Professional Documents

Culture Documents

Mid 039 - Cid 0581 - Fmi 05

Mid 039 - Cid 0581 - Fmi 05

Uploaded by

Walter0 ratings0% found this document useful (0 votes)

114 views4 pagescat324d

Original Title

MID 039 - CID 0581 - FMI 05

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcat324d

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

114 views4 pagesMid 039 - Cid 0581 - Fmi 05

Mid 039 - Cid 0581 - Fmi 05

Uploaded by

Waltercat324d

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

vez021 Acad Ful Toe Search- RENROBAB- 2000, 210, 290, 24D, 2050, 3280, 3280, 280, 9000, 5060, 39602, 400 ant 24002 cat

Troubleshooting

320D, 3210, 323D, 3240, 325D, 326D, 328D, 329D, 330D, 336D, 336D2, 340D and 34002

Excavators, 324D Forest Machine and 323D MHPU, 324D MHPU, 325D MHPU, 329D MHPU, 330D

MHPU and 336D MHPU Mobile Hydraulic Power Units Machine Electronic Control System

Media Number -RENR9S45-31, Publication Date -01/04/2015 Date Updated -07/08/2018

o461820

MID 039 - CID 0581 - FMI 05

SMCS - 5479-038-QY

Conditions Which Generate This Code:

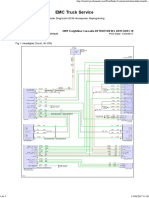

BACKUP_EPR VALVE

POWER SHIFT

PRESSURE 2 ot

SOLENOID 3

o 4

Bet f, H—A788-80 a

2h

235-BK—4

A769-GY

235-BK

MACHINE ECM AP

PS PRESS PRV |) 4 }-L969-WH—)—

PRV RETURN } 20 }-L968-OR—

GROUND

GROUND

Mlustration 1 202357696

Power Shift Pressure solenoid circuit schematic

This diagnostic code is for the Power Shift Pressure solenoid . An FMI 05 diagnostic code indicates the machine

ECM has determined the solenoid circuit current is below normal

Possible causes for this diagnostic code are:

+ The Backup Switch has failed,

* The solenoid has failed.

+ There is an open inthe solenoid circuit

tp sleveb cat comlewebsiswebtechdocecho prin, page|spreturr=esveblsswabfuledtultetheadrniamesetjptcaledpage=Iiswab.. 4

raven ‘Adsonced Full Tex Search RENRS848 - 3200, 321D, 3230, 3240, 3250, 3260, 3280, 8290, 3300, 3360, 33602, 0D are 34002 Esco

© The machine ECM has failed, but is most unlikely.

Note: Poor connections are often the cause of a problem in electrical circuits. Before performing this

procedure, inspect all the machine harnesses and connectors involved in the cireuit. Make sure to verify

that all of the connections in the cireuit are clean, secure, and in good condition. Correct any problems

found with any of the connections. Verify the diagnostic code CID 0581 FMI 05 is still active, before

continuing with this procedure.

Note: The following test procedure may create other diagnostic codes. Ignore all the created diagnostic codes now,

but clear all those codes afier the cause for the original diagnostic code has been corrected

Test Step 1. CHECK THE SWITCH.

Table |

Switch State Switch Contacts Status

Active Contacts 5 & 6 and 11 & 12 | Closed

Active Contacts 5 & 4 and 11 & 10 | Open

Inactive Contacts 5 & 6 and 11 & 12 | Open

Inactive || Contacts 5 & 4 and 11 & 10 || Closed

A. Tum the starter keyswitch and the disconnect switch to the OFF position.

B. Disconnect the Backup Switch from the panel.

C. Toggle the switch from one state to the other. On each of the switch two states, check for continuity on the

switch pins listed on Table 1

Expected Result:

Both states of the switch continuity agree with table 1

Results:

* YES - The switch contimity is correct. Go to Test Step 2.

+ NO- The switch continuity is not correct. The Backup Switch has failed.

Repair: Replace the switch

Go to Test Step 4.

Test Step 2. CHECK THE SOLENOID.

A. The disconnect switch and the starter keyswitch remain in the the OFF position.

B, Reconnect the backup switch.

C. Disconnect the machine harness fiom the Power Shift Pressure solenoid.

D. Inthe machine hamess connector for the solenoid, place a jumper wire fiom the contact for terminal 1 (wire

A768-BU(Blue)) to the contact for terminal 2 (wire A769-GY (Grey) in the solenoid hamess connector,

‘swoblssvebultenfullecheadernforamaseljspcaledpage=Isiswobl.. 2/4

hp sisweb.cat.combieueblslswebtechdoctecdoc_prin_pegesp?returnu

raven ‘Athonced Full Tex Search - RENR9848 - 2200, 3210, 3230, 3240, 3280, 2260, 2280, 2290, 2900, 3960, 39602, HOD and 24902 Ercan

E. Tum the starter keyswitch and the disconnect switch to the ON positon.

F. Observe the status of the CID 0581 FMI 0Sdiagnostic code.

Expected Result:

The CID 0581 FMI 05 diagnostic code is active.

Results:

+ YES - The diagnostic code is active. The solenoid is not the problem. Go to Test Step 3.

* NO- The CID 0581 FMI 05 diagnostic code is not active and has been replaced by an active CID 0581

FMI 05 diagnostic code. The solenoid has failed,

Repair: Replace the solenoid.

Go to Test Step 4.

Test Step 3. CHECK THE SOLENOID CIRCUIT FOR AN OPEN.

A, Turn the starter keyswitch and the disconnect switch to the OFF position.

B, The hamess connector remains disconnected from the solenoid.

C. The jumper wire remains in the solenoid hamess connector,

D. Disconnect the J2 harness connectors from the machine ECM.

E, At the J2 hamess connector, measure resistance from contact J2-4 (wire L969-WH(White)) to 12-20 (wire

L.968-OR(Orange)) in the J2 ECM hamess connector.

Expected Result:

The resistance is less than 5 ohms.

Results:

* YES - The resistance is less than 5 ohms. Go to Test Step 4.

© NO- The resistance is more than 5 ohms, There is an open circuit in the machine harness.

Repair: Repair or replace the hamess.

Go to Test Step 4.

Test Step 4. CHECK THE DIAGNOSTIC CODE STATUS.

‘A. Recomnect all disconected machine hamess connectors. Make sure that all the connectors are filly seated.

Observe thatthe clips for each connector are securely fastened.

B, Tum the key start switch and the disconnect switch to the ON position.

C. Clear all inactive diagnostic codes,

D. Operate the machine,

‘swoblssvebultenfullecheaderinforamaseljspcaledpage=Isiswobl.. 34

raven ‘Adsonced Full Tex Search RENRS848 - 3200, 321D, 3230, 3240, 3250, 3260, 3280, 8290, 3300, 3360, 33602, 0D are 34002 Esco

E. Check the status ofthe CID 0581 FMI 05 diagnostic code.

Expected Result:

The CID 0581 FMI 05 diagnostic code is not active,

Results:

* YES - The CID 0581 FMI 05 diagnostic code is no longer active and does not exist at this time.

Repair: The cause for the diagnostic code has been corrected. Return the machine back to normal

operations.

STOP

+ NO-‘The CID 0581 FMI 05 diagnostic code is sill active, The problem has not been corrected. The ECM

may have failed.

Repair: Ifyou have not inspected the hamess connectors in a previous Test Step, do that now. Clean the

contacts of the hamess connectors. Check the wires for damage to the insulation caused by excessive heat,

battery acid, or chafing Perform a 45 N (10 Ib.) pull test on each of the wires that are associated with the

sensor circuit. Perform a “wiggle test” on the sensor circuit of the machine wiring hamess, using the Caterpillar

Electronic Technician service tool. The “wiggle test” can be used to detect open or shorted connections in the

‘machine wiring harness Reconnect all hamess connectors. Make sure that the connectors are filly seated

Observe that the clips for each connector are fastened. Perform Test Step 4 again. Ifthe problem is not found,

and the original code is still active, the machine ECM may have failed.Prior to replacing an ECM, contact your

Dealership Technical Communicator for consultation with Caterpillar, or the Dealer Solutions Network. This

consultation may greatly reduce repair time. Ifthe ECM needs to be replaced, see Testing and Adjusting,

"Bleetronie Control Module (ECM) - Replace”.

STOP

‘swoblssvabYultenfullecheaderinforamaseljspcaledpage=Isiswobl.. 4/4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MID 039 - CID 1846 - FMI 09: Pantalla AnteriorDocument6 pagesMID 039 - CID 1846 - FMI 09: Pantalla AnteriorWalterNo ratings yet

- Isx cm870 VolvoDocument5 pagesIsx cm870 VolvoWalterNo ratings yet

- DIAGRAMADocument11 pagesDIAGRAMAWalterNo ratings yet

- Interpretacion de CódigosDocument10 pagesInterpretacion de CódigosWalterNo ratings yet

- RENR99640001Document2 pagesRENR99640001Walter100% (1)

- EMC Truck Service: HeadlightsDocument3 pagesEMC Truck Service: HeadlightsWalterNo ratings yet

- RetrievedDocument4 pagesRetrievedWalterNo ratings yet

- MID 039 - CID 1847 - FMI 09: Pantalla AnteriorDocument6 pagesMID 039 - CID 1847 - FMI 09: Pantalla AnteriorWalterNo ratings yet

- Intake Valve Actuation System Oil Pressure CircuitDocument6 pagesIntake Valve Actuation System Oil Pressure CircuitWalterNo ratings yet

- Módulo BCSDocument1 pageMódulo BCSWalter0% (1)

- EMC Truck Service: Exterior LightsDocument4 pagesEMC Truck Service: Exterior LightsWalterNo ratings yet

- Sam Como Sacarlo e InstalarloDocument3 pagesSam Como Sacarlo e InstalarloWalterNo ratings yet

- View All Callouts: Function Isolation ToolsDocument11 pagesView All Callouts: Function Isolation ToolsWalterNo ratings yet

- Control de Velocidad Del Motor: 30/11/2015 Operación Del Sistema (RENR9848)Document13 pagesControl de Velocidad Del Motor: 30/11/2015 Operación Del Sistema (RENR9848)WalterNo ratings yet

- Component Locations: 324D Excavator Hydraulic System - AttachmentDocument2 pagesComponent Locations: 324D Excavator Hydraulic System - AttachmentWalterNo ratings yet

- Ex100 2Document205 pagesEx100 2WalterNo ratings yet

- Caja Super 13 Con Top 2Document30 pagesCaja Super 13 Con Top 2WalterNo ratings yet

- 311 & 312 Excavators Electrical System: Machine Harness Connector and Component LocationsDocument2 pages311 & 312 Excavators Electrical System: Machine Harness Connector and Component LocationsWalterNo ratings yet