Professional Documents

Culture Documents

65 24 Design FORIEGN

65 24 Design FORIEGN

Uploaded by

Ahmed Mohamed AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

65 24 Design FORIEGN

65 24 Design FORIEGN

Uploaded by

Ahmed Mohamed AhmedCopyright:

Available Formats

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

Design, Construction, and Experimental

Testing of a Parabolic Trough Collector for

Process Heat Applications

Husni T. Izweik1, Ahmed M. Ahmed2,3, Abdelhafeed A.Albusefi3

Lecturer, Dept. of Mechanical Engineering, Sabratha Engineering College, Sabratha University, Libya1

Assistant Professor, Dept. of Mechanical Engineering, Faculty of Engineering Science, Nyala University, Sudan2

Assistant Professor, Dept. of Mechanical Engineering, Sabratha Engineering College, Sabratha University, Libya3

ABSTRACT: One of the most important applications of the solar energy is the Parabolic Trough Collector. During last

decades until now; there are several promising developments in the field of the Parabolic Trough Collectors and their

applications. In this research paper design, construction and testing of two Parabolic Trough Collectors fabricated from

the available local materials has been experimentally investigated under local climate conditions of Sabratha City in

Libya (latitude 32.8° N, longitude 12.5°E). Water is choosen as the heat transfer fluid, and the testing period taken from

30th of December 2015 to 5th of April 2016. The testing results showed that the maximum instantaneous thermal

efficiency reached 52.7% for a direct solar radiation of 243 W/m2 at a flow rate of 0.24 L/min at 10:00 AM on 4th of

January 2016. Moreover, a maximum outlet temperature reached 88.1 °C for a direct solar radiation of 944 W/m2 at a

flow rate of 0.24 L/min at 1:00 PM on 30 March 2016. Based on these results, Libya holds a real potential for the PTC

technology to meet the increasing demand for water heating systems.

KEYWORDS: Parabolic Trough Collector, water outlet temperature, collector thermal Efficiency, Collector Design.

I. INTRODUCTION

Parabolic Trough Collectors (PTC) are devices use metal sheet mirrors or aluminum foil sheets in the shape of

parabolic shapes to reflect and concentrate sun radiations towards a receiver tube located at the focus of the parabolic

cylinder. The receiver absorbs the solar radiation and transforms it into thermal energy which was transported by a

fluid medium flowing through the receiver tube. This method of concentrated solar collection has the advantage of high

efficiency and low cost. Therefore, PTC is the leading technology for large scale exploitation of solar energy, and

currently became the most proven solar thermal technology for a solar steam generation.

Libya is one of the biggest countries in Africa with an area about 1,760,000 km2, lies between latitudes 19° and

34°N, and longitudes 9° and 26°E. The total average of global solar irradiance on the horizontal surface ranges between

1600 - 2300 kWh/m2[1], [2]. These values correspond to average daily range between 5 and 7 kWh/m2.day, Thus, it

owns a great potential of solar energy. Recent studies have shown that the significance of renewable energy resources

represents the best alternative to traditional fossil fuel in Libya [3]. The demand of energy for water heating and air-

conditioning is one of the main areas for energy consumption which is proportional to the availability of solar radiation

during the day. Introducing renewable energies on the housing and industrial sectors should lead to energy savings.

Therefore, solar thermal systems became one of the most attractive solutions for these problems.

The application of PTCs can be divided into two main groups[4]: the first group is the industrial processes that

need temperature ranging from 100C to 250C in their processes like space heating, cooling, drying, and refrigeration.

The second group is the parabolic trough solar power generation that requires temperatures ranging from 300C to

400C which is the main application of the concentrated solar power technology. The PTC has been designed and

studied analytically and experimentally by many investigators several decades ago. In his paper, Treadwell considered

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15890

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

how optical and thermal effects influence the efficiency of a PTC [5]. He found that rim angles of 90 minimized the

maximum distance between the parabolic reflector and the focus. Since the receiver diameter is proportional to this

distance, thermal losses, which are proportional to the diameter itself, are reduced. Clark studied the principle design

factors that influence the performance of a PTC[6]. Factors like spectral directional reflectivity of the mirror, the

mirror-receiver tube intercept factor, the end loss, the incident angle modifier, receiver tube misalignment, and effect

of tracking errors are considered for this analysis. Kalogirou et al. presented a PTC design with high stiffness-to-weight

ratio and a low-labor manufacturing process[7]. The structure was made of polyester resin and woven fiberglass cloth,

with plastic conduits that provide reinforcement. Valan Arasu and Sornakumar presented a simple, low-cost hand lay-

up method for manufacturing PTC [8] based on the previous work of Kalogirou et al. [7]. The design proposed consists

of a smooth 90 rim angle, reinforced parabolic trough made of layers of polyester resin and chopped strand fiberglass.

In a paper published in the same year [9], the authors outlined a design optimization method based on three parameters:

the collector aperture, the rim angle, and the receiver diameter. They also proposed a tracking mechanism with a

control system consisting of three light dependent resistors. A torque box structure was also used by Brooks et al. with

a mix of advanced and less sophisticated technologies to manufacture a reflector made of stainless steel sheets covered

with the aluminium film[10]. This solution grants accessibility, accuracy, ease of fabrication, and cost reduction. The

authors also reported that the instantaneous thermal efficiency for a low-temperature PTC that uses a glass cover does

not translate into a significant increase in the efficiency of temperatures near 100 oC. P. Bendt et al.[11] reported an

excellent application of the PTC for line-focus solar concentrators in a Solar Energy Research Institute (SERI).

Venegas-Reyes et al. described a light but robust structure of aluminum made only using hand tools designed for

low-enthalpy steam generation and hot water[12]. This PTC has a rim angle of 45o and the receiver without a glass

cover to reduce costs. In another work published in 2013 [13], the authors presented five PTCs for the same purpose;

three of them have a rim angle of 90 o and the other two have a rim angle of 450. In the construction and assembly of

both collectors, only hand tools are required. The design of both collectors considers unshielded receivers and without

glass cover to reduce manufacturing and transportation costs. They carried out thermal and optical analyses for each

collector, and the results showed the peak efficiency of 35% and 67% for the PTC with a rim angle of 45oand 90o

respectively. Recently, Gianluca Coccia et al.[14] presented a prototype of a PTC with a 90 rim angle and a

concentration ratio of 9.25 built from fiberglass and extruded polystyrene, called UNIVPM.01, with a tracking system

based on a solar position computer program. The main features of their prototype are its cost-effectiveness, low weight,

high mechanical resistance, and ease of manufacture. The thermal efficiency of a PTC is derived and found to be in the

form of a linear equation with intercept is 0.658, and the slope is 0.683which is comparable to other similar collectors

available in the literature. Ahmed M. Ahmed et al. [15] run an experimental evaluation of a PTC under Libyan climate

in the winter season. They used water as heat transfer fluid. Their experimental results showed that the maximum

instantaneous thermal efficiency reached 43.9% for a direct solar radiation of 474 W/m2at a flow rate of 14.4kg/hr, and

the maximum outlet temperature reached 79.5 °C for a direct solar radiation of 650W/m2 at a flow rate of 14.4kg/hr.

They stated that Libya holds a real potential for the PTC technology to meet the increasing demand for water heating.

The first objective of this paper is to design, construct, and test a PTC fabricated at the Sabratha Engineering

College at Sabratha University. The secondary objectives are to produce medium water temperature for residential and

industrial processes.

II. PTC DESIGN

A prototype PTC is made from available local materials. The collector is designed with simple parabolic equations.

A cross section of a PTC is shown in Fig. 1. where various important factors are shown. The incident radiation on the

PTC at the rim of the collector (where the mirror radius, rr is maximum) makes an angle, r with the center line of the

collector, which is called the rim angle. From geometrical relations of the parabolic section, the equation of the

parabola in terms of the coordinate system is given as:

x2 4 f y 1

By substituting y h regarding the focal length and aperture diameter is x a / 2 :

h a 2 /(16 f ) 2

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15891

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

For a parabolic reflector, the radius, r, shown in Fig. 1. is given by:

2f

r 3

1 cos

Where is the angle between the reflected beam and the collector axis at the focus. As varies from 0 to r , r

increases from f to rr , therefore, equation (3) become

2f

rr 4

1 cos r

Another parameter related to the rim angle is the aperture of the parabola, ( a ). From Fig. 1. and simple trigonometry, it

can be found that:

a 2 rr Sin r 5

By substituting equation (4) into equation (5) gives the following:

4 f sin r

a 6

1 cos r

a

tan r 7

2 4 f

The Geometrical concentration ratio C is the ratio of the aperture area Aa , to the receiver surface area Arec

A a

C a 8

Arec D o

The curve length (S) of the reflective surface is given by: [22]

H r r r r

S sec( ). tan( ) In sec( ) tan( ) (9 )

2 2 2 2 2

Where H is the lactus rectrum of the parabola which is calculated by:

H P 4 f tan r / 2 (10)

For the same aperture width, various rim angles are possible as shown in Fig. 2. It is also shown that, for different rim

angles, the focus-to-aperture ratio, which defines the curvature of the PTC changes. It can be announced that, with a rim

angle 90°, the mean focus-to-reflector distance is minimized. The collector surface area decreases as the rim angle is

decreased. There is thus a temptation to use smaller rim angles because the sacrifice in optical efficiency is small, but the

saving in reflective material cost is great[16].

Fig. 1: Parabola focal length and curvature Fig. 2:Cross-section of the PTC with circular receiver

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15892

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

III. PTC CONSTRUCTION

The construction and assembly of the PTC are done at the workshop of the mechanical engineering department at

Sabratha Engineering College at Sabratha University. The body of the first PTC is made of 10 pieces of plywood traded

in parabolic shapes as shown in fig.3(a), fixed in equal spaces by 4 solid steel rods and wooden plates 3 m length at

both length sides as shown in fig.3(b). This assembly allows the PTC to be adjusted and varying its slope through a

manual tracking process. The reflecting surface is made of Formica sheet2.8 m length and 1.04 m width which gives an

effective aperture area of 2.912 m2coated by a bright aluminum foil with a reflectivity value 0.85 as shown in fig.3

(c). The second PTC is made from thin steel sheet 2.0 mm thickness, 2.0m length and 1.04 m width coated by a bright

aluminum foil with the same properties as first PTC. The reflecting surface aperture effective area is 2.08m2. The whole

arrangements are fitted on a steel frame consists of two mechanical assemblies: stationary base assembly and moving

assembly as shown in Fig.3 (d). The two assemblies have the same optical characteristics. Therefore, they are arranged

in series as illustrated in fig. 4, and their receivers are connected by a flexible tube to give a total length of 4.8m.

(a) (b)

(c) (d)

Fig. 3. : PTC Construction (a) Tracing the parabolic shape, (b) Fixing the parabolic surface

(c) Coating the parabolic surface with reflector, (d) Steel frame parabolic collector.

A mild steel tube was selected from the available local tubes to serve as a receiver with an internal diameter

D i

0.017m , external diameter Do 0.021m , absorptivity, emissivity rec 0.9 and thermal conductivity

k 80W / m.0 c . It is acceptable according to the aperture width to give geometrical concentration ratio of 15.763.

rec

The receiver used in this study is chosen to be without glass cover. In fact, the overall heat loss coefficient could be

improved by using a glass-shielded receiver. However, considering the temperature range for heating water purposes

between 70 and 110 oC, it is possible to consider that adding a glass-shielded tube is not necessary because its

fabrication in developing countries like Libya is difficult, and must be imported from abroad. The receiver tube was

painted with black paint, insulated from its upper area and fixed at the reflector focal length, to receive the solar

radiation from the reflector.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15893

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

Fig. 4: Final setup of the experimental work

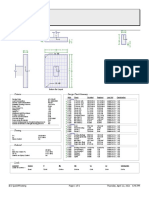

The ratio of focal length to aperture was selected from fig. 2. to be ( f / a) 0.5 then the rim angle r was

calculated from equation (7), the rim radius rr from equation (4). The aperture width a from equation (5), the

parabola lactus rectrum H from equation (10). The curve length of the parabola S from equation (9) and

geometrical concentration ratio C was calculated from equation (8). The characteristics of the designed model have

the following values as given in Table 1.

Table1: Geometrical Characteristics of the PTC model

Characteristic Symbol Value

Aperture width (m) a 1.0

Aperture area (m2) Aa 4.992

Collector height(m) h 0.125

Collector Length(m) L 4.8

Focal length(m) f 0.5

Geometrical concentration ratio C 15.76

Parabola curve length(m) S 1.04

Parabola lactus rectrum(m) H 1.0

Receiver area (m2) Arec 0.3167

Receiver inner diameter(m) Di 0.017

Receiver outer diameter(m) Do 0.021

0

Rim angle( ) r 53.13

Rim radius(m) rr 0.625

IV. EXPERIMENTAL SETUP AND PROCEDURE

A photographic view of the PTC used in the experimental investigation is shown in Fig.4. The experimental

work is done in an open flow from 30th of December 2015 to 5thof April 2016. The test rig is placed in an open space,

and the readings are taken from 10:00 AM to 2:00 PM daily. The system consists of the constructed collector, 1m3

storage tank and measuring instruments. The storage tank is used for storing the cold water, it was made of iron sheet

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15894

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

and fixed at 3m above the collector level so that the water flow due to the gravity. A flexible pipe made of plastic is

used for carrying the cold water from the storage tank to the receiver. A control valve is connected to the storage tank

for controlling the mass flow rate. The flowmeter was connected before the inlet of the receiver tube to measure the

water flow rate. During the experiment, many measurements are taken at a time interval of 15 minutes. The temperature

of water inlet Tin , water outlet Tou , ambient Ta and tube surface temperature Ts are measured using digital

thermometers. Air velocity V was measured using a digital anemometer. Water flow rate m 0 was measured using

flowmeter, and the solar radiation intensity I was measured using digital pyrheliometer. The specifications of the

measuring devices used during the experiment are shown in Table 2.

Table 2 Measuring instruments specifications

Type Fluid Operating range Accuracy

Device

Thermometer Tastotherm MP2000 Water Temperature: (-200–1300) 0C ± 2 0C

Anemometer GM8901-2-#7183 Air Temperature: (0– 45)0C ± 20C

Velocity : (0 –45) m/s ±3%

Flowmeter MPB Water Flow rate : (0 –50) g/s ±2%

Pyrheliometer METEON CMP6 Solar radiation Irradiance: (0 – 2000) w/m2 16.34x10-6 v/w/m2

V. SYSTEM PERFORMANCE CALCULATIONS

Thermal performance of PTC was evaluated using the measured temperatures of heat transfer fluid (HTF) for inlet

and outlet, mass flow rate, ambient temperature, wind speed, and solar radiation intensity.

The useful heat gain is the instantaneous heat energy gained by the HTF during its flow between the inlet and outlet

of the receiver. It is calculated from the flowing equation:

Q u m 0 C p Tou Tin (11)

Where Tin and Tou denote the temperature of the HTF at the inlet and outlet of the receiver measured at the same

time, C p is specific heat of the water in J /(kg.K ) , and m 0 is the mass flow rate of the HTF measured in g / s

The thermal efficiency of the PTC is defined as the ratio of the instantaneous useful heat gained by the HTF, and the

instantaneous solar beam radiation incident I on the given aperture area of the collector Aa . The instantaneous

thermal efficiency th is calculated as follows:

m C p Tou Tin

0

Qu

th (12)

I . Aa I . Aa

VI. RESULTS AND DISCUSSION

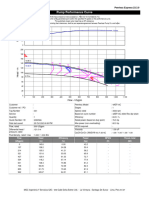

Data of inlet and outlet temperatures along with thermal efficiency calculated from equation (12) and heat gained

calculated from equation (11) are plotted and demonstrated in detail in the following figures:

Fig. 5. shows variations of the solar radiation measured for two selected days, one is at Autumn season

specifically on 26th of January, and the other day is at the beginning of the Spring season specifically on 29th of March

2016. The measured radiation rates are taken from 10:00 AM to 4:00 PM. At 10:00 AM, the solar intensity is low. As

the time passes, the intensity starts to rise until reaching the peak around 1:30 PM. After that time, the intensity

decreases till the end of the experiment. It can be noticed that the solar the value of the radiation increases as the time

was closer to spring, this is due to the increased elevation angle of the sun, where the earth is closer to the sun.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15895

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

Fig.6: Variation of solar radiation with time

Fig. 5: Variation of solar radiation (I) on 26th January and 29th March with time

Fig. 6. shows variations of the useful heat gain calculated from equation (11) for the test days of 26th of January

th

and 29 of March. At 10:00 AM, the gained heat is low due to the low rate of solar radiation, then as time passes, it

starts to increase until reaching the peak around 12:00 to 1:30 PM which indicates that the solar radiation rate

influences the energy collected. After 2:00 PM, the useful heat gain decreases until the end of the experiment as a result

of the decreased solar intensity.

Fig. 6: Variation of useful heat gained (Qu) on 26th January and 29th March with time

Fig. 7. shows the instantaneous thermal efficiency during the experiment period for the two days. It is noticed

that the efficiency is high at the beginning of the experiment because the solar radiation is lower (equation (12)).

Maximum values of the thermal efficiency for these days are 42.7% and 24.1% on 26th of January and 29th of March

respectively. As time passes; the efficiency starts to decrease until it reaches its minimum values at the end of the

experiment because the thermal efficiency is inversely proportional to the solar radiation intensity. It is noticed that the

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15896

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

thermal efficiency on 26th of January is higher 29th of March, the reason is that the solar radiation intensity in January is

lower than March, and the thermal losses in March higher than in January.

Fig. 7: Variation of instantaneous thermal efficiency (η) on 26th January and 29th March with time

Fig. 8. shows the variation of ambient temperature and wind speed with time. At the beginning of the test, the

ambient temperature is low with values around 10 oC to 17.6 oC. It starts to increase as the radiation intensity increases

until it reaches maximum values around 18 oC to 20 oC from 2:30 PM to 3:30 PM. Then, it decreases slightly at the end

of the test. The minimum wind speed is found with a value of 0.1 m/s and the maximum has a value 1.7 m/s, and

between these values, it is fluctuating up and down until the end of the test according to the local weather condition.

Fig. 8: Variation of ambient temperature (T a) and wind speed (V) on 26th January and 29th March with time

Fig. 9. shows the variation of the solar radiation with experiment days between 10:00 AM, and 2:00 PM. It can

be observed that the solar radiation increases gradually from the beginning of the experiments in January till April the

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15897

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

end time of the experimental work. The reason is due increasing the sun elevation angle as the Earth approaching the

Sun at this period of the year, as a result of the movement of the Sun from the Tropic of Capricorn in the south to the

Tropic of Cancer in the north. There are some discrepancies of the solar radiation in a few days due to the presence of

fogs and rain in these days. The maximum value of the solar radiation is 944 W/m2 at 1:00 PM on 30th of March 2016.

Fig. 9: Variation of solar radiation during the experiment days

Fig. 10. shows the variation of the outlet water temperature with experimental days between 10:00 AM, and 2:00

PM. It can be noticed that the outlet water temperature starts to increase each day from the beginning of the experiment

at 10:00 AM to reach its maximum value at 1:00 PM then, it starts to decrease. This variation is same to the solar

radiation behavior because the outlet water temperature depends mainly on the solar radiation intensity.

Fig. 10: Variation of outlet temperature at different times during the experiment days

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15898

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

The maximum outlet temperature obtained during the experimental work is 88.1 °C on 30th of March 2016 at

1:00 PM. This temperature is suitable for residential and industrial uses. There are some fluctuations of the outlet water

temperature in some days due to the presence of fogs and rain in these days. The outlet water temperature is expected to

reach more than 100 °C in summer when the solar radiation reaches its maximum values.

Fig. 11. shows the variation of the thermal efficiency with experimental days between 10:00 AM, and 2:00 PM. It can

be obviously observed that the thermal efficiency at high at January when the solar radiation rates are low, and it

decreases until it reaches its lowest values at the end of the experimental days at the beginning of April when the solar

radiation rates are high. It can also be seen that the thermal efficiency is higher at the beginning of the experimental day

at 10:00 AM and starts to decrease gradually to reach its minimum value at the end of the experimental day at 4:00 PM.

The reason is that thermal efficiency is inversely proportional to the solar radiation intensity (equation 12).

Fig. 11: Variation of efficiency at different times during the experiment days

VII. CONCLUSIONS

Design, construction, and experimental study were presented to evaluate the performance of a PTC under

Sabratha city in Libya. The experiments are taken from 30th of December 2015 to 5th of April 2016. The collector

thermal efficiency and useful heat gained curves showed a similar behavior with the data published by other researchers.

From these results, the maximum value of the thermal efficiency for the test period is 52.5 %, and the maximum value

of the outlet water temperature is found to be 88.1°C. Because it is the first attempt to manufacture such collector

locally, the obtained characteristic curves of the tested collector are considerably lower than that of a typical collector

made by professional companies. This is attributed to the higher thermal losses caused by the absence of the evacuated

glass envelope around the absorber tube, the end losses of the collector, and the inaccuracy of the tracking system. The

following conclusions could be drawn:

Libya climate is suitable for application of the PTC in the area of water heating purposes for residential and

industrial uses.

It is recommended to use a receiver with evacuated glass envelope to improve the thermal efficiency and

reduce the thermal losses of the PTC.

It is recommended to use an automatic tracking system to reduce the end losses of the collector, and hence

improve the thermal efficiency of the PTC.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15899

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 9, September 2016

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the technical support given for this work by the graduate studies department,

Faculty of Engineering, Sabratha University. We also thank the final year students, Taha Algoul and Mohamed Kareem

for their support during the experimental work. Finally, we thank the authors of the references cited in this paper that

helped in the improvement of quality.

REFERENCES

[1] F. Ahwide, A. Spena, and A. El-Kafrawy, “Correlation for the Average Daily Diffuse Fraction with Clearness Index and Estimation of

Beam Solar Radiation and Possible Sunshine Hours Fraction in Sabha, Ghdames and Tripoli - Libya,” APCBEE Procedia, vol. 5, pp. 208–

220, 2013.

[2] F. K. Bannani, T. A. Sharif, and A. O. R. Ben-Khalifa, “Estimation of monthly average solar radiation in Libya,” Theoretical and Applied

Climatology, vol. 83, no. 1–4. pp. 211–215, 2006.

[3] A. M. A. Mohamed, A. Al-Habaibeh, and H. Abdo, “An investigation into the current utilization and prospective of renewable energy

resources and technologies in Libya,” Renew. Energy, vol. 50, pp. 732–740, 2013.

[4] G. Kumaresan, R. Sridhar, and R. Velraj, “Performance studies of a solar parabolic trough collector with a thermal energy storage system,”

Energy, vol. 47, no. 1, pp. 395–402, 2012.

[5] G. W. Treadwell, “Design Considerations For Parabolic- Cylindrical Solar Collectors,” Albuquerque, New Mexico 87115, 1976.

[6] J. A. Clark, “An analysis of the technical and economic performance of a parabolic trough concentrator for solar industrial process heat

application,” Int. J. Heat Mass Transf., vol. 25, no. 9, pp. 1427–1438, 1982.

[7] S. Kalogirou, P. Eleftheriou, S. Lloyd, and J. Ward, “Low-cost high accuracy parabolic troughs construction and evaluation,” Renew.

Energy, vol. 5, no. 1–4, pp. 384–386, 1994.

[8] A. Valan Arasu and T. Sornakumar, “Design, manufacture and testing of fiberglass reinforced parabola trough for parabolic trough solar

collectors,” Sol. Energy, vol. 81, no. 10, pp. 1273–1279, 2007.

[9] S. A. Kalogirou, S. Lloyd, J. Ward, and P. Eleftheriou, “Design and performance characteristics of a parabolic-trough solar collector

system,” Appl. Energy, vol. 47, no. 4, pp. 341–354, 1994.

[10] M. Brooks, I. Mills, and T. Harms, “Design, construction and testing of a parabolic trough solar collector for a developing-country

application,” in proceedings of the ISES Solar World Congress, Orlando, FL, 2005.

[11] P. Bendt, A. Rabl, H. W. Gaul, and K. A. Reed, “Optical Analysis and Optimization of Line Focus Solar Collectors,” Solid. State. Electron.,

vol. 41, no. 11, pp. 1787–1793, 1997.

[12] E. Venegas-Reyes, O. a. Jaramillo, R. Castrejón-García, J. O. Aguilar, and F. Sosa-Montemayor, “Design, construction, and testing of a

parabolic trough solar concentrator for hot water and low enthalpy steam generation,” J. Renew. Sustain. Energy, vol. 4, no. 5, pp. 053103–

1 – 053103–18, 2012.

[13] O. A. Jaramillo, E. Venegas-Reyes, J. O. Aguilar, R. Castrejón-García, and F. Sosa-Montemayor, “Parabolic trough concentrators for low

enthalpy processes,” Renew. Energy, vol. 60, pp. 529–539, 2013.

[14] G. Coccia, G. Di Nicola, and M. Sotte, “Design, manufacture, and test of a prototype for a parabolic trough collector for industrial process

heat,” Renew. Energy, vol. 74, pp. 727–736, 2014.

[15] M. A. Ahmed, A. A. Albusefi, and H. T. Izweik, “Experimental Evaluation of a Solar Parabolic Trough Collector under Libyan climate,”

Int. J. Eng. Trends Technol., vol. 38, no. 1, pp. 32–37, 2016.

[16] H. P. Garg and J. Prakash, Solar Energy: Fundamentals and Applications. Tata McGraw-Hill, 2005.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0509065 15900

You might also like

- Design, Fabrication and Performance Analysis of A Parabolic Trough Solar Collector Water HeaterDocument6 pagesDesign, Fabrication and Performance Analysis of A Parabolic Trough Solar Collector Water HeaterdjemNo ratings yet

- Ijett V38P207Document6 pagesIjett V38P207Ahmed Mohamed AhmedNo ratings yet

- Renewable Energy: Gianluca Coccia, Giovanni Di Nicola, Marco SotteDocument10 pagesRenewable Energy: Gianluca Coccia, Giovanni Di Nicola, Marco Sotteanita galihNo ratings yet

- Design Simulation and Optimization of Solar Dish Collector With Spiral-Coil Thermal AbsorberDocument11 pagesDesign Simulation and Optimization of Solar Dish Collector With Spiral-Coil Thermal AbsorberLima CostaNo ratings yet

- 1 s2.0 S1110016816302551 MainDocument7 pages1 s2.0 S1110016816302551 MainCharly CharlesNo ratings yet

- Thermal SystemsDocument192 pagesThermal SystemsCornel HatieganNo ratings yet

- Low-Thermal-Budget Photonic Processing of Highly Conductive Cu Interconnects Based On Cuo Nanoinks: Potential For Flexible Printed ElectronicsDocument9 pagesLow-Thermal-Budget Photonic Processing of Highly Conductive Cu Interconnects Based On Cuo Nanoinks: Potential For Flexible Printed Electronicsmasa packNo ratings yet

- Design of A Transpired Air Heating Solar Collector With An Invert PDFDocument297 pagesDesign of A Transpired Air Heating Solar Collector With An Invert PDFAtul PandeyNo ratings yet

- Collector With LinsDocument10 pagesCollector With Linsaoauaz2000No ratings yet

- Performance Analysis of Parabolic Trough Collector in Hot ClimateDocument21 pagesPerformance Analysis of Parabolic Trough Collector in Hot ClimateirfanajaiNo ratings yet

- The Wind Structure Interaction Analysis and Optimization of - 2015 - Energy ProDocument7 pagesThe Wind Structure Interaction Analysis and Optimization of - 2015 - Energy Propaween saetaeNo ratings yet

- Bello SpecsDocument73 pagesBello Specsconcurso5 eletricaufmsNo ratings yet

- Effect of Nanoparticle ShapeDocument18 pagesEffect of Nanoparticle Shapeaxel_oscar90No ratings yet

- 352-Article Text-588-1-10-20200108Document21 pages352-Article Text-588-1-10-20200108Vijay Sri ThiruNo ratings yet

- Solar Energy Materials and Solar Cells: S. Mojtaba Tabarhoseini, M. Sheikholeslami, Zafar SaidDocument32 pagesSolar Energy Materials and Solar Cells: S. Mojtaba Tabarhoseini, M. Sheikholeslami, Zafar SaidMohamed AliNo ratings yet

- Literature Review On Adsorption Cooling TechnologyDocument5 pagesLiterature Review On Adsorption Cooling Technologyc5nazs86No ratings yet

- Experimental Investigation of Solar Water Heater Integrated With A Nanocomposite Phase Change MaterialDocument5 pagesExperimental Investigation of Solar Water Heater Integrated With A Nanocomposite Phase Change MaterialEditor IJTSRDNo ratings yet

- Sustainable Energy Technologies and Assessments: E. Bellos, D. Korres, C. Tzivanidis, K.A. AntonopoulosDocument11 pagesSustainable Energy Technologies and Assessments: E. Bellos, D. Korres, C. Tzivanidis, K.A. AntonopoulosObaidNo ratings yet

- Mechanical Design of A Low Cost Parabolic Solar Dish ConcentratorDocument11 pagesMechanical Design of A Low Cost Parabolic Solar Dish ConcentratorkyleNo ratings yet

- CFD Analysis of Solar Flat Plate CollectorDocument6 pagesCFD Analysis of Solar Flat Plate CollectorDimuthu Prasad WijethungeNo ratings yet

- HP 15-3Document7 pagesHP 15-3Sidharth Kashyap BorthakurNo ratings yet

- Final CARBONNANOPARTICLESCEMENT-BASEDMATERIALSFORSERVICELIFEMONITORINGDocument9 pagesFinal CARBONNANOPARTICLESCEMENT-BASEDMATERIALSFORSERVICELIFEMONITORINGDr. Shwan H. Said د. شوان حسين سعيدNo ratings yet

- KTH Master Thesis EnergyDocument4 pagesKTH Master Thesis Energygingermartinerie100% (1)

- Manikandan 2019 Enhancing The Optical and Thermal e PDFDocument17 pagesManikandan 2019 Enhancing The Optical and Thermal e PDFPedro Reynaldo MartinezNo ratings yet

- Sodsri Et Al. - 2017 - Numerical Thermal Performance Study in A Heat Exchanger Tube With Inclined Elliptical RingsDocument8 pagesSodsri Et Al. - 2017 - Numerical Thermal Performance Study in A Heat Exchanger Tube With Inclined Elliptical RingsAsep asepNo ratings yet

- Design and Fabrication of Parabolic Trough Solar Collector: Department of Mechanical EngineeringDocument21 pagesDesign and Fabrication of Parabolic Trough Solar Collector: Department of Mechanical Engineeringameer kannanNo ratings yet

- In Uence of Nano Fluid and Receiver Tube Shape Modification On The Performance of Solar Parabolic Trough Collector With Closed SystemDocument8 pagesIn Uence of Nano Fluid and Receiver Tube Shape Modification On The Performance of Solar Parabolic Trough Collector With Closed Systemmohammed yaseenNo ratings yet

- Mdrsjrns v16n9p437 FaDocument6 pagesMdrsjrns v16n9p437 FaSaeedNo ratings yet

- Development and Experimental Characterization of A Small Scale Solar Powered Organic Rankine Cycle (ORC) (Energy Procedia, Vol. 101) (2016)Document8 pagesDevelopment and Experimental Characterization of A Small Scale Solar Powered Organic Rankine Cycle (ORC) (Energy Procedia, Vol. 101) (2016)Matheus M. DwinantoNo ratings yet

- Cost Benefit Analysis of Implementing A Solar Photovoltaic SystemDocument9 pagesCost Benefit Analysis of Implementing A Solar Photovoltaic SystemAngelica NunezNo ratings yet

- Solar CollectorsDocument5 pagesSolar CollectorsJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Per ETCDocument14 pagesPer ETCRendy YuliantoNo ratings yet

- Analysis For Critical Radius of Insulation For A Cylinder.: September 2013Document8 pagesAnalysis For Critical Radius of Insulation For A Cylinder.: September 2013Rana Javed IqbalNo ratings yet

- 1 s2.0 S2214157X23011747 MainDocument16 pages1 s2.0 S2214157X23011747 MainNura MuazNo ratings yet

- 1 PBDocument23 pages1 PBStefania de Oliveira SilvaNo ratings yet

- Paper 8916Document17 pagesPaper 8916IJARSCT JournalNo ratings yet

- Solar Steamer.Document15 pagesSolar Steamer.AadarshNo ratings yet

- PJST12 1 152Document9 pagesPJST12 1 152Harman Preet SinghNo ratings yet

- G.L. Bajaj Group of Institutions: "Large Hadron Collider"Document27 pagesG.L. Bajaj Group of Institutions: "Large Hadron Collider"ankitupadhyay0209No ratings yet

- Vortex Tube - A Review: NtroductionDocument5 pagesVortex Tube - A Review: NtroductionJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Solar-Assisted Dual-Effect Adsorption Cycle For THDocument8 pagesSolar-Assisted Dual-Effect Adsorption Cycle For THGonzalo BenavidesNo ratings yet

- 1 s2.0 S0735193315000408 MainDocument5 pages1 s2.0 S0735193315000408 MainasalazarhNo ratings yet

- CarrilloDocument8 pagesCarrilloNimble NimbleNo ratings yet

- CFD Presentation Final2Document16 pagesCFD Presentation Final2Taha KhanNo ratings yet

- Creep FatigueDocument12 pagesCreep FatigueMahdi MahnazNo ratings yet

- Performance Investigation of Solar Water Heating System Using Nano UidsDocument6 pagesPerformance Investigation of Solar Water Heating System Using Nano UidsMECHANICAL ENGINEERINGNo ratings yet

- Inventions: Heat Transfer and Its Innovative ApplicationsDocument2 pagesInventions: Heat Transfer and Its Innovative ApplicationsHenry PomaNo ratings yet

- A Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Document9 pagesA Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- 2ahsan SS TEDocument10 pages2ahsan SS TEahsan.iut2No ratings yet

- PHD Research Proposal On Microwave Heationg of Oil Sands CokeDocument4 pagesPHD Research Proposal On Microwave Heationg of Oil Sands CokeAdebimpe EliasNo ratings yet

- Multi Effect Absorption Chillers Powered by The Sun Reali - 2016 - Energy ProceDocument13 pagesMulti Effect Absorption Chillers Powered by The Sun Reali - 2016 - Energy Procebeauty xuNo ratings yet

- Yuan 2015Document8 pagesYuan 2015AdiKurdiNo ratings yet

- Thermal Modeling of Heat Exchanger: A Review: January 2017Document7 pagesThermal Modeling of Heat Exchanger: A Review: January 2017Preciously OmnesNo ratings yet

- Analysis of A Vacuum-Based Photovoltaic Thermal Collector: SciencedirectDocument7 pagesAnalysis of A Vacuum-Based Photovoltaic Thermal Collector: Sciencedirecthansel huacasiNo ratings yet

- 5 2013 Researchpaper - Numerical Simulation of An Al2O3 H2O Nanofluid As A Heat Transfer Agent For A Flat Plate Solar Collector PDFDocument12 pages5 2013 Researchpaper - Numerical Simulation of An Al2O3 H2O Nanofluid As A Heat Transfer Agent For A Flat Plate Solar Collector PDFEman ToraNo ratings yet

- With CharlainDocument24 pagesWith CharlainAro RakNo ratings yet

- Green Energy and TechnologyDocument19 pagesGreen Energy and Technologymy accountNo ratings yet

- Mohammad Mahdi Tafarroj Et Al.Document36 pagesMohammad Mahdi Tafarroj Et Al.Shafier KhanNo ratings yet

- Research Paper On Solar HeaterDocument6 pagesResearch Paper On Solar Heaterxvszcorif100% (3)

- Cold Inflow-Free Solar Chimney: Design and ApplicationsFrom EverandCold Inflow-Free Solar Chimney: Design and ApplicationsMd. Mizanur RahmanNo ratings yet

- ملزمة رياضيات كورس ثانيDocument61 pagesملزمة رياضيات كورس ثانيAhmed Mohamed AhmedNo ratings yet

- معامل انكسار الماءDocument3 pagesمعامل انكسار الماءAhmed Mohamed AhmedNo ratings yet

- Kutum Project - VC0-ReportDocument7 pagesKutum Project - VC0-ReportAhmed Mohamed AhmedNo ratings yet

- Productivity and Eciency of Modied Solar Still Using Convex Lenses On The Glass Cover and Radiating Surfaces InsideDocument5 pagesProductivity and Eciency of Modied Solar Still Using Convex Lenses On The Glass Cover and Radiating Surfaces InsideAhmed Mohamed AhmedNo ratings yet

- Ijett V38P207Document6 pagesIjett V38P207Ahmed Mohamed AhmedNo ratings yet

- Experimental Study On Modified Solar Still Using Convex Lenses On The Glass Cover and Radiating Surfaces InsideDocument14 pagesExperimental Study On Modified Solar Still Using Convex Lenses On The Glass Cover and Radiating Surfaces InsideAhmed Mohamed AhmedNo ratings yet

- Vol 2. No1 (February-201 2) ISSN: 1858 - 6333Document2 pagesVol 2. No1 (February-201 2) ISSN: 1858 - 6333Ahmed Mohamed AhmedNo ratings yet

- Title(s) :: Faculty of Engineering Department of Mechanical EngineeringDocument7 pagesTitle(s) :: Faculty of Engineering Department of Mechanical EngineeringAhmed Mohamed AhmedNo ratings yet

- Publication Certificate: Cience Ngineering EchnologyDocument1 pagePublication Certificate: Cience Ngineering EchnologyAhmed Mohamed AhmedNo ratings yet

- Optimization of Heat Transfer Using CFD Simulation For Concentric Helical Coil Heat Exchanger For Constant Temperature Outer WallDocument45 pagesOptimization of Heat Transfer Using CFD Simulation For Concentric Helical Coil Heat Exchanger For Constant Temperature Outer WallAhmed Mohamed AhmedNo ratings yet

- API Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure, Gerdes, 2010Document8 pagesAPI Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure, Gerdes, 2010Ryan Fenyves100% (1)

- 1the Birth of AstronomyDocument10 pages1the Birth of AstronomyJocelyn TabelonNo ratings yet

- 03 TS-3 (ELECTROSTATICS C-1 To C-10)Document3 pages03 TS-3 (ELECTROSTATICS C-1 To C-10)lakshya rautelaNo ratings yet

- Cone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone EquipmentDocument8 pagesCone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone EquipmentAhmedNo ratings yet

- Práctica Diagramas de BloquesDocument7 pagesPráctica Diagramas de BloquesGuardado EduardoNo ratings yet

- Conceptual DesignDocument98 pagesConceptual DesignMATEUS RODOVALHO EDINGERNo ratings yet

- FR4Document2 pagesFR4Luis MárquezNo ratings yet

- Leakage Potential Through A Shotcrete Lined High-Pressure Headrace Tunnel - An Analysis On A Case From NepalDocument8 pagesLeakage Potential Through A Shotcrete Lined High-Pressure Headrace Tunnel - An Analysis On A Case From Nepalpujan gurungNo ratings yet

- Solving Exponential and LogsDocument2 pagesSolving Exponential and LogsSean andrei AsmaNo ratings yet

- FIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVDocument8 pagesFIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVCrysthian AspilcuetaNo ratings yet

- Aits PT-3 Jee Main 18.12.2021 Solution+qpDocument40 pagesAits PT-3 Jee Main 18.12.2021 Solution+qpRahul PatwarikaNo ratings yet

- Steady Heat ConductionDocument25 pagesSteady Heat ConductionMohd Azhari Mohd RodziNo ratings yet

- Acoustic Treatment Guidelines - Cinema RoomsDocument16 pagesAcoustic Treatment Guidelines - Cinema RoomsMatia CamporaNo ratings yet

- Rotational MotionDocument19 pagesRotational MotionRamkumar SundaramNo ratings yet

- Electrostatic Precipitator: WelcomeDocument43 pagesElectrostatic Precipitator: Welcomeprateet_darshanNo ratings yet

- Matter in Our Surrounding QRDocument48 pagesMatter in Our Surrounding QRomvjanapureNo ratings yet

- CAN-Patterns in NatureDocument26 pagesCAN-Patterns in NaturehellohihihhiNo ratings yet

- Assignmnet Part Textile Physics Static ElectricityDocument5 pagesAssignmnet Part Textile Physics Static ElectricityAbu Mukarram AZADNo ratings yet

- DE10AV20Document19 pagesDE10AV20stillaphenomenonNo ratings yet

- On The Design and Structural Analysis o Fjet Engine Fan Blade StructuresDocument11 pagesOn The Design and Structural Analysis o Fjet Engine Fan Blade StructuresNico ScheggiaNo ratings yet

- Qdoc - Tips Inverted PendulumDocument10 pagesQdoc - Tips Inverted PendulumKrisha Mae ChaNo ratings yet

- Cleanroom PresentationDocument30 pagesCleanroom Presentationjonh366No ratings yet

- Ipt - 2005 PDFDocument669 pagesIpt - 2005 PDFصباح صالح سليمانNo ratings yet

- Practice test: Nguyễn Lâm Tường Minh 1/1 pt 996 998Document23 pagesPractice test: Nguyễn Lâm Tường Minh 1/1 pt 996 998Kim Anh NguyễnNo ratings yet

- Unolastic PDFDocument20 pagesUnolastic PDFJM SubionNo ratings yet

- The 100 Greatest Lies in Physics by Ray Fleming PDFDocument235 pagesThe 100 Greatest Lies in Physics by Ray Fleming PDFAbir Ghosh100% (2)

- New SAT Math Practice 1Document15 pagesNew SAT Math Practice 1Phan Nguyen PhuongNo ratings yet

- Design Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Document6 pagesDesign Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Christian PintoNo ratings yet

- Chris Lls Publications 42610Document11 pagesChris Lls Publications 42610cifarha venantNo ratings yet

- Sist en 12317 2 2010Document9 pagesSist en 12317 2 2010Dinesh PrasharNo ratings yet