximum value 9999 A. 6. Add binary LRC

Motor D12 Requests the calculated value 7. Round to one byte

temperature of the motor thermal model as a 8. The result should be zero

% of motor thermal capacity. Response or status bytes are sent from the starter

The data is four byte decimal as an ASCII string:

ASCII. Minimum value is STX [d1]h [d2]h [d3]h [d4]h LRC1 LRC2 ETX

0000%. Trip point is 0105%. d1 = 30h

d2 = 30h

d3 = 30h plus upper nibble of status byte right shifted

by four binary places

d4 = 30h plus lower nibble of status byte

For example status byte = 1Fh, response is:

STX 30h 30h 31h 46h LRC1 LRC2 ETX

MG.17.F4.02 - VLT is a registered Danfoss trademark 5

MCD Modbus Module

MCD Modbus Module

Appendix A - Modbus Control via Remote Using the Remote Operator with MCD 200

Operator RS485 SERIAL COMMS

MCD 200 REMOTE NETWORK CONNECTION

To control a soft starter via an RS485 serial A1 OPERATOR (MODBUS RTU or AP ASCII)

N2 + GND -

communications network using the Remote

REMOTE

Operator, connect the Remote Operator to the

RS485 4-20 mA RS485 RS485 POWER

SERIAL PORT MCD NETWORK SUPPLY

network as described in the following sections. + GND - + - - GND + - GND + ~/+ ~/-

68 61 69 B10 B11 B1 B2 B3 B6 B7 B8 1 2

Grounding and Shielding

Twisted pair data cable with earth shield is

177HA339.12

recommended. The cable shield should be

connected to a GND device terminal at both ends

4-20 mA SUPPLY VOLTAGE

and one point of the site protective earth. ANALOGUE OUTPUT 18 ~ 30 VAC / VDC

(MOTOR CURRENT)

Termination Resistors Using the Remote Operator with MCD 3000

In long cable runs prone to excessive noise In order to operate correctly on the network, the

interference, termination resistors should be installed MCD 3000 must be set for local operation only (i.e.

between B1 (-) and B3 (+) of the soft starter and the set Parameter 20 = 2). The Remote Operator's

Remote Operator. This resistance should match the default communications protocol setting is AP ASCII.

cable impedance (typically 120 Ω). Do not use wire

wound resistors. The RS485 Network Timeout setting on the Remote

Operator applies to the link between the Remote

Network Remote Operator RS485 Soft Starter Operator and the network. This can be set to any

Master RS485

B8 B3 B3 value between 0 and 100 seconds.

120 120 120 120

B6 B1 B1

177HA377.10

B7 B2 B2

GND GND GND GND MCD 3000 REMOTE OPERATOR RS485 SERIAL COMMS

NETWORK CONNECTION

(MODBUS RTU or AP ASCII)

+ GND -

RS485 Data Cable Connection

RS485 4-20 mA RS485 RS485 POWER

Daisy chain connection is recommended. This is SERIAL PORT STARTER NETWORK SUPPLY

+ GND - + - - GND + - GND + ~/+ ~/-

177HA376.10

achieved by parallel connections of the data cable at B3 B2 B1 B10 B11 B1 B2 B3 B6 B7 B8 1 2

the actual device terminals.

Remote Operator RS485 Network Connection

Specifications

Input impedance: .............................................. 12 kΩ 4-20 mA SUPPLY VOLTAGE

ANALOGUE 18 ~ 30 VAC / VDC

OUTPUT

Common mode voltage range:.............- 7 V to + 12 V

Input sensitivity: .......................................... ± 200 mV The Serial Timeout setting on the MCD 3000

Minimum differential output voltage: (Parameter 24) applies to communications between

.................................1.5 V (with max loading of 54 Ω) the Remote Operator and the MCD 3000. See the

MCD 3000 Operating Instructions for soft starter

configuration details.

6 MG.17.F4.02 - VLT is a registered Danfoss trademark

MCD Modbus Module

MCD

6 Motor FLC (A) 10 1 to 2868

Programming

7 Analogue 100 80 to 120

MCD Modbus Module

The Remote Operator must be configured to operate

Modbus Module

output 4 mA

on the network. In order to access Programming offset (%)

Mode, the Remote Operator must be powered up 8 Start, Stop, 0 0 = Remote Operator

when the soft starter is not running. Quick stop and Network start,

function stop, quick stop

Programming Procedure disable function enabled.

1. To enter Programming Mode, hold down the 1 = Remote Operator

Data/Prog pushbutton for four seconds. The start, stop, quick

default value of the first parameter will be stop function

displayed. enabled. Network

2. Use the Data/Prog pushbutton to advance to start, stop, quick

the next parameter. stop function

3. Use the Stop/+ and Reset/- pushbuttons to disabled.

adjust parameter values. 2 = Remote Operator

Programming Mode closes when the Data/Prog start, stop, quick

pushbutton is pressed after Parameter 8. stop function

disabled. Network

N.B.!: start, stop, quick

There is a 20 second timeout when the Remote stop function

Operator is in Programming Mode. Programming enabled.

Mode will automatically close if no input is 3 = Remote Operator

registered for 20 seconds. Any changes already start, stop, quick

made will be saved. stop function

disabled. Network

Programmable Parameters start, stop, quick

The Remote Operator offers the following stop function

programmable parameters: disabled. ,

Remote Operator Reset/- pushbutton is always

Par . Description Default Adjustable Range

enabled.

No. Setting

RS485 Network reset and forced communication

1 RS485 4 2 = 2400 baud

trip functions are always enabled.

network baud (9600 3 = 4800 baud

rate baud) 4 = 9600 baud

5 = 19200 baud

6 = 38400 baud

2 RS485 20 1 to 99

network

satellite

address

3 RS485 0 0 to 100 seconds

network seconds

timeout (= off)

4 RS485 1 1 = AP ASCII

network (AP protocol

protocol ASCII) 2 = Modbus RTU

protocol

5 Modbus 0 0 = no parity

protocol parity (no 1 = odd parity

parity) 2 = even parity

3 = 10-bit

transmission

MG.17.F4.02 - VLT is a registered Danfoss trademark 7

MCD Modbus Module

MCD Modbus Module

Troubleshooting

The Remote Operator display and status indication LEDs can indicate abnormal operating and system conditions.

The following messages indicate an error in the Remote Operator's link to the RS485 network:

Display Problem Possible Solution

Indication

nEt on display A loss of communication The Remote Operator has an RS485 Network Timeout Protection

has been detected on the setting (Parameter 3). This error is reported when no communication

RS485 link to the network. occurs for longer than the timeout setting. The system will become

active as soon as communication is restored.

To clear nEt from the display, press the Data/Prog pushbutton

momentarily or send a Reset command from the network Master.

SP flashing on Soft starter is off and being Finish soft starter network programming procedure and exit

display programmed from the serial Programming Mode.

network.

Appendix B - Specifications

Enclosure

Dimensions ............................................................................................... 35 mm (W) x 157 mm (H) x 90 mm (D)

Weight ......................................................................................................................................................... 250 g

Protection ...................................................................................................................................................... IP20

Mounting

Spring-action plastic mounting clips (x 2)

Connections

Soft starter ............................................................................................................................ 6-way pin assembly

Network ...................................................................... 5-way male and unpluggable female connector (supplied)

2

Maximum cable size ................................................................................................................................ 2.5 mm

Settings

Protocol .......................................................................................................................... Modbus RTU, AP ASCII

Address range ........................................................................................................................................... 0 to 31

Data rate (bps) ............................................................................................................ 4800, 9600, 19200, 38400

Parity .............................................................................................................................. None, Odd, Even, 10-bit

Timeout ..................................................................................................................... None (off), 10 s, 60 s, 100 s

Certification

C ............................................................................................................................................. IEC 60947-4-2

CE .............................................................................................................................................. IEC 60947-4-2

8 MG.17.F4.02 - VLT is a registered Danfoss trademark

You might also like

- 710-02653-00G Modbus Interface Instructions AuComDocument12 pages710-02653-00G Modbus Interface Instructions AuComJosé Valentin Taveras FriasNo ratings yet

- AucomDocument10 pagesAucomAlberto Suazo BasaezNo ratings yet

- Modbus SiemenDocument8 pagesModbus Siemenpham tuanNo ratings yet

- MODBUS Interface: Communication PrinciplesDocument14 pagesMODBUS Interface: Communication PrinciplesMilson RodriguesNo ratings yet

- Tarjeta de Expansión Neptronic - CMMB106 - 10162022Document12 pagesTarjeta de Expansión Neptronic - CMMB106 - 10162022Cesar Arturo SanchezNo ratings yet

- Manual Técnico Del Módulo IQ ModbusDocument57 pagesManual Técnico Del Módulo IQ ModbusGaleano Castrillonz AndresNo ratings yet

- CL-RM-UDC Modbus NetworkDocument4 pagesCL-RM-UDC Modbus NetworkMarco PorrasNo ratings yet

- Proteus Sdi12 MODBUS Output Operating ManualDocument9 pagesProteus Sdi12 MODBUS Output Operating Manualangel de jesus meriño pabonNo ratings yet

- Modbus Server Box For Energy Meter-Quick GuideDocument2 pagesModbus Server Box For Energy Meter-Quick GuideFreeLatinBirdNo ratings yet

- Important User Information: 2.2. Physical InstallationDocument12 pagesImportant User Information: 2.2. Physical InstallationRodrigo SgrilloNo ratings yet

- Tarjeta de Expansión Neptronic - CMMB100 - 10162021Document8 pagesTarjeta de Expansión Neptronic - CMMB100 - 10162021Cesar Arturo SanchezNo ratings yet

- Modbus Application Protocol V1 1bDocument51 pagesModbus Application Protocol V1 1bDarko NovakovicNo ratings yet

- Me30 24e6 (M)Document6 pagesMe30 24e6 (M)Стефан ПериндевNo ratings yet

- Biotector B3500 Analyzer Modbus V1.1 Addendum: User Manual 10/2019, Edition 1Document32 pagesBiotector B3500 Analyzer Modbus V1.1 Addendum: User Manual 10/2019, Edition 1Rodrigo MuñozNo ratings yet

- Ap Schemetic Modem Schemetic: Huawei Tech Co.,LtdDocument50 pagesAp Schemetic Modem Schemetic: Huawei Tech Co.,LtdJhorgen LopezNo ratings yet

- Modbus Scanner Configuration Overview: Configuring Modbus RTU Master and Modbus/TCP Client OperationDocument1 pageModbus Scanner Configuration Overview: Configuring Modbus RTU Master and Modbus/TCP Client OperationKenawy MohammedNo ratings yet

- User Manual Gw-Dlms - MARCOMDocument14 pagesUser Manual Gw-Dlms - MARCOMars21No ratings yet

- Tarjeta de Expansión Neptronic - CMMB102 - 10152022Document12 pagesTarjeta de Expansión Neptronic - CMMB102 - 10152022Cesar Arturo SanchezNo ratings yet

- Instruction Manual VA 5xx Modbus RTU Slave InstallationDocument28 pagesInstruction Manual VA 5xx Modbus RTU Slave InstallationMuhammad JunaidNo ratings yet

- ME96 - Programming Manual (Modbus) LSPM-0075-0 (07.16)Document94 pagesME96 - Programming Manual (Modbus) LSPM-0075-0 (07.16)Yusuf DwiNo ratings yet

- Modbus Quick StartDocument3 pagesModbus Quick StartNash JungNo ratings yet

- SKY74068-11: Dual-Band, Dual-Mode Transmitter For CDMA, AMPS, and PCS Mobile Handset ApplicationsDocument2 pagesSKY74068-11: Dual-Band, Dual-Mode Transmitter For CDMA, AMPS, and PCS Mobile Handset ApplicationscopslockNo ratings yet

- 2GCS214012A0050 - RS485 User GuideDocument8 pages2GCS214012A0050 - RS485 User GuideChristian MolestinaNo ratings yet

- Selection GuideDocument1 pageSelection GuideF. PratomoNo ratings yet

- MODBUS ADVC Controller Range PDFDocument14 pagesMODBUS ADVC Controller Range PDFv1a2n3e4No ratings yet

- SOL Modbus IM EN DB68-07538A-00 171020Document20 pagesSOL Modbus IM EN DB68-07538A-00 171020Gentrit FejzaNo ratings yet

- Cdsfaq 24510480 280923 1120 271Document3 pagesCdsfaq 24510480 280923 1120 271Олег ЕфимовNo ratings yet

- Modbus Application Protocol V1 1aDocument51 pagesModbus Application Protocol V1 1aGabriel FuchsNo ratings yet

- Honeywell S7810M Modulo ModbusDocument24 pagesHoneywell S7810M Modulo Modbuscamus1125No ratings yet

- 2CDC194005D0201 - MRP31.0 Modbus RTU FBPDocument24 pages2CDC194005D0201 - MRP31.0 Modbus RTU FBPFarshad MahmoudiNo ratings yet

- Red-R DCDocument16 pagesRed-R DCTikno PurwantoNo ratings yet

- Manual LL de Pinter ToshibbaDocument109 pagesManual LL de Pinter ToshibbaSarah MillerNo ratings yet

- AO2020 Modbus MapDocument34 pagesAO2020 Modbus MapcesarintiNo ratings yet

- (Hybrid) Modbus Server For Energy Meter-Quick Guide - 20141001Document2 pages(Hybrid) Modbus Server For Energy Meter-Quick Guide - 20141001Adnan NasrNo ratings yet

- Modbus Guidelines Rev 0.9 May 2020Document18 pagesModbus Guidelines Rev 0.9 May 2020junefirehdNo ratings yet

- MD30C 30A DC Motor Driver User ManualDocument16 pagesMD30C 30A DC Motor Driver User ManualGABRIEL MONDRAGON TRUJILLONo ratings yet

- SECTION 2.35: Esm System CommunicationsDocument12 pagesSECTION 2.35: Esm System CommunicationsKatty CachagoNo ratings yet

- LULC031Document22 pagesLULC031Lucía FontanaNo ratings yet

- Coolmay Manual PLCDocument7 pagesCoolmay Manual PLCCristian VelezNo ratings yet

- GW-7552 (Modbus RTU Master) Example For SIMATIC STEP 7Document20 pagesGW-7552 (Modbus RTU Master) Example For SIMATIC STEP 7AALANTEMESNo ratings yet

- Microcontroller Programming: D.Thulasi Contract Lecturer ECE Quli Qutubshah Government PolytechnicDocument11 pagesMicrocontroller Programming: D.Thulasi Contract Lecturer ECE Quli Qutubshah Government Polytechnicsairam dastariNo ratings yet

- UD70 MD29: Installation GuideDocument15 pagesUD70 MD29: Installation GuidesabilNo ratings yet

- RS485 Modbus Adapter For RVT Controller: User GuideDocument10 pagesRS485 Modbus Adapter For RVT Controller: User GuideMartinCastilloSancheNo ratings yet

- User - Manual GW-DLMS-485-SL7 - 5.59 - enDocument14 pagesUser - Manual GW-DLMS-485-SL7 - 5.59 - enIkhwan Firdaus NurgumilarNo ratings yet

- Irjet V4i3112 PDFDocument4 pagesIrjet V4i3112 PDFrajuNo ratings yet

- 1800R 8Document8 pages1800R 8Raju SkNo ratings yet

- XP10-M Ten Input Monitor Module: Installation and Maintenance InstructionsDocument4 pagesXP10-M Ten Input Monitor Module: Installation and Maintenance InstructionsRobel MTNo ratings yet

- Sound Level MeterDocument20 pagesSound Level MeterEng13No ratings yet

- Transmission Tower DesignDocument4 pagesTransmission Tower DesignAbhishek KumarNo ratings yet

- Cisco Catalyst 9300 Series Switches Hardware Installation GuideDocument122 pagesCisco Catalyst 9300 Series Switches Hardware Installation GuideashokkanhanNo ratings yet

- CH 2Document13 pagesCH 2Hamadi Ben SassiNo ratings yet

- Comunicacion ModbusDocument4 pagesComunicacion ModbusFrancisco FuentesNo ratings yet

- MGate MB3Document2 pagesMGate MB3MUHAMMAD TAUFIQNo ratings yet

- MN DT 958i Ibox Mbs Nid3000Document36 pagesMN DT 958i Ibox Mbs Nid3000Jaroslav AcsNo ratings yet

- BP Obvius Best PracticesDocument12 pagesBP Obvius Best Practicessahil4INDNo ratings yet

- Analog ModuleDocument1 pageAnalog ModuleTrần TàiNo ratings yet

- Manual de Usuario - Cisco 9300 Series ESDocument132 pagesManual de Usuario - Cisco 9300 Series ESJosé FigueroaNo ratings yet

- Chapter 12 MITSUBISHI - MELSEC-A PLCDocument12 pagesChapter 12 MITSUBISHI - MELSEC-A PLCJesús Manuel De León HernándezNo ratings yet

- C673b ModLon II Instruction Sheet PDFDocument48 pagesC673b ModLon II Instruction Sheet PDFRobertNo ratings yet

- LA 5.2 - FunctionsDocument3 pagesLA 5.2 - FunctionsqwertNo ratings yet

- 2021 Free PowerStore Solutions DES-1221 DumpsDocument11 pages2021 Free PowerStore Solutions DES-1221 DumpskaronbillNo ratings yet

- UntitledDocument13 pagesUntitledSonu KumarNo ratings yet

- SFL A en Tcd210216ab Modi 20210902 Catalog WDocument6 pagesSFL A en Tcd210216ab Modi 20210902 Catalog WAbraham GutierrezNo ratings yet

- Solidworks 3D Cad - Solidworks 2020Document7 pagesSolidworks 3D Cad - Solidworks 2020Nisarg MehtaNo ratings yet

- ITIL4 DITS Case StudyDocument8 pagesITIL4 DITS Case StudyAsuka Saito100% (1)

- Access Control & Video Intercom Hikvision 201708 PDFDocument54 pagesAccess Control & Video Intercom Hikvision 201708 PDFmarvi78No ratings yet

- Modul Kombio 2019 PDFDocument72 pagesModul Kombio 2019 PDFFashalli Giovi BilhaqNo ratings yet

- File Do An ThuDocument11 pagesFile Do An Thusanbay phanthietNo ratings yet

- Commission On Higher Education Illana Bay Integrated Computer College, IncDocument4 pagesCommission On Higher Education Illana Bay Integrated Computer College, Incalican karimNo ratings yet

- SDLC ModelsDocument31 pagesSDLC ModelsSandesh AhirNo ratings yet

- Final Year Project Proposal - AgcDocument8 pagesFinal Year Project Proposal - AgcOsei SylvesterNo ratings yet

- Role of Accounting Information Systems and Its Potential Contribution in Tax ComputationsDocument5 pagesRole of Accounting Information Systems and Its Potential Contribution in Tax ComputationsCarrya LovatoNo ratings yet

- 2021 PolycubeDocument19 pages2021 Polycube凌甘No ratings yet

- WWW Folderico Com How To Customize Folderico Menu HTMLDocument7 pagesWWW Folderico Com How To Customize Folderico Menu HTMLJORGE PACHECONo ratings yet

- Infrastructure Administrator LinuxDocument3 pagesInfrastructure Administrator Linuxbiru kumarNo ratings yet

- IBC100-e IntDocument2 pagesIBC100-e IntavryoneNo ratings yet

- LogDocument36 pagesLogTain KucinanNo ratings yet

- Invoice EUINTR21 32330Document1 pageInvoice EUINTR21 32330Emre OralNo ratings yet

- BD 53Document5 pagesBD 53Ahmed AlkabodyNo ratings yet

- Packard Bell Onetwo M3350 / Onetwo M3351 / Onetwo L5350 / Onetwo L5351 All-In-One Computer Service GuideDocument122 pagesPackard Bell Onetwo M3350 / Onetwo M3351 / Onetwo L5350 / Onetwo L5351 All-In-One Computer Service Guidemcgyver972No ratings yet

- Pertemuan 3 - Bad SmellsDocument16 pagesPertemuan 3 - Bad SmellsSuhada RahmatNo ratings yet

- Dsa Cheatsheet: Code LibraryDocument4 pagesDsa Cheatsheet: Code Library20I307 - AKSHAYA BNo ratings yet

- Angularjs - Mock TestDocument5 pagesAngularjs - Mock TestAAtrey jhaNo ratings yet

- Dokumen - Tips Ericsson Rbs Ret Alarms Troubleshooting Guide Flow Chart v2Document1 pageDokumen - Tips Ericsson Rbs Ret Alarms Troubleshooting Guide Flow Chart v2Oscar GonzalezNo ratings yet

- Instruction Manual: HI144 T-LoggerDocument2 pagesInstruction Manual: HI144 T-LoggerJuan Guillermo Morales SaldarriagaNo ratings yet

- Digital Learning Materials: Classification and Implications For The CurriculumDocument2 pagesDigital Learning Materials: Classification and Implications For The CurriculummwasNo ratings yet

- Fs2311001 Autopulse AP 100 Product Overview Us DigitalDocument2 pagesFs2311001 Autopulse AP 100 Product Overview Us DigitalengrjameschanNo ratings yet

- PaperCut MF - Ricoh SmartSDK Embedded Manual-2018-08-10Document40 pagesPaperCut MF - Ricoh SmartSDK Embedded Manual-2018-08-10Vinicius MeversNo ratings yet

- Ib 0600562 EngfDocument25 pagesIb 0600562 EngfGod Damn Fu cking DegenerateNo ratings yet