Professional Documents

Culture Documents

Acst 12

Uploaded by

Eduardo MontielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acst 12

Uploaded by

Eduardo MontielCopyright:

Available Formats

ACST12

Overvoltage protected AC switch

Features

OUT

■ Triac with overvoltage crowbar technology OUT

■ Low IGT (<10 mA) or high immunity

(IGT<35 mA) version

G

■ High noise immunity: static dV/dt > 2000 V/µs G

OUT

COM COM

Benefits

TO-220AB D2PAK

■ Enables equipment to meet IEC 61000-4-5

ACST1210-7T ACST1210-7G

■ High off-state reliability with planar technology ACST1235-7T ACST1235-7G

■ Need no external over voltage protection

■ Reduces the power passive component count Figure 1. Functional diagram

■ High immunity against fast transients

OUT

described in IEC 61000-4-4 standards

Applications

■ AC mains static switching in appliance and

industrial control systems

G

■ Drive of medium power AC loads such as:

– Universal motor of washing machine drum COM

– Compressor for fridge or air conditioner

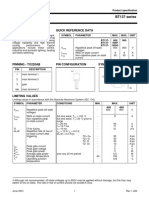

Table 1. Device summary

Description

Symbol Value Unit

The ACST12 series belongs to the ACS™/ACST

power switch family built with A.S.D.® (application IT(RMS) 12 A

specific discrete) technology. This high VDRM/VRRM 700 V

performance device is suited to home appliances

IGT 10 or 35 mA

or industrial systems and drives loads up to 12 A.

This ACST12 switch embeds a Triac structure and

a high voltage clamping device able to absorb the

inductive turn-off energy and withstand line

transients such as those described in the

IEC 61000-4-5 standard. The ACST1210-7 needs

a low gate current to be activated (IGT < 10 mA)

and still provides a high electrical noise immunity

complying with the IEC 61000-4-4 standard. The TM: ACS is a trademark of STMicroelectronics

ACST1235-7 offers an extremely high static dV/dt ®: A.S.D. is a registered trademark of STMicroelectronics

immunity of 2 kV/µs minimum.

December 2010 Doc ID 15238 Rev 4 1/13

www.st.com 13

Characteristics ACST12

1 Characteristics

Table 2. Absolute ratings (limiting values)

Symbol Parameter Value Unit

TO-220AB

Tc = 104 °C 12

D2PAK

IT(RMS) On-state rms current full sine wave A

D2PAK Tamb = 47

2

with 1cm2 of Cu °C

Non repetitive surge peak on-state current F = 60 Hz tp = 16.7 ms 126 A

ITSM

Tj initial = 25 °C,( full cycle sine wave) F = 50 Hz tp = 20.0 ms 120 A

2t

I I2t for fuse selection tp = 10 ms 95 A2s

Critical rate of rise on-state current

dI/dt F = 120 Hz Tj = 125 °C 100 A/µs

IG = 2 x IGT, (tr ≤ 100 ns)

VPP Non repetitive line peak pulse voltage (1) Tj = 125 °C 2 kV

PG(AV) Average gate power dissipation Tj = 125 °C 0.1 W

PGM Peak gate power dissipation (tp = 20 µs) Tj = 125 °C 10 W

IGM Peak gate current (tp = 20 µs) Tj = 125 °C 1.6 A

Tstg Storage temperature range - 40 to + 150 °C

Tj Operating junction temperature range - 40 to + 125 °C

Tl maximum lead soldering temperature during 10 s (at 3 mm from plastic case) 260 °C

1. According to test described in IEC 61000-4-5 standard and Figure 19

Table 3. Electrical characteristics

Value Unit

Symbol Test conditions Quadrant Tj

ACST1210-7 ACST1235-7 Unit

IGT(1) VOUT = 12 V, RL = 33 Ω I - II - III 25 °C MAX. 10 35 mA

VGT VOUT = 12 V, RL = 33 Ω I - II - III 25 °C MAX. 1.0 V

VGD VOUT = VDRM, RL = 3.3 Ω I - II - III 125 °C MIN. 0.2 V

IH(2) IOUT = 500 mA 25 °C MAX. 30 50 mA

IL IG = 1.2 x IGT I - II - III 25 °C MAX. 50 70 mA

dV/dt(2) VOUT = 67% VDRM, gate open 125 °C MIN. 200 2000 V/µs

(dV/dt)c = 15 V/µs MIN. 5.3

(dI/dt)c(2) 125 °C A/ms

Without snubber MIN. 14

VCL ICL = 0.1 mA, tp = 1 ms 25 °C MIN. 850 V

1. Minimum IGT is guaranteed at 5% of IGT max

2. For both polarities of OUT pin referenced to COM pin

2/13 Doc ID 15238 Rev 4

ACST12 Characteristics

Table 4. Static characteristics

Symbol Test conditions Value Unit

VTM(1) IOUT = 17 A, tp = 500 µs Tj = 25 °C MAX. 1.5 V

(1)

VT0 Threshold voltage Tj = 125 °C MAX. 0.9 V

Rd(1) Dynamic resistance Tj = 125 °C MAX. 30 mΩ

IDRM Tj = 25 °C 20 µA

VOUT = VDRM/ VRRM MAX.

IRRM Tj = 125 °C 1.5 mA

1. For both polarities of OUT pin referenced to COM pin

Table 5. Thermal characteristics

Symbol Parameter Value Unit

TO-220AB °C/W

Rth(j-c) Junction to case (AC) 1.5

2PAK

D °C/W

TO-220AB 60 °C/W

Rth(j-a) Junction to ambient

D2PAK with 1 cm2 of Cu 45 °C/W

Figure 2. Maximum power dissipation versus Figure 3. On-state rms current versus case

on-state rms current (full cycle) temperature (full cycle)

P(W)

IT(RMS) (A)

15 13

14 α=180 °

12

13

11

12

10

11

10 9

9 8

8 7

7 6

6 5

5 4

4 3

3

2

2 IT(RMS)(A) TC(°C)

1

1

0

0

0 1 2 3 4 5 6 7 8 9 10 11 12 0 25 50 75 100 125

Figure 4. On-state rms current versus Figure 5. Relative variation of thermal

ambient temperature (free air impedance versus pulse duration

convection full cycle)

IT(RMS)(A) K=[Zth/Rth]

3.0 1.0E+00

D2PAK Z th(j-c)

With 1cm2 of cu

Zth(j-a)

2.5

2.0

TO-220AB

1.5 1.0E-01

1.0

0.5

Tamb(°C)

tp(s)

0.0 1.0E-02

0 25 50 75 100 125 1.0E-03 1.0E-02 1.0E-01 1.0E+00 1.0E+01 1.0E+02 1.0E+03

Doc ID 15238 Rev 4 3/13

Characteristics ACST12

Figure 6. On-state characteristics Figure 7. Non repetitive surge peak on-state

(maximum values) current versus number of cycles

(Tj initial = 25 °C)

ITM (A)

ITSM(A)

1000 130

120

110

t=20ms

100

90 Non repetitive One cycle

100

80 Tj initial=25 °C

70

60

50

10 40

30

Tj max : 20 Repetitive

Vto = 0.90 V 10 TC=104 °C Number of cycles

Tj=125 °C Tj=25 °C Rd = 30 mΩ

VTM (V)

0

1

1 10 100 1000

0 1 2 3 4 5

Figure 8. Non repetitive surge peak on-state Figure 9. Relative variation of gate triggering

current for a sinusoidal pulse and current and gate voltage versus

corresponding value of I2t junction temperature (typical value)

ITSM(A), I2t (A2s) IGT, VGT[Tj] / IGT, VGT[Tj = 25 °C]

10000 3.0

dI/dt limitation: 100 A/µs Tj initial=25 °C

2.5 IGT Q3

1000 ITSM

IGT Q1-Q2

2.0

100 1.5

I²t

1.0 VGT Q1-Q2-Q3

10

0.5

tP(ms) T j(°C)

1 0.0

0.01 0.10 1.00 10.00 -50 -25 0 25 50 75 100 125

Figure 10. Relative variation of holding Figure 11. Relative variation of critical rate of

current (IH) and latching current (IL) decrease of main current (di/dt)c

versus junction temperature versus (dV/dt)c

IH,IL[Tj]/IH, IL[Tj = 25 °C] (di/dt)c[(dV/dt)c] / Specified(di/dt)c

2.5 1.6

1.4

2.0

1.2

ACST12-7Cxx

1.0

1.5

Typical values

0.8

1.0 ACST12-7Sxx

0.6

IL

0.4

0.5

IH

0.2

(dV/dt)c (V/µs)

Tj (°C)

0.0 0.0

0.1 1 10 100

-50 -25 0 25 50 75 100 125

4/13 Doc ID 15238 Rev 4

ACST12 Characteristics

Figure 12. Relative variation of critical rate of Figure 13. Relative variation of static dV/dt

decrease of main current versus immunity versus junction

junction temperature temperature

(dI/dt)c[Tj] / (dI/dt)c[Tj=125°C] dV/dt[Tj] / dV/dt[Tj=125°C]

11 12

VD=VR=469 V

10 11

9 10

9

8

8

7

7

6

6

5

5

4

4

3

3

2 2

1 1

Tj(°C) Tj(°C)

0 0

25 50 75 100 125 25 50 75 100 125

Figure 14. Relative variation of maximum Figure 15. Variation of thermal resistance

clamping voltage, VCL versus junction to ambient versus copper

junction temperature surface under tab

VCL[TJ/VCL[TJ = 25 °C] Rth(j-a)(°C/W)

1.15 80

Epoxy printed circuit board

70 D²PAK

1.10 FR4, copper thickness = 35 µm

60

1.05

50

1.00 40

Minimum values 30

0.95

20

0.90

10

TJ(°C) SCU(cm²)

0.85 0

-50 -25 0 25 50 75 100 125 0 5 10 15 20

Doc ID 15238 Rev 4 5/13

Application information ACST12

2 Application information

2.1 Typical application description

The ACST12 device has been designed to control medium power load, such as AC motors

in home appliances. Thanks to its thermal and turn off commutation performances, the

ACST12 switch is able to drive an inductive load up to 12 A with no turn off additional

snubber. It also provides high thermal performances in static and transient modes such as

the compressor inrush current or high torque operating conditions of an AC motor. Thanks

to its low gate triggering current level, the ACST1210-7 can be driven directly by a MCU

through a simple gate resistor as shown in Figure 16.

Figure 16. Compressor control – typical diagrams

Compressor Compressor

AC Mains

PTC AC Mains

Electronic PTC

ACST

starter

2

1 logical circuitry ACST

Start

3

switch

ACST

Run

switch

Electronic

ACST thermostat

Rg

Rg Rg

Gate Gate

Driver

Power supply Power supply Driver

Compressor with integrated e-starter Compressor with external electronic drive

6/13 Doc ID 15238 Rev 4

ACST12 Application information

Figure 17. Universal drum motor control – typical diagram

Universal motor

Stator Rotor

12V

AC Mains

Motor direction

setting

MCU

ACST

Speed motor Rg

regulation

Vcc

MCU

2.2 AC line transient voltage ruggedness

In comparison with standard Triacs, which are not robust against surge voltage, the ACST12

is self-protected against over-voltage, specified by the new parameter VCL. The ACST12

switch can safely withstand AC line transient voltages either by clamping the low energy

spikes, such as the inductive spikes at switch off, or by switching to the on state (for less

than 10 ms) to dissipate higher energy shocks through the load. This safety feature works

even with high turn-on current ramp-up.

The test circuit of Figure 18 represents the ACST12 application, and is used to stress the

ACST switch according to the IEC 61000-4-5 standard conditions. With the additional effect

of the load which is limiting the current, the ACST switch withstands the voltage spikes up to

2 kV on top of the peak line voltage. The protection is based on an overvoltage crowbar

technology. The ACST12 folds back safely to the on state as shown in Figure 19. The

ACST12 recovers its blocking voltage capability after the surge and the next zero crossing

current. Such a non repetitive test can be done at least 10 times on each AC line voltage

polarity.

Doc ID 15238 Rev 4 7/13

Application information ACST12

Figure 18. Overvoltage ruggedness test circuit for resistive and inductive loads for

IEC 61000-4-5 standards

R = 20 Ω, L = 2 µH, Vsurge = 2 kV

Surge generator

2kV surge

Rgene

Model of the load

Filtering unit

R L

ACST12

AC Mains

Rg

Figure 19. Typical voltage and current waveforms across the ACST12

during IEC 61000-4-5 standard test

V peak = V CL

1.2/50 µs voltage surge

8/20 µs current surge

I

0

8/13 Doc ID 15238 Rev 4

ACST12 Ordering information scheme

3 Ordering information scheme

Figure 20. Ordering information scheme

ACS T 12 10 - 7 G TR

AC switch

Topology

T = Triac

On-state rms current

12 = 12 A

Sensitivity

10 = 10 mA

35 = 35 mA

Voltage

7 = 700 V

Package

G = D²PAK

T = TO-220AB

Delivery mode

TR = Tape and reel (DPAK)

Blank = Tube (TO-220FPAB, DPAK)

Doc ID 15238 Rev 4 9/13

Package information ACST12

4 Package information

● Epoxy meets UL94, V0

● Recommended torque (TO-220AB): 0.4 to 0.6 N·m

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

Table 6. TO-220AB dimensions

Dimensions

Ref. Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

H2 A

D 2.40 2.72 0.094 0.107

Dia C

E 0.49 0.70 0.019 0.027

L5

L7 F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.066

L6

F2 1.14 1.70 0.044 0.066

L2

F2 G 4.95 5.15 0.194 0.202

D

F1 L9 G1 2.40 2.70 0.094 0.106

L4

H2 10 10.40 0.393 0.409

F L2 16.4 typ. 0.645 typ.

M L4 13 14 0.511 0.551

G1 E

L5 2.65 2.95 0.104 0.116

G

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.259

L9 3.50 3.93 0.137 0.154

M 2.6 typ. 0.102 typ.

Diam. 3.75 3.85 0.147 0.151

10/13 Doc ID 15238 Rev 4

ACST12 Package information

Table 7. D2PAK dimensions

Dimensions

Ref. Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 4.30 4.60 0.169 0.181

A

A1 2.49 2.69 0.098 0.106

E

C2

L2 A2 0.03 0.23 0.001 0.009

B 0.70 0.93 0.027 0.037

D

L

B2 1.25 1.40 0.048 0.055

L3 C 0.45 0.60 0.017 0.024

A1

C2 1.21 1.36 0.047 0.054

B2

C R

B D 8.95 9.35 0.352 0.368

G E 10.00 10.28 0.393 0.405

A2 G 4.88 5.28 0.192 0.208

2mm min.

FLAT ZONE

L 15.00 15.85 0.590 0.624

V2 L2 1.27 1.40 0.050 0.055

L3 1.40 1.75 0.055 0.069

R 0.40 0.016

V2 0° 8° 0° 8°

Figure 21. Footprint (dimensions in mm)

16.90

10.30 5.08

1.30

3.70

8.90

Doc ID 15238 Rev 4 11/13

Ordering information ACST12

5 Ordering information

Table 8. Ordering information

Order code Marking Package Weight Base qty Packing mode

ACST1210-7T TO-220AB 2.3 g 50 Tube

2

ACST1210-7G ACST12107 D PAK 1.5 g 50 Tube

2

ACST1210-7GTR D PAK 1.5 g 1000 Tape and reel

ACST1235-7T TO-220AB 2.3 g 50 Tube

2

ACST1235-7G ACST12357 D PAK 1.5 g 50 Tube

2PAK

ACST1235-7GTR D 1.5 g 1000 Tape and reel

6 Revision history

Table 9. Document revision history

Date Revision Changes

02-Dec-2008 1 First issue.

Updated ECOPACK statement. Reformatted for consistency with

13-Apr-2010 2

other datasheets in this product class.

01-Jul-2010 3 Updated Figure 20.

07-Dec-2010 4 Updated Table 3.

12/13 Doc ID 15238 Rev 4

ACST12

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15238 Rev 4 13/13

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- ACS108-6S: Overvoltage Protected AC Switch (ACS™)Document12 pagesACS108-6S: Overvoltage Protected AC Switch (ACS™)SamerNo ratings yet

- Acs108 6sa PDFDocument11 pagesAcs108 6sa PDFJahangir JinguNo ratings yet

- Acs108-8tn TriacDocument14 pagesAcs108-8tn TriacIgnacio ReyesNo ratings yet

- Acst2: Overvoltage Protected AC SwitchDocument14 pagesAcst2: Overvoltage Protected AC Switchdinny blancoNo ratings yet

- Acst6: Over Voltage Protected Ac Power SwitchDocument10 pagesAcst6: Over Voltage Protected Ac Power SwitchJose Carlos SoaresNo ratings yet

- Acs 1026Document11 pagesAcs 1026José InácioNo ratings yet

- Acst2 8SBDocument13 pagesAcst2 8SBoguiaNo ratings yet

- T1235T-8FP: 12 A Snubberless™ TriacDocument9 pagesT1235T-8FP: 12 A Snubberless™ TriacArguetaManuelNo ratings yet

- TriacDocument11 pagesTriacalitoparanaNo ratings yet

- Acst 4Document14 pagesAcst 4Eduardo MontielNo ratings yet

- Datasheet 1 4Document5 pagesDatasheet 1 4HJavi MPNo ratings yet

- 12 A 800 V Snubberless Triac in TO-220AB Package: FeaturesDocument11 pages12 A 800 V Snubberless Triac in TO-220AB Package: FeaturesDelos Santos JojoNo ratings yet

- Datasheet Acs 120 PDFDocument11 pagesDatasheet Acs 120 PDFyudi heriyantoNo ratings yet

- Snubberless Triac: FeaturesDocument5 pagesSnubberless Triac: FeaturesImam MoyoNo ratings yet

- ACST4 Series: Ac Power Switch Asd™ AC Switch FamilyDocument9 pagesACST4 Series: Ac Power Switch Asd™ AC Switch FamilyMohsenNo ratings yet

- Three Quadrant Triacs BTA212 Series B High Commutation: General Description Quick Reference DataDocument6 pagesThree Quadrant Triacs BTA212 Series B High Commutation: General Description Quick Reference DataВасилий ЛитвинNo ratings yet

- Acs 102Document8 pagesAcs 102Alexis RamonNo ratings yet

- TRIACS CatálogoDocument8 pagesTRIACS CatálogoJacy FigueNo ratings yet

- ACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilyDocument10 pagesACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilySamerNo ratings yet

- BT137Document7 pagesBT137Gabriel RacovskyNo ratings yet

- T1020-600W T1030-600W: Snubberless TriacDocument5 pagesT1020-600W T1030-600W: Snubberless Triac2019 Der CHINO GUTIERREZ EDUARDONo ratings yet

- M XyzxrvDocument6 pagesM XyzxrvAltamiro RochaNo ratings yet

- B 12Document13 pagesB 12Mn MsNo ratings yet

- M XyzxrwDocument6 pagesM XyzxrwImam MoyoNo ratings yet

- Triacs BT137X Series D Logic Level: General Description Quick Reference DataDocument6 pagesTriacs BT137X Series D Logic Level: General Description Quick Reference DataSantiago SerranoNo ratings yet

- BT138 SeriesDocument8 pagesBT138 SeriesYogi RuliemNo ratings yet

- Triacs BT137 Series: General Description Quick Reference DataDocument3 pagesTriacs BT137 Series: General Description Quick Reference DataLidice BarreraNo ratings yet

- Mac16Cm, Mac16Cn Triacs: Silicon Bidirectional ThyristorsDocument9 pagesMac16Cm, Mac16Cn Triacs: Silicon Bidirectional ThyristorsAllan DANo ratings yet

- t1635t 8i PDFDocument10 pagest1635t 8i PDFAhmed MataryNo ratings yet

- BTW67 and BTW69 Series: 50A SCRDocument7 pagesBTW67 and BTW69 Series: 50A SCRAdrian FerreyraNo ratings yet

- Features: 12 A SCRDocument8 pagesFeatures: 12 A SCRSem NomeNo ratings yet

- BT139 PhilipsDocument6 pagesBT139 PhilipsDelcu MarinicaNo ratings yet

- C106 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument7 pagesC106 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsOmarNo ratings yet

- DatasheetDocument6 pagesDatasheetratnaNo ratings yet

- XL1225 - Hoja de Datos Del Circuito Integrado PDFDocument3 pagesXL1225 - Hoja de Datos Del Circuito Integrado PDFLoth Matheus Barba MazaNo ratings yet

- Triacs BT137-600D Logic Level: General Description Quick Reference DataDocument7 pagesTriacs BT137-600D Logic Level: General Description Quick Reference DataGabriel Alexander R. MNo ratings yet

- scp25c60Document5 pagesscp25c60ly7123No ratings yet

- Datasheet 2Document8 pagesDatasheet 2YELZAX C.ANo ratings yet

- MCR100W 10M 0-2902672Document12 pagesMCR100W 10M 0-2902672chawkigenieNo ratings yet

- BTW67 STANDARD 50A SCRs - STMicroelectronicsDocument5 pagesBTW67 STANDARD 50A SCRs - STMicroelectronicsAndis MashudNo ratings yet

- STTH212: DescriptionDocument11 pagesSTTH212: DescriptionPablo Gonzalez RivielloNo ratings yet

- BT137 PhiDocument6 pagesBT137 PhiJavierJBVNo ratings yet

- T1620 700W STMicroelectronics PDFDocument5 pagesT1620 700W STMicroelectronics PDFautotronica Santa CruzNo ratings yet

- D Data Sheet: BT131W SeriesDocument9 pagesD Data Sheet: BT131W Seriesuser_scribd54635No ratings yet

- High Temperature 8 A Sensitive Triacs: FeaturesDocument10 pagesHigh Temperature 8 A Sensitive Triacs: Featureselbaron.maintenanceNo ratings yet

- Bt136 SeriesDocument6 pagesBt136 SeriesRudy GunawanNo ratings yet

- TPDV1225 STMicroelectronicsDocument7 pagesTPDV1225 STMicroelectronicsfouad nadjiNo ratings yet

- BTW69 1200Document5 pagesBTW69 1200GiraldoCarpioRamosNo ratings yet

- TXDVXX 12Document7 pagesTXDVXX 12Pedro RochaNo ratings yet

- Snubberless™, Logic Level and Standard 8 A Triacs: FeaturesDocument8 pagesSnubberless™, Logic Level and Standard 8 A Triacs: Featuresjhon7410No ratings yet

- btw69 1200Document9 pagesbtw69 1200Kumar ShresthaNo ratings yet

- Datasheet 4Document5 pagesDatasheet 4Sadegh ShebaniNo ratings yet

- BT151Document8 pagesBT151Javier ParedesNo ratings yet

- High surge silicon controlled rectifierDocument5 pagesHigh surge silicon controlled rectifierBuitinės Technikos RemontasNo ratings yet

- BT137 Series: 8A TriacDocument4 pagesBT137 Series: 8A TriacRenso RodriguezNo ratings yet

- BT131 Series: General Description Quick Reference DataDocument5 pagesBT131 Series: General Description Quick Reference DataDabro FabioNo ratings yet

- Three Quadrant Triacs BTA204S Series B and C High CommutationDocument6 pagesThree Quadrant Triacs BTA204S Series B and C High CommutationAlex SandroNo ratings yet

- Llave de Impacto PDFDocument21 pagesLlave de Impacto PDFmasterfiera1No ratings yet

- Ch06 Allocating Resources To The ProjectDocument55 pagesCh06 Allocating Resources To The ProjectJosh ChamaNo ratings yet

- Friends or Lovers (A Novel by Rory Ridley-Duff) - View in Full Screen ModeDocument336 pagesFriends or Lovers (A Novel by Rory Ridley-Duff) - View in Full Screen ModeRory Ridley Duff92% (24)

- TU20Document6 pagesTU20Manikumar KNo ratings yet

- Chetan Tour and Travel: Pickup Spot: Destination SpotDocument2 pagesChetan Tour and Travel: Pickup Spot: Destination SpotRahulNo ratings yet

- Pilkington Profilit Techn Info enDocument12 pagesPilkington Profilit Techn Info enSalmonelo Abdul RamosNo ratings yet

- Kirkpatricks ModelDocument2 pagesKirkpatricks Modelnazia_ahmed_10No ratings yet

- DP8 Series Manual - English PDFDocument48 pagesDP8 Series Manual - English PDFluis enrique de la rosa sanchezNo ratings yet

- Tutorial MagIC Net 2.XDocument99 pagesTutorial MagIC Net 2.XJuan Diego Aznar Fernández100% (1)

- HOUSEKEEPING SESSION PLANDocument2 pagesHOUSEKEEPING SESSION PLANScarlette Beauty Enriquez100% (1)

- Lucsuhin National High School Daily Lesson Plan on Accounting ConceptsDocument6 pagesLucsuhin National High School Daily Lesson Plan on Accounting ConceptsALMA ACUNANo ratings yet

- JohnsonJohnson 2006 PDFDocument84 pagesJohnsonJohnson 2006 PDFakfar b417No ratings yet

- HMSWeb - Handover Management SystemDocument21 pagesHMSWeb - Handover Management SystemGG GRNo ratings yet

- Index NumbersDocument23 pagesIndex NumbersemmaNo ratings yet

- GUEST REGISTRATION CARDDocument1 pageGUEST REGISTRATION CARDRasmi Ranjan Kar100% (1)

- Arpit Y2Document7 pagesArpit Y2swapnil jainNo ratings yet

- Describe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementDocument3 pagesDescribe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementAlemayehu Demeke80% (5)

- Key Benefits of Cloud-Based Internet of Vehicle (IoV) - Enabled Fleet Weight Management SystemDocument5 pagesKey Benefits of Cloud-Based Internet of Vehicle (IoV) - Enabled Fleet Weight Management SystemVelumani sNo ratings yet

- Meita Juniar - 41921200002 - Teknik Sipil Reg b2 Uas English For EngineerDocument18 pagesMeita Juniar - 41921200002 - Teknik Sipil Reg b2 Uas English For EngineerREG.B/41921200002/MEITA JUNIARNo ratings yet

- Somya Bhasin 24years Pune: Professional ExperienceDocument2 pagesSomya Bhasin 24years Pune: Professional ExperienceS1626No ratings yet

- RAN15.0 Feature ListDocument34 pagesRAN15.0 Feature ListmyososNo ratings yet

- Tender Status Report Delhi-Mumbai Expressway 10.01.19Document66 pagesTender Status Report Delhi-Mumbai Expressway 10.01.19chtrp100% (2)

- J-19-16-III - Bengali - FDocument24 pagesJ-19-16-III - Bengali - FDebayanbasu.juNo ratings yet

- 266DSH Differential Pressure TransmittersDocument36 pages266DSH Differential Pressure TransmittersSibabrata ChoudhuryNo ratings yet

- Career Profile: Nidhi PathakDocument4 pagesCareer Profile: Nidhi PathaknidhipathakNo ratings yet

- Assignment 1 Front Sheet: Qualification BTEC Level 4 HND Diploma in BusinessDocument14 pagesAssignment 1 Front Sheet: Qualification BTEC Level 4 HND Diploma in BusinessQuan PhanNo ratings yet

- DNV Casualty Info 2011 #3Document2 pagesDNV Casualty Info 2011 #3Sureen NarangNo ratings yet

- Bomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceDocument16 pagesBomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceAnonymous Pb39klJNo ratings yet

- OE-254/GRC antenna parts listDocument2 pagesOE-254/GRC antenna parts listVictor GarciaNo ratings yet

- Title Page - Super King Air C90CGTi FusionDocument2 pagesTitle Page - Super King Air C90CGTi Fusionsergio0% (1)