Professional Documents

Culture Documents

Unit 15 Location Strategy: Objectives

Uploaded by

Jyoti YadavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit 15 Location Strategy: Objectives

Uploaded by

Jyoti YadavCopyright:

Available Formats

Distribution Network

Planning UNIT 15 LOCATION STRATEGY

Objectives

After reading this unit you would be able to

• discuss the steps in location planning;

• discuss the interdependence of location decision and distribution decision; and

• describe various measure for warehouse location.

Structure

15.1 Introduction

15.2 Plant Location

15.3 Distribution Problem

15.4 Warehouse Location

15.5 Retail Facility Location

15.6 Summary

15.7 Self Assessment Questions

15.8 References and Suggested Further Readings

15.1 INTRODUCTION

Facilities and their locations are major issues in an organization’s logistics system

efficiency and its ability to successfully implement its competitive advantage. Facility

location decisions are of major importance to a company’s ability to compete in the

market. Determining appropriate locations for facilities such as plants, warehouses,

retail stores, hospitals etc. represents an important strategic decision.

The choice of location for the place of business is one of the earliest problems facing

management. Location decisions come under the category of long-term decisions.

They involve long-term commitments. A plant location decision cannot be reviewed

until after quite sometime as they involve huge investments. Location decisions also

have effect on the operating costs/revenues. For example, a bad location decision

may call for excessive transportation costs, shortage of skilled workforce, loss of

competitive advantage, inadequate supply of raw materials etc.

Organizations are involved in location decisions for a variety of reasons such as the

followings:

• Expansion of existing facilities

• Addition of new facilities

• Closing down the plant at one location and moving to another.

Firms may experience growth in business and wish to increase the plant capacities.

Addition of new plants to complement an existing system is often contemplated.

Firms such as banks, supermarkets, retail stores consider location as a marketing

strategy and look for locations that will help them in expanding their markets.

Let us look at the importance of location in the context of business logistics. Business

logistics refers to the management of all move-store activities that facilitate product

flow to the point of final consumption. Figure 15.1 presents the key elements of a

logistics system or the production / distribution system.

1

Content Digitized by eGyanKosh, IGNOU

Locational Strategy

Suppliers

Planning

Flow of Goods

Flow of Information

Manufacturing

Plant

Warehouse

Retail Store

Customers

Figure 15.1: Production / Distribution System

The key elements of the production/distribution system are: transportation, inventory

and order processing. Raw materials are ordered from the suppliers. These are

transported to the manufacturing plant for production into finished goods. Finished

goods are shifted to warehouse (also called distribution centers) and finally to retail

stores from where they are made available to customers. In order to have an

effective production and distribution system, business logistics coordinates the

production and marketing efforts. One of the important goals of marketing

management is to make the product available to customers at the right place and the

right time. Thus the decision of where a product is produced and stored is very

important. Production management, on the other hand, is concerned with maintaining

high productivity at low cost. A product mix that seeks only to satisfy marketing

goals may lead to inefficiencies in production. Similarly, decisions that consider

only production efficiencies may lead to high distribution costs and low customer

service.

The main objective of location decisions is to position each element of the production

/distribution system with respect to the overall system. A manufacturing plant must

be strategically positioned between its supplies and customers. The location problem

is more complex for large firms; they must position both plants and warehouse

simultaneously with respect to suppliers, retail outlets and each other. Rarely, all these

facilities are located simultaneously.

The typical case involves locating a new plant with respect to suppliers and a given

number of warehouses or locating a set of warehouses with respect to manufacturing

plants and markets.

We shall discuss here the problems of plant location, warehouse location, in the

distribution system and the special cases of locating retail stores and emergency

services.

Content Digitized by eGyanKosh, IGNOU

Distribution Network

Planning 15.2 PLANT LOCATION

Choice of location for a plant is one of the earliest problems facing management. But

location, perhaps, is one of the most neglected aspects of business, although the

manufacturing and distribution costs may vary by over 10 percent simply by virtue of

choice of location. The golden rule of business applies to location decisions as well.

The Golden Rule of Business states that the ones with gold make the rules.

There are two types of factors (or criteria) on which location decisions are based:

quantitative (or objective) factors and qualitative (or subjective) factors. The

objective factors involve cost of land, transportation costs, utilities rates etc. The

subjective factors include labour availability, climate, community environment, quality

of life, local politics etc.

The presence of objective and subjective factors results in greater degree of

complexity in the structure of the plant location problem as well as its solution. A

decision made on these factors is difficult as they are consistent over all locations.

For example, a plant may be located far from work but have lower utility bills related

to the area closer to work. Some factors may be more dominant than others. For

example, on mineral production plants, raw materials dominate the situations due to

which processing is located near mines. On the other hand, output oriented activities,

such as service organizations tend to be located near consumers. Table 15.1 presents

a list of some of the important location factors.

Table 15.1: Location Factors Determining Plant Location

Transportation Utilities Labor Climate, Community, States and Local

Factors Factors Factors Environment etc. Political Factors

• Proximity to • Power • Labor supply • Climate and living • Taxation policies

raw material • Water • Labor management conditions • Tax structure

sources • Fuel relations • Education

• Closeness to • Waste • Availability of • Community attitude

markets disposal skilled labor • Religious factors

• Modes of • Labor costs

transportation

• Transportation

costs

15.2.1 Steps in Location Planning

Location planning involves the following steps:

1) Determine the criteria to evaluate location alternatives (for example: minimize

costs)

2) Identify relevant location factors

3) Develop location alternatives

a) Identify the general region

b) Identify a small number of community site alternatives

4) Evaluate the alternatives and make a selection.

15.2.2 Evaluation of Location Alternatives

As stated earlier, the plant location problem involves both qualitative and quantitative

factors. Finding the best location alternative considering all the above factors is not an

3

Content Digitized by eGyanKosh, IGNOU

easy one. Attempts have been made to combine the qualitative and quantitative Locational Strategy

factors and score the alternatives. One of the scoring (or rating) models is outlined

below (Table 15.2).

The procedure starts by listing the various factors and assigning weight to each factor

to represent the relative importance of various factors. The score for each alternative

is found by multiplying each factor’s score by its weight and summing the results.

Table 15.2 gives the details of this rating approach for two locations A and B.

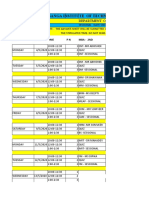

Table 15.2: Rating Approach

Location factor Weight Score (out of 100) Weighted Score

A B A B

1. Labor Costs 0.40 70 90 70 × 0.40=28 90 × 0.40=36

2. Water supply 0.10 80 90 8 9

3. Climate 0.15 80 90 12 13.5

4. Proximity to Raw 0.20 40 70 8 14

Materials

5. Transportation Costs 0.10 80 90 8 9

6. Taxes 0.05 80 80 4 4

Total Score 68 85.5

From Table 15.2, we see that location B that has a higher score is preferred.

However one has to be careful in the use of the rating approach because of the

assessment of scores, which might have involved some amount of subjectivity. For

example, if the total score for location B were 70, which is very close to that of A,

one need to go for further analysis before arriving at the final decision.

15.3 DISTRIBUTION PROBLEM

The distribution problem is concerned with the allocation of goods flow to minimize

overall distribution cost. Most distribution systems are three-tired structures in which

goods start from the plant; flow to warehouse and ultimately to outlets. Warehousing

plays a crucial role in the total distribution system. Consider for example, a large

chain, which manufactures many products, maintains regional distribution centers and

owns a large number of retail store (Figure 15.1). The firm has control over the

location of all intermediate members of the logistics system.

In the absence of any warehouse, shipments of finished goods would have to be

made directly from the plant to the retail stores. If the plant is located far from the

raw material sources, inbound transportation costs would be high and delivery times

would be high, thereby increasing the chances of material shortage for production. If

the plant is located far from the group of retail stores, then also transportation costs

(i.e. outbound transportation costs) would be high and it takes longer to deliver orders

to retail stores. This may result in out-of-stock situations thereby reducing the level of

customer service. Warehouses placed close to the market can provide quick and

efficient delivery to retail stores, while still permitting the plants to be placed near raw

material sources. Warehouses and distribution centers play as important

intermediaries between plants and retail stores. They allow a company to store

finished goods for efficient distribution to points of use. The role of warehouses is

illustrated in Figure 15.2.

Content Digitized by eGyanKosh, IGNOU

Distribution Network

Planning

Plant 1 Plant 2 Plant 1 Plant 2

Warehouse

1 2 3 4 5 1 2 3 4 5

Retail Stores Retail Stores

(a) Without Warehouse (b) With Warehouse

Figure 15.2: Role of Warehouse

It can be seen from Figure 2 that the provision of intermediaries like warehouse

reduces considerably the number of interactions from 10 (i.e. 2 x 5) to 7 (i.e. 2 + 5).

There are other benefits associated with the provision of warehouses since they

support both manufacturing as well as retail stores. For example, warehouse

facilitates consolidation of orders.

A number of decisions should be made with regard to warehousing. Among the most

important warehousing decisions are the determination of number and location of

warehouses. The other decisions include the following:

• Which products should be stored in each warehouse?

• Should public or private warehouses be used?

• What type of material-handling equipment should be used?

• Which customers should be assigned to each warehouse?

We shall discuss the warehouse location problem in the following section.

Activity 1

Write True or False against the following statements.

1. The facility location decision belongs to the tactical decision area.

2. In all location problems, there is a unique location that is superior to all others.

3. Business logistics and facility location are unrelated issues.

4. Logistics management refers to the management of transportation function.

5. In the location of a gasoline station, labor availability is one of the most important

factors.

6. The location of aluminum reduction industry is energy-oriented.

7. For facility location, manufacturing costs are more important than transportation cost,

since the latter are going to be incurred anyway.

8. For facility location, quality of life in a given location is an irrelevant factor.

9. Scoring models are used exclusively in location decisions.

10. There is no difference between location decisions for manufacturing and service

organizations.

11. The major criterion for location of a retail outlet is the volume of demand.

12. One of the principal disadvantages of computerized logistics modeling is the ability to

easily modify data and perform “what if” analysis.

13. The presence of organized labor unions is irrelevant to the location decision.

5

Content Digitized by eGyanKosh, IGNOU

Locational Strategy

15.4 WAREHOUSE LOCATION

In this section we present method(s) for determining the location(s) for

warehouse(s). It is assumed that there are a number of existing facilities in place and

we wish to find the optimum location of a new facility (or new facilities). The existing

facilities could be plants, retail stores. The new facilities could be warehouse. The

approaches take into account the locations of plants and markets, volume of goods

moved and transportation costs. All these models focus on minimizing transportation

costs.

15.4.1 Measures of Distance

Two measures of distance for movement of items are commonly used: Rectilinear

distance and Euclidean (straight line) distance.

The rectilinear distance (also known as metropolitan distance) recognizes that streets

usually run in a crisscross pattern.

Let the existing facility be located at the point (a, b) and let (x, y) be the location of

the new facility. The rectilinear distance between (a, b) and (x, y) is |x – a | + | y – b|,

whereas

The Euclidean distance is √(x–a)2 + (y–b)2

Figure 15.3 illustrates the two distance measures.

Rectilinear

(a,b) distance

Euclidean distance

(x,y)

Figure15.3 : Rectilinear and Euclidean Distance

Rectilinear distance is appropriate for many location problems such as in metropolitan

areas. In many manufacturing situations, material is transported along aisles arranged

in rectilinear pattern. Fortunately, rectilinear distance problem is easier to solve than

Euclidean distance problem.

The problem of locating a simple new facility with respect to a number of existing

problems is known as the single facility location problem whereas the problem of

locating multiple new facilities is known as the multi-facility location problem.

15.4.2 Single Facility Location Problem

In this section you would learn about Single Facility Rectilinear Distance Location

Problem, Squared Euclidean Distance Problem (known as the Gravity Problem) and

the Straight-Line Distance Problem.

6

Content Digitized by eGyanKosh, IGNOU

Distribution Network Single Facility Rectilinear Distance Location Problem

Planning

Let there be “n” existing facilities located at points (a1,b1), (a2,b2)…………,(an,bn).

The objective is to locate the new facility to minimize a weighted sum of the

rectilinear distance from the new facility to existing facilities. The goal is to find the

values of x and y such that

n

minimize ƒ(x,y) = ∑ wi ( x – ai+ y – bi) , where

i =1

wi is the flow of material / goods between the new facility and ith existing facility. The

optimum values of x and y can be determined separately.

ƒ(x,y) = g1(x) + g2(y), where

n n

g1 (x) = ∑

i =1

wi x – ai and g2 (y) = ∑ w y – b

i =1

i i

As we shall see, the x coordinate of the new facility will be same as x coordinate of

some existing facility. Similarly y coordinate of new facility coincides with y

coordinate of same existing facility. An example of the single facility location problem

could be location of a new storage warehouse for a company with an existing

network of production and distribution centers.

Let us consider a case in which there are two existing facilities located at (5,10) and

(20,30) as shown in Figure 15.4. Assume that wi values are all equal to one.

(20,30)

(5,10)

Figure 15.4: Single Facility Rectilinear Location Problem - Two Existing Facilities

The values of g1(x) is equal to 15 for values of x between 5 and 20.

Similarly g2 (y) is 20 for values of y between 10 and 30.

For example, if x = 10 and y = 10

Then g1 (x) = 5 – 10+ 20 – 10 = 15

g2 (y) = 10 – 10 + 30 – 10 = 20

It can be seen that the optimum location for the new facility will be anywhere in the

area bounded by the lines x = 5, x = 20, y = 10 and y = 30.

Any value of x outside the closed interval [5, 20] and any value of y outside the

closed interval [10, 30] gives larger values of g1 (x) and g2 (y). Thus the optimum

solution is (x , y) where 5 ≤ x ≤ 20 and 10 ≤ y ≤ 30 .

The above analysis leads to the Simple Median model, which can be explained, with

the help of the following examples. 7

Content Digitized by eGyanKosh, IGNOU

Suppose there are four existing facilities located at points ( 3 , 3), ( 6 , 9), ( 12 , 8) Locational Strategy

and (12 , 10) and the weights are all of value 1 ( w1 = w2 = w3 = w4 = 1). Rank the x

coordinate in increasing order: 3, 6, 12, 12.

A median value is such that half of values lie above it and half lie below it. Any value

of x between 6 to 12 is a median location and is optimum for this example problem.

The optimum value of g1 (x) is 15.

Similarly ranking the y values 3, 8, 9, 10 gives the median value as any value between

8 and 9 and the minimum value of g2 ( y) = 8. See Figure 15.5.

g1(x) g2(y)

x y

Figure 15.5: Optimum Locations

Let us take another example where there are four existing facilities located at (3,3),

(6,9), (12,8) and (12,10). The weightages are: w1 = 2, w2 = 4, w3 = 3 and w1 = 1.

The problem is equivalent to one where there are two facilities at location (3,3), four

facilities at (6, 9), three facilities at (12, 8) and one facility at (12,10), with weight

equal to 1.

The ranked x value are 3, 3, 6, 6, 6, 6, 12, 12, 12, 12

The median location is x = 6.

The ranked y values are: 3, 3, 8, 8, 8, 9, 9, 9, 9,10.

The median location is any value of y in the interval [8,9].

The optimum value of the objective function is 30 + 16 = 46.

A quicker method of finding the optimum location of the new facility is to compute

the accumulated weight and determine the location (s) corresponding to half of the

accumulated weight as shown below.

Facility X Weight Cummulative Facility X Weight Cummulative

coordinate Weight coordinate

1 3 2 2 1 3 2 2

2 6 4 6 Optimum 3 8 3 5 optimum

X=6 Y is

3 12 3 9 2 9 4 9 between

8 and 9

4 12 1 10 4 10 1 10

(Half of total weight first exceeds at x = 6 (Optimum y is between 8 and 9)

Hence optimum x = 6)

Content Digitized by eGyanKosh, IGNOU

Distribution Network Euclidean Distance Problems

Planning

Although the rectilinear distance measure is applicable in many location problems,

there are situations in which the appropriate measure is the Euclidean or Straight-line

distance. Location of power generating facilities so as to minimize the total length of

electric cable that must be laid out to connect the plant and customer is an example

where the Euclidean distance measure is appropriate.

We shall discuss here the squared Euclidean Distance Problem (known as the

Gravity Problem) and the Euclidean Distance Location Problem.

The Gravity Problem

The Gravity problem corresponds to the case where the distance measure is square

of the Euclidean distance. This measure is appropriate for location of emergency

facilities. The objective is to find the value of (x, y) to minimize

ƒ ( x, y) = ∑ wi [ (x – ai )2 + ( y – bi )2]

The solution to this problem is straight forward and is often used as an approximation

to the more common straight-line distance problem.

To find the optimum value of x and y, the partial derivatives of the objective function

with respect to x and y are found and equated to zero.

∂f ( x, y) n

We get

∂x i =1

∑

= 2 w i (x − a i )

∂f ( x , y ) n

We get

∂y i =1

∑

= 2 w i (y − bi )

Setting these partial derivatives equal to zero and solving for x and y, we get

+

∑w a

i =1

i i

X = n

∑w

i =1

i

+

∑w a

i =1

i i

Y = n

∑w

i =1

i

Thus X+ and Y+ are the weighted averages of x and y coordinates and hence the

name Gravity problem.

The Straight-Line Distance Problem

The straight-line distance measure arises much more frequently than the Gravity

problem. The objective is to find (x, y) to minimize

n

ƒ (x, y) = ∑ wi

i =1

√ (x – ai)2 + (y – bi)2

9

Content Digitized by eGyanKosh, IGNOU

Unfortunately, it is not easy to find the optimum solution mathematically. The partial Locational Strategy

derivatives become undefined when the location of the new facility coincides with

that of an existing facility. There are no known simple algebraic solutions; all existing

methods require an iterative procedure. The Gravity solution is usually selected as the

starting solution for this iterative process.

15.4.3 Multi-facility Location Problem

The problem of locating multiple new facilities with respect to existing facilities is

known as the Multi-facility Location Problem. For example, a countrywide consumer

goods manufacturer might be considering where to locate four new regional

warehouses. There is interaction among new facilities as well as between new and

existing facilities. In some special situations, multi-facility location problem can be

solved as a sequence of single facility location problems.

Linear programming can be used to solve the multi-facility rectilinear distance

location problem. Assume that there are “n” existing facilities located at points

( a1, b1), ( a2 , b2),……(an , bn). Suppose the new facilities are to be located at

(x1 , y1), (x2 , y2), ……….., (xm , ym).

The objective function to be minimized is written as minimize ƒ1 (x) + ƒ2 (y)

m n

Where ƒ1 (x) = ∑ Vjk xj – xk + ∑ ∑ wji xj – ai

i≤j≤k≤m j=1 i=1

m n

and ƒ2 (y) = ∑ Vjk yj – yk + ∑ ∑ wji yj – bi

i≤j≤k≤m j=1 i=1

Vjk represents the interaction between new facilities j and k and wji represents the

interaction between new facility j and existing facility i. The optimum x and y values

can be determined independently as in the case of single facility location problem.

Multi-facility gravity problems require the solution of a system of linear equations, so

that gravity problems involving large number of facilities are easily solved. Multi-

facility Euclidean distance location problems are solved by using multi dimensional

version of the iteration solution procedure described in the previous section.

Activity 2

Fill in the blanks

1) An approach to location analysis that includes both qualitative and quantitative

considerations is ……………………………………………

2) A major advantage of warehousing is that

…………………………………………………………………..

3) The scoring model is both a ……………………………. and

…………………………… model

15.4 RETAIL FACILITY LOCATION

The major criterion used for retail facility location is the volume of demand and hence

estimates of demand must be known for potential locations. Statistical techniques

such as regression analysis can be used to predict demand. For locating facilities that

are oriented toward sales, the principal factors are market related and the important

data are demographic in nature. Other intangible factors, which affect retail location,

are competition, zoning laws, traffic patterns and accessibility etc. Like in plant

location, scoring models may be used to rank potential sites.

10

Content Digitized by eGyanKosh, IGNOU

Distribution Network

Planning 15.4 SUMMARY

As we have seen, the location decision and distribution decision are interdependent.

By considering only one of these, we get poor solutions. Both the problems should be

treated comprehensively.

Comprehensive computerized logistics systems are available to assist management in

achieving efficient solutions. Computerized systems help answering questions such

as: how many warehouses are needed and where they should be located? How

much of each product should be sent to each warehouse from each plant? How

should customers be assigned to warehouse? What modes of transportation are most

economical? For answering such questions, management needs large amounts of data

regarding warehousing and inventory costs, transportation costs, production costs and

so on.

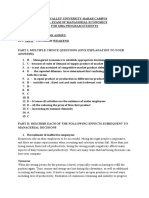

15.5 SELF ASSESSMENT QUESTIONS

1) “The most common method for evaluating non-economic factors in a facility

location study is to use a scoring model” Why? Justify your answer.

2) Is it true that subjective criteria in plant location models focus on long-run cost

effects? If yes, Why?

3) Given the information below, which alternative would you recommend?

Factor Weight Location

A B C

Raw Materials 0.40 50 70 60

Market 0.20 40 40 80

Transportation Cost 0.10 90 70 50

Labor Cost 0.20 40 40 30

Construction Cost 0.10 10 60 30

4) Given the information below, which alternative has the lowest breakeven point?

Alternative Fixed Cost Variable cost/unit Revenue/ Unit

A 30000 10 40

B 40000 15 40

C 50000 20 40

D 60000 30 40

E 70000 40 40

5) Given the following evaluation of subjective factors, find the total score for the

location.

Excellent = 8, Good = 6, Fair = 4, Poor = 3

Factor Rating Weight

Labor Supply Good 40%

Community Attitude Excellent 30%

Government Regulations Fair 20%

Quality of life Good 10% 11

Content Digitized by eGyanKosh, IGNOU

6) Using the following scoring model, select the best location Locational Strategy

Location Attribute 1 2 3 4

Weight 10 25 35 30

A Good Very Good Bad OK

B OK OK Very Good Good

C Good Very Good OK Good

Very Good = 5 points, Good = 4 points, OK = 2 points, Bad = 1 point

15.8 REFERENCES AND SUGGESTED FURTHER

READINGS

1) Ballou R., (1985), Business Logistics Management, Prentice Hall.

2) Francis, R. L. & White J. A. (1974). Facility Layout and Location - An

Analytical Approach, Prentice Hall.

12

Content Digitized by eGyanKosh, IGNOU

You might also like

- 4 - Role of Facilities in The Supply ChainDocument26 pages4 - Role of Facilities in The Supply ChainSYED MURTAZA ABIDINo ratings yet

- L0cation SelectionDocument40 pagesL0cation SelectionbhavnamanajidhengeNo ratings yet

- Location-Decision-And-Case-StudyDocument7 pagesLocation-Decision-And-Case-StudyShynne Abadiano0% (1)

- Facility Location FactorsDocument12 pagesFacility Location FactorsNaveen AmarasingheNo ratings yet

- Location Planning MethodsDocument11 pagesLocation Planning MethodsEdessa MasinasNo ratings yet

- Operational Management POMG2710: Chapter (8) : Location Planning and AnalysisDocument38 pagesOperational Management POMG2710: Chapter (8) : Location Planning and AnalysisلبليايلاNo ratings yet

- Operations Management 12Th Edition Stevenson Solutions Manual Full Chapter PDFDocument61 pagesOperations Management 12Th Edition Stevenson Solutions Manual Full Chapter PDFKaylaVasquezjoqfn100% (9)

- 06 Facility LocationDocument13 pages06 Facility LocationMahad KhadarNo ratings yet

- Chapter 8 - Location Strategy - ClassDocument36 pagesChapter 8 - Location Strategy - ClassVirgo StoreNo ratings yet

- Plant Location and Layout: OutlineDocument26 pagesPlant Location and Layout: OutlineSarahjane TerradoNo ratings yet

- Supply Chain ManagementDocument20 pagesSupply Chain ManagementŞermin ŞahinNo ratings yet

- CUCBA - Op & SCM.21st Batch - Mid.Ch04.Facility LocationDocument25 pagesCUCBA - Op & SCM.21st Batch - Mid.Ch04.Facility LocationCulex PipiensNo ratings yet

- Warehouse Operation Management ReportDocument24 pagesWarehouse Operation Management ReportClinton SamsonNo ratings yet

- Unit 2 VPDocument18 pagesUnit 2 VPVinita ThoratNo ratings yet

- Lesson 6 Location-PlanningDocument28 pagesLesson 6 Location-PlanningSamantha Alice LysanderNo ratings yet

- Plant Location Factors and ModelsDocument38 pagesPlant Location Factors and ModelsDuin Abd AzizNo ratings yet

- Facility LocationDocument27 pagesFacility LocationKaustubh KshetrapalNo ratings yet

- Factors and Quantitative Technique: Submitted To-Dr. Debomalya Ghosh (Assistant Professor)Document24 pagesFactors and Quantitative Technique: Submitted To-Dr. Debomalya Ghosh (Assistant Professor)Akashdeep DebNo ratings yet

- Supply ChainDocument18 pagesSupply ChainmuneerppNo ratings yet

- Unit V Facility, Layout Location and Work MeasurementDocument65 pagesUnit V Facility, Layout Location and Work MeasurementAKASH MNo ratings yet

- Unit - 09 - Facility LocationDocument21 pagesUnit - 09 - Facility Locationnasir mamunNo ratings yet

- Location Planning and Analysis: NotesDocument10 pagesLocation Planning and Analysis: NotesCyrus SantosNo ratings yet

- Assignment 5 Chapter 5Document5 pagesAssignment 5 Chapter 5Abeba GselassieNo ratings yet

- INTL 3003 Module 3 Logistics V1Document41 pagesINTL 3003 Module 3 Logistics V1Manish SadhuNo ratings yet

- How Do You Find Strategic LocationsDocument3 pagesHow Do You Find Strategic LocationsChristine ToledoNo ratings yet

- SCRIPTDocument5 pagesSCRIPTJubeleen DolosaNo ratings yet

- Facility and Location Planning: Learning OutcomesDocument7 pagesFacility and Location Planning: Learning OutcomesMejidana, Rica Mae N.No ratings yet

- Chapter FiveDocument9 pagesChapter FivetibligechtNo ratings yet

- Facility Location FactorsDocument14 pagesFacility Location FactorsReza AunikNo ratings yet

- OSCM Strategy Document SummaryDocument8 pagesOSCM Strategy Document SummaryNi瑾容No ratings yet

- Production and Operations: ManagementDocument62 pagesProduction and Operations: ManagementBhargav KanjariyaNo ratings yet

- 5 Location of FacilitiesDocument8 pages5 Location of FacilitiesMwesigwa DavidNo ratings yet

- Supply Chain Management: Nift, HyderabadDocument19 pagesSupply Chain Management: Nift, HyderabadvishuananthaNo ratings yet

- SMU MBA Semester 2 Spring 2014 Solved AssignmentsDocument3 pagesSMU MBA Semester 2 Spring 2014 Solved AssignmentsRajdeep KumarNo ratings yet

- Operation Management Facility Location FactorsDocument16 pagesOperation Management Facility Location FactorsYash GuptaNo ratings yet

- Study Notes On Distribution & Supply Chain ManagementDocument41 pagesStudy Notes On Distribution & Supply Chain Managementsonu_7krNo ratings yet

- 21MB205 LM1Document44 pages21MB205 LM1Gokul KNo ratings yet

- 9-12 - Location Decision & Facility LayoutDocument63 pages9-12 - Location Decision & Facility LayoutSnehil KrNo ratings yet

- Unit - Iii: Plant Location & Plant LayoutDocument30 pagesUnit - Iii: Plant Location & Plant LayoutVikas SinghNo ratings yet

- UNIT-3: Plant Location and LayoutDocument17 pagesUNIT-3: Plant Location and LayoutJyoti SinghNo ratings yet

- Unit 3: Customer Service: By: Akash JainDocument38 pagesUnit 3: Customer Service: By: Akash JainmohitNo ratings yet

- Facility Location Decisions: Factors to ConsiderDocument21 pagesFacility Location Decisions: Factors to ConsiderShah Maqsumul Masrur TanviNo ratings yet

- Lecture 9 Facility Location ProblemsDocument22 pagesLecture 9 Facility Location ProblemsAMOS SIFUNANo ratings yet

- tối ưu hóa vị trí kho thông qua các quyết định đa tiêu chíDocument20 pagestối ưu hóa vị trí kho thông qua các quyết định đa tiêu chíVo Thi Hong Suong B2003525No ratings yet

- Lecture 03 - Facility LocationDocument33 pagesLecture 03 - Facility LocationThomasaquinos msigala JrNo ratings yet

- 4 5909180511674177039Document25 pages4 5909180511674177039Duke Global100% (1)

- Facility Location Planning and AnalysisDocument63 pagesFacility Location Planning and AnalysisCyrus SantosNo ratings yet

- Operations ManagementDocument6 pagesOperations Managementashish sunnyNo ratings yet

- TQMCH1Document44 pagesTQMCH1Neko MidoriNo ratings yet

- MBA 512 Chapter 1: Introduction to Operations ManagementDocument56 pagesMBA 512 Chapter 1: Introduction to Operations ManagementAnik BhowmickNo ratings yet

- Operations Management 11th Edition Heizer Solutions ManualDocument13 pagesOperations Management 11th Edition Heizer Solutions Manualorlaharveyykh4100% (28)

- Topic 7: Facilities Location and LayoutDocument28 pagesTopic 7: Facilities Location and LayoutCollins AbereNo ratings yet

- Plant Layout & Location FactorsDocument38 pagesPlant Layout & Location FactorsChaitanya DhanawatNo ratings yet

- Build v. Buy A Decision Paradigm For Information Technology ApplicationsDocument8 pagesBuild v. Buy A Decision Paradigm For Information Technology ApplicationsAdrish MukherjeeNo ratings yet

- Supply Chain Design and PlanningDocument25 pagesSupply Chain Design and Planningjoyosakarwyn21No ratings yet

- Chapter 12S Global Sourcing of Production N ServicesDocument43 pagesChapter 12S Global Sourcing of Production N Servicesmark leeNo ratings yet

- Course Mba - 2 Semester Subject Assignment MB0044 - Set 2: Production and Operations ManagementDocument12 pagesCourse Mba - 2 Semester Subject Assignment MB0044 - Set 2: Production and Operations Managementkct_thomasNo ratings yet

- LOCATION PLANNING AND ANALYSISDocument39 pagesLOCATION PLANNING AND ANALYSISKimberlyCondeNo ratings yet

- Week 4 - What Are The Facilities & WarehousingDocument39 pagesWeek 4 - What Are The Facilities & WarehousingHAMNA SYEDNo ratings yet

- Capital Budgeting Under UncertaintyDocument30 pagesCapital Budgeting Under UncertaintyJyoti YadavNo ratings yet

- Strategic Supply Chain ManagementDocument16 pagesStrategic Supply Chain ManagementA vyasNo ratings yet

- Unit 1 Logistics and SCM: An: ObjectivesDocument13 pagesUnit 1 Logistics and SCM: An: ObjectivesA vyasNo ratings yet

- BookingDocument11 pagesBookingJyoti YadavNo ratings yet

- SM Assignments and Service Marketing ConceptsDocument10 pagesSM Assignments and Service Marketing ConceptsJyoti YadavNo ratings yet

- Apple Computer BalDocument2 pagesApple Computer BalJyoti Yadav100% (1)

- Determining Exchange Ratio in MergersDocument2 pagesDetermining Exchange Ratio in MergersJyoti YadavNo ratings yet

- Program-10 Aim:To Study Ms-PowerpointDocument9 pagesProgram-10 Aim:To Study Ms-PowerpointJyoti YadavNo ratings yet

- Unit 18 Design For Supply Chain Management and Greening The Supply ChainDocument16 pagesUnit 18 Design For Supply Chain Management and Greening The Supply ChainkNo ratings yet

- MBA 2 YearDocument120 pagesMBA 2 YearvishalmehandirattaNo ratings yet

- Ugc Net: General Paper On Teaching & Research AptitudeDocument6 pagesUgc Net: General Paper On Teaching & Research AptitudeJyoti YadavNo ratings yet

- Research Methodology Impact Social Media Consumer BehaviorDocument4 pagesResearch Methodology Impact Social Media Consumer BehaviorJyoti YadavNo ratings yet

- Assignments 1Document5 pagesAssignments 1Jyoti YadavNo ratings yet

- Strategic Human Resource Management Quick GuideDocument4 pagesStrategic Human Resource Management Quick GuideSreehari RavindranNo ratings yet

- Sources and Process of Recruitment & Selection at HCLDocument83 pagesSources and Process of Recruitment & Selection at HCLshweta_4666494% (18)

- Sessional Schedule of MbaDocument5 pagesSessional Schedule of MbaJyoti YadavNo ratings yet

- Mba 4TH 2ND Sessional Date SheetDocument4 pagesMba 4TH 2ND Sessional Date SheetJyoti YadavNo ratings yet

- SM Assignments and Service Marketing ConceptsDocument10 pagesSM Assignments and Service Marketing ConceptsJyoti YadavNo ratings yet

- E Commerce Practical FileDocument72 pagesE Commerce Practical FileJyoti Yadav83% (6)

- Ganga Institute video lecture scheduleDocument8 pagesGanga Institute video lecture scheduleJyoti YadavNo ratings yet

- Submitted in The Partial Fulfillment For The Requirement of The Award of Degree ofDocument66 pagesSubmitted in The Partial Fulfillment For The Requirement of The Award of Degree ofJyoti YadavNo ratings yet

- Sessional Schedule of MbaDocument5 pagesSessional Schedule of MbaJyoti YadavNo ratings yet

- EntrepreneurShip Developmet ...Document52 pagesEntrepreneurShip Developmet ...Jyoti YadavNo ratings yet

- Assignment of Strategic HRMDocument1 pageAssignment of Strategic HRMJyoti YadavNo ratings yet

- Ganga Institute video lecture scheduleDocument8 pagesGanga Institute video lecture scheduleJyoti YadavNo ratings yet

- Bba and Mba Sessional Date Sheet (May 2020)Document106 pagesBba and Mba Sessional Date Sheet (May 2020)Jyoti YadavNo ratings yet

- Webinar Attendance (09-05-2020) - MBA 4CDocument1 pageWebinar Attendance (09-05-2020) - MBA 4CJyoti YadavNo ratings yet

- Impact of Demonetization: Keywords: Demonetization, Digital Payments, GDP, Money SupplyDocument7 pagesImpact of Demonetization: Keywords: Demonetization, Digital Payments, GDP, Money SupplyJyoti YadavNo ratings yet

- Program-10 Aim:To Study Ms-PowerpointDocument9 pagesProgram-10 Aim:To Study Ms-PowerpointJyoti YadavNo ratings yet

- Latest Marketing CV Rishabh Jain-1Document1 pageLatest Marketing CV Rishabh Jain-1Shubham RaiNo ratings yet

- National Teachers College ManilaDocument6 pagesNational Teachers College ManilaJeline LensicoNo ratings yet

- Cadbury Schweppes Edition 9 WorksheetDocument3 pagesCadbury Schweppes Edition 9 WorksheetLong Dong Mido0% (1)

- Commercial Invoice Po#6600210291-5057004301 PDFDocument1 pageCommercial Invoice Po#6600210291-5057004301 PDFSandra Lubana Garcia GomezNo ratings yet

- Employee Cost AnalysisDocument9 pagesEmployee Cost AnalysisGokarakonda SandeepNo ratings yet

- 2 Industrial Attachment Final DraftDocument185 pages2 Industrial Attachment Final DraftGolam Rabbi Sagor0% (1)

- HUE Advertising and PhotographyDocument22 pagesHUE Advertising and Photographyhueads100% (2)

- Asasah Islamic Micro FinanceDocument34 pagesAsasah Islamic Micro FinanceAlHuda Centre of Islamic Banking & Economics (CIBE)No ratings yet

- Step 6 Prepare Technology NegotiationsDocument6 pagesStep 6 Prepare Technology NegotiationsjaviarangoNo ratings yet

- Diwali Stock Picks for Samvat 2077/TITLEDocument9 pagesDiwali Stock Picks for Samvat 2077/TITLEJeevan RNo ratings yet

- (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D)Document46 pages(A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D) (A) (B) (C) (D)Mạnh NgọcNo ratings yet

- Political Communication in Local Elections: A Comparative Analysis of France and PolandDocument16 pagesPolitical Communication in Local Elections: A Comparative Analysis of France and PolandDariusz TworzydłoNo ratings yet

- Ebook-ENG-The Ultimate Guide For Visas in Australia-Go Study Australia-1Document41 pagesEbook-ENG-The Ultimate Guide For Visas in Australia-Go Study Australia-1Mico de LeonNo ratings yet

- Alyssa Li ResumeDocument1 pageAlyssa Li ResumeMING JUNo ratings yet

- GQ - November 2015 UKDocument426 pagesGQ - November 2015 UKDanh ẨnNo ratings yet

- AirAsia's Social Responsibility and CSR ProgramsDocument4 pagesAirAsia's Social Responsibility and CSR ProgramsPrivate TitaniumNo ratings yet

- Bedri Managerial Economics ExamDocument3 pagesBedri Managerial Economics ExamBedri M AhmeduNo ratings yet

- Godrej Appliances - Case PDFDocument22 pagesGodrej Appliances - Case PDFAbhijit Kumar100% (1)

- ColregDocument2 pagesColregtedungNo ratings yet

- GROW MORE FACULTY OF MANAGEMENT MCQsDocument51 pagesGROW MORE FACULTY OF MANAGEMENT MCQsChetan Patel (HOD, MBA)No ratings yet

- 5UOM StudyGuide PDFDocument173 pages5UOM StudyGuide PDFAfia LynchNo ratings yet

- A1073a1073m 6194Document4 pagesA1073a1073m 6194AFQBAVQ2EFCQF31FNo ratings yet

- Collection Development PDFDocument3 pagesCollection Development PDFolalekan jimohNo ratings yet

- Process Failure Modes and Effects AnalysisDocument20 pagesProcess Failure Modes and Effects AnalysisHemantNo ratings yet

- UntitledDocument3 pagesUntitleddipeshNo ratings yet

- Ashwini A. AcharyaDocument10 pagesAshwini A. AcharyaDesh Vikas JournalNo ratings yet

- KYC InglesDocument2 pagesKYC InglesJakeNo ratings yet

- B2B Marketing Analysis of DHgate PlatformDocument16 pagesB2B Marketing Analysis of DHgate PlatformDRIP HARDLYNo ratings yet

- DM Using UI PathDocument3 pagesDM Using UI PathAnand GuptaNo ratings yet

- 1-1 Introduction To Failure Analysis and PreventionDocument21 pages1-1 Introduction To Failure Analysis and PreventionIAJM777No ratings yet