Professional Documents

Culture Documents

VP-12-210-001-ALL-P-004 Packing

Uploaded by

Neelam AhmadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VP-12-210-001-ALL-P-004 Packing

Uploaded by

Neelam AhmadCopyright:

Available Formats

DOC. NO.

: VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 2 OF 15

TABLE OF CONTENT

1. APPLICATION

2. PACKAGE SPECIFICATIONS

2.1. PREPARATION OF MATERIALS BEFORE PACKING

2.2. PACKAGE WEIGHT AND DIMENSIONS

2.3. APPLICABLE PACKING STYLE

3. SKID MOUNTED CONSTRUCTION

4. TAGGING

5. SHIPPING MARK

6. MARKING

7. SKID

8. CARE MARK

9. PACKING INSPECTION

10. OTHER REQUIREMENTS

11. APPENDIX

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 3 OF 15

1. APPLICATION

This Procedure is intended as minimum requirements for protecting all Materials by applying the

packing with inside fastening and/or water/moisture proofing application. If these requirements are

incomplete, the best packing particle shall be proposed in order to ensure that all Materials arrive at

the destination in undamaged conditions or safe delivered condition.

This Procedure is integration to Purchaser’s specification and is to be used as guideline for the

packing, protection and marking activities.

Applicable Project Specification :

- LPG4-PGP-004(Rev.A) : “Packing and Marking Specification”

- DEP 31.22.20.31 : “Pressure Vessels”

2. PACKAGE SPECIFICATIONS

2.1. PREPARATION OF MATERIALS BEFORE PACKING

All Materials shall be dry, clean, and free from all defects prior to packing. Protection against

environment corrosion caused by extremes of humidity, condensation, rain, sand, salted air, and sea

spray shall be provided. In general, Rust prevention procedures adopted shall be in accordance with

requirements given in the technical specifications attached to the Purchase Order.

The following requirements shall be considered as minimum essential protective measures for

Materials;

2.1.1 All carbon steel machined surfaces (including flange faces), threads, and weld preps shall

be coated with a heavy greased.

2.1.2 All flanges shall be covered with 6mm steel plates (with at least four bolts) with mastic

sealer or rubber gasket between the flange and the cover. (See Surface preparation and

Painting procedure; Doc No. VP-12-210-001-ALL-P-017)

2.1.3 Spare part and loose part shall be wrapped in fully watertight barrier material adequate to

prevent external moisture from contacting the contents and enclosed in wood containers

adequate to prevent physical damage during shipment.

2.1.4 Small component parts like washer, shim plate, sliding plate, setting bolt, bearing plate,

etc. shall be shipped separately

2.1.5 Pressure vessels that are transported over the ocean shall be purged with an inert gas

such as Nitrogen at a pressure of not less than 35kpa (5 psi). The Principal shall specify if

a purge is required for over-land transport.

Please refer to APPENDIX 5. Nitrogen purge procedure.

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 4 OF 15

2.2. PACKAGE WEIGHT AND DIMENSIONS

2.2.1 Minimum Weight and Volume

Export for dangerous or hazardous items, wherever possible, each consignment should

be made into packages not less than 200kg in weight or not less than 0.5cubic meters in

volume so that theft and loss during transportation may be eliminated. If any packages do

not come within these limits, the Vendor shall immediately inform owner (client)’s liaison

office.

2.2.2 Maximum Weight and Dimensions

The maximum weight and dimensions of each package shall be limited as follows:

1) Weight : up to 20 tons

2) Length : up to 10 meters

3) Width : up to 2.3 meters

4) Height : up to 2.3 meters

2.2.3 Heavy or Oversized Cargo

When individual package dimensions or gross weights exceed the maximum limitations

(para. 2.2.2) due to the nature of Materials, the Vendor shall submit to owner’s liaison

office forty five (45) days prior to the commencement of shipment, packing sketches in

four (4) copies, clearly indication net and gross weight, length, width and height, center of

gravity, positions of skids and their sizes, lifting lugs or traverses, etc., together with any

recommendations for special handling. Packing sketches shall be approved by carrier

2.3. APPLICABLE PACKING STYLE

The Vendor shall suitably pack all Materials based on appendix 1. Packing Style Criteria. If the

Vendor’s packing deviates from the criterion, the vendor shall obtain prior approval from owner’s

liaison office.

2.4. SEAWORTHY PACKING

The Vendor shall make every effort to ensure that all packages or Materials are as compact and

durable as possible.

All packages shall be properly and solidly made to withstand all mechanical and chemical damage that

may be reasonably expected during ocean and land transportation and transportation loads.

All packages design and construction shall also take into account the following eventualities:

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 5 OF 15

2.4.1 Handling at the loading and unloading ports 3 or 4 times.

2.4.2 Outdoor storage for an extended period after shipment.

2.4.3 Significant variation in ambient temperature during ocean shipment.

2.4.4 Because top stage in ship’s hatches cannot be ensured, provision for supporting and

overburden of three or four layers of general cargo shall be included in package design

and construction.

2.4.5 All wood packing and crating materials must meet ISPM (International Standard for

Phytosanitary Measures) 15 requirements and be stamped accordingly.

Extra cost due to nonperformance by the Vendor with these instructions without prior approval by owner shall

be borne by or backhanded to the Vendor

3. SKID MOUNTED CONSTRUCTION

This Procedure is intended as minimum requirements for protecting all Materials by applying the

packing with inside fastening and/or water/moisture proofing application. If these requirements are

incomplete, the best packing particle shall be proposed in order to ensure that all Materials arrive at

the designated place.

Vessel, may be shipped bare, mounted on skids fixed in position with steel wire ropes or flat steel bars

as shown in appendix 3.

The following requirements shall be considered for skid-mounted construction;

1) The size and position of the skids are subject to the minimum requirements given in appendix 3 and

should be sufficient to ensure safe handling during long distance transportation. Steel wire ropes shall

be appropriately tensioned, taking into account possible slack caused by wood shrinkage.

2) The maximum distance between skids shall be 8 meters.

3) The dimensions of the skids shall be determined as shown in Table 1.

Table 1. SKID DIMENSIONS (WOOD)

Net Weight of Package (Tons) Skid Widths (mm)

Under 10 120

10 to under 30 180

30 to under 50 300

50 to under 80 450

80 and over 600

4) When using skids made of two or more pieces of lumber, bolts shall be used. Fastening by wire is

strictly prohibited.

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 6 OF 15

5) For equipment either weight in excess of 15 tons or with a shell plates thickness of 6mm or less,

areas where sling rope and metal surface come into contact shall be covered and protected with

wooden slats.

6) Strips of non-combustible material such as polypropylene cloth shall be placed between skids and

Materials, and between restraining straps/wires and materials.

7) Shipping saddles shall be of steel or of steel reinforced timber construction and shall be contoured

to fit with sufficient contact surface to prevent damage or permanent distortion to the vessel assembly.

The minimum contact arc length shall be 120°. Auxiliary removable spiders, struts, bands, and/or

stiffening rings shall be provided where required. Temporary supports which are in contact with high

alloy vessels during shipping or storage shall not be of a moisture retaining material such as raw wood.

4. TAGGING

Tags shall be attached to all Materials. Tags shall state the following information.

1) Project Name 2) P.O Number

3) Item Number 4) Description

5) Size and Quantity 6) Name of Vendor

5. SHIPPING MARK

Marking shall be carried out in accordance with the Project Packing and Marking Procedure.

The shipping mark shall be stenciled on two opposite side with black, indelible and sea waterproof

paint as follows.

SHIPPING MARK

LPG Train-4 Project

DESTINATION : (PORT NAME) PORT, (COUNTRY)

P/O NO. :

PACKAGE NO. :

ITEM/TAG NO. :

GR/NET WT. :

DIMENSION :

SHIPPING PORT :

MADE IN :

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 7 OF 15

6. MARKING

6.1. See attached appendix 2. Marking specifications for Boxes and shrink-wrapped Packages.

6.2. All vessels that have been post weld heat treated shall have the following markings made, 180°

apart, in letters that are 75mm (3 in) high:

“POST WELD HEAT TREATED – DO NOT BURN OR WELD”

7. SKID

See attached appendix 3. Skid Mounted Construction.

8. CARE MARK

See attached appendix 4-1, 4-2. Position of Main and Auxiliary Shipping Marks.

9. PACKING INSPECTION

9.1. Vendor shall guarantee and warrant that the packing meets the requirements of this instruction.

9.2. Visual, Dimensional and other inspection shall be conducted by the Purchaser’s inspector.

9.3. The Vendor shall notify the Purchaser of the date and place at least ten (10) days prior to the

date of scheduled inspection.

10. OTHRE REQUIREMENTS

10.1. An adequate shock absorbing materials shall be filled in the package to prevent the damage

during transportation.

10.2. In the case of required by purchaser, vessel shall be charged with the specified insert gas (N2)

with pressure gauge

11. APPENDIX

11.1. ***APPENDIX 1-1 ~ 1-3. : PACKING STYLE CRITERIA, BOX AND CRATE CONSTRUCTION,

MAJOR FRAME CONSTRUCTION OF BOX OR CRATE.

11.2. ***APPENDIX 2. : MARKING SPECIFICATIONS FOR BOXES, CRATE AND SHRINK-

WRAPPED PACKAGES.

11.3. ***APPENDIX 3. : SKID MOUNTED CONSTRUCTION.

11.4. ***APPENDIX 4-1 ~ 4-2 : POSITION OF MAIN AND AUXILIARY SHIPPING MARKS.

11.5. ***APPENDIX 5. : NITROGEN PURGE PROCEDURE

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 8 OF 15

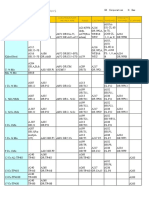

** APPENDIX 1-1.

PACKING STYLE CRITERIA

M W

S

O O W

W T S

I O O

A E T

S D O

T E P E

T C E D

B E S L B A E

U B R N E

O R K A L L

Category Item R O A N

X P I B R L

E X T B

R D U E E D

P E U D

O N T R

R N R

O D U

O D U

F L M

O L M

E

F E

Body 1m (D) x 2m(L) or less X

Body more than 1m(D) x 2m(L) X

Column. Reactor,

Drum, Heat Tray, Internal, small Parts, Test Ring X X

Vessel

Stage, Ladders Handrail, Platform, etc X X

Anchor Bolt X

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 9 OF 15

*** APPENDIX 1-2.

BOX AND CRATE CONSTRUCTION

Style 1. Style 2.

Wooden framed box Box weight up to 450Kg

Net weight 451Kg to 7,000Kg

Style 1. Style 1.

Open crate Crate

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 10 OF 15

*** APPENDIX 1-3.

MAJOR FRAME CONSTRUCTION OF BOX OR CRATE

Unit : Cm

Box Framed Box or Crate

No Frame Description

701 to 2,001 to 4,001 to

Up to 450Kg 451 to 700Kg

2,000Kg 4,000Kg 7,000Kg

1 Skid 9.0 X 4.5 9.0 X 6.0 9.0 X 9.0 9.0 X 9.0 10.0 X 10.0

2 Header 6.0 X 6.0 6.0 X 6.0 9.0 X 6.0 9.0 X 7.5 9.0 X 9.0

3 Lower Frame Member - 3.0 X 9.0 3.5 X 9.0 4.5 X 9.0 4.5 X 9.0

4 Strut 2.4 X 9.0 3.0 X 9.0 3.5 X 9.0 4.5 X 9.0 4.5 X 9.0

5 Upper Frame Member - 3.0 X 9.0 3.5 X 9.0 4.5 X 9.0 4.5 X 9.0

The distance of each vertical struts shall read maximum

6 + Shaped Bracing - 300mm. The distance of each horizontal struts shall read

maximum 600mm.

Sheathing

L = 1.9 L = 1.8 L = 1.8 L = 1.8 L = 1.8

7 L = Lumber

P = 0.9 P = 0.9 P = 0.9 P = 0.9 P = 1.2

P = Plywood

1. Other detailed construction shall be designed by the seller.

2. Frame construction of crates containing over 7 tons must be designed by the seller with the buyer’s approval.

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 11 OF 15

*** APPENDIX 2.

MARKING SPECIFICATIONS FOR BOXES, CRATES

AND SHRINK WRAPPED PACKAGES

INK

MARK

MARK SIZE REMARKS

LOCATION

COLOR MATERIAL

High quality

Optimum size for

Main shipping mark Black waterproof ink or Both sides

each package

oil paint

C Sling mark and

a Center of Both sides

r gravity mark

e High quality

Optimum size for

Red waterproof ink or

each package

M oil paint Top mark : both

a sides and ends

r Other marks

k Others : both

ends

Only for packages exceeding

High quality

Both sides, ends 5tons;

Approximate weight Black waterproof ink or 15cm and over

and top hand writing is permissible;

oil paint

unit shall be tons

Yellow letters on

Upper part of one L :14cm Do not overlap with care

Packing list cover black back- Enamel

end W:18cm mark: use tinplated

ground

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 12 OF 15

*** APPENDIX 3.

SKID MOUNTED CONSTRUCTION

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 13 OF 15

*** APPENDIX 4-1.

POSITION OF MAIN AND AUXILIARY SHIPPING MARKS

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 14 OF 15

*** APPENDIX 4-2.

AUXILIARY SHIPPING MARKS

No. Name of Mark Stenciled Marks and Letters Remarks

1 Center of Gravity At the center of gravity

Where sling wire is to be

2 Sling

applied

When package cannot be

3 Top

placed upside down

For boxes that need

4 Keep dry protection from water and

KEEP DRY moisture

5 Handle with Care For fragile cargo

HANDLE WITH CARE

Heavy weight When center of gravity is on

6

this end one side

HEAVY WEIGHT THIS END

ALPHA TECHWIN CO., LTD.

DOC. NO. : VP-12-210-001-ALL-P-004

PACKING PLAN REV. NO. : 3

PAGE : 15 OF 15

*** APPENDIX 5.

NITROGEN PURGE PROCEDURE

1. Cleaning the Vessel inside

Those of the vessel shall be completely and thoroughly cleaned from all loose scales, weld slags,

chips, debris and other foreign matters prior to N2 purging.

2. Sealing the opening of vessel

The opening of nozzles or flanges shall be sealed or welded with min.6mm thickness of steel plate

or stainless plate with the gasket, and it will be fastened with at least four bolt & nuts.

3. Preparation for N2 purge

One set of the pressure gauge will be installed, one is to be installed vessel top side and the other is

to be installed bottom-side, N2 pressure gauge may be prepared as followed sketch.

4. Nitrogen purging and charging

The vessel inside shall be purged N2 gas until to raised above 35kpa (5psi), this pressure shall be

checked two gauges, located top and bottom of the equipment, and then leakage check shall be

performed by soap-bubble spray test for each flanges.

ALPHA TECHWIN CO., LTD.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument17 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument8 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Astm Designation of Materials: SK Corporation H. BaeDocument4 pagesAstm Designation of Materials: SK Corporation H. BaeNeelam AhmadNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- VP-12-210-001-ALL-P-010 Spare Parts ListDocument4 pagesVP-12-210-001-ALL-P-010 Spare Parts ListNeelam AhmadNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- SATR-L-2001 Rev. 5Document10 pagesSATR-L-2001 Rev. 5Neelam AhmadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- CV For Ac TechnicianDocument3 pagesCV For Ac TechnicianNeelam Ahmad100% (6)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 5.1. 402020-01391-08-PI-SPC-0001 Rev0Document58 pages5.1. 402020-01391-08-PI-SPC-0001 Rev0sumit kumarNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- O'Bannon Well Servicing Tools-1Document28 pagesO'Bannon Well Servicing Tools-1Praveen ChoudharyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Akaki Metal FactoryDocument104 pagesAkaki Metal Factoryßélå Åß MélÉssê75% (4)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Rovalve Fig 220 Knife Gate Valve 2 - 24 InchDocument2 pagesRovalve Fig 220 Knife Gate Valve 2 - 24 InchCapacitacion TodocatNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- IDS 302 1001 002 General Purpose MEK BlackDocument3 pagesIDS 302 1001 002 General Purpose MEK BlackFarid DiazNo ratings yet

- Quality Assurance Plan: Sheet MetalDocument2 pagesQuality Assurance Plan: Sheet Metalsabir hussain0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Introduction To Manufacturing: Chapter 13: RollingDocument19 pagesIntroduction To Manufacturing: Chapter 13: RollingLue niNo ratings yet

- Belts Mishuboshi (Industrial Power Transmission Products)Document90 pagesBelts Mishuboshi (Industrial Power Transmission Products)dangdinhthyNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Metal Mining Sector Update - MNC SekuritasDocument8 pagesMetal Mining Sector Update - MNC SekuritasZhuanjian LiuNo ratings yet

- Butler Basic Erection GuideDocument68 pagesButler Basic Erection Guidekarim hassanNo ratings yet

- ME8351-Manufacturing Technology-IDocument12 pagesME8351-Manufacturing Technology-IShrinath MPCBNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Proposal For Chemical Shed at Keraniganj - 15.04.21Document14 pagesProposal For Chemical Shed at Keraniganj - 15.04.21HabibNo ratings yet

- ATECC BQ Template Door and WindowDocument21 pagesATECC BQ Template Door and WindowAizuddinNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fme6 Activity2 PDFDocument7 pagesFme6 Activity2 PDFFred BorjaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Part 1: Multi Panel System General: 30BXD Ceiling Panels Can Be Featured With A 30 MM Open JointDocument3 pagesPart 1: Multi Panel System General: 30BXD Ceiling Panels Can Be Featured With A 30 MM Open JointBogdan MucenicaNo ratings yet

- Chapter 03 Tools and FastenersDocument5 pagesChapter 03 Tools and FastenersRajvir GrewalNo ratings yet

- On The Balance Trade David HumeDocument6 pagesOn The Balance Trade David HumeaguspastelinNo ratings yet

- 1 in GEM CLAMP - 21-MEC - WITH PLATEDocument19 pages1 in GEM CLAMP - 21-MEC - WITH PLATEbubbacupcakeNo ratings yet

- Hole Saws: HSS Bi-Metal Hole Saws, With Varied ToothingDocument1 pageHole Saws: HSS Bi-Metal Hole Saws, With Varied ToothingFahd AfifiNo ratings yet

- GeM Bidding 2895906Document25 pagesGeM Bidding 2895906Hussain ShaikhNo ratings yet

- Overview of DRI & Pellet in Iran:, Sirjan Jahn Steel ComplexDocument38 pagesOverview of DRI & Pellet in Iran:, Sirjan Jahn Steel Complexsoheil_vjNo ratings yet

- World Directory of LBMA-Accredited RefineriesDocument3 pagesWorld Directory of LBMA-Accredited RefineriesSamscribdingNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- GLHuyettPinsCat2015 WebSecure PDFDocument276 pagesGLHuyettPinsCat2015 WebSecure PDFJose BonifazNo ratings yet

- 19M024 Internship ReportDocument59 pages19M024 Internship ReportEALMER100% (1)

- Manufacturing Process - 3rdDocument2 pagesManufacturing Process - 3rdKodok SuperNo ratings yet

- Fitting LabDocument8 pagesFitting LabArun kumar rouniyarNo ratings yet

- Handling and Storage of Reinforcing BarsDocument2 pagesHandling and Storage of Reinforcing BarsLiyakhat aliNo ratings yet

- Consumables CatalogDocument128 pagesConsumables CatalogJabbar FarajNo ratings yet

- Introduction To Extrusion Blow MouldingDocument24 pagesIntroduction To Extrusion Blow MouldingZailaniMuhammadNo ratings yet

- EE Rejillas Magnéticas (SB-200DD)Document24 pagesEE Rejillas Magnéticas (SB-200DD)angelsiddhartaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)