Professional Documents

Culture Documents

Hks Evc

Uploaded by

Kok Leong Wong0 ratings0% found this document useful (0 votes)

490 views16 pagesThe Eve is not capable of reaching boost levels lower than stock (OEM) levels. The serial numbers must match on the control unit and the stepping motor. Miswiring or shock will damage the unit. Do not place near extreme heat, water, or areas prone to dirt and dust.

Original Description:

Original Title

hks evc

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Eve is not capable of reaching boost levels lower than stock (OEM) levels. The serial numbers must match on the control unit and the stepping motor. Miswiring or shock will damage the unit. Do not place near extreme heat, water, or areas prone to dirt and dust.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

490 views16 pagesHks Evc

Uploaded by

Kok Leong WongThe Eve is not capable of reaching boost levels lower than stock (OEM) levels. The serial numbers must match on the control unit and the stepping motor. Miswiring or shock will damage the unit. Do not place near extreme heat, water, or areas prone to dirt and dust.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

DRIVING PERFORMANCE

ELECTRONIC VALVE CONTROLLER INSTALLATION INSTRUCTIONS PART # 4S003-BKOOI

v.31303

NOTICE

Read this entire manual to understand how the EVe functions before beginning the installation process. Do not attempt to install or adjust the EVe without thorough knowledge of how this unit works. This manual assumes that you have the knowledge in the operation of tools and equipment that are necessary to safely perform service operations on your vehicle. This manual also assumes that you are familiar with typical automotive systems and basic service and repair procedures. Always have access to a factory repair manual as some of the procedures and specifications required for the proper installation of this product may be referenced to the factory repair manual. To avoid the risk of personal injury, follow the lifting, supporting, and safety precautions contained in the factory repair manual.

r---

USER NOTES

• The Eve can be used on both internal and external waste gate type turbochargers.

• The EVe is not capable of reaching boost levels lower than stock (OEM) levels.

• The EVe will maintain its programming even if the vehicle's battery is disconnected or the head unit is unplugged.

• The serial numbers must match on the control unit and the stepping motor in order for the unit to function properly.

• The EVC is a sensitive electronic component and must be handled with extreme care. Miswiring or shock will damage the unit.

Do not place near extreme heat, water, or areas prone to dirt and dust.

• Most factory turbocharged vehicles come equipped with a secondary boost limiting system (fuel-cut system or pop-off valve) to protect against waste gate failure. Due to this, the EVC alone will not be able to raise the boost pressure beyond the point of the factory limit. If this condition occurs, consult your HKS distributor for information regarding products that can assist in this situation (HKS Fuel Cut Defencer, HKS Vein Pressure Converter, HKS Programmed Fuel Computer, etc.).

• If the vehicle has a fuel cut defense system such as the HKS FCD, make certain that the vehicle's boost pressure is not raised excessively, as this will lead to engine and/or turbocharger damage. HKS will not warranty any damage caused be excessive boost levels.

• Make sure the vehicle has a proper fuel management system that can handle higher boost pressures than stock (OEM) levels. HKS will not warranty damage caused by improper fuel management (lean air/fuel ratio).

• The Eve cannot control boost pressure above the maximum efficiency point of the turbocharger. Boost pressure drop at high rpm may not be totally eliminated. The EVC will not be able to compensate for pressure loss due to turbocharger sizing. Boost creep or boost spikes due to inadequate waste gate flow capacity, lean air/fuel ratio, poor compressor design, or excessive backpressure may not be fully alleviated.

• Increasing the boost pressure will also increase the intake air temperature. If the intake air pressure exceeds 220 degrees Fahrenheit (100 deg. Celsius), performance increases may be minimal and detonation may occur.

• F or best performance and to safeguard against detonation, always use the highest octane gasoline available (9 l-octane minimum).

• Do not rely on the factory boost meter (if equipped) when adjusting the maximum boost pressure. Install an HKS auxiliary boost pressure meter to monitor manifold boost pressure levels.

• The utilization of an HKS AIF Knock Amp (air/fuel ratio meter) or an HKS exhaust gas temperature (EGT) meter is recommended to monitor engine (rich or lean) conditions.

• Mount the EVe control unit, display unit and harness away from high-power amplifiers, two-way radios, mobile phones, and their respective antenna cables to prevent malfunction of the EVC unit.

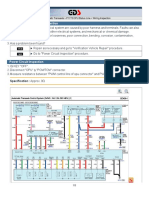

c== ~ C_O_N_~_m_C_T_I_O_N_D_I_A_G_RAM ~

( -I Ground (BLACK)

12 Volt Ignition (RED}

STEPPING MOTOR

DISPLAY UNIT

CONTROL UI'-lIT

2-PIN Connector

3-PIN Conn e ctot

4-PIN Conu e ctor i 3-PIN Connector

TROUBLESHOOTING

Notes

• If at any time the EVC does not adjust, the lock code number is forgotten, or the display reads an error code of "100" (no stepping motor memory) the display unit will have to be reset (see EVC Set-Up instructions, 7.2).

• If error code "001" (communication error) is displayed, at least one of the wires on the 3-pin harness has lost continuity.

• As a safety feature, if volume knob A or B was moved when the EVC power was off, the button(s) will flash until the knob is returned to its original position.

• When changing the SW<>PO selection switch, the vehicles 12-volt ignition must be "on" with the EVC power button "off ", otherwise the EVC will not switch over and the power button will flash red. When the EVC power button is turned back on, the display in the upper left comer will illuminate the selected setting --S-- (SW) or --P-- (PO) for about 4 seconds.

• If the ignition is shut-off before 10 seconds after the last setting was made, the last setting may not hold memory.

EVC Control Unit Will Not Illuminate:

• Power Connection- There must be a constant 12-volt power source under all conditions with the ignition "ON".

• Ground Connection- In some cases, paint, rust, or a loose bolt will cause a bad ground.

• Electronic Splice Connector- Visually from the outside, wire connections may look good. In some cases, the wires are not making

contact inside the connector. Check the wires at both ends using a voltmeter to ensure continuity.

EVC Will Not Control Boost:

• Make sure the SW<>PO switch on the back of the unit is in the correct position.

• Check the hose connections at ports 2 (In) & 3 (Out) on the EVC stepping motor. EVC III, IV, and EZ stepping motors differ

from EVC I, II and the new EVC stepping motors (see installation diagrams).

• Check for continuity at each wire on the 3-pin harness for a possible break in a wire. Error code "001" will be displayed. Vehicle Is Not Building Enough Boost (Underboosting):

• Slowly turn up the underboosting A or B volume knob or adjust off-set (see page 11-12 ofEVC Set-Up instructions).

• Make sure the stock boost solenoid is disconnected.

• Make sure the boost warning level is not set too low.

• Check for possible improper set-up of the EVC display or control units. Read the manual again to verify that you are following

the correct procedures.

• The vacuum filters (4 & 6mm) may be clogged or dirty. Vehicle Is Building Too Much Boost (Overboosting):

• Tum down the overboosting A or B volume knob or adjust off-set (see page 11-12 ofEVC Set-Up instructions).

• Verify that there are no leaks in the hoses, and that all connections are tight. Check for hose damage such as pinholes or tears.

• Wastegate valve may be too small or actuator may be too weak.

• Turbocharger capacity may be too small (In this case, the boost curve will drop off during high rpm compared to the factory boost curve).

• Check for possible improper set-up of the EVC display or control units. Read the manual again to verify that you are following the correct procedures.

• Make sure the vacuum filters (4 & 6mm) are not damaged or cracked.

PARTS LIST

Q

D

C

uantity escription omments

1 Display Unit PSI

1 Control Unit

1 Step_f)in_g Motor

1 3-Pin Harness L=2.7m (106'1

1 2-Pin Harness L=1.5m (59")

1 4mm Hose L=1 m (39")

1 6mm Hose L=1 m (39")

1 Tee Fitting 4x4x4mm

1 Vacuum Filter 4mm

1 Vacuum Filter 6mm

2 Spring Clamp 6mm

1 Double-Sided Tape

5 Tie Wraps L=100mm (4")

1 Stepping Motor Hardware Set

1 Instruction Manuals Install & Set-Up 4

DRIVING PERFORMANCE

Quick Manual

ELECTRONIC VALVE CONTROLLER SET-UP INSTRUCTIONS

PART # 4S003-BKOOI

PART # 4S999-BKOOI

V.31303

1. Ignition ON

Tum the key so the ignition is in the "ON" position. There is no need to start the engine.

2. Set the wastegate switch. SW or PO

Make sure the power on the EVe is off, if not, hold the (PWR) button down for more than 1 sec to tum the unit off. Then set the bypass switch shown below to the correct setting.

Rear Panel of the Control Unit

Wastegate Selection Switch

Swing Valve Type

• For vehicles us.no an Internal wastegate (Actuator)

Poppet Valve Type

• Forvehlcles usmo an external wastegate

............. -

==tIll ISWHpol

in!

ISW++pol

3. Turn the EVe power ON.

Hold down the power (PWR) button on either the display unit or control unit for more than I sec. and tum

the power of the EVe "ON" .

OR

360

- - 0-

.. 0

./

\

4. Setting the Warning Values.

First, the warning values need to be set.

To prevent turbo or engine damage caused by over-boosting, a warning value must be set.

(1) Decide on a target boost for mode A and mode B.

Example: Mode A 17.5 PSI, and mode B 14.5 PSI.

(2) Press the (MOD) button 3 times to get into "Warning Value Setting Mode".

A "-3-" should display on the top left comer of the screen.

5. Setting the boost for mode AlB

(3) Add 1.5 PSI to the higher boost setting between mode A and mode B.

Example: 17.5 PSI + 1.5 PSI = 19 PSI

(4) Press the (MOD) button once to save and go back to the main mode.

• For safety reasons, do not adjust the EVC while driving. Park the vehicle in a safe and designated area to make adjustments.

"~~ ~

PN"l/&L

125

- .. 0- _ 0

125

- - o

_ S

(I) Make sure the'" on volume knob A is lit up red.

If it's green, press the (PWRISEL) button once (short press).

(2) Press volume knob A to pop the knob up. Then tum it all the way counter clockwise.

(3) Cross reference the digital display (large screen) and tum volume knob A slowly clockwise to add to the set value.

J30

- (w_

_ -11.0-

130

- .. !fJ3

_ -IJ.lJrm

130

- .. !fJ3

_ -IJ.[Jrm

130

: -Ml> ...

130 -

_ -/7.0-

Red

(4) Try to use the highest gear possible (3rd or 4th gear) and apply load on the car on full open throttle.

(5) Verify the peak hold value.

(6) If the peak hold value is not close to your target boost, repeat steps (3) ~ (5) again.

(7) When the setting is done, push volume knob A back in.

(8) Hold the (SELl A) button for more than Isec.on the digital display unit to reset the peak hold value.

(9) Press the (PWRISEL) button once (short press) and verify that the A on volume knob B is lit up red.

(10) Press volume knob B to pop the knob up. Then tum it all the way counter clockwise

IrS

- IlIIII

D

-J10er,

IrS

- - o

... 5

(11) Repeat steps (3) - (5).

(12) Once the setting is over, push volume knob B back in.

(13)To select between mode A and mode B, press the (PWRISEL) switch once (short press). The selected volume knob will light up red.

Example: The diagram shows when the mode A boost setting is selected.

4

How to operate other fimctions

Display Unit

<::~"O;;): Press the Mode Button

~ Hold down the Mode Button for more than 1 sec

~ Hold down the Power Button for more man 1 sec

Control Unit

(Q): Press tile Power/Select SWitch

Power OFF

Power ON

Monitor Mode

I~

Reset the Peak Hold Settings

1. Monitor mode 1. 1. Boost control

Ignition ON

Scramble Setting Mode

~: Press the Select/Up Button

.Ia':!rt > Hold down the Select/Up Button for more tt-Jan 1 SE;lC

c§:~c-c_~ Press the Scramble/Down Button

~ Hold down the Power/Select SWltcrl for more than 1 sec

Scramble Time Setting Mode

Warning Setup Mode

Display Setting Mode

Lock Code Setting Mode

Mode A Offset Setting Mode

Mode B Offset Setting Mode

t

After Scramble Time Expires

Scramble

Setting boost levels for both mode A and B must be done through the control unit.

(l) With the ignition ON, make sure the power button is ON.

The 0 of the (PWRISEL) button will light up red.

The A of volume knob A or B will either be red or green. Red indicates the current selected knob. If it's green, press the (PWRISEL) button once (short press) to switch over.

•

•

(2) Once the A or B volume knob is selected, push out the knob to adjust the boost level.

(3) Start full counter clockwise and slowly tum the knob to a desired boost level.

•

As a reference point ONLY, use the display's set value to add (by %) to the stock (baseline) boost level. For example: If the known baseline boost is 10 PSI. by entering 50 (%) as the set value, the actual boost level should increase to about 15 PSI (50% increase). Adjust knob accordingly afterward.

The control unit increments are not a set value so cross-reference it with the digital display (large screen) to check the actual boost level.

•

(4) When you are done. push the knob back in.

5

Notes

• If a setting is not performed within 4 seconds after the. is lit up red, the display value (large) will return to monitor mode.

• Make sure the volume knob is pushed in whenever a setting is finished. If the knob is left popped up, there is a chance that the boost may change if accidentally hit.

• For vehicles equipped with sequential turbos, the primary turbo may not hit its maximum boost level until the secondary turbo kicks in.

• Boost lag may occur on vehicles equipped with actuators with soft (weak) springs.

1. 2. Peak Hold

When in monitor mode, the EVC will record and display its highest boost level reading. The memory of the peak/hold level will be updated automatically and can be reset manually.

c'lO

- CD

i!:JS

_ -17D-

• The number on the digital display value will reset and will read "0".

• When a new peak level is reached, the P.H. will flash and display a new peak reading.

(1) By holding down the (SELl") button for more than 1 second, the peak/hold level will be reset. 1. 3. Scramble Mode

Hit the (SBC/T) button to activate the scramble mode.

(1) Press the (SBC/T) button.

• When the scramble mode is activated, the (SBC/T) will tum red, the display will flash along with a quick set of audible beeps.

2. Scramble Setup Mode

This mode is used to set a value which adds to the set boost pressure when the scramble mode is activated.

3. Scramble Time Setup Mode

(1) If the display unit is in monitor mode, press the (MOD) button once. If it is in any other mode, scroll through the modes until it displays a "-1-", which is the scramble setup mode.

• The indicator will display "SET" on the screen.

(2) Use the (SELl") or (SBC/T) button to input the values.

• The digital display value (large) indicates the value currently being set. The digital display value (small) indicates the previous set value.

• The setting value range is from o~ 100% in increments of2'% (this is not actual boost pressure). This gain % figure will be added to the previously set boost level.

6

This mode will set the time interval in which the scramble mode is active.

{j_~ _ ~ (1) From the monitor mode, press the (MOD) button twice. If

,I _ §~ ("~,c '; i it is in any other mode, scroll through the modes until it

~"-lr/ displays a "-2-", which is the scramble time setup mode.

• The indicator will display "SET" on the screen.

I -~-

I 1m

I C:3

8-

(2) Use the (SELl"') or (SBC/T) button to input the values.

• The digital display value (large) indicates the seconds currently being set The digital display (small) indicates the previous set time.

• The setting value range is from 0~40sec. in increments of 1 second.

Note

• When the (SBC/T) button is pressed, the scramble function will activate but will not start until the button is let go.

4. Warning Setup Mode

If the pressure in the surge tank exceeds the set boost warning level, it will trigger the warning function. When the warning is activated, the boost level will return to stock (baseline).

-3- .".. .... ,'''\111

~ mil

. 350m

l1li 36.0

155

- - 150

... -1'7.0-

(1) In monitor mode, press the (MOD) button 3 times. The top left comer should display a "-3-".

• The indicator will display "SET" on the screen.

(2) Use the (SELl"') or (SBc/T) button to input the values.

• The digital display value (large) indicates the value currently being set The digital display value (small) indicates the previous set value.

• The setting value range is from 0~36 PSI in

increments of .5 PSI.

• Initial setting is 36.0.

(3) Press (MOD) button to return to the main screen.

• Make sure to return to monitor mode or the new set

values will not be recorded.

• If the values are not recorded, the values will go back to default when the ignition or EvC power is turned OFF.

7

Notes

• As long as the boost level is set below the warning level, the warning will activate if the EVC see's

1.5 PSI (for more than .5 seconds) over the set warning level.

• If for some reason the boost level is set above the warning level, the warning will activate when the EVC see's about 0.7 PSI (for more than .5 seconds) over the set warning level.

• When the warning is activated, the "WRN" on the display unit will light up, a series of audible beeps

will be heard and the digital display value (small) will flash.

• When the surge tank pressure goes below 1.5 PSI it will cancel the warning.

5. Display Setting Mode

This mode will determine the range of the bar graph.

- 'I- ~"\\"tI ~ - 350-

l1li 36.0

Note

(1) In monitor mode, hold the (MOD) button down for more than 1second. The top left comer should display a "-4-".

• The indicator will display "SET" on the screen.

(2) Use the (SELl"') or (SBC/T) button to input the desired bar graph range.

• The digital display value (large) indicates the value currently being set. The digital display value (small) indicates the previous set value.

• The bar graph range is from 0~36 PSI in increments

of.5 PSI.

• Initial setting is 36.0.

• If the bar graph is set to the same value as the warning boost level, the bar graph can be used to quickly glance at the display to see the real time boost level in relation to the warning level. The bar graph is much easier to see than the digital display value.

6. Backlight Brightness Adjustment Mode

This mode will adjust the brightness of the digital display.

(1) In monitor mode, hold the (MOD) button down for more than I second and press (MOD) I more time. The top left comer should display a "-5-".

-5- ~

filii" -

., 5D

l1li 50.

(2) Use the (SELl"') or (SBC/T) button to input the values.

• The digital display value (large) indicates the value currently being set. The digital display value (small) indicates the previous set value.

• The brightness setting range is from O~ I 00% in

increments of 1 %

• As the values decrease. the display will get darker.

• Initial setting is 100%.

8

7. Lock Code Setting Mode

To lock in valuable settings/data use the lock code setting.

7.1. Setting the Lock Code

-5~

Em

. 0000

... 10000

i

II

u

-5-

a .. 0000

J/!I!I e 3 "10

(1) In monitor mode, hold the (MOD) button down for more than I second and press (MOD) 2 times. The top left corner should display a "-6-".

• The digital display value (small) will display as follows .

"0000" : Lock code not set : Lock code set

(2) Use the (SELl"') or (SBC/T) button to input a lock code number.

• The digital display value (large) indicates the code number currently being set. The digital display value (small) indicates the previously set code number.

• The setting value range is from O~ 10000 in increments

of 1.

• Initial setting is 10000.

(3) Press (MOD) once to activate the lock code and return to monitor mode.

• The (MOD) button will light up red when the lock code is activated.

Note

• When the lock code is set, the EVC (display & control unit) power ON/OFF, changing the boost between A & B, re-setting the peak hold level, and scramble are still active. For any other changes, the lock code must be released (see 7.2 Lock Code Release).

7.2. Lock Code Release

-6-

-

----

.. 0000

-6-

-

- .... -

l1li 23"10

(1) In monitor mode, hold the (MOD) button down for more than I second and press (MOD) 2 times. The top left corner should display a "-6-".

• The digital display value (small) will show a "----".

(2) Use the (SELl"') or (SBC/T) button to input the lock code number.

9

(3) Press (MOD) once to release the lock code and return to monitor mode.

• If the number inputted in step (2) matches the previously set lock code number, it will release the lock. If the number does not match, it will not release the lock and you will have to try again.

• The (MOD) button will light up green when the lock code is released.

Note

• If the lock code number is forgotten, a data reset (see below) must be done. When the data is reset, all stored memory will be lost. The only time the EVC should be reset is if the lock code is forgotten.

Data Reset

©~()Q:

\ Pvt< • '"'£1. A·Volume B-Volume

_ .. /

[j5] ..... [EjJ

Isw~pol ISWwPOI

,-;;-":=- ============::

[;~~

Ii If l!;-

-5-

a ODOO

.. 10000

(1) Hold down the (PWRISEL) button until the EVC power shuts OFF.

• The 0 of the (PWRISEL) switch will light up green, with both lights on the ... of AlB volume knobs turned off.

(2) Simultaneously hold down the (PWRISEL) button on the control unit and flip/reverse the bypass switch (SW/PO) on the back ofthe unit.

• The display unit should beep for about 2 seconds.

• The diagram shows an example in which the bypass switch is set on swing valve (SW).

• The vehicles ignition (12V) must remain on.

(3) Flip the bypass switch back to its original position.

• The (PWRISEL) button does not have to be held down during this step.

• The diagram shows an example in which the bypass switch was originally set on swing valve (SW).

(4) Tum the power ON by holding down the (PWRISEL) button down for more than

I second.

• The (PWRISEL) button will light up red .

• The Lock Code should return to default.

• If the (PWRISEL) button is flashing, make sure the bypass switch is back to its original position.

10

8.1. Mode A Offset Setting Mode

This mode adjusts the boost response and stability for Mode A

II,(,~, """'_",-;= (1) While in the Display Setting Mode, hold down

......... '=1.7 '-'= the (MOD) button for more than 1 second, If the

display IS not in the Display Setting Mode, follow the

I flow chart to get to the Mode A Offset Setting Mode,

I • The selected boost should be on "A",

indicator on "SET", unit on "%", and the mode on "-7-",

• Even if the boost control is on Mode B, it will temporarily change to Mode A

(2) Use the (SELl A.) and (SBC/T) buttons to input the necessary offset values,

• The digital display value (large) indicates the offset value currently being set. The digital display value (small) indicates the previously set offset value,

• The setting value range is from 10 - 200% in 1 % increments,

• When the Mode A Offset Setting value is changed, the boost setting for Mode A will remain the same but the maximum boost level will change,

• Initial setting is 100%

8. Offset Setting Mode

- , - S 1[10

• 100.

I 'r w;j """"

I I

i I

I 1

I

.;'1- ~'" S _

100

• 1'-10.

8.2 Mode B Offset Setting Mode

This mode adjusts the boost response and stability for Mode B.

(I) While in the Display Setting Mode, hold down the (MOD) button for more than 1 second followed by a short press. If the display is not in the Display Setting Mode, follow the flow chart to get to the Mode B Offset Setting Mode,

• The selected boost should be on "B", indicator on "SET", unit on "%", and the mode on "-8-",

• Boost control will change to Mode B, (2) Use the (SELl A.) and (SBC/T) buttons to input the necessary offset values,

• The digital display value (large) indicates the offset value currently being set. The digital display value (small) indicates the previously set offset value,

• The setting value range is from 10 - 200% in 1 % increments,

• When the Mode B Offset Setting value is changed, the boost setting for Mode B will remain the same but the maximum boost value will change,

• Initial setting is 100%,

(3) Press the (MOD) button once to return to the Monitor Mode,

11

Notes

• Refer to the table below to determine the characteristics of maximum boost in relation to the offset and wastegate settings.

• In most cases, when using a swing valve, a quicker response can be obtained by setting the offset somewhat higher.

Offset Value Swing Valve Poppet Valve

(Internal Wastegate) (External Wastegate)

Decreasing value Maximum boost goes up Maximum boost goes down

Increasing value Maximum boost goes down Maximum boost goes up • For a Troubleshooting List, please refer to the EVe Installation Instruction Manual.

12

INSTALLATION

1. Disconnect the negative battery cable from the battery.

2. EVC stepping motor installation-

• Determine an ideal mounting location for the stepping motor.

• Mount the stepping motor to the chassis using the hardware provided with this kit.

• Do not install the stepping motor close to the exhaust manifold or any area of high temperature.

• Do not install the stepping motor where it will be exposed to water or

moisture.

• Ports 1 (B), 2 (I), and 3 (0) must face upward.

• Lengths on all hoses must be kept as short as possible. 3. Vacuum Filter Installation-

• Install vacuum filters per diagram to the right. Make sure the filters are within 1 Oem (3.9") length from the stepping motor.

• The 6mm vacuum filter should be installed with the short side facing the stepping motor.

• Inspect the filters every 3000 miles. They must be clean for the EVC to function correctly. If the filter is contaminated or dirty, replace with a new (4mm) 4599-RA017 or (6mm) 4599-RA.016.Do not attempt to clean the vacuum filter. If the filters frequently need replacement, relocating the pressure source may solve the problem.

4. Connect the red wire (2-pin harness) from the EVC to a 12-volt ignition source, Utilizing a voltmeter, fmd a wire that receives at least 12 volts with the key in the "IGNITION" position.

5. Connect the black wire (2-pin harness) from the EVC to a chassis ground. Make sure there is no paint or rust on the ground surface. If there is, sand the surface until bare metal is exposed.

6mm Hose 6mm Vaccum

~ Filter

Ir-'-"""_'/ ;~i~:~uum

4mm Hose

• Determine if the vehicle is equipped with an internal wastegate (single port actuator), dual port actuator, or an external wastegate, then proceed to the corresponding installation instructions.

INTERNAL WASTEGATE (SINGLE PORT ACTUATOR) INSTALLATION INSTRUCTIONS

Port #1 (B) - Connect to an uninterrupted intake manifold pressure source after the throttle body such as a compressor bypass signal line using the 4mm hose.

• Do not connect port #1 to the line that operates the fuel pressure regulator unless the supplemental instructions tell you to do so.

• This hose should be as short as possible and should not exceed 100cm (3'4").

• Install the 4rnm vacuum filter within 10cm (3.9") of port #1 on the EVC stepping motor.

Port #2 (I) - Connect to a source of pressurized air such as a turbocharger compressor housing (discharge side) or compressor outlet pipe (before the intercooler) using the 6rnm hose.

• This hose should be as short as possible and should not exceed 100cm(3'4").

• Install the 6rnm vacuum filter within 10cm (3.9") of port #2 (In) on the EVC stepping motor.

Port #3 (0) - Connect to the port on the waste gate actuator.

• This hose should be as short as possible and should not exceed lOOcm (3' 4").

Turbocharger

Airflow Meter

EXTERNAL WASTEGATEfDUAL PORT ACTUATOR INSTALLATION INSTRUCTIONS J

Port #1 (B) - Connect to an uninterrupted intake manifold pressure source after the throttle body such as a compressor bypass signal line using the 4mm hose.

• Do not connect port #1 to the line that operates the fuel pressure regulator unless the supplemental instructions tell you to do so.

• This hose should be as short as possible and should not exceed I OOcm (3' 4").

• Install the 4mm vacuum filter within l Ocm (3.9") of port #1 on the EVC stepping motor.

Port #2 (I) - Connect to a source of pressurized air such as the turbocharger compressor housing (discharge side) or compressor outlet pipe (before the intercooler) using the 6mm hose. Use the tee fitting supplied with this kit to connect a pressure line to the secondary port on the wastegate actuator.

• Both lines should be as short as possible and should not exceed 1 OOcm (3' 4").

• Install the 6mm vacuum filter within lOcm (3.9") of port #2 (In) on the EVC stepping motor.

Port #3 (0) - Connect to the port above the diaphragm on the wastegate actuator or wastegate.

• This hose should be as short as possible and should not exceed 1 OOcm (3' 4").

External Wastegate

T urb o chnrqer

Airflow Meter

Throttle Plate

Dual Port Actuator

Turbocharger

Airtlow Meter

You might also like

- EVC ManualDocument12 pagesEVC ManualMuaiyad AL-baluchiNo ratings yet

- OGO Dual Mode MAP-MAF Sensor EnhancerDocument5 pagesOGO Dual Mode MAP-MAF Sensor EnhancerDotunder GroundNo ratings yet

- KDE11-100SS GENERATOR SET Maintenance ManalDocument105 pagesKDE11-100SS GENERATOR SET Maintenance ManalDuvan Garridt MillanNo ratings yet

- Diagnose and service GM trucks' Kelsey-Hayes 4WAL ABS systemDocument5 pagesDiagnose and service GM trucks' Kelsey-Hayes 4WAL ABS systemcuchuflina100% (1)

- Mpez-6 Installation Manual - Inline 201007Document8 pagesMpez-6 Installation Manual - Inline 201007api-244989438No ratings yet

- Service Manual: Beaverstate Dental, IncDocument30 pagesService Manual: Beaverstate Dental, Incpetercoyote67No ratings yet

- Iboost Manual v0.6Document12 pagesIboost Manual v0.6106tunerNo ratings yet

- Omegas Plus: Software ManualDocument40 pagesOmegas Plus: Software ManualВіктор ЛялькаNo ratings yet

- Glow Plug DriverDocument2 pagesGlow Plug DrivercooldamageNo ratings yet

- Candy Washing Machine Auto-Test Error Code GuideDocument5 pagesCandy Washing Machine Auto-Test Error Code Guideshalku0% (1)

- Cathodic Disbondment Mul Tiple Channel Testing Unit MODEL #CD-16Document10 pagesCathodic Disbondment Mul Tiple Channel Testing Unit MODEL #CD-16Masood AlamNo ratings yet

- CP-30 Instruction ManualDocument28 pagesCP-30 Instruction Manualsuryadhy100% (1)

- Deh 2350ubDocument62 pagesDeh 2350ubLuis XoocNo ratings yet

- Samsung ML-1610 Service Manual - 06 - TroubleshootingDocument23 pagesSamsung ML-1610 Service Manual - 06 - Troubleshootingiraklitosp100% (2)

- VW Polo Classic 1.4 Technical Specifications and Service AdjustmentsDocument6 pagesVW Polo Classic 1.4 Technical Specifications and Service AdjustmentsAndrej BuberNo ratings yet

- Autohelm 6000 Power Pilot Installation and Operating Handbook PDFDocument18 pagesAutohelm 6000 Power Pilot Installation and Operating Handbook PDFМилен НанковNo ratings yet

- Coach Bat. Diconnect Solenoid How It Works 5322019100Document9 pagesCoach Bat. Diconnect Solenoid How It Works 5322019100Clifton Jamison100% (1)

- QDB-2 Instructions For UseDocument17 pagesQDB-2 Instructions For UseCarlos Castillo100% (1)

- Viscosity Control SystemDocument4 pagesViscosity Control SystemTarek mahmood rahathNo ratings yet

- Brake System: 1991 Mitsubishi MonteroDocument14 pagesBrake System: 1991 Mitsubishi MonteroAnimemanuel MuñozNo ratings yet

- MERCEDES 722.6: Ause OmplaintDocument1 pageMERCEDES 722.6: Ause OmplaintVjollcaCuciNo ratings yet

- Installation Instructions EMS 30-1320 / 30-1320UDocument10 pagesInstallation Instructions EMS 30-1320 / 30-1320Urogerio100% (1)

- ES Series Hardware Manual170413Document64 pagesES Series Hardware Manual170413Oscar MontañezNo ratings yet

- P1775 OPU Status Line Wiring InspectionDocument3 pagesP1775 OPU Status Line Wiring InspectionLojan Coronel José HumbertoNo ratings yet

- VaraDocument8 pagesVaraCesar Alfonso Saldivar MontoyaNo ratings yet

- Sony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3Document34 pagesSony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3pasantito100% (1)

- Vizio Jv50p Hdtv10a Plasma TV SMDocument114 pagesVizio Jv50p Hdtv10a Plasma TV SMraver1213No ratings yet

- Instrument Panel: 1991 Mitsubishi MonteroDocument11 pagesInstrument Panel: 1991 Mitsubishi MonteroAnimemanuel MuñozNo ratings yet

- 2port-Efr Thu-6404Document255 pages2port-Efr Thu-6404AntonioMataNo ratings yet

- Defogger Rear WindowDocument5 pagesDefogger Rear WindowAnimemanuel MuñozNo ratings yet

- Tripplite 3000 UPS Banco de BateriasDocument20 pagesTripplite 3000 UPS Banco de Bateriasalger64No ratings yet

- Isw2001nbf - Aeb (Versione 6.1.3) - Cad - EngDocument35 pagesIsw2001nbf - Aeb (Versione 6.1.3) - Cad - EngDerioNo ratings yet

- C8Samsung: KA2263 Linear Integrated CircuitDocument4 pagesC8Samsung: KA2263 Linear Integrated CircuitHanse69No ratings yet

- Power Steering Ecu Assy: ReplacementDocument22 pagesPower Steering Ecu Assy: ReplacementMusat Catalin-MarianNo ratings yet

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- Rocktron Patchmate Loop FloorDocument32 pagesRocktron Patchmate Loop FloorrazvskarbuNo ratings yet

- Understanding the LE-Jetronic Fuel Injection and Electronic Ignition SystemsDocument32 pagesUnderstanding the LE-Jetronic Fuel Injection and Electronic Ignition SystemsLivio CaramanNo ratings yet

- CVVT System CVVT SystemDocument15 pagesCVVT System CVVT SystemSubbu Kannappan SrinivasanNo ratings yet

- Ac Heater System ManualDocument21 pagesAc Heater System ManualAnimemanuel Muñoz100% (1)

- Dzb200 SeriesDocument54 pagesDzb200 SeriesAkos Pocik100% (1)

- PAL MaintenanceDocument4 pagesPAL MaintenanceLucas PrimaniNo ratings yet

- Oil filter manual for on-load tap-changersDocument30 pagesOil filter manual for on-load tap-changersRAPRATSINNo ratings yet

- Instruction Manual Zoje ZJ953-13H-ED2 PDFDocument19 pagesInstruction Manual Zoje ZJ953-13H-ED2 PDFMaskusyani0% (1)

- CNCmakers-EP100 B QuickGuide-EN - EP100Document14 pagesCNCmakers-EP100 B QuickGuide-EN - EP100Angelica PeñarandaNo ratings yet

- DEH 2250UB OperationDocument112 pagesDEH 2250UB OperationAmkorWarFreakNo ratings yet

- Te 804 Controller ManualDocument38 pagesTe 804 Controller ManualBarba Luis50% (2)

- AD INTERNATIONAL Model 950Document21 pagesAD INTERNATIONAL Model 950Zoeloe_2No ratings yet

- AxpertKS 1 5KVA ManualDocument35 pagesAxpertKS 1 5KVA ManualBoban Butrić100% (1)

- Shanny SN600SC USER MANUALDocument12 pagesShanny SN600SC USER MANUALBali0% (1)

- Sheen Color LED Async Controller Software User Manual V1.4 PDFDocument30 pagesSheen Color LED Async Controller Software User Manual V1.4 PDFRuben ArteagaNo ratings yet

- TS-V6W 3G GPS Vehicle Tracker 2017Document8 pagesTS-V6W 3G GPS Vehicle Tracker 2017zelalem100% (1)

- Pioneer Avh-X5500 Avh-X5550 Avh-X5590 SM PDFDocument190 pagesPioneer Avh-X5500 Avh-X5550 Avh-X5590 SM PDFCarlos Alonso Gonzalez VazquesNo ratings yet

- ISW2001NBF - AEB (VERSIONE 6.1.3) - Installatore - ENG PDFDocument33 pagesISW2001NBF - AEB (VERSIONE 6.1.3) - Installatore - ENG PDFEden AleixoNo ratings yet

- HKS EVC V Boost Controller Setup InstructionsDocument7 pagesHKS EVC V Boost Controller Setup InstructionsDave_B100% (2)

- Engine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsDocument10 pagesEngine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsVictor ValenciaNo ratings yet

- Drive startup manual guideDocument12 pagesDrive startup manual guidehoumeniNo ratings yet

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyNo ratings yet

- Installation and Operation Manual For E4OD/4R100 TransmissionsDocument27 pagesInstallation and Operation Manual For E4OD/4R100 TransmissionsJou PowerNo ratings yet

- 14 CUX Cold Start UpdateDocument16 pages14 CUX Cold Start UpdateAldous Cosmo GitlesNo ratings yet

- DTC P0011Document9 pagesDTC P0011Ronald MoonNo ratings yet