Professional Documents

Culture Documents

37 Ijirset Paper Eathe

Uploaded by

kylealamangoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

37 Ijirset Paper Eathe

Uploaded by

kylealamangoCopyright:

Available Formats

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 7, July 2017

Design and Development of Earth Air Tunnel

Heat Exchanger

Ashwin Victor Pinto

G. Student, Department of Mechanical Engineering, Acropolis Institute of Technology and Research, M.P., India

ABSTRACT: The Earth Air Tunnel Heat Exchanger (EATHE) is a hybrid passive way of cooling. The hybrid way

suggests that it involves an active agent fan for the flow of air, but the cooling and heating of air is done with the help

of a passive agent ground soil. In this pipes are buried underground and air is flown through it to cool or heat according

to the season since the temperature of soil underground remains constant and at near human comfort level. EATHE can

be used and in some places it still in use cool homes, buildings and other systems. There is a need to make a shift from

high energy consuming active user to low energy consuming techniques. And EATHE is one of those techniques.

There has been a lot of research done over it with the development of algorithms to design the heat exchanger, CFD

analysis etc. This paper aims to contribute for further development of EATHE. We had developed an algorithm in

which we assumes a maximum load in a room and with this input factor we design a heat exchanger, in which we find

out the required diameter and length of the pipe to cool the load in the room. We assume some required factors like

required temperature in the room, maximum outside temperature, velocity of air. This paper aims to bring ground

source cooling into use and research. We acknowledge the limitations of EATHE systems over AC systems and hope

this paper would help others to work over it.

KEYWORDS: Earth, Air, Heat Exchanger, Sustainable Energy, Ground source.

I. INTRODUCTION

Energy has been a most important factor for human beings since Stone Age. The use of energy in active cooling

systems especially for HVACs in homes building and other recreations has been tremendous. Energy demand for space

cooling is growing rapidly with time in India and so as along the world, driven by rising income, lowering cost of

technology and natural preference of ambient human comfort level temperature. Air conditioners are among the most

prevalent purchases for the growing middle class, with its sales increasing by 20 percent in the recent times. In US now

almost 87% owns air conditioners, says the latest data from EIA’s residential energy consumption survey. A base case

estimates a consumption of 42 terawatt-hour in 2010 for air conditioners. All that air conditioning does is to throwing

the indoor heat out, warming up the outdoors, increasing the green house effect. Dependency of air conditioners on

CFCs, HCFCs and others has increased the effect of global warming too by depleting the ozone layer. All these facts

lead to changing the source of cooling and most importantly the energy. Earth air tunnel heat exchanger (EATHE) is

one such solution to all of the problems mentioned against air conditioners. EATHE as the name suggests is a pipe

matrix arrangement led underground, in which ambient air is passed. The temperature of soil being lesser than the air in

summer cools down and vice versa happens in winter. This cooled air in summer or hot air in winter is then directed in

the houses or buildings. The temperature of the soil remains constant throughout the year after a certain depth, mostly

after 2.5-3 meters depending upon the geological areas, climatic conditions and soil type

II. RELATED WORK

The heat transfer to and from Earth tube heat exchanger system has been the subject of many theoretical and

experimental investigations. Girja Sharan and Ratan Jadhav installed a single pass earth-tube heat exchanger (ETHE) to

study its performance in cooling and heating mode. ETHE is made of 50 m long ms pipe of 10 cm nominal diameter

and 3 mm wall thickness. ETHE is buried 3 m deep below surface. A 400 w blower pumps ambient air through it. Air

velocity in the pipe is 11 m/s. ETHE was able to reduce the temperature of hot ambient air by as much as 14°C in May.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0607037 12713

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 7, July 2017

The basic soil temperature in May was 26.6°C. It was able to warm up the cold ambient air by a similar amount in the

nights of January. The coefficient of performance (COP) in cooling mode averaged to 3.3. Fabrizio Ascione, Laura

Bellia and Francesco Minichiello the energy performances achievable using an earth-to-air heat exchanger for an air-

conditioned building have been evaluated for both winter and summer. By means of dynamic building energy

performance simulation codes, the energy requirements of the systems have been analyzed for different Italian climates,

as a function of the main boundary conditions. Trilok Singh Bisoniya has developed a one-dimensional model of the

EAHE systems using a set of simplified design equations and discovered the factors that affected the performance.

III. METHODOLOGY

There are mainly two commonly methods used to design a heat exchanger depending upon the input factors. It can be

done either by using the logarithmic mean temperature difference (LMTD) method or the effectiveness and number of

transfer units (NTU) method. LMTD method is used to design the heat exchanger when the inlet and outlet

temperatures, the flow rate and overall heat transfer coefficient are given and the heat exchanger’s diameter and length

are designed accordingly. The Number of Transfer Units (NTU) Method is used to calculate the rate of heat

transfer in heat exchangers (especially counter current exchangers) when there is insufficient information to calculate

the Logarithmic Mean Temperature Difference (LMTD). In this method, the fluid inlet and outlet temperatures are

specified or can be determined by simple energy balance. In this paper the LMTD method is used.

Assumptions

1. The soil surrounding the pipe is isotropic, with homogenous thermal conductivity in all ground strata.

2. The thermal resistance of the pipe material is negligible (thickness of the pipe is very small).

3. The surface temperature of the ground can be approximated to the ambient air temperature, which equals the inlet

air temperature.

4. The pipe is of uniform circular cross-section.

5. The soil temperature near the pipe is not influenced by the pipe, so the surface temperature of the pipe is uniform in

the axial direction.

6. Thermo-physical properties (density, viscosity, thermal conductivity and specific heat capacity etc.) of air and soil

are constant.

A general equation for the rate of heat transfer is given by,

Q = ṁ×cp×∆T

Where,

Q = maximum cooling load in the room (system) (Joule/sec). Since the main aim of this paper is to replace AC

with an EATHE system giving equivalent output, hence the maximum cooling load is the maximum cooling

capacity of AC that meant to be replaced.

ṁ = mass flow rate of air into the room (kg/sec). This is to be found out from the above equation.

cp = specific heat of air at an average temperature of air (J/kg/K).

∆T = temperature difference of air at the inlet i.e. ambient temperature Ta and at the outlet of the pipe i.e. room

temperature Tr (Kelvin). For this data the inlet and outlet temperature needs to be fixed according to the

maximum surrounding temperature and the required temperature of the room respectively. The inlet

temperature would be the maximum outdoor temperature since we are designing the system for an extreme

condition. And the outlet of pipe or the room temperature would be the required room temperature needed.

From the above equation the mass flow rate for the required cooling load and the temperature difference is found out.

Since,

mass low(m)

discharge (volume low rate of air), q =

density of air at average temperature(ρ)

Diameter (d) of the duct of the heat exchanger can be calculated using the continuity equation, q = AV.

Hence,

(π × d )

q = V ×

4

The velocity of air between 2-15 m/s is economical.

Now to find the length of the heat exchanger LMTD method is used which is govern by the equation,

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0607037 12714

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 7, July 2017

Q= ha ×A×Tlm

Where,

Q= is the cooling load.

ha = is the heat transfer coefficient.

A = surface area of heat exchanger from where heat will be exchanged between the pipe and the soil.

Tlm = logarithmic mean temperature difference.

The calculations process for the above parameters takes place as follows

i. Calculation of heat transfer coefficient.

Since for forced convection heat transfer coefficient is given by,

Nu × k

ha =

d

Where,

Nu = Nusselt no.

k = Conductivity of air.

D = diameter of air.

For Nusselt no. Renolds no.(Re) need to be found out, which is given by

V×d

Re =

ν

Where,

V = velocity of air.

d = diameter of pipe.

= dynamic viscosity of air. It is constant at constant temperature

If RE < 10000, it would be laminar flow

If Re > 10000, hence it is a turbulent flow

For most of the cases Re >10000. So for turbulent flow in circular tube Nusselt no. is given by Petukhov equation i.e,

(f/8) × (Re − 1000) × Pr

Nu =

1 − 12.7 × f/8 × (Pr / − 1)

Where, f is friction coefficient = (0.79 × lnRe − 1.64)

Hence putting the values Nu can be found out.

Hence, now the heat transfer coefficient can be found out using,

×

ha =

ii. Calculation of logarithmic mean temperature difference, Tlm.

Given by,

(Ɵ Ɵ )

Tlm= (Ɵ / Ɵ )

Where,

Ɵ1=Ta-Ts

Ɵ2=Tr-Ts

There would be two conditions between the room temperature Tr and soil temperature Ts.

When Tr ≥ Ts. this happens during summer,

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0607037 12715

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 7, July 2017

Tr ≤ Ts, this happens mostly during winter

The temperatures are needed to be fixed as we are using LMTD method and so we are designing the heat exchanger

according to the inlet and outlet temperatures as an input. This can be fixed according to our needs and environmental

datas. The temperature of the soil is different in different geographical areas. This temperature is found out

experimentally. The temperature of the room is fixed to a human comfort temperature that lies between 22-27 deg C.

The temperature of the environment is variable naturally. It changes with time. And so we need to take the max

temperature that can be predicted as we are designing for an extreme condition.

iii. Calculation of Length of heat exchanger.

Since the area of the heat exchanger where the heat is going to be exchanged is just the curved surface area of the duct

and since we are using cylindrical pipe and assuming heat exchange in any other area to be zero,

Hence

A= 2πrL.

Hence putting this equation in equation,

Q= ha×A×Tm,

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0607037 12716

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 7, July 2017

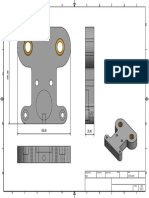

length of the pipe can be discovered. Hence design of the heat exchanger is complete. Below is a schematic diagram of

EATHE.

Since now our design is fixed hence effectiveness of heat exchanger is also fixed because of the factors it depends upon.

Effectiveness is given by,

Ɛ= 1-eUA/Cp

The only parameter that will vary will be the ambient environment temperature. And ambient temperature and room

temperature in relation with fixed design is given by,

Tr =Ta – (Ta-Ts)×Ɛ

The behaviour of room temperature Tr with respect to Ta can be seen in the graph for two cases.

a. When Ɛ=1.

b. And when Ɛ<1.

The graph also acknowledges the relationship between Tr and Ts in summer and winter i.e.

a. When Tr ≥ Ts.

b. And when Tr ≤ Ts.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0607037 12717

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 7, July 2017

IV. RESULTS

The output of EATHE depends upon the effectiveness of the heat exchanger, as can be seen from the graph. As Ɛ tend

to 1and Tr tend to Ts and so the change of Tr with respect to Ta is less. This can be only be achieved when the

fabrication of EATHE is just done according to the design and assumptions. The more effectiveness Ɛ tends to 1, the

better the performance.

V. CONCLUSION

Earth air tunnel heat exchanger is a very reliable way to cool homes and buildings. Besides having all the advantages of

a passive cooling technique, it is a long term plan. Its life span is 3-4 times that of an AC sys00t1ems. EATHE can also

be used to reduce load on AC reducing energy consumption. EATHE can also be used in winter to heat and ventilate

the atmospheric.

There is a need of shift of technology from a non-renewable source to a renewable one. And this method helps to make

that shift. The design model helps to develop EATHE for any required cooling load.

REFERENCES

[1] G. Sharan, R. Jadhav, Performance of single pass earth-tube heat exchanger: an experimental study, Journal of Agricultural Engineering,

(2003), pp 1–8.

[2] Fabrizio Ascione , Laura Bellia , Francesco Minichiello Earth-to-air heat exchangers for Italian climates. Renewable Energy, 36 (2011), pp

2177-2188.

[3] Trilok Singh Bisoniya, Design of earth–air heat exchanger system, Bisoniya Geothermal Energy (2015), pp 3-18.

[4] Akshay khot, Analysis of various designing parameters for earth air tunnel heat exchanger system, volume 5, issue 12, december (2014), pp.

118-125.

[5] NiyuktiSogale, Swati Thombare, Ivy Lopes, Ashwathi Nair, Sanjay Lohar, Design and Development of Earth Tube Heat Exchanger for Room

Conditioning, volume 7, issue 3, march (2017), pp. 5039-5042.

[6] Trilok Singh Bisoniya, Anil Kumar, Prashant Baredar, “Experimental and analytical studies of earth–air heat exchanger (EAHE) systems in

India: A review”, Renewable and Sustainable Energy Reviews, 19 (2013),pp 238–246.

[7] Yunus A. Cengel and Afshin Jahanshahi Ghajar, Heat and mass transfer 4e.

[8] Er. R. K. Rajput, Heat and mass transfer S. Chand.

[9] http://economictimes.indiatimes.com/industry/energy/power/indias-power-consumption-to-grow-on-rise-in-ac-

sales/articleshow/49569791.cms

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0607037 12718

You might also like

- Electricians Licence 'A' (Domestic) - Maltese SyllabusDocument307 pagesElectricians Licence 'A' (Domestic) - Maltese Syllabusdavidegrima100% (17)

- Experiment 3 Acid and Base TitrationDocument9 pagesExperiment 3 Acid and Base TitrationMuhamad Faris86% (49)

- Aama 2603-13Document14 pagesAama 2603-13Van Hien LeNo ratings yet

- Design and Performance Analysis of Double Pipe Heat ExchangerDocument7 pagesDesign and Performance Analysis of Double Pipe Heat ExchangerAidiaiem KhawaijNo ratings yet

- Earth Air Heat Exchanger in Parallel ConnectionDocument5 pagesEarth Air Heat Exchanger in Parallel Connectionseventhsensegroup100% (1)

- 1 s2.0 S1877705817350178 MainDocument6 pages1 s2.0 S1877705817350178 MainLUIS CHRISTOPHER ROJAS MUÑOZNo ratings yet

- Performance Evaluation of Air Conditioner Using Earth Air Tunnel Heat ExchangerDocument5 pagesPerformance Evaluation of Air Conditioner Using Earth Air Tunnel Heat ExchangerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Construction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemDocument6 pagesConstruction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemijeteeditorNo ratings yet

- Performance Analysis of Earth-Air Tunnel System Used For Air-Conditioning of The College ClassroomDocument9 pagesPerformance Analysis of Earth-Air Tunnel System Used For Air-Conditioning of The College ClassroomkylealamangoNo ratings yet

- For Summer COolingDocument4 pagesFor Summer COolingBoris Joshua Q. TeodoroNo ratings yet

- Earth Air Heat Exchanger Project ReportDocument20 pagesEarth Air Heat Exchanger Project ReportAMAR SAINo ratings yet

- The Design of Earth Air Tunnel Heat Exchanger System For An Institute LibraryDocument5 pagesThe Design of Earth Air Tunnel Heat Exchanger System For An Institute LibraryInnovative Research PublicationsNo ratings yet

- Report On EaheDocument15 pagesReport On EaheAMAR SAINo ratings yet

- A Review Paper On Computational Study of Earth Tube Heat Exchanger SystemDocument7 pagesA Review Paper On Computational Study of Earth Tube Heat Exchanger SystemIJRASETPublicationsNo ratings yet

- IJREAMV04I0642045 (5)Document8 pagesIJREAMV04I0642045 (5)Vãmßhí Yøūth MenuguNo ratings yet

- APPLICATION OF THERMOACOUSTIC EFFECT TO COOLING OF AIR USING ACOUSTIC WAVES Ijariie6525Document6 pagesAPPLICATION OF THERMOACOUSTIC EFFECT TO COOLING OF AIR USING ACOUSTIC WAVES Ijariie6525Ali HassanNo ratings yet

- Condensation Heat Transfer Coefficient of A Mini TubeDocument8 pagesCondensation Heat Transfer Coefficient of A Mini TubegiangfvuNo ratings yet

- Design and Operation of Double Pipe Heat Exchanger: February 2017Document27 pagesDesign and Operation of Double Pipe Heat Exchanger: February 2017tasosNo ratings yet

- Comparison of heating systems on air flow and particlesDocument38 pagesComparison of heating systems on air flow and particlesMortezaAli MasoomiNo ratings yet

- Iarjset 26Document7 pagesIarjset 26Otman MchachtiNo ratings yet

- 1 s2.0 S0375650519301208 MainDocument13 pages1 s2.0 S0375650519301208 MainLUIS CHRISTOPHER ROJAS MUÑOZNo ratings yet

- To Enhance The Heat Transfer Rate in Thermoelectric Cooler: A ReviewDocument6 pagesTo Enhance The Heat Transfer Rate in Thermoelectric Cooler: A Reviewankita awasthiNo ratings yet

- COP Enhancement of Vapor Compression RefrgerationDocument5 pagesCOP Enhancement of Vapor Compression RefrgerationRana Abdul RehmanNo ratings yet

- Effects of Parameters On Performance of Earth Air Heat Exchanger System (EAHE) : A ReviewDocument4 pagesEffects of Parameters On Performance of Earth Air Heat Exchanger System (EAHE) : A ReviewShubham AryaNo ratings yet

- Earth Tube Heat ExchangerDocument5 pagesEarth Tube Heat ExchangerIJRASETPublicationsNo ratings yet

- 2019-Liu-Enhancing A Vertical EAHE System Using PCM PDFDocument31 pages2019-Liu-Enhancing A Vertical EAHE System Using PCM PDFKamal Kumar AgrawalNo ratings yet

- Earth TubeDocument2 pagesEarth TubeNitish ShresthaNo ratings yet

- Earth TunnelingDocument9 pagesEarth TunnelingNishita NaikNo ratings yet

- Paper 25Document4 pagesPaper 25Editor IJSETNo ratings yet

- The Potential of Earth-Air Heat Ex Changers For Low Energy Cooling of BuildingsDocument2 pagesThe Potential of Earth-Air Heat Ex Changers For Low Energy Cooling of BuildingsCristi IonescuNo ratings yet

- BelloufiDocument10 pagesBelloufiأيــمـنNo ratings yet

- 2021-Morshed-Heating Performance of The PVC Earthair Tubular Heat Exchanger Applied To A GreenhouseDocument19 pages2021-Morshed-Heating Performance of The PVC Earthair Tubular Heat Exchanger Applied To A GreenhouseraviNo ratings yet

- Experimental Investigation of Gravity Heat Pipe Exchanger Applied in Communication Base StationDocument8 pagesExperimental Investigation of Gravity Heat Pipe Exchanger Applied in Communication Base StationaliNo ratings yet

- Experimental Investigation On Air Heating and Natural Ventilation of A Solar Air CollectorDocument9 pagesExperimental Investigation On Air Heating and Natural Ventilation of A Solar Air CollectorResearcherzNo ratings yet

- Energy: Dawid Taler, Jan Taler, Marcin TrojanDocument14 pagesEnergy: Dawid Taler, Jan Taler, Marcin Trojankota naikNo ratings yet

- 2020-Dehina-Energy Modelling of A New Co-Current Coaxial Earth-Water To Air-Heat ExchangerDocument8 pages2020-Dehina-Energy Modelling of A New Co-Current Coaxial Earth-Water To Air-Heat ExchangerraviNo ratings yet

- Miniature Refrigeration SystemDocument7 pagesMiniature Refrigeration SystemRameshkumar RNo ratings yet

- Design of Earth - Air Heat Exchanger System: Research Open AccessDocument10 pagesDesign of Earth - Air Heat Exchanger System: Research Open AccessAnuj MalewarNo ratings yet

- Research Inventy: International Journal of Engineering and ScienceDocument5 pagesResearch Inventy: International Journal of Engineering and ScienceinventyNo ratings yet

- Effect of Heat Spreading on Performance of Heat Sink via Vapor ChamberDocument11 pagesEffect of Heat Spreading on Performance of Heat Sink via Vapor ChamberIan Azarya AryantoNo ratings yet

- The Seasonal Storage of Thermal Solar Energy in IraqDocument9 pagesThe Seasonal Storage of Thermal Solar Energy in IraqInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 2020-Khan-Earth-Tube System To Control Indoor Thermal Environment in Residential BuildingsDocument8 pages2020-Khan-Earth-Tube System To Control Indoor Thermal Environment in Residential BuildingsraviNo ratings yet

- An Experimental Investigation of Gas Geyser's Heat Exchanger With Addition of EconomizerDocument5 pagesAn Experimental Investigation of Gas Geyser's Heat Exchanger With Addition of EconomizerijaertNo ratings yet

- Free and Forced Convection Heat TransferDocument10 pagesFree and Forced Convection Heat Transferhayder alaliNo ratings yet

- 2021-Malviya-Eco-friendly Cooling System Design For A Hostel BuildingDocument15 pages2021-Malviya-Eco-friendly Cooling System Design For A Hostel BuildingraviNo ratings yet

- Heat Transfer in Spray Quenching: The Focus of This Experiment Is ToDocument3 pagesHeat Transfer in Spray Quenching: The Focus of This Experiment Is ToJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Experiment On Heat Transfer Through Fins Having Different NotchesDocument4 pagesExperiment On Heat Transfer Through Fins Having Different NotcheskrantiNo ratings yet

- Miroslaw Zukowski Bialystok Technical University 15-351 Bialystok, Ul. Wiejska 45E - PolandDocument8 pagesMiroslaw Zukowski Bialystok Technical University 15-351 Bialystok, Ul. Wiejska 45E - Polandzahirshah1436923No ratings yet

- Cooling of Electronic Equipmentteam8Document7 pagesCooling of Electronic Equipmentteam8Amey Puranik100% (1)

- An Investigation On Thermo-Hydraulic Performance of Shell and Tube Heat Exchanger With RecyclesDocument14 pagesAn Investigation On Thermo-Hydraulic Performance of Shell and Tube Heat Exchanger With RecyclesTJPRC PublicationsNo ratings yet

- Synopsis - Geothermal Heating & Cooling SystemDocument13 pagesSynopsis - Geothermal Heating & Cooling SystemShubham KumarNo ratings yet

- 2018-Misra-Field InvestigationEnergyDocument9 pages2018-Misra-Field InvestigationEnergyraviNo ratings yet

- Building and Environment: Xing Jin, Xiaosong Zhang, Yajun Luo, Rongquan CaoDocument8 pagesBuilding and Environment: Xing Jin, Xiaosong Zhang, Yajun Luo, Rongquan Caoanon_144521603No ratings yet

- Ijmet: ©iaemeDocument14 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- IJETR021660Document8 pagesIJETR021660erpublicationNo ratings yet

- Study and Fabrication of Thermoelectric Air Cooling and Heating SystemDocument11 pagesStudy and Fabrication of Thermoelectric Air Cooling and Heating SystemInternational Journal of Engineering Inventions (IJEI)100% (1)

- IJERT CFD Analysis of Double Pipe Counte (Lab 11)Document13 pagesIJERT CFD Analysis of Double Pipe Counte (Lab 11)bjuanlunabNo ratings yet

- Natural ConvectionDocument6 pagesNatural ConvectionSarvajot SinghNo ratings yet

- Ijmet 10 01 031Document10 pagesIjmet 10 01 031IAEME PUBLICATIONNo ratings yet

- Exergy Analysis of A Dual-Evaporator RefrigerationDocument10 pagesExergy Analysis of A Dual-Evaporator Refrigerationbagiyo condroNo ratings yet

- IJMET - 10 - 01 - 031 With Cover Page v2Document11 pagesIJMET - 10 - 01 - 031 With Cover Page v2Dibyendu KonarNo ratings yet

- Modelling and Analysis of Thermo Electric Cooler Module Using AnsysDocument10 pagesModelling and Analysis of Thermo Electric Cooler Module Using AnsysTJPRC PublicationsNo ratings yet

- Namur Solenoid Valve DatasheetDocument2 pagesNamur Solenoid Valve DatasheetkylealamangoNo ratings yet

- IOM Pneumatic ActuatorsDocument15 pagesIOM Pneumatic Actuatorskylealamango100% (1)

- Socket Welding Instructions: How to Hot Weld Pipes and FittingsDocument3 pagesSocket Welding Instructions: How to Hot Weld Pipes and FittingskylealamangoNo ratings yet

- Hand Truck Sop - CleanedDocument1 pageHand Truck Sop - CleanedkylealamangoNo ratings yet

- Weld-On Solvent Welding GuideDocument24 pagesWeld-On Solvent Welding GuidekhairulakbarNo ratings yet

- Ms 13 151Document128 pagesMs 13 151Dağhan ArpacıNo ratings yet

- James Caterers - Menu 2 (Smallpdf - Com)Document4 pagesJames Caterers - Menu 2 (Smallpdf - Com)kylealamangoNo ratings yet

- James Caterers - PACKAGES (Smallpdf - Com)Document2 pagesJames Caterers - PACKAGES (Smallpdf - Com)kylealamangoNo ratings yet

- Metal Chop Saw SopDocument2 pagesMetal Chop Saw SopkylealamangoNo ratings yet

- Hammerita Paint - 2021Document15 pagesHammerita Paint - 2021kylealamangoNo ratings yet

- James Caterers - Menu 5 (Smallpdf - Com)Document5 pagesJames Caterers - Menu 5 (Smallpdf - Com)kylealamangoNo ratings yet

- Angle Grinder SopDocument2 pagesAngle Grinder SopkylealamangoNo ratings yet

- Underground Tunnel Transfer in Airport - Fire SafetyDocument11 pagesUnderground Tunnel Transfer in Airport - Fire SafetykylealamangoNo ratings yet

- James Caterers - Menu 3 (Smallpdf - Com)Document4 pagesJames Caterers - Menu 3 (Smallpdf - Com)kylealamangoNo ratings yet

- Aluminum With Brass BushesDocument1 pageAluminum With Brass BusheskylealamangoNo ratings yet

- James Caterers - Menu 1 (Smallpdf - Com)Document4 pagesJames Caterers - Menu 1 (Smallpdf - Com)kylealamangoNo ratings yet

- Street Lighting Design GuidelinesDocument117 pagesStreet Lighting Design GuidelinesBadhon Biswas50% (2)

- Tunnel Fire SafetyDocument13 pagesTunnel Fire SafetykylealamangoNo ratings yet

- Study On The Heat Load Characteristics of Underground StructuresDocument9 pagesStudy On The Heat Load Characteristics of Underground StructureskylealamangoNo ratings yet

- TM National Cycling StrategyDocument106 pagesTM National Cycling StrategykylealamangoNo ratings yet

- Ventilation and Air-Conditioning System: Detailed Project Report For Ludhiana Metro May 2009Document15 pagesVentilation and Air-Conditioning System: Detailed Project Report For Ludhiana Metro May 2009Aniket SinghNo ratings yet

- Susutainble Ventilation For Moder Subway SystemsDocument32 pagesSusutainble Ventilation For Moder Subway SystemskylealamangoNo ratings yet

- A Psychosocial Approach To Understanding UndergrouDocument7 pagesA Psychosocial Approach To Understanding UndergroukylealamangoNo ratings yet

- Energy Optimization in Tunnel LightingDocument18 pagesEnergy Optimization in Tunnel LightingkylealamangoNo ratings yet

- 1983 Transportation VanderVoordt VanWegen UnderpassesDocument13 pages1983 Transportation VanderVoordt VanWegen UnderpassesJananiNo ratings yet

- Ventilation System - WGT - TunnelVentilationonDocument2 pagesVentilation System - WGT - TunnelVentilationonkylealamangoNo ratings yet

- Ventilation System - WGT - TunnelVentilationonDocument2 pagesVentilation System - WGT - TunnelVentilationonkylealamangoNo ratings yet

- Modern Subway Ventilation System DesignDocument5 pagesModern Subway Ventilation System DesignkylealamangoNo ratings yet

- Energy Optimization in Tunnel LightingDocument18 pagesEnergy Optimization in Tunnel LightingkylealamangoNo ratings yet

- Exploring Amino Acids Ex 091723Document4 pagesExploring Amino Acids Ex 091723Mai Abdallah El KelanyNo ratings yet

- MSS SP53Document9 pagesMSS SP53nile_asterNo ratings yet

- AminesDocument53 pagesAminesasheethio4No ratings yet

- Safety in The LaboratoryDocument10 pagesSafety in The LaboratoryRhemia Li CapisanNo ratings yet

- Brochure - Genuine Oil SPECIFICATIONS OILDocument14 pagesBrochure - Genuine Oil SPECIFICATIONS OILBouslimi SouhaibNo ratings yet

- Using HSC Allows Longer Spans and Shallower BridgesDocument21 pagesUsing HSC Allows Longer Spans and Shallower BridgesMahbub AlamNo ratings yet

- Azeotropic & Extractive DistillationDocument39 pagesAzeotropic & Extractive Distillationsatyacrazy100% (3)

- RILEM TC 191-ARP Recommended Test Method for Detecting Alkali-Reactivity in Concrete AggregatesDocument8 pagesRILEM TC 191-ARP Recommended Test Method for Detecting Alkali-Reactivity in Concrete AggregatesJorge Guerra LópezNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Chemical and of The SupplierDocument8 pagesSafety Data Sheet: Section 1: Identification of The Chemical and of The SupplierFikriey AbdullahNo ratings yet

- A Case Study in Lime Production: No.2. Improved Techniques at Chenkumbi, MalawiDocument6 pagesA Case Study in Lime Production: No.2. Improved Techniques at Chenkumbi, MalawiMilian Asha Bio MuradNo ratings yet

- 2022-Gang Chen-Photomolecular Effect Leading To Water Evaporation Exceeding Thermal LimitDocument45 pages2022-Gang Chen-Photomolecular Effect Leading To Water Evaporation Exceeding Thermal Limit154920076No ratings yet

- Astm 2017-F2059Document5 pagesAstm 2017-F2059laythNo ratings yet

- Sika PDS - E - SikaGrout - 212 GP PDFDocument2 pagesSika PDS - E - SikaGrout - 212 GP PDFlwin_oo2435No ratings yet

- Environmental ScienceDocument11 pagesEnvironmental ScienceKimberly kate AlambraNo ratings yet

- Pre-Qualification Docs ListDocument11 pagesPre-Qualification Docs ListNikhil RajuNo ratings yet

- Argan Oil MSDSDocument10 pagesArgan Oil MSDSCrina BanuNo ratings yet

- API 577 Key Points - Chapter 5Document4 pagesAPI 577 Key Points - Chapter 5muhammadazharNo ratings yet

- Influence of Heat Treatment On Antioxidant Capacity and (Poly) Phenolic Compounds of Selected VegetablesDocument8 pagesInfluence of Heat Treatment On Antioxidant Capacity and (Poly) Phenolic Compounds of Selected Vegetablesgisella_sc603No ratings yet

- Unmsm/Fqiq/Epiq/Daadp/Inglés Técnico/Ef12/2020-I: Chapter 4. Chemical Product Design What You Will LearnDocument3 pagesUnmsm/Fqiq/Epiq/Daadp/Inglés Técnico/Ef12/2020-I: Chapter 4. Chemical Product Design What You Will LearnKevin Javier QuispeNo ratings yet

- EagleBurgmann - Fluaflex Expansion Joints - ENDocument5 pagesEagleBurgmann - Fluaflex Expansion Joints - ENsavanNo ratings yet

- New Creep Rupture Assessment of Grade 91Document11 pagesNew Creep Rupture Assessment of Grade 91AndreasNo ratings yet

- Huntsmann EU ELECTRONICS-Selector-GuideDocument24 pagesHuntsmann EU ELECTRONICS-Selector-GuideXavierNo ratings yet

- Extrusion - Artical - Making The Breaker Plate of An Extruder and Efficient Mixing Device - Rios, Satanach, Gramann, RauwendaalDocument7 pagesExtrusion - Artical - Making The Breaker Plate of An Extruder and Efficient Mixing Device - Rios, Satanach, Gramann, RauwendaalOwner MonolithicNo ratings yet

- Chemical Etching: Created in COMSOL Multiphysics 5.4Document14 pagesChemical Etching: Created in COMSOL Multiphysics 5.4Василь ІванинаNo ratings yet

- Ligao National High School - Senior High School Science, Technology, Engineering, and MathematicsDocument25 pagesLigao National High School - Senior High School Science, Technology, Engineering, and MathematicsMaria Kyla Peñafiel TeodoroNo ratings yet

- Chemistry: NO CHODocument12 pagesChemistry: NO CHOPrasann KatiyarNo ratings yet

- Mock Test Gat - (28-3-22)Document8 pagesMock Test Gat - (28-3-22)Dhruva Chandra PandeyNo ratings yet

- Carboxylic Acids and Their Derivatives.Document31 pagesCarboxylic Acids and Their Derivatives.AmanyNo ratings yet