Professional Documents

Culture Documents

MDX - Uk DP Gauge Bourdon Haeni

Uploaded by

KUSNOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDX - Uk DP Gauge Bourdon Haeni

Uploaded by

KUSNOCopyright:

Available Formats

MDX/MDA/MDE Bellows pressure gauges

Ø 150 mm

Bellows pressure gauges

For corrosive process fluids and atmospheres

The MDX pressure gauge enables measurement of differential pressures

from 0 + 0.1 bar (1.5 psi) to 0+25 bar (0+400 psi) at static pressures from

0.6 to 100 bar (1500 psi) (see table overleaf).

A set of two stainless steel bellows mounted on a force balance enables

direct reading of the actual differential pressure. Each bellow of the pressure

gauge can withstand the full static pressure without any damage or shifting

being caused to the instrument for P ≤ 25 bar (400 psi); a by-pass valve

is not necessary.

The MDA pressure gauge enables measurement of absolute pressures (from

0.1 bar A to 16 bar A). The low pressure bellow (where vacuum has been

drawn) is used as reference. Not for differential pressures.

The MDE pressure gauge enables measurement of gauge pressures

with high overpressures (from 0 + 0.06 bar G to 0 + 10 bar G). Not for

Low High

differential pressures.

pressure pressure

Specifications (20°C) Options

Ranges MDX, MDA, MDE, see tables overleaf. Coded options

Standard accuracy ± 2% full scale for st. graduations and accuracy

(see table overleaf) BH version : the watertight case can be filled with a vibration dampening liquid with

a degradation of the accuracy of 1%.

Standard degree of protection IP 65 according to EN 60529.

Sensing element Two 1.4404 (AISI 316 L) stainless steel bellows.

Balance effect by high tensile leaf spring ;

mechanical start and end-of-travel stops to Uncoded options (have to be listed after the code number)

withstand full static pressure. Index or set pointer

Connections and parts in contact with process fluid : 1.4401 (AISI 316 L) stainless steel case

1.4401 (AISI 316 L) stainless steel. G 1/2 or 1/2 NPT threads Toughened or laminated glass or perspex window

Operating temperature -40° to + 80° C Degreased for oxygen service or cleaned to other specifications (laboratory,

nuclear...) (Please consult us).

Case and Bezelring 1.4301 (AISI 304) stainless steel. Bayonet lock type. Threads smaller than or equal to G 1/2.

Window Glass, 3 mm thick.

Window gasket Elastomer, ensures a tight seal between glass

window and case.

Movement All stainless steel. Type

Mounting

Direct D F

Surface mounting by means of removable

back flange A E

Flush panel mounting with front flange

welded to case C B

Dial Aluminium alloy, with elastomer zero stop, black

figures and graduations on white background.

Pointer Aluminium alloy, balanced, black painted.

Blow-out disc Elastomer. Positionned on the top of the pressure gauge.

Ensures pressure balance with atmosphere.

Blows out when pressure inside the case

exceeds 0.6 bar (10 psi).

Weight 1.6 kg ("dry" gauge)

2.5 kg (filled with dampening liquid)

www.bourdon-haenni.com Data Sheet A24.02

Design and specifications subject to change without notice Page 1

Dimensions (mm)

MDX - MDA - MDE

3 holes dia. 55 3 holes dia. 55

TYPE C TYPE A TYPE D at 120°

at 120°

MDA - MDE only (1 pressure port)

Panel

cut-out

TYPE B or C

TYPE CAD TYPE BEF

Codification - MDX/MDA/MDE

MDx7 xxx xxxxxx

Family 1 digit

MDX Static pressure

MDX

Pressure gauges M Choose a differential

UK/11-2002 This data sheet may only be reproduced in full

pressure range ∆P

corresponding to the

Type 2´...3´ digit maximum static pres-

MDX DX sure that the instrument

is to withstand. For

MDA DA an intermediate static

MDE DE pressure, take the value

of the static pressure

immediately above.

Dial diameter 4´ digit

Ø 150 mm 7 Code 12 15 16 18 19 20 22 24 26 27 29 31

Type of mounting 5´ digit MDA Overpressure MDA / MDE

bottom connection, back flange A Choose an absolute

pressure range (MDA)

back connection, front flange B or a gauge pressure

bottom connection, front flange C range(MDE) corres-

bottom connection D ponding to the maxi-

mum over pressure

back connection, back flange E that the instrument is

back connection F to withstand. For an

intermediate over

pressure, take the value

Hydraulic connection 6´ digit of the over pressure

G 1/2 3 Code 12 15 16 18 19 20 22 24 26 27 29 31 immediately above.

G 1/2 NPT 6

MDE Overpressure

Type of liquid filling 7´ digit Graduations on 270°

Standard accuracy ± 2 %

Without 0

BH1 filling (-20° to + 70° C) 1 Standard accuracy

BH2 filling (0° to + 90° C) 2 > ± 2 % on 270°

BH3 filling (-40° to + 100° C) 3 Scale < 270°

BH4 filling (-60° to + 100° C) 4 Standard accuracy > ± 2 %

BH5 filling (-15° to + 100° C) 5

BH7 filling (-35° to + 100° C) 7

Code 12 15 16 18 19 20 22 24 26 27 29 31

Unit of measurement 8´ digit

bar B

kPa D

kg/cm2 F

psi H

Pressure range 9´...10´ digit

See codes in table Ranges : ∆P (MDX), absolute (MDA), gauge (MDE), xx

see standard graduations above

Unit of measurement 11´ digit

bar B

kPa D

kg/cm2 F

psi H

Pressure range 12´...13´ digit

See codes in table Static pressure (MDX) overpressure (MDA, MDE) xx

see above

www.bourdon-haenni.com Data Sheet A24.02

Design and specifications subject to change without notice Page 2

You might also like

- Signals Alarms CatalogDocument92 pagesSignals Alarms CatalogSrta IncognitaNo ratings yet

- List of Affordable Housing in SarawakDocument13 pagesList of Affordable Housing in SarawakMohammad Hanafi0% (1)

- Curricula Simplificada UPDATED Oct 2019Document3 pagesCurricula Simplificada UPDATED Oct 2019BJ JOs100% (1)

- Quotation: Stirrup Bender WG 16F-2Document14 pagesQuotation: Stirrup Bender WG 16F-2Andreea IstrateNo ratings yet

- Characteristic Data Standard MaterialsDocument6 pagesCharacteristic Data Standard MaterialsSuresh Kumar MittapalliNo ratings yet

- Po Terms 85 2870030374 3 Us PDFDocument169 pagesPo Terms 85 2870030374 3 Us PDFPrabhavathi RamasamyNo ratings yet

- Theben Timer SUL 181DDocument2 pagesTheben Timer SUL 181DFerdiNo ratings yet

- RegO Pop-Action ValveDocument1 pageRegO Pop-Action ValveSwapnil JawaleNo ratings yet

- 2013-m100k Int'l SparesDocument3 pages2013-m100k Int'l SparesabdulNo ratings yet

- Solar Street Light: Shenzhen Leadray Optoelectronic Co.,LtdDocument7 pagesSolar Street Light: Shenzhen Leadray Optoelectronic Co.,LtdbenyNo ratings yet

- 03.02 - SEW Motor PDFDocument228 pages03.02 - SEW Motor PDFthamirislopesNo ratings yet

- pw-9242v Om KR PDFDocument12 pagespw-9242v Om KR PDFtest2004587No ratings yet

- Camfly PVC Ceilings Catalogue 2Document7 pagesCamfly PVC Ceilings Catalogue 2Onesmas TwinomugishaNo ratings yet

- High Hardness & Toughness New General-Purpose Cold Die SteelDocument2 pagesHigh Hardness & Toughness New General-Purpose Cold Die SteelSinan YıldızNo ratings yet

- Bermad WD 700 Es - Price List - Eur - 2008Document1 pageBermad WD 700 Es - Price List - Eur - 2008Daniel B. BalmoriNo ratings yet

- Ib-4325 Circuit Diagram (New Era Dairy Engineers Pvt. LTD.)Document11 pagesIb-4325 Circuit Diagram (New Era Dairy Engineers Pvt. LTD.)Electrical GyanNo ratings yet

- RFQ 58 - BWallDocument5 pagesRFQ 58 - BWallMahmoud ShakerNo ratings yet

- AA4Document19 pagesAA4Karthik P MuraliNo ratings yet

- Sf-Series Balance Scale: FeaturesDocument1 pageSf-Series Balance Scale: FeaturesEong Huat Corporation Sdn BhdNo ratings yet

- Catalog v1.1 en Web SizeDocument260 pagesCatalog v1.1 en Web SizeMohamed ElbahyNo ratings yet

- Spare Part List MNS 2.0 and MNS 3.0 R0Document12 pagesSpare Part List MNS 2.0 and MNS 3.0 R0Jatupol Pongsirisart33% (3)

- Mat 1400 For Suppliers PDFDocument3 pagesMat 1400 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Rudolf TransducerDocument14 pagesRudolf TransducerBruno Sacchi ArmelimNo ratings yet

- Thermoweld Master - Catalog - by AsiaphilDocument276 pagesThermoweld Master - Catalog - by Asiaphilperijoy100% (1)

- Quo - Sukma Budi Enterprise - MPC 3002 PDFDocument3 pagesQuo - Sukma Budi Enterprise - MPC 3002 PDFZaihanadiah Zainalabidin0% (1)

- Acmv - Symbols & Legend: For TenderDocument1 pageAcmv - Symbols & Legend: For TenderVan DiepNo ratings yet

- 2021-11 Signify Price ListDocument43 pages2021-11 Signify Price Listrajesh chowdary NNo ratings yet

- Rudrra Catalogue PDFDocument36 pagesRudrra Catalogue PDFManikannanNo ratings yet

- Lube Specs PDFDocument94 pagesLube Specs PDFbiggertvNo ratings yet

- DownLight 21WDocument7 pagesDownLight 21Womar bostamiNo ratings yet

- Ceni IntlSalesPriceList (August2015)Document8 pagesCeni IntlSalesPriceList (August2015)Dragan SokolovskiNo ratings yet

- MeDocument381 pagesMeVictor EugenNo ratings yet

- Ebook Ramsey Flex Belt ScalesDocument23 pagesEbook Ramsey Flex Belt ScalesRaymond Ballad100% (1)

- MS-01-181 Stainless Steel Seamless Tubing - Fractional, Metric and ImperialDocument4 pagesMS-01-181 Stainless Steel Seamless Tubing - Fractional, Metric and ImperialJacques StrappeNo ratings yet

- Poi2022 01 Me 0081Document3 pagesPoi2022 01 Me 0081V.Sampath RaoNo ratings yet

- Sandvik Quotation Die Pre-Heater Oven System - India PDFDocument5 pagesSandvik Quotation Die Pre-Heater Oven System - India PDFMalgudi Shiva100% (1)

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- Empanelment of Vendors For Major Electrical Items in DMRC PDFDocument17 pagesEmpanelment of Vendors For Major Electrical Items in DMRC PDFSatish KumarNo ratings yet

- EbharaDocument73 pagesEbharahippong niswantoroNo ratings yet

- Mitsubishi Heavy Industries KX2 SMDocument212 pagesMitsubishi Heavy Industries KX2 SMАртур Бобкин100% (1)

- Electric Actuator Catalogue - Complete2Document22 pagesElectric Actuator Catalogue - Complete2Bhupal Raju100% (1)

- ID Fan Dodge BRGDocument4 pagesID Fan Dodge BRGjhanduNo ratings yet

- Prosintech CatalogDocument6 pagesProsintech CatalogDeepak PatelNo ratings yet

- Anderson International Corp 8" Expander-Extruder-CookerDocument2 pagesAnderson International Corp 8" Expander-Extruder-CookertauNo ratings yet

- Structure and Features: Mounting Holed Type High Rigidity Crossed Roller Bearings VDocument14 pagesStructure and Features: Mounting Holed Type High Rigidity Crossed Roller Bearings VMuhammad JunaidNo ratings yet

- Gexol PDFDocument36 pagesGexol PDFclaudiogut123No ratings yet

- Fly Ash BrickDocument8 pagesFly Ash BrickYashraj PatidarNo ratings yet

- CG Price List W.e.f.14.03.11Document38 pagesCG Price List W.e.f.14.03.11viksursNo ratings yet

- Ge Gas Engine 18 MWDocument1 pageGe Gas Engine 18 MW123habib123fikriNo ratings yet

- 2010-05-31 Schunk Carbon-Brush Shaft GroundingDocument7 pages2010-05-31 Schunk Carbon-Brush Shaft GroundingcorsairsanNo ratings yet

- Standard Products: INR Price List No. DFL-08 Effective 1st Oct 2018Document11 pagesStandard Products: INR Price List No. DFL-08 Effective 1st Oct 2018RAHUL RICONo ratings yet

- JBJBDocument116 pagesJBJBk.saikumarNo ratings yet

- Data Sheet Wind Turbine SWT 3-6-120Document3 pagesData Sheet Wind Turbine SWT 3-6-120ermarmonNo ratings yet

- Purchase Order-PO - 01333 - 22-23Document2 pagesPurchase Order-PO - 01333 - 22-23Jayapal100% (1)

- Sewage Treatment Plant 350CmD (MBBR)Document2 pagesSewage Treatment Plant 350CmD (MBBR)John Axl LajomNo ratings yet

- Mat 3800 For Suppliers PDFDocument3 pagesMat 3800 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Bourdon Tube Pressure Gauges Stainless Steel, Safety Pattern Version, High Overpressure Safety Model 232.36/233.36, Without/with Liquid FillingDocument2 pagesBourdon Tube Pressure Gauges Stainless Steel, Safety Pattern Version, High Overpressure Safety Model 232.36/233.36, Without/with Liquid FillingRichard EVNo ratings yet

- DTS Ks-Sil2 01-2019 Eng PDFDocument8 pagesDTS Ks-Sil2 01-2019 Eng PDFMiguel Ángel CenamorNo ratings yet

- Low Noise Solenoid Controlled Relief ValvesDocument7 pagesLow Noise Solenoid Controlled Relief ValveshectorNo ratings yet

- Bourdon Tube Pressure Gauges Stainless Steel Series Model 232.50/233.50, Without/with Liquid FillingDocument2 pagesBourdon Tube Pressure Gauges Stainless Steel Series Model 232.50/233.50, Without/with Liquid Fillingkholik arenNo ratings yet

- Dwyer - l6 - Series - Level - Switch - Manual - LEVEL TANK WATER CHILLER LQDocument4 pagesDwyer - l6 - Series - Level - Switch - Manual - LEVEL TANK WATER CHILLER LQKUSNONo ratings yet

- Datasheet Ordering Vibration Switch Metrix Model 5550Document1 pageDatasheet Ordering Vibration Switch Metrix Model 5550KUSNONo ratings yet

- ALTOSONIC IV - Technical Datasheet - 20FT - 001 - Test SeparatorDocument4 pagesALTOSONIC IV - Technical Datasheet - 20FT - 001 - Test SeparatorKUSNONo ratings yet

- Belt Loader Pinch Point Caught InbetweenAGSP 5-20-16 Kusno WeweDocument3 pagesBelt Loader Pinch Point Caught InbetweenAGSP 5-20-16 Kusno WeweKUSNONo ratings yet

- Confined Spaces Physical HazardsDocument1 pageConfined Spaces Physical HazardsKUSNONo ratings yet

- Union Test Prep Nclex Study GuideDocument115 pagesUnion Test Prep Nclex Study GuideBradburn Nursing100% (2)

- Moquerio - Defense Mechanism ActivityDocument3 pagesMoquerio - Defense Mechanism ActivityRoxan MoquerioNo ratings yet

- Mozal Finance EXCEL Group 15dec2013Document15 pagesMozal Finance EXCEL Group 15dec2013Abhijit TailangNo ratings yet

- EKRP311 Vc-Jun2022Document3 pagesEKRP311 Vc-Jun2022dfmosesi78No ratings yet

- 1.SDH Basics PDFDocument37 pages1.SDH Basics PDFsafder wahabNo ratings yet

- Hazardous Locations: C.E.C. ClassificationsDocument4 pagesHazardous Locations: C.E.C. ClassificationsThananuwat SuksaroNo ratings yet

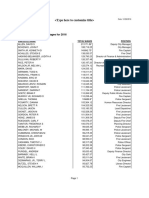

- 2016 W-2 Gross Wages CityDocument16 pages2016 W-2 Gross Wages CityportsmouthheraldNo ratings yet

- Student Management SystemDocument232 pagesStudent Management Systemslu_mangal73% (37)

- CORP2165D Lecture 04Document26 pagesCORP2165D Lecture 04kinzi chesterNo ratings yet

- Project Formulation and Appraisalpdf PDFDocument12 pagesProject Formulation and Appraisalpdf PDFabhijeet varadeNo ratings yet

- Who Trs 993 Web FinalDocument284 pagesWho Trs 993 Web FinalAnonymous 6OPLC9UNo ratings yet

- Marketing Channels: A Strategic Tool of Growing Importance For The Next MillenniumDocument59 pagesMarketing Channels: A Strategic Tool of Growing Importance For The Next MillenniumAnonymous ibmeej9No ratings yet

- 928 Diagnostics Manual v2.7Document67 pages928 Diagnostics Manual v2.7Roger Sego100% (2)

- Aliping PDFDocument54 pagesAliping PDFDirect LukeNo ratings yet

- UM-140-D00221-07 SeaTrac Developer Guide (Firmware v2.4)Document154 pagesUM-140-D00221-07 SeaTrac Developer Guide (Firmware v2.4)Antony Jacob AshishNo ratings yet

- Chapter 1Document6 pagesChapter 1Grandmaster MeowNo ratings yet

- Statistics and Probability: Quarter 4 - (Week 6)Document8 pagesStatistics and Probability: Quarter 4 - (Week 6)Jessa May MarcosNo ratings yet

- Matka Queen Jaya BhagatDocument1 pageMatka Queen Jaya BhagatA.K.A. Haji100% (4)

- Current Concepts in Elbow Fracture Dislocation: Adam C Watts, Jagwant Singh, Michael Elvey and Zaid HamoodiDocument8 pagesCurrent Concepts in Elbow Fracture Dislocation: Adam C Watts, Jagwant Singh, Michael Elvey and Zaid HamoodiJoão Artur BonadimanNo ratings yet

- Product NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Document14 pagesProduct NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Paras ShardaNo ratings yet

- Walking in Space - Lyrics and Chord PatternDocument2 pagesWalking in Space - Lyrics and Chord Patternjohn smithNo ratings yet

- Codan Rubber Modern Cars Need Modern Hoses WebDocument2 pagesCodan Rubber Modern Cars Need Modern Hoses WebYadiNo ratings yet

- VMP 930 Veterinary Parasitology: Paragonimus KellicottiDocument63 pagesVMP 930 Veterinary Parasitology: Paragonimus KellicottiRenien Khim BahayaNo ratings yet

- The Wayland News October 2014Document16 pagesThe Wayland News October 2014Julian HornNo ratings yet

- Satish Gujral - FinalDocument23 pagesSatish Gujral - Finalsatya madhuNo ratings yet

- M. Ircham Mansyur 07224005 Microprocessor-2 (H13)Document7 pagesM. Ircham Mansyur 07224005 Microprocessor-2 (H13)emiierNo ratings yet

- Mathematics BQP 2022Document43 pagesMathematics BQP 2022muhammadmansuri815No ratings yet

- Top 100 Chemical CompaniesDocument11 pagesTop 100 Chemical Companiestawhide_islamicNo ratings yet

- Decision Trees For Management of An Avulsed Permanent ToothDocument2 pagesDecision Trees For Management of An Avulsed Permanent ToothAbhi ThakkarNo ratings yet

- Top Activist Stories - 5 - A Review of Financial Activism by Geneva PartnersDocument8 pagesTop Activist Stories - 5 - A Review of Financial Activism by Geneva PartnersBassignotNo ratings yet