Professional Documents

Culture Documents

JIS B 7503 Dial Gauges 1992

JIS B 7503 Dial Gauges 1992

Uploaded by

kumar0 ratings0% found this document useful (0 votes)

77 views18 pagesOriginal Title

85616954-JIS-B-7503-Dial-Gauges-1992

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

77 views18 pagesJIS B 7503 Dial Gauges 1992

JIS B 7503 Dial Gauges 1992

Uploaded by

kumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

JAPANESE INDUSTRIAL STANDARD

Dial gauges

D) JIS B 7503-»

Translated and Published

by

Japanese Standards Association

Printed in Japan

ube 5317175

9s

In the event of any doubt arising,

the ofiginal Standard in Japanese is to be final authority

UDC 531 717.5

@) JAPANESE INDUSTRIAL STANDARD JIs

Dial gauges B 7503-1992

1 Scope This Japanese Industrial Standard specifies the dial gauges of 0.01

mm in scale interval and 1 mm in spindle movement per one revolution of long

pointer, and of 0.001 mm in scale interval and 0.2 mm in spindle movement per

one rotation of long pointer (hereafter referred to as the "dial gauges”)

Furthermore, the measuring ranges in respect to the scale intervals shall

be as given in the following:

(1) 5 mm and 10 mm for the dial gauges of 0.01 mm in scale interval

(2) 1mm, 2 mm and 5 mm for the dial gauges of 0.001 mm in scale interval.

Remarks: The standards cited in this Standard are as given in the follow-

ing:

JIS B 0205-Metric coarse screw threads

JIS B 0209-Limits of sizes and tolerances for metric coarse

screw threads

JIS B 1501-Steel balls for ball bearings

JIS B 7506-Gauge blocks

JIS Z 8108-Glossary of terms used in instrumentation

2 Definitions For the purpose of this Standard, the following definitions

apply, and others are in accordance with JIS Z 8103

(1) dial gauge That measuring instrument of which spindle with a measur-

ing pointer transmits the linear motion in parallel to a circular dial

mechanically to the long pointer at a terminal in a rotary motion, and this

long pointer indicates the displacement of the spindle on a dial having

graduation lines which have divided the whole circular periphery at equal

intervals

(2) accuracy on wide range pressing-in The difference between the highest

point and the lowest point on the ordinate of the error diagram (see

Attached Figs. 1 and 3) over the entire measuring range when the spindle

is pressed in.

(3) accuracy on narrow range pressing-in Within the measuring range when

the spindle is pressed in, the difference between the highest point and the

lowest point on the ordinate of the error diagram (see Attached Figs. 2 and

4) for the initial one revolution (narrow range)

(4) narrow range adjacent error In respective cases where the spindle is

pressed in and goes out, the maximum value of the differences of errors at

two positions by 10 scales apart within a narrow range

2

B 7503-1992

(5) retrace error The maximum value of the differences of indications for the

Same measuring quantity when the spindle is pressed in and goes out.

(6) repeatability At an arbitrary position within a measuring range, the max-

Enum differance of the indicated values in the case where measurements

have been repeated under the working conditions as given in the following.

(a) Apply the measuring point at various speeds against a plane which is

not deformed as far as possible.

(b) Place the paralleled-plane plate being touched with the measuring

pointer in a plane vertical to the axial line of spindle, and allow it to

move in an arbitrary direction

3. Names The names of the principal part of the dial gauge shall be as

given in Fig 1

Fig. 1. Names of principal parts

Outer frame Tnner frame

Limit pointer. ee ee \

Long pointer __ ros Dial

Back cover

Ear metal

Short pointer _

Stem

7

Cover plate

Spindle

Messuring pointer___

Remarks: This Figure shall not be that for giving the standard of shapes

and construction, but for indicating the names of respective parts.

4 Performances

4.1 Accuracies of indications The tolerances on accuracies of indications of

dial gauges shall be in accordance with Table 1

3

B 7503-1992

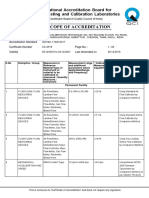

Table 1. Tolerances on accuracies of indications

Unit: pm

aa [Mees eamasen | eet, [seroma | nae | agents

(mm) | (mm) — |pressingin | of pressing-in

001 5 10 8 5 3 3

10 15

0.001 1 3 2 1s 2 03

2 5 - = |

[5 8 |

Remarks: The values of this Table shall be those of at 20°C

Informative reference: The values of this Table for 0.001 mm in scale inter-

val are those when the spindle of dial gauge has been

held vertical and downward or the dial has been held

upward in horizontal, and in the cases of other pos-

tures, these may be increased up to 25 %

42 Measuring force The measuring force of the dial gauge shall be in accord-

ance with the following:

(1) In the case where the spindle has been placed in vertical and downward,

the maximum measuring force shall not exceed 1.5 N.

(2) The difference between the maximum value and the minimum value of the

measuring force in respect to the same moving direction of the spindle

shall not exceed 0.6 N. However, for that of 0.001 mm in scale interval

and 5 mm in measuring range shall not exceed 0.7 N.

(3) At an arbitrary position in the measuring range, the difference between the

measuring forces, when the spindle is pressed in and goes out, shall not ex-

ceed 0.6 N for the dial gauge of 0.01 mm in scale interval and shall not ex-

ceed 0.7 N for the dial gauge of 0.001 mm in scale interval. However, for

that of 0.001 mm in scale interval and 5 mm in measuring range, it shall

not exceed 0.9 N

5 Shapes and dimensions

5.1 Shapes and dimensions of principal parts ‘The shapes and dimensions of

the principal parts of the dial gauges shall be in accordance with Fig. 2

4

B 7503-1992

Fig. 2. Shapes and dimensions of principal parts

With ear metal Unit: mm Without ear metal

Seale interval

oor

0001 31 10 35

52 Dimensions of attaching part of measuring pointer and dimensions of

measuring-pointer end The dimensions of the attaching part of measuring

pointer of dial gauges shall be in accordance with Fig. 3. However, the attach-

ing screw thread shall be M 25 of JIS B 0205, and its accuracy shall be 6 H/6g

of JIS B 0209.

Furthermore, the radius of spherical surface of measuring-pointer end shall

be 1.2 mm or over.

5

B 7503-1992

Fig. 3. Dimensions of attaching part of measuring pointer

Unit: mm

53 Dimensions of scale and long pointer The dimensions of the scale and

long pointer of the dial ga Guages shall be ts accordance with Fig. 4

6

B 7503-1992

Fig. 4. Dimensions of scale and long pointer

In the case of 0.01 mm In the case of 0.001 mm Unit: mm

in scale interval in scale interval

W=10min W307 min

LeWwiswW L=18Wo2W

Remarks1. It should be preferable that the thickness of graduation line

and the width of long-pointer end is equal

2, In order to facilitate the reading of the scale, graduation lines

shall be attached with corresponding numerals,

6, Functions ‘The functions of the dial gauges shall be in accordance with

the following:

(1) When the spindle is being pressed in, the long pointer shall rotate in the

clockwise direction

(2) When the stroke of spindle (displacement) has been read by the rotation of

the long pointer, the stroke of the spindle shall be as given in the following:

Furthermore, the cardinal point shall be the farthest position on the

dial from the measuring pointer

(a) For the dial gauge of 0.01 mm in scale interval, that point where the

long pointer has moved by 0.1 mm from its standstill point shall be

considered to be the cardinal point of the measuring range, and it

shall be 02 mm or over exceeding the terminal point of the specified

measuring range

7

B 7503-1992

(>) For the dial gauge of 0.001 mm in scale interval, that point where the

long pointer has moved by 0.02 mm from its standstill point shall be

considered to be the cardinal point of the measuring range, and it

shall be 0.05 mm or over exceeding the terminal point of the specified

measuring range

(2) In the dial gauge of 0.001 mm in scale interval, the amount of movement of

the spindle exceeding the terminal point of measuring range shall be 2.5

mm or over for that of 1 mm in measuring range, and be 15 mm or over

for that of 2 mm in measuring range. However, for that of 5 mm in

measuring range, no prescription shall be made.

(4) The rotation of the outer frame shall be smooth, and the dial shall be

capable of being fixed at an arbitrary position

(5) The clearance between the end pointed part of long pointer and the dial

shall be 1 mm or under, and the clearance during rotation of the long

pointer shall be uniform

(6) The short pointer shall be so constructed as to indicate the number of

revolutions of the long pointer or the effective stroke of the spindle. How-

ever, in the case where particularly specified, the short pointer may also be

omitted

7. Material and hardness The material of the end point of the measuring

point of the dial gauge shall be in accordance with JIS B 1501, or that of equal

to or superior to this in hardness

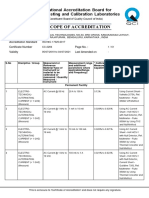

8 Measuring methods of performances The measuring methods of the perfor-

mances of the dial gauges shall be in accordance with Table 2

8

B 7503-1992

“sojutod jo saurpeas

ou) Woy yuauaysUT JuLINSBoUE Jo s3Ut

-pear ayy Suryoeaiqns fq paquasep woaq

sey YoIyA WUIseIp JosZa WE wos UIEAqO

pUE ‘ZaA0 gO WUE T 105 ORO uM Z'9 PUR

quiod [eurpaeo yy woay um T Jo [earezUT

ue Joy Yous wut ¢o'9 oFuvs TuLMsou UL

iu g pue uM Z Jo asoyy sO pu ‘WU ZO

OF Ypes UU go'9 puL yuIod jeurpzes a

au} WoI ZeA0 40 WUE Z'9 JO wAroVUE UE -Suissosd

40} yous wim 19°79 ‘eBuea Sutanseam ayy jo aBuvs

jo quiod jeurw0} oy3 07 oypurds oy} ysnd —|mozzeu wo

qquazoyurt opeos ut wr TOO" Jo YI Z0g (z) | APBANDOY]

“soqutod jo sduypeer

9 woay quounaysut Surnseour Jo sBut

aig -puaa auf] Suryovanqns £q poquosop wo9q

ananaa qa] Sey YOY Weep zoase ue wo] wrEyq

ls prowtmivanent ea pur ‘soA0 10 uM | 10) Yous war gg PUT

qutod [eutpres oy} woay uur | Jo PBAIAyUT

creas anne ue Joy you wun 19 ‘eBuer Suanseow our

Sugaoddns pue ‘(20020 Jo qutod jeurensoy ox op ofpurds ox ysnd

Teyuounaysut ut unt TF TwaIO}UE o[Os UT WHE TO Jo FYI JOT (T) ae

‘qeazoqut obos ‘oouoxojor sv odned | -Surssord

ur gopun 40 wii [) yuoW [ei 941 Jo ojvas Oy) Jo sBurpeor oy} Surya} no | Jo aBues

snaysut Suuseour MIU | saa sgiq’ Aaavo ‘({eyUozOY Ut TEI oy} 20) preMUMOP puE| “epLH UO

40 peay sayouoL91yy Twayyz0n ut anes [erp et Jo e[purds ayy Furproyy | Aoeanooy | 1

quoumnaysur Surunseoyy, woneasntiy poyjam Sunseay way | oN

soouvmuosxad Jo poyeur Suunsmoyy “z O1qeS,

B 7503-1992

9082 U Sif Ut peyroods:

ypoiq anes | apeay

purys Suysoddng

pure

Suuiaseoyy

aoyq 28809)

sere t]

“suorjearpur jo aouaaaypip ue 24)

ureyqo pur ‘auex Suunseour aq) ut Lor,

asod Areaygze we ye {YS pu yor ur pue

vas puB JWoRY UL LoystE 04 Yooq ones

9} MO[[e ‘puL}s TuLMseoUL oy} Jo o90y

-ang gaddn oy wo pooeyd soyq anes oq)

uo AywaHs04 soyuIOd FuLMseow ayy Ajddy

‘oduva Sutmsvour oyy wt

uontsod Kavayique uv qe sawNy aay <[Mols

pue

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kosaka Lab Scope CC 2611Document50 pagesKosaka Lab Scope CC 2611kumarNo ratings yet

- Model Pax - 1/8 Din Analog Input Panel Meters: C Us ListedDocument36 pagesModel Pax - 1/8 Din Analog Input Panel Meters: C Us ListedkumarNo ratings yet

- $/0 (02 Phdvxulqjv/Vwhpirufdoleudwlqjfolpdwlffkdpehuv Dvshujxlgholqh'$Nn6'.'5Document2 pages$/0 (02 Phdvxulqjv/Vwhpirufdoleudwlqjfolpdwlffkdpehuv Dvshujxlgholqh'$Nn6'.'5kumarNo ratings yet

- ASTM International Committee E20 On Temperature MeasurmentDocument2 pagesASTM International Committee E20 On Temperature MeasurmentkumarNo ratings yet

- Scope CC 2193Document26 pagesScope CC 2193kumarNo ratings yet

- Euro Calibration Technique Scope Location 1 CC-2519Document22 pagesEuro Calibration Technique Scope Location 1 CC-2519kumarNo ratings yet

- Scope Location 1 CC-2319 P TEJ CALIBRATION CENTREDocument64 pagesScope Location 1 CC-2319 P TEJ CALIBRATION CENTREkumarNo ratings yet

- Scope-CC-2777 Industrial Cal Services UTM CTMDocument5 pagesScope-CC-2777 Industrial Cal Services UTM CTMkumarNo ratings yet

- Wavecal Technologies Scope Location 1 CC-2284Document61 pagesWavecal Technologies Scope Location 1 CC-2284kumarNo ratings yet

- Cal Labs P - LTD - NABL - Scope-CC-2850Document63 pagesCal Labs P - LTD - NABL - Scope-CC-2850kumarNo ratings yet

- NABL Scope - TranscalDocument93 pagesNABL Scope - TranscalkumarNo ratings yet

- XK3190 C8Document1 pageXK3190 C8kumarNo ratings yet

- Light Intensity Measuring Instrument: Testo 540 - Pocket-Sized Lux MeterDocument2 pagesLight Intensity Measuring Instrument: Testo 540 - Pocket-Sized Lux MeterkumarNo ratings yet

- Scope-CC-2555 BAGSONDocument67 pagesScope-CC-2555 BAGSONkumarNo ratings yet

- Horizontal Laminar Air Flow: Product CatalogDocument6 pagesHorizontal Laminar Air Flow: Product CatalogkumarNo ratings yet

- Adi Artech: DescriptionDocument1 pageAdi Artech: DescriptionkumarNo ratings yet

- Nabl 122 08Document15 pagesNabl 122 08kumarNo ratings yet

- SS RoundDocument1 pageSS RoundkumarNo ratings yet

- Reference Materials For The Calibration of UV/visible Light SpectrophotometersDocument5 pagesReference Materials For The Calibration of UV/visible Light SpectrophotometerskumarNo ratings yet