Professional Documents

Culture Documents

Activity #9

Uploaded by

Mariella Alyzza InciongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Activity #9

Uploaded by

Mariella Alyzza InciongCopyright:

Available Formats

Activity #9

Name: Rench Juben M. Apuntar

Course: Basic Workshop and Machining

Year/section: MexE-3101

Date: 22/11/2020

Review questions

1. What is the purpose of the thread-cutting dial during screw-cutting?

The thread dial is mounted on a spindle at the opposite end of which gear in

mesh with the lead screw to achieve the accuracy of engagement of the split nut on the

lead screw for each cut. Due to this, the screw will travel along the same path as the

previous cut.

2. Name two pieces of equipment used to prevent long slender workpieces flexing during

machining on a center lathe.

To counter long slender workpieces flexing during machining on a center lathe, a

two-point travelling steady and three-point fixed steady are clamped in the machine

bed.

3. What is a mandrel used for?

A mandrel is used to mount workpiece which has a finished bore and requires

the outside to be turned concentric to it. It is placed between centers and the work is

machined already described for between-centers work.

4. State the two important capacities of a center lathe.

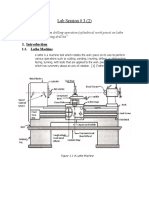

Center lathes are used to manufacture cylindrical shapes from range of materials

including steels and plastics. Two of its important capacities are the largest diameter

which can be rotated over the bed of the machine known as the swing and the maximum

length of workpiece which can be held between the centers of the machine.

5. What is the purpose of using a center drill?

The purpose of a center drill is to produce centers in a workpiece for turning

between centers. It provides a suitable guide to start the drill in the center of the bar and

are available in various sizes.

6. Name four types of work holding equipment used on a center lathe.

Work holding equipment are used to hold workpieces in a center lathe. Types of

work holding equipment includes chuck, faceplate, chuck keys and centers.

7. Why is it essential to have the cutting tool set at the center height of the workpiece?

It is essential to have cutting tool set at the center height of the workpiece

because tool set too high can reduce the clearance and will rub, while tool set too low

decreases the rake angle. Setting the cutting toll right at the center of the workpiece will

give the right measurements for rake and clearance angle resulting to best finish.

8. Give two reasons why a boring operation would be carried out on a center lathe.

Boring is the process of enlarging the hole that has already been drilled. It can be

performed through center lathe because boring is used to achieve greater accuracy of

the diameter of hole and can be used to cut a tapered hole. Also, boring can be viewed

as the internal diameter counterpart to turning, which cuts external diameter.

9. Why is it necessary to have a direct relationship between rotation of the work and the

longitudinal movement of the tool during screw-cutting?

Longitudinal feed is the movement of the cutting tool parallel to the axis of the

workpiece. A direct relationship between rotation of the work and the longitudinal

movement of the tool during screw-cutting to cut an accurate thread.

10. Describe three methods used to turn a taper.

Taper turning means to provide a conical surface by gradual reduction or

increase in diameter from a cylindrical workpiece. The three common methods used to

turn taper are with a form tool, with a top or compound slide and with a taper-turning

attachment. In using form tool, a form tool is set to the work at half taper angle and is fed

straight into the work to generate a tapered surface. It is used in turning short length of

taper. The method with a top or compound slide employs the principle of turning taper by

rotating the workpiece on the lathe axis and feeding the tool at an angle to the axis of

rotation of the workpiece.

You might also like

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Machine ShopDocument6 pagesMachine ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- Lathe MachineDocument16 pagesLathe MachineM Arslan AshrafNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Machine Shop: Principal Parts of A LatheDocument7 pagesMachine Shop: Principal Parts of A LatheArchika YaduNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- 5.workshop Practice - Machine Shop - ES-ME192 - or - 292Document10 pages5.workshop Practice - Machine Shop - ES-ME192 - or - 292Priyanshu BanerjeeNo ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Lab 3Document6 pagesLab 3Khurram SattarNo ratings yet

- A Study On Types of Lathe Machine and Operations: ReviewDocument6 pagesA Study On Types of Lathe Machine and Operations: ReviewJames UgbesNo ratings yet

- Me2207 Manufacturing Technology I Lab ManualDocument71 pagesMe2207 Manufacturing Technology I Lab ManualKarthick N91% (11)

- M AchingDocument10 pagesM AchingSnehasishNo ratings yet

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocument13 pagesVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNo ratings yet

- LatheDocument4 pagesLatheAnees Calicut100% (1)

- Machining Processes - I MT 164: LatheDocument45 pagesMachining Processes - I MT 164: LatheMusab LatifNo ratings yet

- WORKSHOP PRACTICE-B.Tech IIDocument46 pagesWORKSHOP PRACTICE-B.Tech IIrawat7233abhayNo ratings yet

- Manufacturing Engineering-1 - DPME-304Document27 pagesManufacturing Engineering-1 - DPME-304Vikas YadavNo ratings yet

- Diploma Workshop Practice IIDocument30 pagesDiploma Workshop Practice IISagir Musa SaniNo ratings yet

- Operations in TurningDocument8 pagesOperations in Turningcanavarsanayok100% (1)

- Lathe Workholding and Operations GuideDocument4 pagesLathe Workholding and Operations GuideBOT-X GAMING100% (1)

- Machine Shop Guide to Lathe Parts and OperationsDocument17 pagesMachine Shop Guide to Lathe Parts and OperationsJohn Borja100% (1)

- Chapter 2Document49 pagesChapter 2zelalemmekonnen823No ratings yet

- Dhaka University IPE Dept Machine Shop PracticeDocument24 pagesDhaka University IPE Dept Machine Shop Practicesujoy kunduNo ratings yet

- IME_Module 2 NotesDocument27 pagesIME_Module 2 Noteskdshakuntala40No ratings yet

- Study and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeDocument9 pagesStudy and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeSazzadNo ratings yet

- Machine Tools LAB Manual PDFDocument77 pagesMachine Tools LAB Manual PDF5F2 SHAIK PALUR SAMEENANo ratings yet

- Machine Lab - ReportDocument11 pagesMachine Lab - Reportsaiq kamranNo ratings yet

- Chapter 11Document32 pagesChapter 11Mark Angelo M. BubanNo ratings yet

- Lab ManualDocument43 pagesLab ManualTech OriginNo ratings yet

- Manufacturing Technology Lab IDocument43 pagesManufacturing Technology Lab IMECHANICAL SMCETNo ratings yet

- 4.conventional MachiningDocument7 pages4.conventional MachiningpriyanshuvraoNo ratings yet

- Mechanical Engineering Answer Key and Forces Acting on Cutting ToolsDocument7 pagesMechanical Engineering Answer Key and Forces Acting on Cutting Toolskarthik jNo ratings yet

- MCP 101 Lab Manual 2016Document66 pagesMCP 101 Lab Manual 2016Sankalp GargNo ratings yet

- Module 3. Midterms. Workshop Theory and Practice. MidtermsDocument10 pagesModule 3. Midterms. Workshop Theory and Practice. MidtermsmanuelNo ratings yet

- Imp Lab ManualDocument36 pagesImp Lab ManualAnas MuhammedNo ratings yet

- Lathe MachineDocument6 pagesLathe MachineJuno Eron TalamayanNo ratings yet

- Study On Basic Lathe Machining: AIM: To Study The Construction Details and Working Principle of Basic MachiningDocument12 pagesStudy On Basic Lathe Machining: AIM: To Study The Construction Details and Working Principle of Basic Machininggirma workuNo ratings yet

- ACFrOgBo6Ox3g06ZxeiCrCoUDBHsMSAOD8Z-4pR8DuGGt1ubF33vpbe0ymRER8wI KUnd39t UJPAF1hwbp 5 3 FgyxR9Zvi16mHKP XDGdJl-R9L321jMxjXcOqCHSh5bR1hzRGUD3iwHrwzeeDocument5 pagesACFrOgBo6Ox3g06ZxeiCrCoUDBHsMSAOD8Z-4pR8DuGGt1ubF33vpbe0ymRER8wI KUnd39t UJPAF1hwbp 5 3 FgyxR9Zvi16mHKP XDGdJl-R9L321jMxjXcOqCHSh5bR1hzRGUD3iwHrwzeeKashif SultanNo ratings yet

- Machining ToolsDocument4 pagesMachining Toolshirocode zeroNo ratings yet

- MCP 101 Product Realization Lab ManualDocument75 pagesMCP 101 Product Realization Lab ManualjasvindersinghsagguNo ratings yet

- ME 2207 - Manufacturing Technology 1 - Lab ManualDocument57 pagesME 2207 - Manufacturing Technology 1 - Lab ManualMohan Prasad.M71% (17)

- Drilling & Related OperationsDocument11 pagesDrilling & Related OperationsGonKilNo ratings yet

- Threads and Thread Cutting Operations: Arul R ApmechDocument22 pagesThreads and Thread Cutting Operations: Arul R ApmecharulsivagiriNo ratings yet

- Drilling Total Unit For Diploma StandardDocument41 pagesDrilling Total Unit For Diploma StandardRoyalmechNo ratings yet

- Lathe OperationsDocument28 pagesLathe OperationsKrunal PatilNo ratings yet

- Lathe Lab Report on Cylindrical Job Facing and TurningDocument5 pagesLathe Lab Report on Cylindrical Job Facing and TurningKashif SultanNo ratings yet

- Module 6 Part 2 Bme-1Document17 pagesModule 6 Part 2 Bme-1joeste965No ratings yet

- Quiz1 ReviewerDocument17 pagesQuiz1 ReviewerJag MasterNo ratings yet

- Lab MannualsDocument15 pagesLab MannualsJatin PahujaNo ratings yet

- Chapter 2 Different Types of FixturesDocument20 pagesChapter 2 Different Types of FixturesaragawNo ratings yet

- MACHINE SHOP SAFETYDocument9 pagesMACHINE SHOP SAFETYJeevan MandalaNo ratings yet

- TurningDocument6 pagesTurningShivshankar Singh0% (1)

- Machine Tools Lab Manual (13-14)Document39 pagesMachine Tools Lab Manual (13-14)Krishna Murthy100% (1)

- Lathes and Lathe Machining OperationsDocument18 pagesLathes and Lathe Machining Operationssarasrisam100% (1)

- Lathe Machine Ex. No. 4Document3 pagesLathe Machine Ex. No. 4Rodgie Christian CruzNo ratings yet

- Production Technology Assignment1Document22 pagesProduction Technology Assignment1shah shakeel rssNo ratings yet

- Shop Practice Number 4Document9 pagesShop Practice Number 4JantzenCaliwliwNo ratings yet

- Mohamed Baksh 1036007 Assignment 6Document11 pagesMohamed Baksh 1036007 Assignment 6Mohamed BakshNo ratings yet

- Shop-4-Cross Peen Hammer HeadDocument8 pagesShop-4-Cross Peen Hammer HeadJag MasterNo ratings yet

- Mayne Pharma Annual Report 2012Document78 pagesMayne Pharma Annual Report 2012Deepa DevanathanNo ratings yet

- Abdulbasit MohammedDocument170 pagesAbdulbasit MohammedGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Designing An AirshipDocument100 pagesDesigning An AirshipFrik van der Merwe100% (2)

- 737 Flow and ChecklistDocument7 pages737 Flow and ChecklistarelundhansenNo ratings yet

- Lorenzo Tan National High School 2018-2019 Federated Parent Teacher Association Officers and Board of DirectorsDocument4 pagesLorenzo Tan National High School 2018-2019 Federated Parent Teacher Association Officers and Board of DirectorsWilliam Vincent SoriaNo ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- Capital Harness XC LaunchDocument36 pagesCapital Harness XC LaunchnizarfebNo ratings yet

- Questionnaire For ThesisDocument5 pagesQuestionnaire For ThesisRamiz HassanNo ratings yet

- 1081 Camid Vs Op DigestDocument2 pages1081 Camid Vs Op DigestLennart Reyes67% (3)

- JohnsonJohnson 2006 PDFDocument84 pagesJohnsonJohnson 2006 PDFakfar b417No ratings yet

- S3 Unseen PracticeDocument7 pagesS3 Unseen PracticeTanush GoelNo ratings yet

- GUEST REGISTRATION CARDDocument1 pageGUEST REGISTRATION CARDRasmi Ranjan Kar100% (1)

- Tourism and Development Planning: Slide 9.1Document19 pagesTourism and Development Planning: Slide 9.1English TimeNo ratings yet

- Moisture Control Guidance For Building Design, Construction and Maintenance (2013)Document144 pagesMoisture Control Guidance For Building Design, Construction and Maintenance (2013)Schreiber_Dieses100% (1)

- Social and cultural geographies of Southeast Asia exploredDocument18 pagesSocial and cultural geographies of Southeast Asia exploredJohn Lemuel MagnayeNo ratings yet

- Water Supply Improvement SchemeDocument110 pagesWater Supply Improvement SchemeLeilani JohnsonNo ratings yet

- Ict OhsDocument26 pagesIct Ohscloyd mark cabusogNo ratings yet

- Davall Stock Gears Worm Wheel Gear Sets 17pages PDFDocument17 pagesDavall Stock Gears Worm Wheel Gear Sets 17pages PDFharish ahireNo ratings yet

- Plan & Elevation of Dog-Legged StaircaseDocument1 pagePlan & Elevation of Dog-Legged Staircasesagnik bhattacharjeeNo ratings yet

- CHEM F313: Instrumental Methods of AnalysisDocument12 pagesCHEM F313: Instrumental Methods of AnalysisAYUSH SHARMANo ratings yet

- ADUHAI @herman & Rhoca - Lyrics and Music by Rhoma Irama Arranged by - HERMAN - BOY - SmuleDocument4 pagesADUHAI @herman & Rhoca - Lyrics and Music by Rhoma Irama Arranged by - HERMAN - BOY - SmuleHERMAN BOYNo ratings yet

- OPTION STRATEGIES PAYOFF CALCULATOR v2Document9 pagesOPTION STRATEGIES PAYOFF CALCULATOR v2Jay KewatNo ratings yet

- WheelHorse Power Take Off Manual 8-3411Document4 pagesWheelHorse Power Take Off Manual 8-3411Kevins Small Engine and Tractor ServiceNo ratings yet

- Thermodynamics d201Document185 pagesThermodynamics d201Rentu PhiliposeNo ratings yet

- Macalintal v. PETDocument5 pagesMacalintal v. PETJazem AnsamaNo ratings yet

- EN - Ultrasonic Sensor Spec SheetDocument1 pageEN - Ultrasonic Sensor Spec Sheettito_matrixNo ratings yet

- 2DArtist Issue 019 Jul07 Lite PDFDocument53 pages2DArtist Issue 019 Jul07 Lite PDFViviane Hiromi Sampaio FurukawaNo ratings yet

- Post-Operative Nutrition: Things You Need To Know AboutDocument2 pagesPost-Operative Nutrition: Things You Need To Know AboutJannen CasasNo ratings yet

- HOUSEKEEPING SESSION PLANDocument2 pagesHOUSEKEEPING SESSION PLANScarlette Beauty Enriquez100% (1)

- 20-Sdms-02 (Overhead Line Accessories) Rev01Document15 pages20-Sdms-02 (Overhead Line Accessories) Rev01Haytham BafoNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressRating: 5 out of 5 stars5/5 (1)

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)From EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Rating: 4.5 out of 5 stars4.5/5 (5)

- Autodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersFrom EverandAutodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersNo ratings yet

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersFrom EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNo ratings yet

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.From EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.No ratings yet

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsFrom EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsRating: 4.5 out of 5 stars4.5/5 (10)