Professional Documents

Culture Documents

SEW-EURODRIVE Develops G..7 Wire Rope Hoist Lifting Drive System

Uploaded by

naren1202Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEW-EURODRIVE Develops G..7 Wire Rope Hoist Lifting Drive System

Uploaded by

naren1202Copyright:

Available Formats

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 1

SEW-EURODRIVE – A global market leader in drive engineering

New Product:

G..7 Wire Rope Hoist Lifting Drive System

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 2

Development Background

In crane industry, SEW is able to provide almost all drives for it. For example,

SEW has gear brake motor, inverter for trolley and travelling system, IG gearbox for

the hoist lifting of the bridge crane or others.

However, SEW doesn’t has products for electric wire rope hoist like conical rotor

motor. In Chinese market, the so called “European style Electric wire rope hoist” has

become more and more popular and replace of Traditional Electric Hoist since 10

years ago. In spite that it is not a new technology and high price, the final users

appreciate it more and more, because that the “new” design has higher efficiency ,

less noise and maintenance-free design. Sometimes OEM can use electric hoist to

bridge crane for reducing cost and get compact design.

A lot of OEMs in China suggested SEW to develop the lifting drive of Electric Hoist,

because they have only one supplier of ABM, but the delivery time, service , price of

ABM can’t be satisfied.

For good market expectation and the demand from some very important customers,

the top management of SEW-China decided to start the G project in 2013

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 3

Typical Hoist Lifting System of Crane

�Hoist Type using IG

gearbox(big load and

heavy duty) �European type Electric wire rope hoist

or C type drive

�Traditional Electric hoist

used conical rotor

motor(small load up to

16tons,light duty)

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 4

Typical Electric Hoist

Smart Electric Wire Rope Hoist (Smart-EWRH)

single-girder crane

Hoisting drum

Trolley system

travelling system

Main lifting drive(brake gear motor)

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 5

Structure comparison

Structure of Smart electric wire rope hoist Traditional wire rope hoist

The advantage of Smart-EWRH:

� Higher payload up to 100 tons

� High efficiency

� High speed

� Higher lifting height

� Gear motor can be disassembly alone from hoist

� Compact design

� Low noise, maintenance-free design

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 6

Appearance Overview

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 7

Dimension Overview of G77/G97

G77DRS.. Dimension sheet G97DRS… dimension sheet

� Thinner than F..7

� Longer center distance than F..7

� Short solid spline shaft

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 8

G..7 Gearmotor Mount to hoist

� Four locating pin fixing the position

� Four long screws through the housing , and mount it to the plate of

hoist

� The spline shaft of gearbox insert to the drum and support it

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 9

G..7 gearbox connect to motor

� Flange of motor connect to gearbox directly。

� Almost the same dimension design as standard gearmotor Series

� Bigger pinion shaft of motor than standard

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 10

G..7 construction overview

216E 309E-C3

6405

6311-Z-J-C3 307E-C3

6405

G97

� Three-stage design (parallel assignment)

� Split type of housing

� Solid spline output shaft as standard design

� Housing material : cast aluminium(ASTM B26 A356 T6 )

� First stage is same as F..7 gearbox

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 11

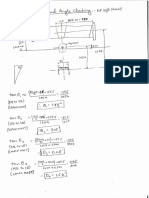

G..7 Design Standard / Calculation

Fload = 34796 N

Fload = 34796 N Fdrum/rope = 711 N

Fdrum/rope = 711 N

Mamax = 5132 Nm *

(ux = uy = uz = 0) (ux = uy = 0)

GM (m = 115kg)

GM (m = 115 kg)

� Load calculation according to

L1, L2, L3, L4 F.E.M.1001.2/1001.9

� Finite life time defined by FEM standard

� Gear calculation base on DIN3990-6, finite life

time

� Shaft calculation standard:DIN741

� Key: DIN6892

� Screw:VDI2230

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 12

G..7 Life time testing

In order to testify the new design and follow FEM standard, all sizes

must be done life time testing with full load or over load.

� G97: four testing had been completed(M5 class)

� 200 hours testing for first prototype to prove the design

and assembly process

� 1600 hours according to Chinese standard

� 3840 hours according to SEW’s designer

� 1920 hours according to FEM standard(running time)

� G77: one test has been finished(1920 hours running time) on

July.

� G67: one test is doing in SEW now

� G107: one test is preparing in Germany and will be started

soon.

All results showed the design of G..7 is very wonderful!

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 13

G..7 Benefits for customer

� G..7 design consider of enough dynamic factor

according to F.E.M standard.

� Compact design to save mounting space

� Longer center distance can mount big drum,

realizing bigger lifting height.

� More diameter of drum are available for

customer.

� Second dimension of output shaft as option

� Aluminum housing reduce the weight

� More ratios of gearbox

� More combination with motors

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 14

G..7 Project Planning

� Mounting Position: M3 as normal, M5,M6 are available

M1 must be check, M2/M4 are not available

M5 M3 M6

� Recommended direction of wire rope should be same as catalogue, different

direction of wire rope need to recalculate by SEW.

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 15

G..7 Vs competitors

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

Standard gear unit development

Smart Electric Wire Rope Hoist Drive 16

Thank you for your attention!

2017.9 .Tianjin,China SEW-EURODRIVE - Driving the World

You might also like

- DRS Catalog 2007Document216 pagesDRS Catalog 2007jaime cerdaNo ratings yet

- PBL Series K CatalougeDocument117 pagesPBL Series K CatalougeankitkanujiyaNo ratings yet

- Maintenance Manual: Manufacturing Number GenericDocument64 pagesMaintenance Manual: Manufacturing Number GenericManh PhamNo ratings yet

- Technical Data Hoist Drive GH 5000ADocument1 pageTechnical Data Hoist Drive GH 5000AEricNo ratings yet

- Gear Coupling 2014Document4 pagesGear Coupling 2014Dado Maja ArseninNo ratings yet

- 6885 1Document1 page6885 1ajeshNo ratings yet

- Brugg Catalog enDocument28 pagesBrugg Catalog enSinoj V AntonyNo ratings yet

- Benzlers Series E Catalogue PDFDocument92 pagesBenzlers Series E Catalogue PDFIndra SeptiawanNo ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- Catalogo de Seleccion Sew PDFDocument812 pagesCatalogo de Seleccion Sew PDFHugo AcevedoNo ratings yet

- Install and Maintain Industrial GearboxesDocument24 pagesInstall and Maintain Industrial GearboxesManisankar IrukuvajjalaNo ratings yet

- ABM Traction Drivers For Cranes and HoistDocument7 pagesABM Traction Drivers For Cranes and Hoistcangrejo91No ratings yet

- L-Series Installation MaintenanceDocument61 pagesL-Series Installation MaintenanceCraig PretoriusNo ratings yet

- MaterialsDocument4 pagesMaterialsSilvio VarricchioNo ratings yet

- Is Iso 7425 1 1988Document10 pagesIs Iso 7425 1 1988Claudio De Sa OliveiraNo ratings yet

- Operating instructions for gearboxes AFM 04, AFM 05, AFM 06Document20 pagesOperating instructions for gearboxes AFM 04, AFM 05, AFM 06Bang OchimNo ratings yet

- GEARBOX PART LISTDocument3 pagesGEARBOX PART LISTjosechr6No ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- MDR Serie ISO 3320: Guide to Choosing Hydraulic Cylinder Rod DiameterDocument22 pagesMDR Serie ISO 3320: Guide to Choosing Hydraulic Cylinder Rod DiameterMauricio MpintoNo ratings yet

- Gears FundamentalDocument24 pagesGears FundamentalVIMAL ANo ratings yet

- C-Series and D-Series Modular Gear Units Product CatalogueDocument176 pagesC-Series and D-Series Modular Gear Units Product CatalogueCarlos Catalán PinoNo ratings yet

- Ramsey Conveyor Protection SwitchesDocument6 pagesRamsey Conveyor Protection SwitchesArif AmirNo ratings yet

- Assy Gear Box AgitatorDocument1 pageAssy Gear Box Agitatorer_winwibowoNo ratings yet

- ABUS cranes make light work of liftingDocument21 pagesABUS cranes make light work of liftingsajay2010No ratings yet

- Ring FederDocument0 pagesRing Federrudolf_laszlokNo ratings yet

- High Speed Gear: Quality Driven High Speed Gears For The WorldDocument5 pagesHigh Speed Gear: Quality Driven High Speed Gears For The WorldNur YantoNo ratings yet

- Wheel Model 6 CatalogDocument40 pagesWheel Model 6 CatalogHernan LopezNo ratings yet

- Grooved Drum ArticleDocument2 pagesGrooved Drum ArticleLizardladNo ratings yet

- SWF Training Program 2016 en KleinDocument10 pagesSWF Training Program 2016 en KleinBenny YacilaNo ratings yet

- ISO Gear Standards GuideDocument6 pagesISO Gear Standards GuideEslam YehiaNo ratings yet

- SDG PLUMMER BLOCK HOUSINGS FOR SPHERICAL ROLLER BEARINGSDocument26 pagesSDG PLUMMER BLOCK HOUSINGS FOR SPHERICAL ROLLER BEARINGSSandip GhoshNo ratings yet

- Mod10 1ToothBendingDocument4 pagesMod10 1ToothBendingMario AndradeNo ratings yet

- Chains and Sprockets: Inverted ToothDocument32 pagesChains and Sprockets: Inverted ToothU.vijaya SarathiNo ratings yet

- As B199-1962 Undercuts and Runouts For Screw ThreadsDocument4 pagesAs B199-1962 Undercuts and Runouts For Screw ThreadsSAI Global - APACNo ratings yet

- DIN 13-1 (1999) - General Purpose ISO Metric Screw ThreadsDocument4 pagesDIN 13-1 (1999) - General Purpose ISO Metric Screw Threadsbriano100% (1)

- Crane Wheel Heat Treating MethodsDocument20 pagesCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- Iso 6336 Hohn PDFDocument6 pagesIso 6336 Hohn PDFmgualdiNo ratings yet

- Palm OilDocument8 pagesPalm OilAndy Wijaya HadrunNo ratings yet

- Operating Manual For Bevel Gear Boxes: DrehmoDocument16 pagesOperating Manual For Bevel Gear Boxes: DrehmohamzaNo ratings yet

- Section Q: Splined Hubs, Drive KitsDocument8 pagesSection Q: Splined Hubs, Drive KitshaggNo ratings yet

- Loading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesDocument12 pagesLoading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesNenad VulićNo ratings yet

- Eei PM1 El02Document61 pagesEei PM1 El02Mohd A IshakNo ratings yet

- Design Guide, Spring, Pin, Coiled, SPIROLDocument24 pagesDesign Guide, Spring, Pin, Coiled, SPIROLDerekNo ratings yet

- As 1065-1988 Non-Destructive Testing - Ultrasonic Testing of Carbon and Low Alloy Steel ForgingsDocument8 pagesAs 1065-1988 Non-Destructive Testing - Ultrasonic Testing of Carbon and Low Alloy Steel ForgingsSAI Global - APACNo ratings yet

- A Method to Optimize Brass Synchronizer RingDocument6 pagesA Method to Optimize Brass Synchronizer RingaravindhNo ratings yet

- Semi-Topping Shaper CuttersDocument4 pagesSemi-Topping Shaper CuttersalemarlonstosNo ratings yet

- MD30.1 Flender Sig en PDFDocument300 pagesMD30.1 Flender Sig en PDFnm_rangaNo ratings yet

- Synchronous Belt Drives - Automotive PulleysDocument14 pagesSynchronous Belt Drives - Automotive Pulleystv-locNo ratings yet

- Series H MetricDocument123 pagesSeries H MetricJames Pacheco100% (1)

- SewDocument396 pagesSewVarun SanganiNo ratings yet

- 6.4 Tooth-Bearings TechnicalData KGSTOCKGEARSDocument3 pages6.4 Tooth-Bearings TechnicalData KGSTOCKGEARSLuis TestaNo ratings yet

- Hardness Conversion ChartDocument34 pagesHardness Conversion ChartAshutosh SinghNo ratings yet

- Large Industrial Gearbox Brochure PDFDocument16 pagesLarge Industrial Gearbox Brochure PDFmuthushakibNo ratings yet

- Fabrication of Mini Conveyor Using Mechanical (Geneva) Mechanism4Document14 pagesFabrication of Mini Conveyor Using Mechanical (Geneva) Mechanism4Nilesh patilNo ratings yet

- SegwayDocument21 pagesSegwayParveen KumarNo ratings yet

- Electric Skateboard Incorporating Foot Operated Ackerman Steering SystemDocument7 pagesElectric Skateboard Incorporating Foot Operated Ackerman Steering SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Active Electromagnetic Suspension System For Improved Vehicle DynamicsDocument7 pagesActive Electromagnetic Suspension System For Improved Vehicle DynamicsMagdiel SchmitzNo ratings yet

- Gearless Transmission SystemDocument5 pagesGearless Transmission SystemSyed Ubaid ur RehmanNo ratings yet

- Fabrication of A Power Generation System For A Two Wheeler Suspension SystemDocument3 pagesFabrication of A Power Generation System For A Two Wheeler Suspension SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Guide For Shaft Keyway Design, Shaft Key Size Calculation and SelectionDocument15 pagesGuide For Shaft Keyway Design, Shaft Key Size Calculation and Selectionnaren1202No ratings yet

- Magnet OfferDocument5 pagesMagnet Offernaren1202No ratings yet

- Normal Battery BackupDocument1 pageNormal Battery Backupnaren1202No ratings yet

- Battery BackupDocument1 pageBattery Backupnaren1202No ratings yet

- Battery Backup DiagramDocument1 pageBattery Backup Diagramnaren1202No ratings yet

- Crane Duty Chart 21.02.2019Document9 pagesCrane Duty Chart 21.02.2019naren1202No ratings yet

- FA57 - G DRS80M4BE2HR - GM015433.00.3 - 23-ModelDocument1 pageFA57 - G DRS80M4BE2HR - GM015433.00.3 - 23-Modelnaren1202No ratings yet

- Hillmar Industrial Disc Brakes Product GuideDocument14 pagesHillmar Industrial Disc Brakes Product Guidenaren1202No ratings yet

- 33 Money LessonsDocument37 pages33 Money Lessonsraj100% (3)

- Find Out - How Are Gifts Taxed in India - Yahoo India FinanceDocument4 pagesFind Out - How Are Gifts Taxed in India - Yahoo India Financenaren1202No ratings yet

- En9 070M55Document1 pageEn9 070M55Jerry CliffordNo ratings yet

- En3a 070M20Document1 pageEn3a 070M20Debrup Banerjee100% (1)

- Lead Angle-4 FallDocument1 pageLead Angle-4 Fallnaren1202No ratings yet

- CT Wheel Load AnalysisDocument4 pagesCT Wheel Load Analysisnaren1202No ratings yet

- 2013 - 11 - 25 STD Plate Sizes & STD SectionsDocument2 pages2013 - 11 - 25 STD Plate Sizes & STD Sectionsnaren1202No ratings yet

- Bbs - BNCDocument1 pageBbs - BNCSumit GuptaNo ratings yet

- BEST LaptopDocument2 pagesBEST Laptopnaren1202No ratings yet

- EMI With FD ComparisonDocument8 pagesEMI With FD Comparisonnaren1202No ratings yet

- Tabel Konversi SatuanDocument1 pageTabel Konversi SatuanSutopo AhmadNo ratings yet

- Mum 2 DelhiDocument3 pagesMum 2 Delhinaren1202No ratings yet

- Eurostyle GB PDFDocument8 pagesEurostyle GB PDFtintucinbNo ratings yet

- Morris Crane DataDocument9 pagesMorris Crane DataMohamed EssamNo ratings yet

- Operating and Maintenance Instructions Yalelift - 360Document12 pagesOperating and Maintenance Instructions Yalelift - 360Vitor OlivettiNo ratings yet

- As 2550.5-2002 Cranes Hoists and Winches - Safe Use Mobile CranesDocument8 pagesAs 2550.5-2002 Cranes Hoists and Winches - Safe Use Mobile CranesSAI Global - APACNo ratings yet

- RTG Family BrochureDocument9 pagesRTG Family BrochureHaluk KayaNo ratings yet

- KBK SistemiDocument28 pagesKBK SistemiGogy100% (1)

- Mobile Crane Inspection ChecklistDocument2 pagesMobile Crane Inspection ChecklistaymenmoatazNo ratings yet

- Cascades 60E Sideshifter ManualDocument12 pagesCascades 60E Sideshifter ManualReid AllawayNo ratings yet

- Suspended Platform System Conform UlDocument19 pagesSuspended Platform System Conform UlEmerson OliveiraNo ratings yet

- Bridon Crane Rope CatalogueDocument80 pagesBridon Crane Rope CataloguePete Swift100% (1)

- COSH Crane SafetyDocument44 pagesCOSH Crane SafetyJeffrey Lumba100% (2)

- Rope Towed Trolley or Machinery Trolley PDFDocument11 pagesRope Towed Trolley or Machinery Trolley PDFAdhitya ReNo ratings yet

- List Down Some of The Benefits Obtained From Implementing A Good Material Handling SystemDocument11 pagesList Down Some of The Benefits Obtained From Implementing A Good Material Handling SystempenihaniNo ratings yet

- As 1755-1986 Conveyors - Design & FabricationDocument66 pagesAs 1755-1986 Conveyors - Design & FabricationCristhian Solano Bazalar100% (1)

- Goa Factories Rules 1985Document392 pagesGoa Factories Rules 1985jacobpm2010No ratings yet

- CMAA Most Asked Action AlertsDocument27 pagesCMAA Most Asked Action Alertstggjr100% (1)

- Setup Venture Basic Rigging Training EnglishDocument34 pagesSetup Venture Basic Rigging Training EnglishAhmad LuqmanNo ratings yet

- Bridon Service Procedure 1Document5 pagesBridon Service Procedure 1Ahmed ButtNo ratings yet

- Demag Cranes BruchureDocument24 pagesDemag Cranes BruchureAnand TornekarNo ratings yet

- Manual de Taller WA450-3MCDocument854 pagesManual de Taller WA450-3MCValdeleyLima100% (1)

- Cleasby Conveyors MaintenanceDocument2 pagesCleasby Conveyors MaintenanceRino AdityaNo ratings yet

- ROO-HSE-PRO-0052 REV 12 - Lifting Operations - Eng - CompressedDocument157 pagesROO-HSE-PRO-0052 REV 12 - Lifting Operations - Eng - CompressedMohamad sharul nizam RusliNo ratings yet

- Donggwang Clark Corporation OLDDocument49 pagesDonggwang Clark Corporation OLDwallyNo ratings yet

- Is 6938Document13 pagesIs 6938Dhanashri Patil100% (1)

- User Manual - Man BasketsDocument14 pagesUser Manual - Man BasketsKin Lai KongNo ratings yet

- Lift Planning & Hoist ProcedureDocument34 pagesLift Planning & Hoist ProcedureAdham Abo bakrNo ratings yet

- Grúa Torre Liebherr 53K (Ing)Document24 pagesGrúa Torre Liebherr 53K (Ing)Carlos Alfredo LauraNo ratings yet

- Coal Handling Process and EquipmentDocument6 pagesCoal Handling Process and EquipmentSandeep ChhabraNo ratings yet

- EPC Tuban Jetty Piling WorkDocument28 pagesEPC Tuban Jetty Piling WorkDito NarendraNo ratings yet

- BGR Energy 20-10T TechnicalDocument1 pageBGR Energy 20-10T Technicalkarthik RajendranNo ratings yet