Professional Documents

Culture Documents

Detroit Diesel 80837305

Detroit Diesel 80837305

Uploaded by

luis garcia0 ratings0% found this document useful (0 votes)

5 views663 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views663 pagesDetroit Diesel 80837305

Detroit Diesel 80837305

Uploaded by

luis garciaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 663

IMPORTANT SAFETY NOTICE

Proper service and repair is important 10 the safe, reliable operation

all motor vehicles. The service procedures recommended by Detroit

Diesel Allison and described in this service manual are effective

methods for petformiing service operations, Some of these service

operations requite the use of tools specially designed for the purpose.

‘The special tools should be used when and as recommended.

portant to note thas some warnings against the use of specific

ice methods that can damage the vehicle or render ft unsafe are

stated in this service manaal. [tis also important to understand these

warnings are not exhaustive. Detroit Diese! Allison could not possibly

know, evaluate and dse the service trade of all conceivable ways in

which service might be done or of the possible hazardous

consequences of each way. Consequently, Detroit Diesel Allison has

not undertaken any such broad evaluation. Nec

a service procedure oF ol which I not r

Diesel Allison must first satisfy himself thoroughly that neither his

safely nor vebicte safety wil be jeopardized by the service method he

selects.

6SE380 (Rev. 3/79)

Service

Manual

Detroit Diesel Engines

SERIES 92

Qs Detroit Diesel Allison

Printed in U.S.A. © 1979 General Motors Corp.

FOREWORD

This manual contains instructions on the overhaul, maintenance and

operation of the basic V-92 Detroit Diesel Engines.

Full benefit of the long.tife and dependability built, into these

engines can be realized through proper operation and: maintenanes.

‘Of equal importance is the use of proper procedures dusing engine

overhaul

Personnel responsible for engine operation and maintenance shouid

study the sections of the manual pertaining to their particular duties.

Similarly, before beginning a repair or overhaul job, the serviceman

should read the manual carefully to familiarize himself with the

pacts or sub-assemblies of the engine with which he will be

‘concerned.

‘The information, specifications and illustrations in this publication

are based on the information in effect at the time of approval for

printing. This publication is revised and reprinted periodically. It is

recommended that users contact an authorized Detroit Diese! Allison

Service Outlet for information on the latest revisions. The right is

reserved to make changes at any time without obligation.

TABLE OF CONTENTS

SUBJECT SECTION

GENERAL INFORMATION

ENGINE [less major assemblies) uJ

FUEL SYSTEM AND GOVERNORS

AIR INTAKE SYSTEM.

LUBRICATION SYSTEM.

COOLING SYSTEM

EXHAUST SYSTEM

ELECTRICAL EQUIPMENT, INSTRUMENTS AND PROTECTIVE SYSTEMS

POWER TAKE-OFF AND TORQMATIC CONVERTER

TRANSMISSIONS

SPECIAL EQUIPMENT

OPERATION

TUNE-UP

PREVENTIVE MAINTENANCE, TROUBLE SHOOTING AND STORAGE

©1977 General Motors. Corp. Mar., 1977

General information DETROIT DIESEL 92

SCOPE AND USE OF THE MANUAL

‘This manval covers the basic V-92 diesel engines built by the Detroit Diesel Allison Division of General Motors

Corporation, Complete insructonson opestion,adjusiment (tne), preventive malmenance and lricaton

‘and repair (including complete overhaul) are covered. The manual was written primarily for persons servicing and

overhauling the engine and, in addition, contains all of the instructions essential to the operators and users. Basic

maintenance and overhaul procedures are common to all V-92 engines and therefore apply to all engine models,

The manval is divided into numbered sections. The first section covers the engine (less major assemblies), The

following sections cover a complete system such as the Fuel system, lubrication system or air system. Each scetion is

divided into sub-sections which contain complete maintenance and operating, instructions for a specific sub-

assembly on the engiae. For example, Section 1, which covers the basic engine, contains sub-section 1.1 pertaining

4 the cylinder block, sub-section 1.2 covering the cylinder head, etc. The subjects and sections are listed in the

Table of Contents on the preceding page. Pages are numbered consecutively, starting with anew Page 1 at the

beginning of each sub-section, The illisrations are also numbered consecutively, beginning with a new Figure | at

the start of each sub-section,

Information regarding general subject, such as the lubrication system, can best be located by using the Table of

Contents. Opposite each subject in the Table of Contents is a section number which registers with a tab printed on

the first page of each section throughout the manual. Information on a specific sub-assembly or acoessory can then

be fond by consulting the list of contents on the first page of the section. For example, the cylinder liner is part of

the basic engine, therefore, it will be found in Section 1. Looking down the list of contents on the first page of

Section 1, the cylinder liner is found to be in sub-section 1.6.3. An Alphabetical Index at the back of the manual

hhas been provided as an additional aid for locating information.

SERVICE PARTS AVAILABILITY

Genuine Detroit Diesel Allison service parts are available in the United States from authorized distributors and

service dealers totalling over 2300 outlets, in Canada from the distributor organization of Diesel Division, GM of

Canada Ltd. and abroad through the sales and service outlets of Detroit Diesel Allison International

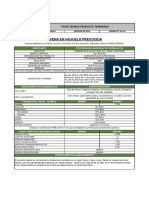

CLEARANCES AND TORQUE SPECIFICATIONS

Clearances of new patts and wear limits on used parts are listed in tabular form at the end of each section

throughout the manual. It should be specifically noted that the “New Parts” clearances apply only when all new

pacts are used at the point where the various specifications apply. This also applies 1 refecences within the text of

the manval. The column entitled “Limits” lists the amount of wear or increase in clearance which can be tolerated

in used engine parts and still assure satisfactory performance. It should be emphasized that the figures given as

“Limits” must be qualified by the judgment of personnel responsible for installing new parts. These wear limits

fare, in general, listed only for the parts more frequently replaced in engine overhaul work. For additional e

information, refer to the paragraph entitled Inspection under General Procedures in this section.

Bolt, nut and stud torque specifications are also listed in tabular form at the end of each section.

Page 4 © 1977 General Motors. Corp.

e

x

DETROIT DIESEL 92

General Information

PRINCIPLES OF OPERATION

The diesel engine is an internal combustion power

unit, in which the heat of fuel is converted into work

in the cylinder of the engine.

In the diesel engine, air alone is compressed in the

cylinder; then, after the air has been compressed, a

charge of fuel is sprayed into the cylinder and ignition

is accomplished by the heat of compression.

The Two- Cycle Principle

In the two-cycle engine, intake and exhaust take place

during part of the compression and power strokes

respectively as shown in Fig. 1. In contrast, a four

cycle engine requires four piston strokes to complete

an operating cycle; thus, during one half of its

operation, the four-cycle engine functions merely as

an air pump.

A blower is provided to force air into the cylinders for

expelling the exhaust gases and to supply the cylinders

with fresh air for combustion. The «ylinder wall

contains a row of ports which are above the piston

when it is at the bottom of its stroke. These ports

admit the air from the blower into the cylinder as soon

‘as the rim of the piston uncovers the ports as shown in

Fig. 1 (scavenging),

The unidirectional flow of air toward the exhaust

valves produces a scavenging effect, leaving the

cylinders full of clean air when the piston again covers

the inlet ports.

‘As the piston continues on the upward stroke, the

exhaust valves close and the charge of fresh air is

subjected to compression as shown in Fig. 1

(compression).

Shortly before the piston reaches its highest position,

the required amount of fuel is sprayed into the

combustion chamber by the unit fuel injector as shown

in Fig. | (power). The intense heat generated during

the high compression of the air ignites the fine fuel

spray immediately. The combustion continves until the

Fuel injected has been burned.

The resulting pressure forces the piston downward on

its power stroke. The exhaust valves are again opened

when the piston is about half way down, allowing the

burned gases to escape into the exhaust manifold as

shown in Fig. 1 (exhaust). Shortly thereafler, the

downward moving piston uncovers the inlet ports and

the cylinder is again swept with clean scavenging air.

This entire combustion cycle is completed in each

cylinder for each revolution of the crankshaft, or, in

other words, in two strokes; hence, itis a “two-stroke

ycle™

SCAVENGING.

COMPRESSION

Power EXHAUST

Fig. 1 - The Two-Stroke Cycle

© 1976 General Motors Corp.

August, 1976 Page 5

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Norma ASTM D1200Document4 pagesNorma ASTM D1200Sara Quiroz100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- 250 Really Useful Idioms by Oyster EnglishDocument46 pages250 Really Useful Idioms by Oyster EnglishAnastasia An100% (1)

- Manual For 3D Nls PDFDocument73 pagesManual For 3D Nls PDFmark100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Planned Independent Requirement NotesDocument34 pagesPlanned Independent Requirement NotesNiraj KumarNo ratings yet

- SkypeDocument18 pagesSkypeRodrigo BenavidesNo ratings yet

- Ejercicios Practicos FluidsimDocument26 pagesEjercicios Practicos FluidsimVictor RinconNo ratings yet

- Curso de Camaras de Seguridad IDocument71 pagesCurso de Camaras de Seguridad Iserkab100% (3)

- Telc B1 DTB WortschatzDocument22 pagesTelc B1 DTB WortschatzMehmet Uğur BahadırNo ratings yet

- Organizador Gráfico Deber 1Document1 pageOrganizador Gráfico Deber 1José MéndezNo ratings yet

- Estrategia AA3Document13 pagesEstrategia AA3Berenice yanina Rojas ponceNo ratings yet

- Cópia de Controle E-Leaning 2021 - Qualidade 28 05 21Document10 pagesCópia de Controle E-Leaning 2021 - Qualidade 28 05 21MateusNo ratings yet

- Control de LecturaDocument3 pagesControl de LecturaJairIbañezNo ratings yet

- INFORME MantenimientoDocument11 pagesINFORME MantenimientoDavid IgnacioNo ratings yet

- Mcsorley 442Document52 pagesMcsorley 442Nicolas SirtakysNo ratings yet

- Psi Mud Agitators Product SheetDocument2 pagesPsi Mud Agitators Product SheetPRASHANT KANTENo ratings yet

- Uso de Equipos de ProteccionDocument2 pagesUso de Equipos de ProteccionNathaniel PortilloNo ratings yet

- Pa Test Bank Psych Assessment Test BankDocument120 pagesPa Test Bank Psych Assessment Test BankfanchasticommsNo ratings yet

- Plaintiff-Appellee Vs Vs Defendants Appellant Ramon Diokno Ramon SalinasDocument8 pagesPlaintiff-Appellee Vs Vs Defendants Appellant Ramon Diokno Ramon SalinasBeya AmaroNo ratings yet

- Introducción Al Control InternoDocument45 pagesIntroducción Al Control InternoPato TorresNo ratings yet

- Amr Ami Sys en 11-08Document8 pagesAmr Ami Sys en 11-08Ludlow_thompsonNo ratings yet

- Whitepaper Tableau Server9.0scalability Eng 2Document37 pagesWhitepaper Tableau Server9.0scalability Eng 2nomuseNo ratings yet

- FT70D VARA FM Portable StationDocument9 pagesFT70D VARA FM Portable Stationjuan pelotasNo ratings yet

- Auditoria IDocument11 pagesAuditoria IAdrian MeridaNo ratings yet

- Plegable Del SGADocument4 pagesPlegable Del SGAErvin Omar Lizcano PrietoNo ratings yet

- CV Marta HenriquezDocument2 pagesCV Marta HenriquezWILBERNo ratings yet

- Higiene - Seguridad III - Tercer AñoDocument3 pagesHigiene - Seguridad III - Tercer AñoCamila AlarcónNo ratings yet

- International Journal of Wireless & Mobile Networks (IJWMN)Document2 pagesInternational Journal of Wireless & Mobile Networks (IJWMN)John BergNo ratings yet

- FICHA TECNICA AVENA HOJUELA DEL TROPICO X 200gDocument2 pagesFICHA TECNICA AVENA HOJUELA DEL TROPICO X 200gHogar Infantil MambrúNo ratings yet

- Arogyamasika May2020 N PDFDocument116 pagesArogyamasika May2020 N PDFjose_sebastian_2No ratings yet