Professional Documents

Culture Documents

Workspaces For Storing Hazardous Materials and For Heavy Construction Equipment Have Higher Risks Than Other Workspaces

Workspaces For Storing Hazardous Materials and For Heavy Construction Equipment Have Higher Risks Than Other Workspaces

Uploaded by

Mohammed Salman Khan0 ratings0% found this document useful (0 votes)

9 views2 pages1) Workspaces for storing hazardous materials and heavy equipment, as well as excavation sites, pose higher safety risks and should be properly identified and protected.

2) There is a need for a proactive safety plan to reduce construction accidents, as current methods are insufficient for ensuring safety measures are properly implemented.

3) Prioritizing construction site safety through training, barriers, and hazard awareness boosts worker productivity and morale by preventing injuries and fatalities from falls and electrocutions.

Original Description:

Description of Unsafe Equipment Storage in construction

Original Title

Unsafe Equipment Storage

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Workspaces for storing hazardous materials and heavy equipment, as well as excavation sites, pose higher safety risks and should be properly identified and protected.

2) There is a need for a proactive safety plan to reduce construction accidents, as current methods are insufficient for ensuring safety measures are properly implemented.

3) Prioritizing construction site safety through training, barriers, and hazard awareness boosts worker productivity and morale by preventing injuries and fatalities from falls and electrocutions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesWorkspaces For Storing Hazardous Materials and For Heavy Construction Equipment Have Higher Risks Than Other Workspaces

Workspaces For Storing Hazardous Materials and For Heavy Construction Equipment Have Higher Risks Than Other Workspaces

Uploaded by

Mohammed Salman Khan1) Workspaces for storing hazardous materials and heavy equipment, as well as excavation sites, pose higher safety risks and should be properly identified and protected.

2) There is a need for a proactive safety plan to reduce construction accidents, as current methods are insufficient for ensuring safety measures are properly implemented.

3) Prioritizing construction site safety through training, barriers, and hazard awareness boosts worker productivity and morale by preventing injuries and fatalities from falls and electrocutions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Salman

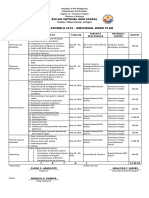

ID: 011 Risk: Unsafe Equipment Storage Date: 04/25/2021

Type: Threat

Risk Owner: Organization: Risk Analysis

Contact No.: 1 888 888 8888 Email:

Description:

Workspaces for storing hazardous materials and for heavy construction equipment have higher risks than

other workspaces. Other than spaces that should be protected by physical fences, there are many spaces on

site that should be identified for the safety of workers. Apart from this, there should be a proper and secure

place to store power charging systems and other heavy equipment to prevent electrocution.

Cause or Initiating Event:

The identification of potential accidents on construction sites has been a major concern in the construction

industry and it needs a proactive safety plan to reduce the risk of accidents. There are no efficient methods

for checking if safety measures are taken properly on construction sites. Consequently, workers on site are

not given enough awareness about dangerous areas.

Impact, Effect or Consequence:

Keeping the construction site safe is a priority for all construction companies. Safe construction sites boost

the morale of the workers, which increases productivity and improves work quality. Out of the construction

workers that suffer from fatal injuries, more are involved in falls than any other single cause. Falls account

for double the number of deaths caused by electrocution or being buried in trenches. Therefore, it is a

priority to place safety barriers and guard-rails around the hazard areas, excavations, and trenches.

Assessment

Probability (likelihood) of occurring:

Usually less than 10%

Potential Schedule impact:

If the event happens, there is not much significant delay.

Potential Cost impact:

Compensation for the loss of life must be paid if the event happens.

Potential Performance or Quality impact:

The risk does not carry much potential for quality impact.

Risk Handling: Avoid, Transfer, Mitigate, Accept

Monitoring Strategy:

Safety inspections should be occasionally conducted to measure the worker’s exposure to hazards on site.

Workers with proper training should only be allowed to use the equipment. Material Safety data sheets

outline potential health and fire hazards. Tracking these will inform how health and safety risks can be

mitigated.

Prevention Strategy:

Workers must comply with general safety and health standards (OSHA training). These training should be

reinforced with site specific safety team members. Workers should be wearing appropriate Personal

Protection Equipment (PPE) for each construction activities. Proper awareness and sign boards should be

deployed describing the potentially hazardous areas on the project site.

Salman

Recovery Strategy:

The health risks for the course of construction phase should be documented by general health and safety

specialists within the management team. Proper medical treatment and financial compensation must be

well taken care of the affected worker. The cause of the accident should immediately be discussed and

rectified. Additionally, any accidents or injuries should be discussed openly with employees to ensure all

parties take away lessons from what has happened.

Notes:

You might also like

- Zero ToleranceDocument114 pagesZero ToleranceGómez Bonilla Darwin100% (1)

- Top Safety Measures at Construction SitesDocument3 pagesTop Safety Measures at Construction Sitesananthu.uNo ratings yet

- Development of Emergency Response Procedures For Incidents Involving Dangerous GoodsDocument5 pagesDevelopment of Emergency Response Procedures For Incidents Involving Dangerous GoodsJulius Ceasar SanorjoNo ratings yet

- Parts CatalogueDocument503 pagesParts CataloguePrince Boney100% (1)

- The Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsFrom EverandThe Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsNo ratings yet

- CHE 534 Module 1Document37 pagesCHE 534 Module 1Precious JamesNo ratings yet

- Wind Energy ChecklistDocument23 pagesWind Energy ChecklistBalaji_Rajaman_2280No ratings yet

- Safety Measures During High-Rise Building ConstructionDocument9 pagesSafety Measures During High-Rise Building Constructionarnel sungkipNo ratings yet

- Safety in Process Plant Design SKF4163Document94 pagesSafety in Process Plant Design SKF4163hoikliangNo ratings yet

- EFE Gyratory CrusherDocument152 pagesEFE Gyratory CrusherVladimir Sepulveda100% (2)

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- SUBTOPIC 1 Basic Safety Procedures in High Risk Activities and IndustriesDocument54 pagesSUBTOPIC 1 Basic Safety Procedures in High Risk Activities and Industriesian jasper nathan100% (1)

- Employee Welfare ServiceDocument6 pagesEmployee Welfare ServicekrishnaNo ratings yet

- Safety PDFDocument7 pagesSafety PDFPratik SudraNo ratings yet

- Notes Shipyard ManagementDocument90 pagesNotes Shipyard ManagementHaziqMajid100% (1)

- Health & Safety AssignmentDocument10 pagesHealth & Safety AssignmentLeo SerasingheNo ratings yet

- Risk Management in IndustryDocument6 pagesRisk Management in Industrykasa1981100% (6)

- Production and OperationsDocument11 pagesProduction and OperationsniteshNo ratings yet

- Construction Project Risk ManagementDocument14 pagesConstruction Project Risk ManagementAdriano ZvNo ratings yet

- 2023 Handout 6 Risk Management, Goal Setting, Time ManagementDocument68 pages2023 Handout 6 Risk Management, Goal Setting, Time Managementeddiemasiga3100% (1)

- Homemade Liposomal CDocument8 pagesHomemade Liposomal CDennis LipterNo ratings yet

- Chapter 1-5 Group 2Document24 pagesChapter 1-5 Group 2Johnbill Barangan80% (5)

- Safety in Design EngineeringDocument3 pagesSafety in Design EngineeringOladimeji TaiwoNo ratings yet

- Delair DT26 Open Payload Brochure en 201904Document10 pagesDelair DT26 Open Payload Brochure en 201904Wahyu PriyantonoNo ratings yet

- Construction SafetyDocument36 pagesConstruction SafetyAlvin ConcepcionNo ratings yet

- May Nebosh Paper SoutionDocument10 pagesMay Nebosh Paper SoutionRebel KhanNo ratings yet

- Unit 8 Risk in The WorkplaceDocument11 pagesUnit 8 Risk in The WorkplaceAnonymous WalvB8No ratings yet

- Accident Prevention TechniquesDocument8 pagesAccident Prevention TechniquesvsrslmNo ratings yet

- Guidance On Mooring System Management Plans (MSMP)Document39 pagesGuidance On Mooring System Management Plans (MSMP)PJ Apostol Alpacas100% (5)

- Safety (Unit-1)Document15 pagesSafety (Unit-1)aditya raajNo ratings yet

- Christopher E. Layupan BCE 327-11259 Topic: Occupational Safety and Health Standard Date: June 19,2021 Speaker: Engr. Dionisio M. Delalamon Jr. LearningsDocument3 pagesChristopher E. Layupan BCE 327-11259 Topic: Occupational Safety and Health Standard Date: June 19,2021 Speaker: Engr. Dionisio M. Delalamon Jr. LearningsChristopher Toff LayupanNo ratings yet

- Unit-5 Disaster ManagementDocument19 pagesUnit-5 Disaster Managementholalo6378No ratings yet

- Safety in Construction Industry - Causes of Accidents, Remedial MeasuresDocument11 pagesSafety in Construction Industry - Causes of Accidents, Remedial MeasuresHKK 169No ratings yet

- Oil and Gas Risk ManagmentDocument4 pagesOil and Gas Risk ManagmentM Kafeel KhanNo ratings yet

- Lecture 7 Industrial Safety - BDocument22 pagesLecture 7 Industrial Safety - BRain bowNo ratings yet

- Ishwar Adhikari CSM NoteDocument109 pagesIshwar Adhikari CSM NoteBinit BänstøłäNo ratings yet

- DocumentDocument4 pagesDocumentAderayo OluwabunmiNo ratings yet

- Construction Site Workers' Awareness On Using Safety Equipment: Case StudyDocument8 pagesConstruction Site Workers' Awareness On Using Safety Equipment: Case StudyAi-lynn Calit RagayNo ratings yet

- Maintainance Health and Safety environment-SARDocument38 pagesMaintainance Health and Safety environment-SARMohammedSajidNo ratings yet

- Unit IIDocument38 pagesUnit IIParadise BirdNo ratings yet

- Molding Protection in BuildingDocument3 pagesMolding Protection in BuildingFarizanNo ratings yet

- 1.1.0. Introduction To Health and SafetyDocument6 pages1.1.0. Introduction To Health and SafetyMashal KhanNo ratings yet

- CM&PM ReportDocument18 pagesCM&PM ReportMiles MacayaNo ratings yet

- PGD1 Safety in EngineeringDocument37 pagesPGD1 Safety in EngineeringAbdulrauf Ismail BusayoNo ratings yet

- Accident PreventionDocument3 pagesAccident PreventionAasif EqubalNo ratings yet

- Safety ManagementDocument4 pagesSafety ManagementMahesh ChNo ratings yet

- Safety and The EnvironmentDocument10 pagesSafety and The EnvironmentYong Kai MingNo ratings yet

- Risk AssesmentDocument23 pagesRisk AssesmentMohamed ReezaNo ratings yet

- Introduction To OSHDocument30 pagesIntroduction To OSHSivmey ChhilNo ratings yet

- Module 1Document11 pagesModule 1Mandanas GabrielNo ratings yet

- JOB CERT 2 Information Sheet Plumbing 2024Document66 pagesJOB CERT 2 Information Sheet Plumbing 2024wallendelroyNo ratings yet

- Control of Industrial HazardsDocument19 pagesControl of Industrial Hazardsnickokinyunyu11No ratings yet

- Basic Safety + WPDocument55 pagesBasic Safety + WPEffective Vastu Tips A Happier HomeNo ratings yet

- Question Answers On RiskDocument7 pagesQuestion Answers On RiskManoj PainNo ratings yet

- Protecting Employees Who Work On Homeland Security and Critical Infrastructure ProjectsDocument11 pagesProtecting Employees Who Work On Homeland Security and Critical Infrastructure ProjectsAjendra SinghNo ratings yet

- Importance of Construction SafetyDocument5 pagesImportance of Construction SafetyfrancisNo ratings yet

- Hse PlanDocument5 pagesHse PlanAllan Khatasio100% (1)

- Madda Walabu University: Construction Health and Safety Management COTM 5303Document47 pagesMadda Walabu University: Construction Health and Safety Management COTM 5303ABU BEBEK AhmNo ratings yet

- Engineering Ethics ENGR001-20871 Assignment-4Document3 pagesEngineering Ethics ENGR001-20871 Assignment-4Ahmad ShhadiNo ratings yet

- Lecture 10Document27 pagesLecture 10gamingzonedead880No ratings yet

- Case Study: Safety and Precautionary Measures On SiteDocument7 pagesCase Study: Safety and Precautionary Measures On SiteFrances Nicole QuitoNo ratings yet

- Introduction To Safety ProcessesDocument5 pagesIntroduction To Safety ProcessesGerry LouNo ratings yet

- Construction Safety - Part 1 (Intro)Document33 pagesConstruction Safety - Part 1 (Intro)Henry TuraldeNo ratings yet

- Safety Management Term PapersDocument5 pagesSafety Management Term Papersafdtwadbc100% (1)

- Job Hazard Analysis in Construction Project ManagementDocument11 pagesJob Hazard Analysis in Construction Project ManagementAyesha Amie G. De LeonNo ratings yet

- Incident Management Procedure MCDocument9 pagesIncident Management Procedure MCmolokoluki25No ratings yet

- Medford Police Station Feasibility Study Appendix: Existing ConditionsDocument799 pagesMedford Police Station Feasibility Study Appendix: Existing Conditionsalex_ruppenthalNo ratings yet

- Aggregate Planning Using LINGODocument7 pagesAggregate Planning Using LINGOvitrahulNo ratings yet

- AAW H22 Accessory Connection Kit PDFDocument2 pagesAAW H22 Accessory Connection Kit PDFcodeNo ratings yet

- Hangcha 10TNDocument2 pagesHangcha 10TNFreddy AndresNo ratings yet

- Product Datasheet: Circuit Breaker Compact Nsx100F, 36ka at 415vac, Ma Trip Unit 50A, 3 Poles 3DDocument3 pagesProduct Datasheet: Circuit Breaker Compact Nsx100F, 36ka at 415vac, Ma Trip Unit 50A, 3 Poles 3DRizki PratamaNo ratings yet

- Unit 1 Concept and TheoryDocument57 pagesUnit 1 Concept and TheoryRahaf HammadNo ratings yet

- Polypoxy SL 20: Epoxy Resin Based Self Levelling Floor ToppingDocument2 pagesPolypoxy SL 20: Epoxy Resin Based Self Levelling Floor ToppingAlexi ALfred H. TagoNo ratings yet

- 3400 - Ms Thesis-Keivan Neshvadian, Final VersionDocument71 pages3400 - Ms Thesis-Keivan Neshvadian, Final VersionLimotim BryantNo ratings yet

- Hi-Tech Projects: (An Industrial Monthly Magazine On New Project Opportunities and Industrial Technologies)Document17 pagesHi-Tech Projects: (An Industrial Monthly Magazine On New Project Opportunities and Industrial Technologies)Shridhar L MallapurNo ratings yet

- Brigada Eskwela Individual Plan 2019Document1 pageBrigada Eskwela Individual Plan 2019Arangote GlennNo ratings yet

- Choose The Correct Answer Test For BeginnersDocument4 pagesChoose The Correct Answer Test For BeginnersMai FaweNo ratings yet

- Wiring Diagram: Rear Window DefoggerDocument1 pageWiring Diagram: Rear Window DefoggerAlexgavgray GNo ratings yet

- Sheldon Cooper - Quotes - The Big Bang TheoryDocument15 pagesSheldon Cooper - Quotes - The Big Bang TheoryV4RUNNo ratings yet

- Orifice Cal. SheetDocument8 pagesOrifice Cal. SheetAndrew RobertsonNo ratings yet

- 2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerDocument10 pages2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerLong Nguyễn HoàngNo ratings yet

- Covalent BondingDocument20 pagesCovalent BondingNadji Gadji-BaxisNo ratings yet

- FINAL LIST OF JOB ROLES FOR PMKVY 2 (Release Date 26-08-16)Document8 pagesFINAL LIST OF JOB ROLES FOR PMKVY 2 (Release Date 26-08-16)udi969No ratings yet

- Ind New - Delhi.421820 IshraeDocument10 pagesInd New - Delhi.421820 IshraeRohit KumarNo ratings yet

- STR FinalDocument2 pagesSTR FinalAnAs FFNo ratings yet

- EconMark-May17 (Infrastructure Financing) - FINAL-BLASTDocument52 pagesEconMark-May17 (Infrastructure Financing) - FINAL-BLASTAdri UsmanNo ratings yet

- Fuji Dri-Chem Immuno Au10vDocument3 pagesFuji Dri-Chem Immuno Au10vSpital Veterinar AndivetNo ratings yet

- Mechanical Design Technical Infomation - 2Document15 pagesMechanical Design Technical Infomation - 2Paco LMNo ratings yet

- Unit 4 Typological of Learners With DifficultiesDocument33 pagesUnit 4 Typological of Learners With DifficultiesMerry Carlien RudasNo ratings yet