Professional Documents

Culture Documents

Design and Development of A Lead Screw Gripper For Robotic Application

Uploaded by

TranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Development of A Lead Screw Gripper For Robotic Application

Uploaded by

TranCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/335305038

Design and Development of a Lead Screw Gripper for Robotic Application

Article in SSRN Electronic Journal · January 2019

DOI: 10.2139/ssrn.3434232

CITATION READS

1 912

1 author:

Krithikanand Krishnamoorthy

NA

2 PUBLICATIONS 1 CITATION

SEE PROFILE

All content following this page was uploaded by Krithikanand Krishnamoorthy on 20 September 2020.

The user has requested enhancement of the downloaded file.

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

DESIGN AND DEVELOPMENT OF A LEAD SCREW

GRIPPER FOR ROBOTIC APPLICATION

Krithikanand Krishnamoorthy

Engineering services professional & Individual researcher, India

Email: krithik44@yahoo.com

ABSTRACT

This paper gives details on the electromechanical design concept and prototype development of a lead

screw linear actuated, parallel robotic gripper. Robotic applications are known to be catering to many

industries from a range of tasks namely pick & place, material handling, as fixtures, tool & instrument

holders etc. These application specific robots are equipped with end effectors customised with design

appropriate for the application. In this paper, presented are the details for the design of an end effector

also known as the gripper which works on a lead screw linear mechanism actuated by a dc motor. The

gripper of stroke 100 mm is designed to hold bottles, tools or pick and place objects of rectangular section

of 90mm x 90mm or of circular section of 90mm diameter and up to 3kg weight. Mechanical assembly

comprises a sheet metal fixture plate holding the actuating components and a sheet metal gripper plate

performing the gripping action. The motor is driven by a 24V, 2A dc motor driver. The gripping action is

sensed and signalled by a force sensitive resistor. Prototype development of the gripper and on/off testing

for the gripping action is investigated. The mechanical construction for this unique lead screw gripper is

observed to be robust and can be used as an end effector to a suitable robotic arm.

KEYWORDS

Lead screw, dc motor driver, sheet metal fabrication, force sensitive resistor

1. INTRODUCTION

Robotic technology has become a purely interdisciplinary field with embedded electronics,

computer algorithms & mathematical models and mechanical design being the major contributing

domains for research. Nowadays, a lot of research work is being executed with the advent of

artificial intelligence in robotics. The scope of this paper is to describe the mechanical system

development of a robotic end effector called the lead screw gripper - "l.s.gripper". The design is

complimented by the principles of mechatronic design. Among the broad category of grippers,

the l.s.gripper comes under the type of electric actuated parallel jaw grippers [1]. A novel method

of lead screw linear actuation of 100 mm stroke is implemented in the development of the

gripper.The specification of the l.s.gripper is to hold and grip objects of up to weight of 3kg and

90 mm2 sectional area or in the range of 5 - 90 mm diameter. This gripper is expected to be

integrated to a robotic arm as a possible option of an end effecter which can be used to hold and

assist with tools or pick & place bottles as demanded by the application.

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

2. MECHANICAL DESIGN

2.1. Mechanical Function & Component Definition

The design of robotic end effectors is progressed to a high level wherein more importance being

given to the shape, form and aesthetic features resembling human like hands & fingers. This

involves construction of complex mechanical systems as demanded by the level of dexterity

required by the end application [2]. This paper describes a simple construction of a parallel

gripper which will grip and hold objects efficiently.

Figure 1. CAD assembly model of l.s.gripper

An overview of the mechanical design of the l.s.gripper is shown in the CAD assembly model

picture as in figure 1. A popular CAD software tool is used for the CAD modelling. The gripper

plate is designed hold the object against the fixture plate with force exerted by the nut moving on

the lead screw. The lead screw is driven by a geared dc motor coupled with a flexible coupling.

The lead screw rotates in the bearing housed in the fixture. There is a guide rod attached to the

fixture along which the gripper plate moves linearly. The l.s.gripper system design starts off with

the basic calculation needed to grip and effectively hold bottles of weight 3kg by the linear lead

screw mechanism.

The condition for effective grip for the parallel jaw gripper during normal object pick &

movement is mathematically given by

Gripping force, F(grip) > (m.g/µ(grip))*f.o.s, N

m = weight of the object being gripped, kg

g = acceleration due to gravity, m/s2

µ(grip) = coefficient of friction between the object and gripping surface [11]

f.o.s = factor of safety recommended based on motion

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

The f.o.s is generally taken to be 2 for normal movement of the gripper and could be around 5 to

6 for accelerative movements.

Figure 2. Theoretical calculation for gripping force & motor torque

Mathematical formulations of the gripping are made in earlier studies for the intended compliance

and dexterity of the end effector [6]. However, the scope and simplicity of the parallel l.s.gripper

allows us to make use of straight forward engineering calculations. Objects of various shapes are

often handled by modular robotic grippers [3]. The calculation shown in figure 2. helps to select

the lead screw size & motor for the torque & current specifications required for the specified

weight and size that can be handled by the l.s.gripper.

2.2. Mechanical Construction - A Novel Approach

Parallel grippers are made with internal rotating gear linkages and have been commonly found to

be used in the industrial factory floors. Prior studies on ball screw/lead screw actuated electric

grippers have been conducted wherein the mechanism is constructed with end fingers attached to

pivoted links which are connected to the sliding block and operates to grasp or un-grasp objects

with the motion of the sliding block [7]. Not many lead screw actuated electric grippers with end

finger directly connected to the sliding block are available in the industrial market [10]. Few

research studies have been devoted to this type of gripper. Here the advantage is that the number

of linkages is reduced and thereby the gripping action is performed by low cost sheet metal parts

which also decrease the weight of the gripper. This improves the robustness and the design

methodology is followed keeping in view of enhancing the system reliability as well [8]. The

fixture plate is designed to have a feature which will easily enable it to be attached to the wrist

joint of a robotic arm. Therefore, the method of lead screw based direct gripping action along

3

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

with minimal number of functional components is considered to be a unique and novel feature in

this end effector development presented in this paper.

Figure 3. Component selection & specification

2.3. Component Selection

Based on the theoretical calculation, and also keeping in mind the sourcing & cost criteria,

components are selected. The dc motor is of 24V, 330 rpm capable of delivering a torque of 0.12

Nm at maximum efficiency and stall torque of 0.39 Nm with 1.9 A current. This gives a factor of

safety of 4 on the load torque perspective when operating at maximum efficiency. Lead screw is

selected for a nominal diameter of 8mm, 2 mm lead and 150 mm length. The Brass nut offers a

low friction when it turns over the stainless steel lead screw. The coupling selected is of flexible

type capable of taking up small angular misalignment of shafts. It couples the motor shaft of 6

mm diameter to the 8 mm nominal diameter lead screw. The bearing selected is a pillow block

housing type of 8 mm internal diameter. For the radial load of 3kg, the L10 life of the bearing is

calculated to be around 3.6e9 revolutions. The linear guide rod is a polished steel rod of 6mm

diameter. Standard cap head steel screws are used for fastening and assembly of the components.

3. MECHATRONIC SYSTEM CONCEPT

The mechatronic approach gives a blend of sensing, actuation and control to the mechanical

design. The level of intelligence needed by the system is limited by the degree of sophistication

required and cost of development for the intended application. Figure 4 gives an overview of the

mechatronic concept for the l.s.gripper design.

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

Along with the objective to design & develop a robust mechanical construction for the l.s.gripper,

we understand the performance of the lead screw by means of on/off signal given to the motor

actuator and also observe the output of the tactile sensor during gripping. As quoted earlier the

lead screw actuator is powered by the 24V dc motor. Also shown in the figure 5, is a dc motor

driver is employed which is based on the integrated chip L298 and is capable of bidirectional

control of dc and stepper motors.

Figure 4. Mechatronic system concept for the l.s.gripper

The tactile sensor which is a force sensitive resistor, f.s.r of size 40 mm x 40 mm as shown in the

figure 6, gets compressed by the object held between the gripper [5]. The resistance output of the

f.s.r is converted to a voltage output via a voltage divider circuit made on the bread board. The

full scale output of the f.s.r can thus be calibrated to give a 24V feedback signal indicating the

gripping action. The controller part of the system is not investigated in the system prototype

development. This could be an embedded controller which should take the feedback signal from

the f.s.r for further processing and control.

Figure 5. L298 DC motor driver board

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

Figure 6. Force sensitive resistor, 40x40 mm area

4. SYSTEM DEVELOPMENT & TESTING

Engineering manufacturing drawings are developed for the sheet metal fabrication process

through which the fixture & gripper plates are developed. Again, the manufacturing drawings are

created with the help of the CAD tool. 'Design for manufacturing' principle is employed in

designing these sheet metal parts wherein standard bend features, standard uniform hole sizes and

addition of slots for weight reduction are considered in the design. Finger-like features are added

to the parts to give them look typical to a hand shaped robotic end effector. Figure 7 and figure 8

show the manufacturing drawings created for the fixture plate and gripper plate models which

were made and sourced from a sheet metal fabrication shop. The 'design for assembly' practice is

adopted while designing the assembly of the l.s.gripper in CAD. The sequence of assembly is as

follows. The motor with coupling is first fastened to the fixture plate. The gripper plate is

fastened to the nut mounted on the lead screw with standard M2 screws. The linear guide rod is

inserted into the hole provision in the gripper plate. The lead screw assembly is then coupled to

the coupling along with the guide rod to be fastened to the fixture plate. The bearing being the

finally assembly component is mounted to the fixture plate while locating the screw rod in the

bearing. All fastenings with the fixture plate is made uniform with standard M3 screws.

Figure 9 shows the assembled l.s.gripper and the motor-driver wiring & operation is depicted in

figure 10. The f.s.r is attached to the fixture plate in a sandwich manner between a foam piece and

fixture plate and held by an adhesive tape. As seen in figure 10, operating the motorised system

via the motor driver moves the gripper plate linearly until it touches and holds the object, a 200

ml coke bottle in this case. The foam piece provides a cushioning effect while gripping the bottle

which subsequently sets on the f.s.r. The f.s.r full scale reading gives a voltage close to 24V as

per its specification which is around 21.3V as observed in the voltage meter in figure 10. This is

indicative that the bottle has been gripped and held tightly and at this point, the motor actuation

can be stopped. Again when the bottle needs to be un-gripped the motor is rotated in the opposite

direction by means of the motor driver.

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

Figure 7. Manufacturing drawing of fixture plate

Figure 8. Manufacturing drawing of gripper plate

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

Figure 9. L.S.Gripper assembly construction

Figure 10. L.S.Gripper assembly operation

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

4.1. Functional Verification

To ascertain whether the l.s.gripper performs the gripping action as expected, further verification

experiments are performed. The object is held between the gripper plates by slowly actuating the

lead screw until a point where the object does not move when pulled out manually. This is

visually indicative of the well-gripped condition which is also confirmed by the full scale 24V

reading output of the f.s.r. Once the object is gripped, the motor is switched off and the l.s.gripper

is disconnected from the driver board and can be made standalone with the gripped object.

Figure 11. Analog weighing scale & gripper weight measurement

Figure 12. Weight measurement of water filled Quechua & Milton bottles

In this condition, experimental verification is taken up for evaluating the gripping performance of

the l.s.gripper for gripping 2 bottles, wherein the gripper is shaken and visually inspected for

slipping of the bottles. Similar verification studies have been conducted earlier which are seen to

be a simple evaluation method for studying the gripping action [9]. The individual weight of the

gripper is measured to be 0.25 kg. A standard analog gauge is used to measure the weight and

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

also the respective weights of the bottles are measured and evaluated which are shown by the red

needle in figures 11 & 12.

Figure 13 shows the first case of gripping a 750 ml Quechua water bottle of diameter 81mm.

Snapshots are taken while shaking the bottle held by the gripper. As was measured, the weight of

this bottle is 3 times the weight of the l.s.gripper. The l.s.gripper holding the bottle is repeatedly

shaken and thereby good gripping is thus observed.

Figure 13. L.S.Gripper performance verification with Quechua bottle

Figure 14 shows the second case of holding a stainless steel Milton bottle of 1 litre capacity and

diameter 88mm. This steel bottle when completely filled with water is 1.25 kg which is around 5

times the weight of the gripper. Since the steel bottle is rigid as compared to the plastic one, the

gripper plate showed some sliding while holding the bottle standalone. The shaking test is

therefore performed holding the bottle instead of the gripper wherein the moments are observed

to be lesser to cause slippage. The gripping was rather satisfactory and in this case, attaching a

gripper pad to the gripper plate would result in better grip on the metal surface is understood.

Figure 14. L.S.Gripper performance verification with Milton bottle

10

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

5. CONCLUSION

The l.s.gripper working and performance gave positive results in holding bottles of 750 ml, 1 litre

capacities and 81mm, 88mm diameter sizes respectively. The robustness of the mechanical design

involving the fixture & gripper plates is understood. Observing the performance of the motor

actuated lead screw and the force sensitive resistor gave satisfactory results on gripping action

since the lead screw is known have negligible backlash. Functional verification of the l.s.gripper

by manual shaking experiments by gripping the bottles gave satisfactory results on the gripping

performance. Using the PLC (programmable logic controller) or an embedded controller to

interpret the f.s.r feedback signal and close the control system loop will be a matter of further

scope from a control engineering standpoint. The mechanical design is made keeping in view of

attaching this standalone end effector to a robotic arm. This could be a standard pick & place

robotic application in industry.

ACKNOWLEDGEMENTS

The author would like to thank his family & the scientific and engineering community!

REFERENCES

[1] Jernej Preseren, Dejan Avgustin, Tadej Mravlje (2005) “Guidelines for the design of robotic gripping

systems”, Ljubljana.

[2] Thomas Wurtz, Chris May, Benedikt Holz, C. Natale, G. Palli, C. Melchiorri (Aug 2010) "The twisted

string actuation system, modeling & control", IEEE/ASME Transactions on Mechatronics.

[3] Anna Maria Gil Fuster (Jun 2015) "Gripper design and development for a modular robot", Bachelor

thesis, Technical University of Denmark.

[4] Krishnaraju A, Ramkumar R, Lenin V R (2015) "Design of three fingered robot gripper mechanism",

International Journal on Mechanical Engineering and Robotics. (IJMER)

[5] Albert Aparisi I Escriva (Jun 2016) "Design of a smart gripper for industrial applications", Master of

Science thesis, Tampere University of Technology

[6] Xuance Zhou, Carmel Majidi, Oliver M. O'Reilly (2015) "Soft hands: An analysis of some gripping

mechanisms in soft robot design", International Journal of Solids and Structures

[7] Byoung-Ho Kim (2012) "Design and Analysis of Ball screw-driven Robotic gripper"

[8] N. Bensaid Amrani, L. Saintis, D. Sarsri, M. Barreau (May 2016) "Evaluating the Predicted

Reliability of Mechatronic Systems: State of the Art", Mechanical Engineering: An International

journal (MEIJ), Vol. 3, No. 2

[9] Tae-Jin Jung, Jun-Ho Oh (April 2013) "Design of a Robot Gripper for a Rapid Service Robot", 6th

IFAC Symposium on Mechatronic Systems, Hangzhou, China

[10] Elisabeth Eitel (Jan 2010) "A history of gripping and gripper technologies and the available options

for today's engineer", https://www.machinedesign.com/print/26685

[11] UK3H Angular Grippers-Technical Catalogue, Parker

11

Electronic copy available at: https://ssrn.com/abstract=3434232

Mechatronics and Applications: An International Journal (MECHATROJ), Vol. 2, No.1

Author

12

View publication stats Electronic copy available at: https://ssrn.com/abstract=3434232

You might also like

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- IRJET V6I5165rahularghodeDocument5 pagesIRJET V6I5165rahularghodeSebin MathewNo ratings yet

- Robotic End Effector Using 4-ReportDocument39 pagesRobotic End Effector Using 4-Reportkarthikds91100% (3)

- Design and Analysis of Hydraulic Arm With GripperDocument6 pagesDesign and Analysis of Hydraulic Arm With GripperIJRASETPublicationsNo ratings yet

- Cotter Joint CoferenceDocument5 pagesCotter Joint CoferenceMuhammad AliNo ratings yet

- Power HacksawDocument30 pagesPower Hacksawbilal shaikh100% (2)

- Design and Realization of A Welding OscillatorDocument12 pagesDesign and Realization of A Welding Oscillatorgonzalez2678No ratings yet

- Thesis Designandfabricationofpickandplace PDFDocument12 pagesThesis Designandfabricationofpickandplace PDFWolderuphael KassahunNo ratings yet

- Four Way Hacksaw Machine Ijariie2053Document6 pagesFour Way Hacksaw Machine Ijariie2053ParvezRazaNo ratings yet

- Pipe Inspection RobotDocument7 pagesPipe Inspection RobotSharanabasappa SajjanNo ratings yet

- 360 Degree Conveyor Belt PDFDocument4 pages360 Degree Conveyor Belt PDFUpendra BingundiNo ratings yet

- ReportDocument4 pagesReportTanjid Al TajimNo ratings yet

- Analysis of A Permanent - Magnet Brushless DC Motor With Fixed DimensionsDocument4 pagesAnalysis of A Permanent - Magnet Brushless DC Motor With Fixed Dimensionslupillorivera9981No ratings yet

- Modeling and Analysis of Cotter Joint REPORT R20ER055Document21 pagesModeling and Analysis of Cotter Joint REPORT R20ER055Akash AkashNo ratings yet

- Design and Development of Robotic Arm For Cutting Tree PDFDocument10 pagesDesign and Development of Robotic Arm For Cutting Tree PDFHamza HebNo ratings yet

- Design and Development of Pick and Place Arm Robot: September 2020Document8 pagesDesign and Development of Pick and Place Arm Robot: September 2020Evelyn CarrilloNo ratings yet

- 1 s2.0 S2214785320343170 MainDocument8 pages1 s2.0 S2214785320343170 MainXhoniNo ratings yet

- Design and Fabrication of An Oldham Coupling Mechanism: Term ProjectDocument20 pagesDesign and Fabrication of An Oldham Coupling Mechanism: Term ProjectSidharth MalohtraNo ratings yet

- Final 1Document43 pagesFinal 1cejoshua42No ratings yet

- Progress Report 1Document10 pagesProgress Report 1saqibNo ratings yet

- Design and Fabrication of Motorized Hacksaw MachineDocument9 pagesDesign and Fabrication of Motorized Hacksaw MachineIJRASETPublicationsNo ratings yet

- Icram19 10 01 19 06 10 57 ModifiedDocument7 pagesIcram19 10 01 19 06 10 57 ModifiedAjit ParwaniNo ratings yet

- About I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018Document8 pagesAbout I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018npatil_10No ratings yet

- Performance Analysis of Mixed Flow Pump Impeller Using CFDDocument6 pagesPerformance Analysis of Mixed Flow Pump Impeller Using CFDFauzi AkmalNo ratings yet

- Stress Analysis of Spur Gear by Using Different Materials: A ReviewDocument9 pagesStress Analysis of Spur Gear by Using Different Materials: A Reviewafaq AhmadNo ratings yet

- Expert System For Rolling Load Prediction in 20 Hi Sendzimir MillDocument5 pagesExpert System For Rolling Load Prediction in 20 Hi Sendzimir MillIAEME PublicationNo ratings yet

- BLDC Motor 2Document6 pagesBLDC Motor 2MOHAN RAJ NNo ratings yet

- Sckotch Yoke MechanismDocument5 pagesSckotch Yoke MechanismShubham Magdum100% (1)

- Industrial Robotics and Control Assignment: Q) 1 Explain Industrial Internet of Things?Document8 pagesIndustrial Robotics and Control Assignment: Q) 1 Explain Industrial Internet of Things?vara prasadNo ratings yet

- Liu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1043 032037Document11 pagesLiu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1043 032037ntik 23No ratings yet

- Failure Analysis of A Two High Gearbox ShaftDocument10 pagesFailure Analysis of A Two High Gearbox ShaftNguyễnVănLăngNo ratings yet

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- Design and Analysis of Portable Power Hacksaw With Coolant and Lubrication SystemDocument15 pagesDesign and Analysis of Portable Power Hacksaw With Coolant and Lubrication SystemSurya MilipelliNo ratings yet

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- JETIR1906R84Document10 pagesJETIR1906R84Vignesan MechNo ratings yet

- Design and Analysis of Pipe Bending MachineDocument7 pagesDesign and Analysis of Pipe Bending MachineSelahadin Al AyubNo ratings yet

- IJCRT2306900Document7 pagesIJCRT2306900Shanu KumarNo ratings yet

- Bharadwajpaper2 2020Document6 pagesBharadwajpaper2 2020Mengistu BirukeNo ratings yet

- Small-Scale Filament Winding Machine For ProducingDocument14 pagesSmall-Scale Filament Winding Machine For ProducingAlfonso CostasNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument8 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- Acknowledgment: Ranjeetkumar Singh For TheirDocument49 pagesAcknowledgment: Ranjeetkumar Singh For Theirsavani24No ratings yet

- Final Year ProjectDocument23 pagesFinal Year ProjectKarthik SubramaniNo ratings yet

- A Review On Grasping Principle and Robotic GrippersDocument6 pagesA Review On Grasping Principle and Robotic GrippersNima panahiNo ratings yet

- Delhi IUTAM SympDocument11 pagesDelhi IUTAM Symphieuhuech1No ratings yet

- A Micro-Project Report On: " Modeling and Analysis of Cotter Joint "Document14 pagesA Micro-Project Report On: " Modeling and Analysis of Cotter Joint "Vikram MagarNo ratings yet

- Natrayan 2018Document7 pagesNatrayan 2018Agastin RubanNo ratings yet

- Design Optimization of EOT Crane GirderDocument5 pagesDesign Optimization of EOT Crane Girdermech_abhiNo ratings yet

- A Low Cost Open Source Metal 3 D PrinterDocument8 pagesA Low Cost Open Source Metal 3 D PrinterJayNo ratings yet

- Ijaer Cmss CNCDocument11 pagesIjaer Cmss CNCDuy TrầnNo ratings yet

- Study For Design of Magneto Rheological DamperDocument8 pagesStudy For Design of Magneto Rheological DamperAnonymous lPvvgiQjRNo ratings yet

- 3 DOF ManipulatorDocument6 pages3 DOF ManipulatorKhaled SaadNo ratings yet

- .Design, Analysis and Optimization of Heavy Metal Roll Lifting Bracket Assembly For Steel Industry With CalculationsDocument5 pages.Design, Analysis and Optimization of Heavy Metal Roll Lifting Bracket Assembly For Steel Industry With CalculationsEmílio BeckerNo ratings yet

- Qi2020 Article DesignAndResearchOfDeepSlotUniDocument13 pagesQi2020 Article DesignAndResearchOfDeepSlotUniArunNo ratings yet

- Ijireeice 2022 10509Document5 pagesIjireeice 2022 10509Prajwal TilekarNo ratings yet

- Spur Gear MechanismDocument10 pagesSpur Gear MechanismPusapati Saketh Varma ed21b048No ratings yet

- Irjet V7i9635Document7 pagesIrjet V7i9635valengape13No ratings yet

- Laser Cutting Machines For 3-D Thin Sheet Parts: ArticleDocument7 pagesLaser Cutting Machines For 3-D Thin Sheet Parts: ArticleMohamad GhosenNo ratings yet

- A Low-Cost Open-Source Metal 3-D PrinterDocument8 pagesA Low-Cost Open-Source Metal 3-D PrinterLong GiaNo ratings yet

- Microfabrication and Precision Engineering: Research and DevelopmentFrom EverandMicrofabrication and Precision Engineering: Research and DevelopmentNo ratings yet

- 01 BASIC v2021.1 MAY17 2021Document161 pages01 BASIC v2021.1 MAY17 2021TranNo ratings yet

- Stand-Alone Display: Electronics & SoftwareDocument1 pageStand-Alone Display: Electronics & SoftwareTranNo ratings yet

- STM32 Configuration and Initialization C Code GenerationDocument7 pagesSTM32 Configuration and Initialization C Code GenerationNam NguyenNo ratings yet

- Instruction Manual: Kistler GPS Sensor Compact Travel Sensors Type CGPSSADocument46 pagesInstruction Manual: Kistler GPS Sensor Compact Travel Sensors Type CGPSSATranNo ratings yet

- Cheps80000061d 3 0 PDFDocument44 pagesCheps80000061d 3 0 PDFNguyen QuocNo ratings yet

- WWW - Servorepair.ca: Scroll Down To View Your Document!Document62 pagesWWW - Servorepair.ca: Scroll Down To View Your Document!TranNo ratings yet

- Model S Owners Manual North America en UsDocument188 pagesModel S Owners Manual North America en UsSowndofDethNo ratings yet

- T1 PCM Ind DSDocument4 pagesT1 PCM Ind DSTranNo ratings yet

- Lecture2 PDFDocument23 pagesLecture2 PDFTranNo ratings yet

- Course Literature: Dept. Electrical Engineering Vehicular Systems Link Oping University SwedenDocument11 pagesCourse Literature: Dept. Electrical Engineering Vehicular Systems Link Oping University SwedenTranNo ratings yet

- MasterRoc MP 368 TIXDocument3 pagesMasterRoc MP 368 TIXZimplemente Kimizita Dominguez CampoNo ratings yet

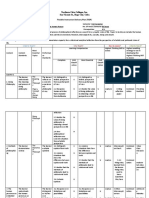

- Northern Cebu Colleges, Inc. San Vicente ST., Bogo City, Cebu Flexible Instruction Delivery Plan (FIDP)Document6 pagesNorthern Cebu Colleges, Inc. San Vicente ST., Bogo City, Cebu Flexible Instruction Delivery Plan (FIDP)Jilmore Caseda Cantal100% (1)

- Human Freedo M: Manuel B. Dy, JRDocument30 pagesHuman Freedo M: Manuel B. Dy, JRFRITZI MAE GAPUZNo ratings yet

- Grade Filipino 7 Week 1-2Document10 pagesGrade Filipino 7 Week 1-2SALEM DE LA CONCEPCIONNo ratings yet

- Thermoports K-KB Series Operating InstructionsDocument5 pagesThermoports K-KB Series Operating InstructionsMuhammad Ali HaiderNo ratings yet

- Effect of Oxygen On Surface Tension of Liquid Ag-Sn AlloysDocument5 pagesEffect of Oxygen On Surface Tension of Liquid Ag-Sn AlloysBurak ÖZBAKIRNo ratings yet

- A Study On Five International Scientists: Micro Project ReportDocument18 pagesA Study On Five International Scientists: Micro Project ReportAishwarya MohanNo ratings yet

- Critically Discuss About Major Features of Water Resource Act, 2049 B.SDocument12 pagesCritically Discuss About Major Features of Water Resource Act, 2049 B.SPurple DreamNo ratings yet

- Grammar: Frequency AdverbsDocument2 pagesGrammar: Frequency AdverbsRedamanNo ratings yet

- Green Chemistry ModuleDocument17 pagesGreen Chemistry ModuleAniruddhNo ratings yet

- Engg Mechanics Paper Dec 2019 As Per CODocument4 pagesEngg Mechanics Paper Dec 2019 As Per COPiyush BhandariNo ratings yet

- Report Group 1Document67 pagesReport Group 11706112No ratings yet

- TCS NQT Solved PaperDocument49 pagesTCS NQT Solved PaperOjas DhoneNo ratings yet

- Dokumen PDFDocument4 pagesDokumen PDFI Komang Agus Adi Merta 07No ratings yet

- Performance Comparison of Simulated Annealing GA and ACO Applied To TSPDocument8 pagesPerformance Comparison of Simulated Annealing GA and ACO Applied To TSPSaurav AcharyaNo ratings yet

- Housekeeping Services NCII Quarter 3 PDF HousekeepingDocument1 pageHousekeeping Services NCII Quarter 3 PDF HousekeepingSalve RegineNo ratings yet

- Cl-9 E. Lang B, Term-1, Week-1, Student Book, PG 4-12, 27-29 July 21, Sub 13.06.21Document9 pagesCl-9 E. Lang B, Term-1, Week-1, Student Book, PG 4-12, 27-29 July 21, Sub 13.06.218C-Ahmed Musawwir - Dj067No ratings yet

- ROBOTICS (MEB-465) : Quiz QuestionsDocument21 pagesROBOTICS (MEB-465) : Quiz QuestionsVishal Dhiman100% (2)

- FEM R&S Information Bulletin 10 - Warehouse Building - Racking - FINALDocument21 pagesFEM R&S Information Bulletin 10 - Warehouse Building - Racking - FINALMa PonyNo ratings yet

- Cantilever Retaining Wall ExampleDocument8 pagesCantilever Retaining Wall ExampleRahul Sinha100% (1)

- Plutchik Emotion Theorie POSTER PDFDocument1 pagePlutchik Emotion Theorie POSTER PDFauggi100% (3)

- RubanMurugesan WebOfScience Researcher CV 20230718Document2 pagesRubanMurugesan WebOfScience Researcher CV 20230718Mr.M.Ruban Vels UniversityNo ratings yet

- Solved Numerical Problems On Porter Governor: Solution: GivenDocument5 pagesSolved Numerical Problems On Porter Governor: Solution: GivenVenkat GamingNo ratings yet

- Department of Education: Republic of The PhilippinesDocument2 pagesDepartment of Education: Republic of The PhilippinesTips & Tricks TVNo ratings yet

- Hacking, Ian - Estilos de RazonamientoDocument18 pagesHacking, Ian - Estilos de RazonamientoBadtz MaruNo ratings yet

- E702.3M-18 - Acceptance of Concrete Compressive Strength Test Results According To ACI 318M-14Document6 pagesE702.3M-18 - Acceptance of Concrete Compressive Strength Test Results According To ACI 318M-14Christos Leptokaridis100% (1)

- 7 Ways To Better Your LetteringDocument5 pages7 Ways To Better Your LetteringLuciana Freire0% (2)

- Historical FoundationDocument13 pagesHistorical Foundationᜃᜒᜈ᜔ᜎᜒ ᜇᜒᜋᜈ᜔ᜇᜒᜋᜈ᜔No ratings yet

- Chemical EtchDocument18 pagesChemical EtchznpfgNo ratings yet

- Declaration KitDocument4 pagesDeclaration KitJITANSHUCHAMPNo ratings yet