Professional Documents

Culture Documents

Avk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004

Uploaded by

Ariane Joy LucasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Avk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004

Uploaded by

Ariane Joy LucasCopyright:

Available Formats

AVK SUPA PLUS™ FLANGE ADAPTOR, PN 10/16 623/10

Tensile, for PE and PVC pipes, incl. flange gasket 004

AVK Supa Plus™ is a range of tensile couplings, flange adaptors and end caps dedicated for PE and uPVC

pipes. Supa Plus™ couplings offer a great flexibility and are very easy to mount due to the combined

compression gasket which enables ±3.5° angular deflection and makes it easy to insert the pipe ends even in

the large dimensions. The external M16 bolts of anti-friction coated stainless steel and the high quality coating

offer a durable corrosion protection.

Product Description:

Supa Plus™ adaptor tensile for PE/uPVC pipes for drinking water and neutral liquids to max. 70°C

Standards:

• Designed according to EN 12842

• Standard flange drilling to EN1092-2 (ISO 7005-2), PN 10/16

Features:

• The combined gasket of drinking water approved EPDM rubber with tensile grip segments of RG5 bronze

enables ±3.5° angular deflection

• The design with external bolts prevents corrosion between sleeve and bolts

• The M16 bolts of stainless steel A2 and the nuts of acid-resistant stainless steel A4 are anti-friction coated to

offer easy tightening and to prevent galling

• The bolt ends are protected with plastic caps

• The compression type gasket makes it easy to insert the pipe end, even in large dimensions

• Sleeve and bracket of ductile iron with epoxy coating according to DIN 30677-2 and AVK guidelines

COPYRIGHT©AVK GROUP 2014 Version no. 53 - 9-3-2014 1:49

1/3

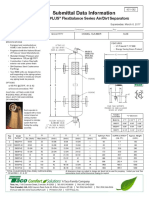

AVK SUPA PLUS™ FLANGE ADAPTOR, PN 10/16 623/10

Tensile, for PE and PVC pipes, incl. flange gasket 004

8

L1

7

6

5

4

3

D Dd

1

L

Component List:

1. Adaptor flange Ductile iron GJS-500-7 (GGG-50) 2. Combined gasket NF approved EPDM rubber/RG5 bronze

3. Flange gasket EPDM 4. Bracket Ductile iron GJS-500-7 (GGG-50)

5. Cap Plastic 6. Nut Acid resistant stainless steel A4

7. Washer Stainless steel A2 8. Rectangular bolt Stainless steel A2

Components may be substituted with equivalent or higher class materials without prior notification.

Reference Nos. and Dimensions:

DN Dd Flange D L L1 Theoretical

AVK ref. nos

mm mm drilling mm mm mm weight kg

623-10-040-6161 (1) 40 40 PN10/16 150 122 62 3.6

623-10-050-6161 (1) 40 50 PN10/16 150 122 62 3.7

623-10-063-6161 (1) 50 63 PN10/16 180 123 63 4.4

623-10-075-6161 (1) 65 75 PN10/16 185 123 63 4.5

623-10-090-6161 (1) 80 90 PN10/16 200 122 62 4.7

623-10-110-6161 (1) 100 110 PN10/16 220 123 63 6.6

623-10-125-6161 (1) 125 125 PN10/16 250 125 63 6.8

623-10-125-6241 (1) 100 125 PN10/16 240 125 63 6.8

623-10-140-6161 (1) 125 140 PN10/16 250 125 63 6.9

623-10-160-6161 (1) 150 160 PN10/16 285 125 63 8.3

623-10-180-6161 (1) 150 180 PN10/16 285 125 63 10

623-10-200-6061 200 200 PN10 340 126 64 14

623-10-200-6161 200 200 PN16 340 126 64 14

623-10-225-6061 200 225 PN10 340 141 64 15

623-10-225-6161 200 225 PN16 340 141 64 15

623-10-250-6161 (1) 250 250 PN10/16 405 179 88 25

623-10-250-6241 (1) 200 250 PN10/16 405 179 88 25

623-10-280-6061 250 280 PN10 405 179 88 25

623-10-280-6161 (1) 250 280 PN16 405 179 88 25

623-10-315-6161 (1) 300 315 PN10/16 460 179 88 29

The designs, materials and specifications shown are subject to change without notice. This is due to the continuous development of our product programme.

Version no. 53 - 9-3-2014 1:49

2/3

DN Dd Flange D L L1 Theoretical

AVK ref. nos

mm mm drilling mm mm mm weight kg

623-10-315-6241 (1) 250 315 PN10/16 460 179 88 29

(1)

10/16 = Universal drilling

The designs, materials and specifications shown are subject to change without notice. This is due to the continuous development of our product programme.

Version no. 53 - 9-3-2014 1:49

3/3

You might also like

- FK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsDocument6 pagesFK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsNguyen KhaNo ratings yet

- Data Base Security and Privacy Question BankDocument46 pagesData Base Security and Privacy Question Bankalgatesgiri100% (1)

- 621-41-001 - Avk130 - en 2206 - 478821Document2 pages621-41-001 - Avk130 - en 2206 - 478821bre brilianNo ratings yet

- Pipa/flangeDocument2 pagesPipa/flangeDimas Ageng PurnamaNo ratings yet

- 21-50-007 AVK Resilient Seated Gate Valve DN50-400Document2 pages21-50-007 AVK Resilient Seated Gate Valve DN50-400Ferdi SagalaNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- 02 60 AVK Gate Valve F5 Long-BodyDocument3 pages02 60 AVK Gate Valve F5 Long-BodyArshad IqbalNo ratings yet

- Avk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument2 pagesAvk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- 601-A-006 - Avk021 - en 2232 - 471287Document2 pages601-A-006 - Avk021 - en 2232 - 471287bre brilianNo ratings yet

- Avk Dismantling Joint, Pn16 265/30-141: Reduced Tie Rods 25% of The Holes, A4 Stainless Steel Bolts, 300 M EP CoatingDocument2 pagesAvk Dismantling Joint, Pn16 265/30-141: Reduced Tie Rods 25% of The Holes, A4 Stainless Steel Bolts, 300 M EP CoatingFiroz HussainNo ratings yet

- AVKDocument2 pagesAVKpiscesguy78No ratings yet

- 910 21 001 PDFDocument3 pages910 21 001 PDFMatt SterlingNo ratings yet

- Avk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300Document2 pagesAvk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300kad-7No ratings yet

- Codeline - Octa 80S Series - 80S15, 80S30, 80S45,: Exploded View & Details (Coded Models)Document1 pageCodeline - Octa 80S Series - 80S15, 80S30, 80S45,: Exploded View & Details (Coded Models)igo badrNo ratings yet

- Avk Double Orifice Air Valve Dn25 851/20: MaterialsDocument2 pagesAvk Double Orifice Air Valve Dn25 851/20: Materialsbre brilianNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn6/10/16 820/00-019: Loose EPDM Liner For Drinking Water, With Electric ActuatorDocument2 pagesAvk Centric Wafer Butterfly Valve, Pn6/10/16 820/00-019: Loose EPDM Liner For Drinking Water, With Electric Actuatorbre brilianNo ratings yet

- Gfps Datasheet 561 562 Cone Check Valve enDocument8 pagesGfps Datasheet 561 562 Cone Check Valve encarnaticshankNo ratings yet

- Avk Centric U-Section Butterfly Valve, PN 10 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric U-Section Butterfly Valve, PN 10 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDavidRNunesNo ratings yet

- 876-01-001 Avkcms enDocument3 pages876-01-001 Avkcms enbre brilianNo ratings yet

- Catalogo StafsjoDocument12 pagesCatalogo StafsjoBruno Bassotti SilveiraNo ratings yet

- Waterstop PVC BalbeckDocument7 pagesWaterstop PVC BalbeckLuis Carlos EsquivelNo ratings yet

- Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal SeatedDocument3 pagesAvk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seatedbrilian pungkyNo ratings yet

- 06-35-006 Avkcms en 427228Document2 pages06-35-006 Avkcms en 427228bre brilianNo ratings yet

- Dual Seal Super-Rapid Fittings Series 8000Document3 pagesDual Seal Super-Rapid Fittings Series 8000icsNo ratings yet

- Avk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001Document3 pagesAvk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001AgieYogaswaraNo ratings yet

- Installation Components: TubingDocument31 pagesInstallation Components: TubingZahir KhiraNo ratings yet

- 3) Catalogue - Convex CouplingDocument8 pages3) Catalogue - Convex CouplingmarcusNo ratings yet

- Avk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300Document2 pagesAvk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300kad-7No ratings yet

- Avk Universal Supa® Step Coupling, Pn16 602: Product DescriptionDocument3 pagesAvk Universal Supa® Step Coupling, Pn16 602: Product DescriptionArshad IqbalNo ratings yet

- Recoil Check Valve Data SheetDocument2 pagesRecoil Check Valve Data SheetDeepak JoyNo ratings yet

- Avk Gate Valve, Flanged, Pn10/16 02/66-006: EN 558-2 S.15/DIN F5, Position Indicator, NBR, DN40-400Document3 pagesAvk Gate Valve, Flanged, Pn10/16 02/66-006: EN 558-2 S.15/DIN F5, Position Indicator, NBR, DN40-400kad-7No ratings yet

- 5900 FlexBalance Plus Series Separators Submittal 401-082 102319Document1 page5900 FlexBalance Plus Series Separators Submittal 401-082 102319Rafael SalazarNo ratings yet

- Brochure - AVK Gate Valve OS&Y ANSI, Prepared For Actuator 2012Document2 pagesBrochure - AVK Gate Valve OS&Y ANSI, Prepared For Actuator 2012crni rokoNo ratings yet

- 76-71-012 Avkcms enDocument2 pages76-71-012 Avkcms enbre brilianNo ratings yet

- Catalog 79027ENG HOKE 7C Series Valve English 101414Document12 pagesCatalog 79027ENG HOKE 7C Series Valve English 101414kaniappan sakthivelNo ratings yet

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- Avk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020Document2 pagesAvk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020lan bautistaNo ratings yet

- 33GS-80GS Submersible Pumps Tech BrochureDocument12 pages33GS-80GS Submersible Pumps Tech BrochureDecsih RuizNo ratings yet

- P2 - B1 - 16 - Coolingsystem, Propulsion Parts, Aux and Consumables - Battery LugsDocument7 pagesP2 - B1 - 16 - Coolingsystem, Propulsion Parts, Aux and Consumables - Battery LugsWeslie CaputeNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- Brass Ball Valve (BBV) V0816Document1 pageBrass Ball Valve (BBV) V0816Saiful Islam SagorNo ratings yet

- CPS - Bridge PlugDocument8 pagesCPS - Bridge PlugJOGENDRA SINGHNo ratings yet

- AVK Gate Valve With Polyethylene Pipe EndDocument3 pagesAVK Gate Valve With Polyethylene Pipe Endklatheesh72No ratings yet

- Catalog Mud Pump 25864Document24 pagesCatalog Mud Pump 25864agus100% (1)

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- General Service Solenoid Valves: ConstructionDocument3 pagesGeneral Service Solenoid Valves: ConstructionAditya B. RyantoNo ratings yet

- TF100-32C - STD Tube SZ and Variable Dia V-Band CoupDocument16 pagesTF100-32C - STD Tube SZ and Variable Dia V-Band CoupScaricatore92No ratings yet

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocument2 pagesWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- PipeCatalog2014 EP42451US1Document176 pagesPipeCatalog2014 EP42451US1Yogeshwar AgrawalNo ratings yet

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureKavan PatelNo ratings yet

- 702G Quick Pressure Relief Control VavleDocument8 pages702G Quick Pressure Relief Control VavleThinh Chu100% (1)

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- F80 Manual RevE PDFDocument17 pagesF80 Manual RevE PDFNaseer HydenNo ratings yet

- AVK Gate Valve Series 37 50 004 IOMDocument9 pagesAVK Gate Valve Series 37 50 004 IOMomarNo ratings yet

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureMurli RamchandranNo ratings yet

- Valvulas CheckDocument4 pagesValvulas CheckLAM AAANo ratings yet

- Large Dia. Butterfly ValveDocument15 pagesLarge Dia. Butterfly ValvepntripathiNo ratings yet

- MOTORTECH SalesFlyer Spark Plug Extensions For WAUKESHA Gas Engines 01.15.051 en 2017 04Document4 pagesMOTORTECH SalesFlyer Spark Plug Extensions For WAUKESHA Gas Engines 01.15.051 en 2017 04RobertNo ratings yet

- Description: 3.1 Target GroupDocument16 pagesDescription: 3.1 Target GroupAriane Joy LucasNo ratings yet

- Dear - : Lesson Suggested Number of Days To StudyDocument36 pagesDear - : Lesson Suggested Number of Days To StudyAriane Joy LucasNo ratings yet

- Precast Concrete Manhole Watertight Joints TechnoteDocument4 pagesPrecast Concrete Manhole Watertight Joints TechnoteAriane Joy LucasNo ratings yet

- Rubber Expansion Joint Double Sphere (Flanged End) PN16 911-2Document2 pagesRubber Expansion Joint Double Sphere (Flanged End) PN16 911-2Ariane Joy LucasNo ratings yet

- Avk Dismantling Joint With Tie Rods & Centre Flange 265/50: Product Description: Standards: Test/ApprovalsDocument3 pagesAvk Dismantling Joint With Tie Rods & Centre Flange 265/50: Product Description: Standards: Test/ApprovalsAriane Joy LucasNo ratings yet

- Group 3 - SRM Project ReportDocument10 pagesGroup 3 - SRM Project ReportAkash IyappanNo ratings yet

- Excel VLOOKUP ExamplesDocument8 pagesExcel VLOOKUP ExamplesYoucef BOUSBANo ratings yet

- P O W E R Learning Strategies For Success in College and Life 9Th Edition Robert Feldman Full Chapter PDF ScribdDocument67 pagesP O W E R Learning Strategies For Success in College and Life 9Th Edition Robert Feldman Full Chapter PDF Scribdsteven.hendrix700100% (6)

- ISaGRAF Devices - EN - Rev1.1Document29 pagesISaGRAF Devices - EN - Rev1.1huskeeNo ratings yet

- Python Function Question and Answers PDFDocument25 pagesPython Function Question and Answers PDFRAJESHNo ratings yet

- Napa 1069 Oil FilterDocument1 pageNapa 1069 Oil Filterkman548No ratings yet

- En-Masse Drag Conveyor SellSheet Print-Nobleed 10-30-2014Document2 pagesEn-Masse Drag Conveyor SellSheet Print-Nobleed 10-30-2014hevertonNo ratings yet

- IOT Based Android App Using MIT App Inventor For Automatic Fire Detection and Alert SystemDocument1 pageIOT Based Android App Using MIT App Inventor For Automatic Fire Detection and Alert SystemSoundaryaNo ratings yet

- Basic ElectronicsDocument1 pageBasic ElectronicsBibin K VijayanNo ratings yet

- General Catalogue 2012Document120 pagesGeneral Catalogue 2012Irina AureliaNo ratings yet

- Getting Started With Autosar - Rev June 25 2019 PDFDocument319 pagesGetting Started With Autosar - Rev June 25 2019 PDFkakathiNo ratings yet

- Artigo Sons Respira o Edvan InglesDocument6 pagesArtigo Sons Respira o Edvan InglesBruno SantosNo ratings yet

- The Blender Quick Start Guide: by Darrin LileDocument23 pagesThe Blender Quick Start Guide: by Darrin LileMiguel Alberto Dávila SacotoNo ratings yet

- Module in CC102 Computer Programming 1Document100 pagesModule in CC102 Computer Programming 1Bryan CabridoNo ratings yet

- Cookie StuffingDocument22 pagesCookie StuffingMendez SusanNo ratings yet

- Task 3 PDFDocument68 pagesTask 3 PDFFathihah AnuarNo ratings yet

- DX3316 IP QAM Modulator User Manual 201605Document22 pagesDX3316 IP QAM Modulator User Manual 201605vmereciNo ratings yet

- Inventaris Lsa & FfaDocument8 pagesInventaris Lsa & FfaRoby AditamaNo ratings yet

- Tekla Tedds 2022 User GuideDocument634 pagesTekla Tedds 2022 User GuideVaibhav PhalakNo ratings yet

- DCNM - Wliion - Dicentis Battery PackDocument3 pagesDCNM - Wliion - Dicentis Battery PackAndrew Halim RamadanNo ratings yet

- 23-24 AP PC Q3 # 2 PSET STUDENT Due Mar 7,8Document14 pages23-24 AP PC Q3 # 2 PSET STUDENT Due Mar 7,8reemfallaha08No ratings yet

- Test 1Document4 pagesTest 1IbrahimNo ratings yet

- The Experience MapDocument9 pagesThe Experience MapHasan Basri KartalNo ratings yet

- DBDocument18 pagesDBSrinidhi PNo ratings yet

- Tim Hortons Cover Letter SampleDocument4 pagesTim Hortons Cover Letter Sampleafllwwtjo100% (1)

- Recruitment AE Poster SoCtronicsDocument1 pageRecruitment AE Poster SoCtronicsSaivenkat BingiNo ratings yet

- Individual Daily Accomplishment Report Annex2Document5 pagesIndividual Daily Accomplishment Report Annex2rose lima guitaNo ratings yet

- STK1R-EN-61-0-A Rev0-1Document98 pagesSTK1R-EN-61-0-A Rev0-1LudovicoNo ratings yet

- View Log Files: Viewed at Thu 21 Apr 2005 07:42:25 PM AKDTDocument68 pagesView Log Files: Viewed at Thu 21 Apr 2005 07:42:25 PM AKDTAlex KtNo ratings yet