Professional Documents

Culture Documents

EL 2200 EH 2900 GB Epoxy Laminating System Product Datasheet

Uploaded by

Wellington SilvaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EL 2200 EH 2900 GB Epoxy Laminating System Product Datasheet

Uploaded by

Wellington SilvaCopyright:

Available Formats

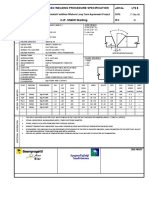

EL-2200 / EH-2900

Epoxy Laminating and Multipurpose Resin

Room temperature curing, unfilled, low viscosity

© RAMPF Tooling Solutions GmbH & Co. KG MAEI - Rev.Status: 01-2021/07/01 - GB Page 1/ 2

Key Properties Applications

● Room temperature curing ● Universal production of tools and tooling aids

● Good compatibility with glass fibers and fillers ● Binder for quartz sand and fabrics

● With short glass fibers (6mm) also suitable for

coupling layers

● With mineral and metallic fillers suitable as

backing casting

Processing Properties

Unit EL-2200 EH-2900

Color visual colorless yellowish

Mix ratio pbw 100 20

Density ISO 1183 g/cm³ ca. 1.10 ca. 1.03

Viscosity at 25 °C DIN 53019-1 mPa·s 2,000 - 3,000 450 - 750

Unit EL-2200 / EH-2900

Mix viscosity at 25 °C DIN 53019-1 mPa·s 1,000 - 1,300

Pot life at 25 °C 500 ml min 70 - 90

Max. layer thickness mm 8

Demold time h 16

Cured / Mechanical Properties

Unit EL-2200 / EH-2900

Cure 7 days at RT or 14h at 40°C

01 Color visual yellowish

02 Density ISO 1183 g/cm³ ca. 1.10

03 Deflection temperature, HDT ISO 75 °C 53 - 58

04 Glass transition temperature, Tg DSC °C 55 - 60

05 Flexural strength ISO 178 MPa 110 - 115

06 Flexural modulus ISO 178 MPa 2,500 - 3,000

RAMPF Tooling Solutions GmbH & Co. KG

Robert-Bosch-Str.8 - 10 |D-72661Grafenberg

E tooling.solutions@rampf-group.com

www.rampf-group.com

EL-2200 / EH-2900

Epoxy Laminating and Multipurpose Resin

Room temperature curing, unfilled, low viscosity

© RAMPF Tooling Solutions GmbH & Co. KG MAEI - Rev.Status: 01 - 2021/07/01 - GB Page 2/ 2

Processing

The processing temperature and material temperature should be between 20-25°C.

Degassing is recommended.

Impregnate each layer of cloths to construct the laminate layer by layer.

Post curing will improve final properties.

Packaging

RAKU® TOOL EL-2200 1.000 kg, 220 kg, 25 kg

RAKU® TOOL EH-2900 204 kg, 22 kg, 5 kg

Storage

Original containers should be kept tightly sealed and stored at ambient temperatures (15°C to 30°C). If properly stored

the products have the shelf-life indicated on the product label. Partly used containers should always be sealed

appropriately and used up as soon as possible.

Handling precautions

Good workplace ventilation is to be ensured during processing. At the same time, the employer’s liability insurance

association’s industrial hygiene safety regulations regarding the handling of reaction resins and their hardeners are to

be observed. Please take heed of the appropriate safety data sheets.

RAMPF Tooling Solutions GmbH & Co. KG Our recommendations on the use of the material are based on many years of experience

Robert-Bosch-Str.8 - 10 | D-72661Grafenberg and current scientific and practical knowledge. They are, however, provided without any

obligation on our part and do not relieve the buyer of the need for suitability tests. They do

T+49.71 23.93 42-1600

not constitute a legal relationship, nor are any protected third party rights whatsoever

+49.71 23.93 42-16 66 affected thereby. The technical data sheet is not a specification, but contains only

E tooling.solutions@rampf-group.com approximate values.

www.rampf-group.com

EL-2200-001|E2200_001_V1

You might also like

- Poweroil To 1020 60 SNX: SR No Characteristics Unit Test Method Guaranteed Data Min MaxDocument1 pagePoweroil To 1020 60 SNX: SR No Characteristics Unit Test Method Guaranteed Data Min MaxWellington SilvaNo ratings yet

- 11.SDS To 1020 60 SNXDocument8 pages11.SDS To 1020 60 SNXWellington SilvaNo ratings yet

- 11.SDS To 1020 60 SNXDocument8 pages11.SDS To 1020 60 SNXWellington SilvaNo ratings yet

- Poweroil To 1020 60 Ux: SR No Characteristics Unit Test Method Guaranteed Data Min MaxDocument1 pagePoweroil To 1020 60 Ux: SR No Characteristics Unit Test Method Guaranteed Data Min MaxWellington SilvaNo ratings yet

- 11.SDS To 1020 60 SNXDocument8 pages11.SDS To 1020 60 SNXWellington SilvaNo ratings yet

- EL 2200 EH 2900 GB Epoxy Laminating System Product DatasheetDocument2 pagesEL 2200 EH 2900 GB Epoxy Laminating System Product DatasheetWellington SilvaNo ratings yet

- Annual Report 2010Document137 pagesAnnual Report 2010Wellington SilvaNo ratings yet

- SC0x LiveEvent2 StatisticsDocument14 pagesSC0x LiveEvent2 StatisticsWellington SilvaNo ratings yet

- s2c-s h6r AccDocument5 pagess2c-s h6r AccWellington SilvaNo ratings yet

- 7ST30I00Document8 pages7ST30I00Wellington SilvaNo ratings yet

- 7BL70XXDocument6 pages7BL70XXWellington SilvaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Shell EnsisFluidDocument2 pagesShell EnsisFluidEmiliano BoggianoNo ratings yet

- Asian Paints Woodtech Aquadur Dent FillerDocument2 pagesAsian Paints Woodtech Aquadur Dent FillerKedar PendharkarNo ratings yet

- Meat Grinder ReportDocument10 pagesMeat Grinder Reportadem3521No ratings yet

- Manufacturing Process of Plastic BottlesDocument13 pagesManufacturing Process of Plastic BottlesAparna SamuelNo ratings yet

- Trickling FilterDocument26 pagesTrickling FilterMayank SaxenaNo ratings yet

- Work Permit FormatDocument12 pagesWork Permit FormatAejaz Mujawar0% (1)

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Corrothane I Zinc PrimerDocument4 pagesCorrothane I Zinc PrimerImam SitumeangNo ratings yet

- Glosario de Terminos en ExtrusionDocument11 pagesGlosario de Terminos en ExtrusionWalter MirandaNo ratings yet

- Omega Air Product Data Sheet Filter Element HF-R v3.02Document2 pagesOmega Air Product Data Sheet Filter Element HF-R v3.02VictorNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Logan Fishing Bumper Sub (English)Document26 pagesLogan Fishing Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaNo ratings yet

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- 5 Paint TypesDocument136 pages5 Paint TypesManohar Seetharam100% (2)

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocument3 pagesMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNo ratings yet

- Protek Composite Wear PadDocument1 pageProtek Composite Wear PadWilliam ChipanaNo ratings yet

- GCSE Woods Paper & Card TheoryDocument6 pagesGCSE Woods Paper & Card TheoryMissparish8No ratings yet

- REPORT Eng TrainingDocument11 pagesREPORT Eng TrainingTareq Al HasanNo ratings yet

- Ovr Dossier.Document93 pagesOvr Dossier.suria qaqcNo ratings yet

- Tinta SprayDocument9 pagesTinta SprayManuel F O MouraNo ratings yet

- PRT 203 - Metal Forming and FabricationDocument130 pagesPRT 203 - Metal Forming and FabricationNiyonase OlivierNo ratings yet

- Cold Drawn Lap Defect - Google SearchDocument2 pagesCold Drawn Lap Defect - Google SearchIvan GutierrezNo ratings yet

- Screw JackDocument1 pageScrew Jackhola100% (1)

- Steel As Construction MaterialDocument21 pagesSteel As Construction MaterialMinari SonNo ratings yet

- How To Make A DIY Wood HeadboardDocument4 pagesHow To Make A DIY Wood HeadboardRi SovannaphumiNo ratings yet

- Forging SDocument14 pagesForging SGowrisanthosh PalikaNo ratings yet

- Gyproc 2Document3 pagesGyproc 2Govind NataniNo ratings yet

- Nitobond EPDocument2 pagesNitobond EPabhay_joshi2002No ratings yet

- Design & Analysis of Portable Shell Moulding MachineDocument5 pagesDesign & Analysis of Portable Shell Moulding MachineNeelNo ratings yet

- Linemans Apprentice Tool List - Clickable PDFDocument11 pagesLinemans Apprentice Tool List - Clickable PDFRoshNo ratings yet