Professional Documents

Culture Documents

Features: Surface Mount Glass Passivated Single Phase Bridge Rectifier Reverse Voltage 1000V Output Current 2.0A

Uploaded by

Teudis Naranjo OrtizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features: Surface Mount Glass Passivated Single Phase Bridge Rectifier Reverse Voltage 1000V Output Current 2.0A

Uploaded by

Teudis Naranjo OrtizCopyright:

Available Formats

E91207AU

Surface Mount Glass Passivated Single Phase Bridge Rectifier

Reverse Voltage 1000V Output Current 2.0A

Features

• Glass passivated Bridge Rectifiers

• Ideal for automated placement

• Very low profile - max height 1.2 mm

• Moisture sensitivity: level 1, per J-STD-020

• High temperature soldering guaranteed: 260℃/10 seconds

Mechanical Data case: E91

• Case:E91,Molding compound meets UL 94V-0 flammability rating

• Terminals:Matte tin plated leads,solderable per MIl-STD-750 Method 2026,J-STD-002 and

JESD22-B102

Typical Applications

General purpose use in ac-to-dc bridge full wave rectification for TV,Monitor,SMPS,Adapter,

Printer,Audio equipment,and Home Applications application

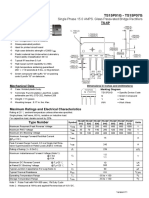

Maximum Ratings (TA = 25 °C unless otherwise noted)

Parameter Symbol E91207AU Unit

Maximum repetitive peak reverse voltage VRRM 1000 V

Maximum RMS voltage VRMS 700 V

Maximum DC blocking voltage VDC 1000 V

Maximum average output rectified current Io(AV) 2.0 A

Peak forward surge current 8.3 ms single half sine-

IFSM 70 A

wave superimposed on rated load

Rating for fusing (t≤8.3ms) I2t 20 A2s

Peak forward surge current at 1 ms single square wave IFSM 140 A

at 2 ms single square wave

IFSM 100 A

superimposed on rated load (ta=25℃)

TJ,

Operating junction and storage temperature range -55 to +150 °C

TSTG

Electrical Characteristics (TA = 25 °C unless otherwise noted)

Parameter Test Conditions Symbol E91207AU Unit

Maximum instantaneous

IF=2.0A VF 1.1 Volts

forward voltage

Maximum DC reverse TA=25℃ 5.0

current at rated DC blocking IR µA

voltage TA=125℃ 50

Typical junction capacitance 4.0 V, 1 MHz CJ 20 pF

www.goodark.com 1/4 2017.04-Rev.A

E91207AU

Surface Mount Glass Passivated Single Phase Bridge Rectifier

Reverse Voltage 1000V Output Current 2.0A

Thermal Characteristics (Ta=25℃ unless otherwixe noted)

Parameter Test Conditions Symbol E91207AU Unit

1)

Typical thermal resistance juntion to ambient RθJA 45

1)

juntion to case RθJC 12.6

℃/W

2)

juntion to ambient RθJA 29.8

2)

juntion to case RθJC 8.4

Note:1), The thermal resistance from junction to ambient and case, mounted on glass epoxy FR-4 P.C.B with recommended copper pads

2), The thermal resistance from junction to ambient and case, mounted on glass epoxy FR-4 P.C.B with 13*13mm copper pads

Ratings and Characteristics Curves

(TA = 25℃ unless otherwise noted)

2.8 70

Peak Forward Surge Current

Rectified Current, (A)

Bridge Output Full Wave

2.4 60

2 50

1.6

(A)

40

1.2 30

0.8 20

0.4 10

0

0

0 25 50 75 100 125 150

1 10 100

Case temperature(℃) Number of Cycles at 60Hz

Figure 1.Forward Current Derating Curve Figure 2.Maximum Non-Repetitive Peak

Forward Surge Current

100 100000

Instantaneous Forward Current

Instantaneous Reverse Current

10000 25℃ 125℃

10 1000 150℃

100

(A)

1 10

(uA)

25℃

1

Pulse width=0.3ms

125℃

0.1 0.1

150℃

0.01

0.01 0.001

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 0 20 40 60 80 100 120

Percent of Rated Peak Reverse Voltage (%)

Instantaneous Forward Voltage (V)

Figure 3. Typical Instantaneous Forward Figure 4. Typical Reverse Characteristics

Characteristics

www.goodark.com 2/4 2017.04-Rev.A

E91207AU

Surface Mount Glass Passivated Single Phase Bridge Rectifier

Reverse Voltage 1000V Output Current 2.0A

Package Outline Dimensions

Mounting Pad

layout,unit:mm

(Unit:mm)

Dim Min Nom. Max Dim Min Nom. Max

A 1.10 1.17 1.20 L3 5.7 5.9 6.1

C 0.20 0.25 0.35 L4 0.6 0.80 1

D 8.3 8.4 8.6 L5 1.4 1.6 1.8

HE 10.0 10.2 10.4 P1 3.0 REF

E 9.1 9.30 9.5 P2 7.4 REF

E1 5.28 REF P3 3.1 REF

L1 1.4 1.60 1.80 P4 3.68 REF

L2 1.0 1.2 1.4

www.goodark.com 3/4 2017.04-Rev.A

E91207AU

Surface Mount Glass Passivated Single Phase Bridge Rectifier

Reverse Voltage 1000V Output Current 2.0A

Disclaimers

These materials are intended as a reference to assist our customers in the selection of the Suzhou

Good-Ark product best suited to the customer’s application; they do not convey any license under

any intellectual property rights, or any other rights, belonging to Suzhou Good-Ark Electronics Co.,

Ltd.or a third party.

Suzhou Good-Ark Electronics Co., Ltd. assumes no responsibility for any damage, or infringement

of any third-party’ s rights, originating in the use of any product data, diagrams, charts, programs,

algorithms, or circuit application examples contained in these materials.

All information contained in these materials, including product data, diagrams, charts, programs and

algorithms represents information on products at the time of publication of these materials, and are

subject to change by Suzhou Good-Ark Electronics Co., Ltd. without notice due to product

improvements or other reasons. It is therefore recommended that customers contact Suzhou Good-

Ark Electronics Co., Ltd. or an authorized Suzhou Good-Ark Electronics Co., Ltd. for the latest

product information before purchasing a product listed herein. The information described here may

contain technical inaccuracies or typographical errors. Suzhou Good-Ark Electronics Co., Ltd.

assumes no responsibility for any damage, liability, or other loss rising from these inaccuracies or

errors. Please also pay attention to information published by Suzhou Good-Ark Electronics Co., Ltd.

by various means, including our website home page.

(http://www.goodark.com)

When using any or all of the information contained in these materials, including product data,

diagrams, charts, programs, and algorithms, Please be sure to evaluate all information as a total

system before making a final decision on the applicability of the information and products. Suzhou

Good-Ark Electronics Co., Ltd. assumes no responsibility for any damage, liability or other loss

resulting from the information contained herein.

The prior written approval of Suzhou Good-Ark Electronics Co., Ltd. is necessary to reprint or

reproduce in whole or in part these materials.

Please contact Suzhou Good-Ark Electronics Co., Ltd. or an authorized distributor for further details

on these materials or the products contained herein.

www.goodark.com 4/4 2017.04-Rev.A

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- IIT KGP SyllabusDocument6 pagesIIT KGP SyllabusHemant SaraswatNo ratings yet

- Power Supplies & RegulatorsDocument15 pagesPower Supplies & RegulatorsNarasimha Murthy YayavaramNo ratings yet

- Features: Surface Mount Glass Passivated Single Phase Bridge Rectifier Reverse Voltage 1400V Ountput Current 2.0ADocument4 pagesFeatures: Surface Mount Glass Passivated Single Phase Bridge Rectifier Reverse Voltage 1400V Ountput Current 2.0ATeudis Naranjo OrtizNo ratings yet

- SM5817 THRU SM5819: Surface Mount Schottky Barrier RectifiersDocument1 pageSM5817 THRU SM5819: Surface Mount Schottky Barrier RectifiersStuxnetNo ratings yet

- DF10M PDFDocument2 pagesDF10M PDFAnonymous IeIEHSANo ratings yet

- KBF201 Thru KBF210: FeaturesDocument3 pagesKBF201 Thru KBF210: FeaturesBoyet PasionNo ratings yet

- Ug2A, Ug2B, Ug2C, Ug2D: Vishay General SemiconductorDocument5 pagesUg2A, Ug2B, Ug2C, Ug2D: Vishay General SemiconductorKhan SahibNo ratings yet

- Datasheet (Puente de Diodos - MB6S)Document3 pagesDatasheet (Puente de Diodos - MB6S)camilo portelaNo ratings yet

- Data SheetDocument2 pagesData Sheetalain rougetNo ratings yet

- 2.0A Rectifier: DO-15 Dim Min Max A B C D All Dimensions in MMDocument2 pages2.0A Rectifier: DO-15 Dim Min Max A B C D All Dimensions in MMPedro Andre Rodrigues NetoNo ratings yet

- P1A Thru P7A: FeaturesDocument5 pagesP1A Thru P7A: FeaturesFrank LunaNo ratings yet

- SB160 Schottky Diode 60V 1a PDFDocument3 pagesSB160 Schottky Diode 60V 1a PDFdemostenessNo ratings yet

- RL204 PDFDocument4 pagesRL204 PDFFederico TorreNo ratings yet

- FR201 Thru FR207: 2.0 A Fast Recovery Silicon RectifierDocument2 pagesFR201 Thru FR207: 2.0 A Fast Recovery Silicon RectifierMega GhostNo ratings yet

- Rectron: SemiconductorDocument2 pagesRectron: SemiconductorAVRPICNo ratings yet

- 1N5817,1N5818,1N5819 1N58:, 20 SeriesDocument4 pages1N5817,1N5818,1N5819 1N58:, 20 Seriespre freedaNo ratings yet

- Vishay General Semiconductor: FeaturesDocument4 pagesVishay General Semiconductor: FeaturesYacine BàssotiNo ratings yet

- 3.0A Rectifier: DO-201AD Dim Min Max A B C D All Dimensions in MMDocument2 pages3.0A Rectifier: DO-201AD Dim Min Max A B C D All Dimensions in MMyoubobbyNo ratings yet

- Rohs Rohs: Creat by ArtDocument2 pagesRohs Rohs: Creat by ArtИльнур ТагировNo ratings yet

- File 201709281703398218Document3 pagesFile 201709281703398218Victor CaprielNo ratings yet

- SK32 - SK36: Surface Mount Schottky Barrier RectifierDocument2 pagesSK32 - SK36: Surface Mount Schottky Barrier RectifierAnonymous 50FYYM2No ratings yet

- Assignment 1 DevicesDocument5 pagesAssignment 1 DevicesChou Zen HangNo ratings yet

- 3.0A RectifierDocument2 pages3.0A RectifierAdrianoEngelNo ratings yet

- SWRTHRJDocument1 pageSWRTHRJvineeth MNo ratings yet

- RL201G THRU RL207G: Chenyi ElectronicsDocument3 pagesRL201G THRU RL207G: Chenyi ElectronicslucasmosnaNo ratings yet

- Datasheet Diode IN4002GDocument3 pagesDatasheet Diode IN4002GPoupée De SoieNo ratings yet

- Features: Lead Free Finish, Rohs Compliant (Note 3)Document3 pagesFeatures: Lead Free Finish, Rohs Compliant (Note 3)Därî Bööm GäńgNo ratings yet

- KBPXXM, 3N2Xx: Vishay General SemiconductorDocument4 pagesKBPXXM, 3N2Xx: Vishay General SemiconductorReynaldo CastilloNo ratings yet

- 2N5060 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument8 pages2N5060 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsAndresNo ratings yet

- Silicon Rectifier: VOLTAGE RANGE 1200 Volts CURRENT 1.0 AmpereDocument8 pagesSilicon Rectifier: VOLTAGE RANGE 1200 Volts CURRENT 1.0 AmpereVachara MongNo ratings yet

- LM4001 THRU LM4007: Surface Mount Silicon RectifiersDocument2 pagesLM4001 THRU LM4007: Surface Mount Silicon RectifiersEliecer MenesesNo ratings yet

- SBL2030PT, SBL2040PT: Vishay General SemiconductorDocument4 pagesSBL2030PT, SBL2040PT: Vishay General SemiconductortallertecuNo ratings yet

- MBRS140T3 Surface Mount Schottky Power RectifierDocument4 pagesMBRS140T3 Surface Mount Schottky Power RectifierfreddyNo ratings yet

- Gu1m eDocument2 pagesGu1m eAlexandre SoaresNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- D ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TDocument6 pagesD ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TMindSet MarcosNo ratings yet

- RL201 - RL207 Silicon Rectifier: Mechanical Data FeaturesDocument2 pagesRL201 - RL207 Silicon Rectifier: Mechanical Data FeaturesJoelCNNo ratings yet

- Shanghai Sunrise Electronics Co., LTD.: Ss32 Thru Ss36Document1 pageShanghai Sunrise Electronics Co., LTD.: Ss32 Thru Ss36Nando AguilarNo ratings yet

- 1N5400 Thru 1N5408: 3.0A Rectifier 3.0A Rectifier Comchip ComchipDocument3 pages1N5400 Thru 1N5408: 3.0A Rectifier 3.0A Rectifier Comchip Comchipmiguel angelNo ratings yet

- GP20A-Sunmate DiodaDocument2 pagesGP20A-Sunmate Diodadavorp1402No ratings yet

- Diodo Rectif ds29008Document3 pagesDiodo Rectif ds29008Mela SobanNo ratings yet

- DatasheetDocument2 pagesDatasheetالملك العقربNo ratings yet

- TS15P01G TaiwanSemiconductorDocument2 pagesTS15P01G TaiwanSemiconductoralex castroNo ratings yet

- Single-Phase Bridge RectifierDocument4 pagesSingle-Phase Bridge RectifiercarlosNo ratings yet

- Datasheet ReleDocument2 pagesDatasheet ReleGuillermo Pocovi L.No ratings yet

- DB101 Sepelectronic 1Document2 pagesDB101 Sepelectronic 1Lope GarciaNo ratings yet

- Acst 12Document13 pagesAcst 12Eduardo MontielNo ratings yet

- Shanghai Sunrise Electronics Co., LTD.: Us2Aa Thru Us2MaDocument1 pageShanghai Sunrise Electronics Co., LTD.: Us2Aa Thru Us2MaVinhNo ratings yet

- ds26008 PDFDocument3 pagesds26008 PDFwxapazmiNo ratings yet

- Datasheet DiodoDocument2 pagesDatasheet DiodoDayana Serrano ParedesNo ratings yet

- TE RelayDocument2 pagesTE RelayPrabha Karan.nNo ratings yet

- MUR460Document4 pagesMUR460Oussama MessaoudiNo ratings yet

- sk13 DiodeDocument3 pagessk13 DiodeДрагиша Небитни ТрифуновићNo ratings yet

- Silicon Rectifier: Thru 1N4 1N4001Document9 pagesSilicon Rectifier: Thru 1N4 1N4001Jeffrey ValleNo ratings yet

- Glass Passivated Single-Phase Bridge RectifierDocument4 pagesGlass Passivated Single-Phase Bridge Rectifieretovive1No ratings yet

- 1N4933 THRU 1N4937: Plastic Fast Recovery RectifierDocument3 pages1N4933 THRU 1N4937: Plastic Fast Recovery RectifierFrancisco Fernando SouzaNo ratings yet

- 31 GF 6Document4 pages31 GF 6Mehdi MohammadiNo ratings yet

- 1N5817 Thru 1N5819: Schottky Barrier RectifierDocument4 pages1N5817 Thru 1N5819: Schottky Barrier Rectifierprofe321No ratings yet

- Power Diodes: SchottkyDocument2 pagesPower Diodes: SchottkyRoserox25No ratings yet

- Diode RR2LAM6STFDocument8 pagesDiode RR2LAM6STF강이석No ratings yet

- Closed Loop Control of Hexagram Inverter: G.Renukadevi, K.RajambalDocument8 pagesClosed Loop Control of Hexagram Inverter: G.Renukadevi, K.Rajambalrenunila100% (1)

- l1718sbn 17 LCD MonitorDocument35 pagesl1718sbn 17 LCD Monitorlitos_plusNo ratings yet

- A Technical Report On Students Industrial Work Experience Sheme (Siwes)Document29 pagesA Technical Report On Students Industrial Work Experience Sheme (Siwes)Daniel BayodeNo ratings yet

- An Electronic Ballast With Power Factor Correction For Fluorescent LampsDocument5 pagesAn Electronic Ballast With Power Factor Correction For Fluorescent Lampsjeeva_ebookNo ratings yet

- Electronics Project FinalDocument45 pagesElectronics Project Finalfiraol temesgenNo ratings yet

- GBJ25MDocument2 pagesGBJ25MVinod DawraNo ratings yet

- New Static Var Control Using Force Commutated Inverters PDFDocument9 pagesNew Static Var Control Using Force Commutated Inverters PDFrakeshee2007No ratings yet

- Design and Simulation of PFC Based CUK CDocument6 pagesDesign and Simulation of PFC Based CUK CSameer AnandNo ratings yet

- Ec8351 Electron Devices and CircuitsDocument1 pageEc8351 Electron Devices and CircuitsAnonymous yO7rcec6vuNo ratings yet

- Ti - Isolated Current SensingDocument11 pagesTi - Isolated Current SensingIvana PrezimeNo ratings yet

- Empire Telegraph CommunicationsDocument29 pagesEmpire Telegraph CommunicationsNur Hidayah NazriNo ratings yet

- Sect 1Document30 pagesSect 1Sry SantosNo ratings yet

- ELE 22/3AJM000608-059 ACS6000 Drive Backup ControlDocument14 pagesELE 22/3AJM000608-059 ACS6000 Drive Backup ControlForce MomentumNo ratings yet

- Comparison of HVDC Line Models in PSB Simulink BasedDocument6 pagesComparison of HVDC Line Models in PSB Simulink BasedAlan DrewNo ratings yet

- Statron s3000 EN - mrz2021Document4 pagesStatron s3000 EN - mrz2021Nicolas LecourtNo ratings yet

- Tps 40057 PWPDocument33 pagesTps 40057 PWPcatsoithahuong84No ratings yet

- Ador WeldDocument130 pagesAdor Weldjignesh sutariyaNo ratings yet

- TD1410 TechcodeDocument15 pagesTD1410 TechcodegrooyoNo ratings yet

- Crown - K-Series - k1 - k2 - Full - SM - 2 - Cópia PDFDocument129 pagesCrown - K-Series - k1 - k2 - Full - SM - 2 - Cópia PDFEulerMartinsDeMello100% (1)

- 4.e-Beam Process SystemsDocument3 pages4.e-Beam Process SystemsekkawatNo ratings yet

- GR Bee PPTS Unit - I To IvDocument205 pagesGR Bee PPTS Unit - I To IvSri HarshaNo ratings yet

- Rectifier Power Factor and Pulse-Width Modultion Controlled Rectifier CircuitsDocument23 pagesRectifier Power Factor and Pulse-Width Modultion Controlled Rectifier CircuitsChristopher RoblesNo ratings yet

- ACS-Applied Materials and Interfaces - BiFeO3 and PDMS NanogeneratorDocument8 pagesACS-Applied Materials and Interfaces - BiFeO3 and PDMS NanogeneratorNeeraj Panwar100% (1)

- Byg 22 ADocument5 pagesByg 22 AAnonymous xTGQYFrNo ratings yet

- Chapter 2 - Diode ApplicationsDocument27 pagesChapter 2 - Diode ApplicationsOnechoNo ratings yet

- C 3677 - DC/DC Converter: Page 1/3Document3 pagesC 3677 - DC/DC Converter: Page 1/3Petre GabrielNo ratings yet

- Project Report KKKDocument36 pagesProject Report KKKAmit SinghNo ratings yet

- Shindengen: Super Fast Recovery RectifiersDocument7 pagesShindengen: Super Fast Recovery RectifiersJose Carlos SoaresNo ratings yet