Professional Documents

Culture Documents

Tda1591td T

Uploaded by

ahmed0 ratings0% found this document useful (0 votes)

20 views14 pagesTda1591td t

Original Title

Tda1591td t

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTda1591td t

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views14 pagesTda1591td T

Uploaded by

ahmedTda1591td t

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

Philips Semiconductors

SL

PLL stereo decoder and noise blanker

ES

FEATURES

* Adjustment-free voltage controlled PLL oscillator for

‘ceramic resonator (f = 456 kHz)

+ Pilot signal dependent mono/stereo switching

‘+ Analog control of mono/stereo change over

GENERAL DESCRIPTION

‘The TDA1591 is a monolithic bipolar integrated circuit

providing the stereo decoder function and noise blanking

for FM car radio applications,

Product specification

TDA1591

The device operates in a power supply range of

Istereo blend, Stereo Noise Controller (SNC)] 7510 12V.

‘* Adjacent channel noise suppression (114 kHz)

‘* Pilot canceller

‘+ Analog control of de-emphasis; High Cut Control (HCC)

* Applicable as source selector for AM/FM/cassette

switching

* Separate interference noise detector

‘+ Integrated input low-pass fiter for delayed noise.

blanking

‘+ Noise blanking at MPX-demodulator outputs,

‘+ Internal voltage stabilization.

QUICK REFERENCE DATA

SYMBOL PARAMETER min. | typ. | Max. | UNIT

Ve. ‘supply voltage (pin 5) 75 10 12 v

le ‘Supply current - 12 = mA,

Votes) ‘audio output signal (RMS value) = 900, = mV,

THD total harmonic distortion - Ot 03, %

‘SIN signal-to-noise ratio = 76 = 0B

Gs channel separation = 40 = @B

Vurigg interference voltage trigger level = 10 = mV

ORDERING INFORMATION

TYPE PACKAGE.

NUMBER | NAME DESCRIPTION VERSION

TDA1591 DIP20_[ plastic dual in-line package; 20 leads (300 mil) ‘SOTH46-1

TOAIS91T. ‘$020 _| plastic small outline package; 20 leads; body width 7.5 mm ‘SOT163-1

1996 Sep 02 2

@™ 721082 0108035 2b mm

Product specification

Philips Semiconductors

TDA1591

PLL stereo decoder and noise blanker

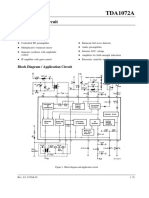

BLOCK DIAGRAM

"now 180 se pesn ose ‘siueuodwoo jewierXe YM WeIBEIP YOK 1'BIL}

DoreMGOUER Hes ei Jo HOO! BA SBIEMUIS (1)

wowrw —wooon | aw =e * (Ev OES IVC) uBR eouRsepeIUT md

" azo : #) | geen wl oa

oma \ [a wn | Sem Lg at

stax = ) tla lé : = .

— é ay 5 =

x muy rad 1 — wre

i 3

fear 4V =_[- [oa fae

Voratesy [DO offset voltage (pins 10 and 11) after muting = [= [2400 [mv

HCC (pin 15)

‘CRasom | control range of de-emphasis 360 Figs 7 and 8

for European standard Ceo = 6.8 NF so |- 150 Jus

for USA standard Capon = 10.0F 75 |- [225 |us

Viesr [control voltage (pin 18 due to pin 17) in both |iower value CRasen [= JO [= [mv

standards upper value CRgcem_ od -300 |- mv

Noise interference detector

Vera ‘rigger threshold (pin 6) fon = 120 KHZ

Vegoc) = 7.7 V Be tory aay

Veqoc) = 6.7 V - {100 [- [mv

‘AVe ‘voltage offset as a function of Viigg Vo tigg = 10 mV = [200 |- [mv

Vo tig = 100 mV = es _[-_|v

Tew "AF suppression time; pulse width = [ao [= [as

hase input offset current (pins 13 and 14) during AF suppression |- [20 [- [nd

time

Vpuse | tigger sensitivity (pin 6) puss = 10 us =o [- [av

1996 Sep 02 7

wm 7320826 0208040 683

Philips Semiconductors Product specification

PLL stereo decoder and noise blanker TDA1591

Notes

1. Intermodulation suppression [Beat Frequency Components (BFC)}:

Vofsignan (at 1 kHz)

= Vetsianat

IM2 = 7

TAT fo = (2x10 KH) - 19 kHz

pious)

Vogigny (2t 1 KHZ)

Tapay TRS

‘measured with 91% mono signal; mos = 10 kHz of 13 KHz; 9% pilot signal

2. ARI suppression:

Vegan (tt kHz)

Vopr (a0 KHz 225 Fz)

measured with 91% stereo signal: nog = 1 KHZ; 9% pilot signal; 6% ARI subcarrier

(fg =57 KHZ; fnoa = 23 Ha; AM m = 0.6)

3. Subsidiary Communication Authorization (SCA):

Matouman (OE KH2) (2:98 kez) ~ 67 Kt

gy = Hf, = (2x38 kHz) ~67 kHz

87 Taio (OTS RF)

measured with 81% mono signal; fnoa = 1 KH2; 9% pilot signal; 10% SCA subcarrier (

4, Adjacent Chane! interference (ACI)

Vegan (1 HE)

184 = Tony CUA RZD |

Vetsgray(@t 1 KH2)

ot

Oe 5 f= 186 kHz ~ (5 «98 kHz)

Voputous (4 KHZ)

‘measured with 90% mono signal; Imag = 1 KHZ; 9% pilot signal; 1% spurious signal

(fg = 110 kHz or 186 kHz, unmodulated).

IMs = f, = (3x1 kHz) ~38 kHz

57ARI =

67 kHz, unmodulated).

= 110 kHz ~ (3x38 kHz)

1996 Sep 02 8

mB 7110826 0108041 SIT mm

Philips Semiconductors Product specification

PLL stereo decoder and noise blanker TDA1591

A —

Minx) | |

o

109 200) 19) 00

Fig.3 Input signal as a function of series input resistor RI,

- so

ne I

ey

7 ik

Fy

10} - |

0 ~ 40 Fe, Ra 0) 60 =100 0

conto votage Vag_17 (mV)

Fig.4 Overall signal gain as a function of feedback

resistors R2 and R3 (R1 = 150 kQ). Fig.5. Stereo blend characteristic (SNC).

1996 Sep 02 9

mm 7220825 0108042 4Sb

Philips Semiconductors

Product specification

PLL stereo decoder and noise blanker TDA1591

0 a

os

ry 1 1

o |

0 +

I

so | L | |

C

| {Il

|

"| [2 | |

10 Ht t

| | |

©. - L .

‘0 1a 107 Ope

(0) Caupng capactor Cx apn 20= 10.

2) Coupling capaci Cx spn 200.1 HF

Fig.6 Channel separation as a function of audio frequency.

2 - 1 7 1

oar | |

o o tl

e | : ++

co @ |

aq

10, 1 -

‘0 1 +e ‘erty “ot

(1) Vierr=0

@) Vier =-300mv,

Fig.7 HCC as a function of audio frequency (pin 7 connected to GND; without pre-emphasis).

1996 Sep 02

mm 7310825 0108043 392

10

Philips Semiconductors Product specification

PLL stereo decoder and noise blanker TDA1591

° sce

AV 7 |

ey

aff

aah

“ - -

| _ |

| |

| |

ee |

60

“200 100

control vetape Vi5-s7(mv)—°

Fig.8 HCC with frog = 10 kHz.

1996 Sep 02 7)

mm 7120826 0108044 229 mm

Philips Semiconductors. Product specification

PLL stereo decoder and noise blanker TDA1591

‘TEST INFORMATION

&

bai |

“CS aire |

WH => |

iif DS

Co USS? |

7 agit

See's b

@ - e

Fig.9 TDA1591 test board (component side).

1996 Sep 02 12

we 7120826 0308045 16S mM

Philips Semiconductors Product specification

PLL stereo decoder and noise blanker TDA1591

PACKAGE OUTLINES.

Dipz0:

lastic dual in-line package; 20 leads (300 mil) SOT146-4

+ seating pane

tin ind t

p*—-—-—-—

5 10mm

toe

DIMENSIONS (inch eimensions are derived trom the orginal mm dimensions)

a] As | aa | es 20)

unt | he, | AR | atk | ® . fe & | me jm | ow

t T

_ | ¥73 | oso | ass | 2502] 640 | a5, | p—q | 360 | 825 | 100

I 42 | ost | 32 | 150 | 038 | ozs | aes | ez | 25 | 782 | 305 | 700 | 8a | 02] 20

inaes | 017 | 00a | ova | 2088 | 01 | 0014 | 1060] 025 014 | 032 | 039 | 95)

aoe 043 | cost | oots | ooo | tas | 24 | 9 | 9 | or2 | o3t | 03a | OO" | 9078

Note

1. Plast or metal provusions of 0.25 mm maximum per sida aro not includes

ourune | REFERENCES EUROPEAN

‘ = ISSUE DATE

VERSION | eo = imal PROJECTION

sorts ‘S080 eae | See |

1996 Sep 02 13

mm 7120826 0108046 OT) mm

Philips Semiconductors Product specification

PLL stereo decoder and noise blanker TDA1591

$020: plastic small outline package; 20 leads; body width 7.5 mm ‘SOT163-1

{Oy)

THLALALA IB A A

Poe

‘a

IY

HOU El

oo

co

, od

gio

oS

° 10mm

DIMENSIONS (inch dlmensions are derived from the original mm dimensions)

ww fata | a fa] ase] e [ome elm lelulel y|w]y|z|e

om | bas ova | oa | 120] 7a 108s 71] 4 Toa} ae

tmm | 285 | Ono | 226 | 925 | 028 | aaa | ree | ra | *27 [tooo] 4 | oa | v0 | 925] 025| 07 | 4 | ge

‘mows oxo [2012 [0.086 ‘0.019 [0013] 051 | 090 042 ‘0.083 | 0043 oss] °°

0.004 | 0.089 | °°" |o.014 | 0.009] 0.48 | 0.29 | 995°} 9,29 | 9-955] o.016| 0.099] 991 | 201 | 0.008] garg

Note

1. Paseo mts potions o 0.15 mm maximum pr sie een Ince

ro anon er ;

VERSION = = rr) Provection | 'SSUEDATE

sories: vseo4 wsorane eso | She

1996 Sep 02 14

mm 7120826 0108047 738 mm

Philips Semiconductors,

Product specification

PLL stereo decoder and noise blanker

TDA1591

SOLDERING

Introduction

‘There is no soldering method that is Ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

‘on one printed:-circuit board. However, wave soldering Is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. in these

situations reflow soldering is often used.

‘This text gives a very brief insight toa complex technology.

‘A more in-depth account of soldering ICs can be found in

‘our "IC Package Databook” (order code 9398 652 90011)

DIP

‘SOLDERING BY DIPPING OR BY WAVE

‘The maximum permissible temperature of the solder is

260°C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

ime of successive solder waves must not exceed

5 seconds.

‘The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

‘specified maximum storage temperature (Tig max) W the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit,

REPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead{s) of the package, below the seating plane or not

‘more than 2 mm above it. f the temperature of the

soldering iron bit is less than 300 °C it may remain in

‘contact for up to 10 seconds. I the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds,

so

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be appliod

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

1996 Sep 02

mm 7210826 0108048 974

15

Several techniques exist for retlowing: for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250°C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45°C.

WAVE SOLDERING

Wave soldering techniques can be used forall SO

packages if the following conditions are observed:

+ A doublo-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

‘+ The longitudinal axis ofthe package footprint must be

parallel tothe solder flow.

‘+ The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

‘Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

‘A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

REPAIRING SOLDERED JOINTS.

Fix the component by frst soldering two diagonally-

opposite end leads, Use only a low voltage soldering iron

(less than 24 V) applied tothe flat part of the lead, Contact,

time must be limited to 10 seconds at up to 300 °C, When

using a dedicated tool, all other leads can be soldered in

‘one operation within 2 to § seconds between

270 and 320°C.

You might also like

- LP339 Ultra-Low Power Quad Comparator: General DescriptionDocument10 pagesLP339 Ultra-Low Power Quad Comparator: General DescriptionahmedNo ratings yet

- LV48 Series Programmers: Power Tools For The Development EngineerDocument4 pagesLV48 Series Programmers: Power Tools For The Development EngineerahmedNo ratings yet

- LSA-Compact 1000W Manual en Rev BDocument44 pagesLSA-Compact 1000W Manual en Rev BahmedNo ratings yet

- Data Sheet: FM/IF Amplifier/demodulator CircuitDocument16 pagesData Sheet: FM/IF Amplifier/demodulator CircuitahmedNo ratings yet

- Illustrated Assembly Manual K4004BDocument16 pagesIllustrated Assembly Manual K4004BahmedNo ratings yet

- TDA1545ATTDocument20 pagesTDA1545ATTahmedNo ratings yet

- Data Sheet: Integrated FM Tuner For Radio ReceiversDocument11 pagesData Sheet: Integrated FM Tuner For Radio ReceiversahmedNo ratings yet

- TDA1519BDocument12 pagesTDA1519BahmedNo ratings yet

- Data Sheet: Stereo Cassette Head Preamplifier and EqualizerDocument16 pagesData Sheet: Stereo Cassette Head Preamplifier and EqualizerahmedNo ratings yet

- TDA1553QDocument10 pagesTDA1553QahmedNo ratings yet

- TDA1516BQDocument11 pagesTDA1516BQahmedNo ratings yet

- TDA1518BQDocument11 pagesTDA1518BQahmedNo ratings yet

- TDA1072A: AM Receiver CircuitDocument7 pagesTDA1072A: AM Receiver CircuitahmedNo ratings yet

- TDA1180P: TV Horizontal ProcessorDocument12 pagesTDA1180P: TV Horizontal ProcessorahmedNo ratings yet

- Data Sheet: TDA1516BQDocument12 pagesData Sheet: TDA1516BQHaja MohamedNo ratings yet

- TDA1306TDocument24 pagesTDA1306TahmedNo ratings yet

- Data Sheet: TDA1300T TDA1300TTDocument20 pagesData Sheet: TDA1300T TDA1300TTahmedNo ratings yet

- TDA1085C Universal Motor Speed Controller: C Suffix Plastic Package CASE 648 PdipDocument12 pagesTDA1085C Universal Motor Speed Controller: C Suffix Plastic Package CASE 648 PdipahmedNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)