Professional Documents

Culture Documents

ACS108-6S: Overvoltage Protected AC Switch (ACS™)

Uploaded by

SamerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACS108-6S: Overvoltage Protected AC Switch (ACS™)

Uploaded by

SamerCopyright:

Available Formats

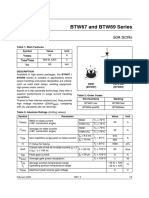

ACS108-6S

Overvoltage protected AC switch (ACS™)

Datasheet − production data

Features

■ Needs no external protection snubber or

varistor

■ Enables equipment to meet IEC 61000-4-5

COM

■ Reduces component count by up to 80%

OUT

■ Interfaces directly with the micro-controller

■ Common package tab connection supports G

connection of several alternating current SMBflat-3L

switches (ACS) on the same cooling pad ACS108-6SUF

■ Integrated structure based on A.S.D.®

technology

■ Overvoltage protection by crowbar technology

■ High noise immunity - static dV/dt > 500 V/µs

Applications Figure 1. Functional diagram

■ Alternating current on/off static switching in OUT

appliances and industrial control systems

■ Drive of low power high inductive or resistive

loads like:

G

– relay, valve, solenoid,

– dispenser, door lock

– pump, fan, low power motor

COM

Description COM Common drive reference to connect

to the mains

OUT Output to connect to the load.

The ACS108-6S belongs to the AC line switch G Gate input to connect to the controller

family. This high performance switch can control a through gate resistor

load of up to 0.8 A.

The ACS108-6S switch includes an overvoltage Table 1. Device summary

crowbar structure to absorb the overvoltage

energy, and a gate level shifter driver to separate Symbol Value Unit

the digital controller from the main switch. It is IT(RMS) 0.8 A

triggered with a negative gate current flowing out VDRM/VRRM 600 V

of the gate pin.

IGT 10 mA

®: A.S.D. is a registered trademark of STMicroelectonics

TM: ACS is a trademark of STMicroelectronics

June 2012 Doc ID 11962 Rev 4 1/12

This is information on a product in full production. www.st.com 12

Characteristics ACS108-6S

1 Characteristics

Table 2. Absolute maximum ratings (Tamb = 25 °C, unless otherwise specified)

Symbol Parameter Value Unit

Tamb = 62 °C 0.45 A

IT(RMS) On-state rms current (full sine wave)

Ttab = 113 °C 0.8 A

Non repetitive surge peak on-state F = 60 Hz t = 16.7 ms 7.6

ITSM current A

(full cycle sine wave, Tj initial = 25 °C) F = 50 Hz t = 20 ms 7.3

I2t I²t Value for fusing tp = 10 ms 0.38 A2 s

Critical rate of rise of on-state current

dI/dt F = 120 Hz Tj = 125 °C 100 A/µs

IG = 2xIGT, tr ≤ 100 ns

VPP Non repetitive line peak mains voltage(1) Tj = 25 °C 2 kV

IGM Peak gate current tp = 20 µs Tj = 125 °C 1 A

VGM Peak positive gate voltage Tj = 125 °C 10 V

PG(AV) Average gate power dissipation Tj = 125 °C 0.1 W

Tstg Storage junction temperature range -40 to +150

°C

Tj Operating junction temperature range -30 to +125

1. according to test described by IEC 61000-4-5 standard and Figure 19

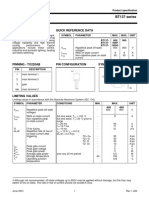

Table 3. Electrical characteristics (Tj = 25 °C, unless otherwise specified)

Symbol Test conditions Quadrant Value Unit

IGT(1) II - III Max. 10 mA

VOUT = 12 V, RL = 33 Ω

VGT II - III Max. 1 V

VGD VOUT = VDRM, RL =3.3 kΩ, Tj = 125 °C II - III Min. 0.15 V

IH (2) IOUT = 100 mA Max. 25 mA

IL(2) IG = 1.2 x IGT Max. 30 mA

dV/dt(2) VOUT = 67% VDRM, gate open, Tj = 125 °C Min. 500 V/µs

(dI/dt)c(2 A/ms

) Without snubber (15 V/µs), turn-off time ≤ 20 ms, Tj = 125 °C Min. 0.3

VCL ICL = 0.1 mA, tp = 1 ms, Tj = 125 °C Min. 650 V

1. Minimum IGT is guaranteed at 10% of IGT max

2. For both polarities of OUT referenced to COM

2/12 Doc ID 11962 Rev 4

ACS108-6S Characteristics

Table 4. Static electrical characteristics

Symbol Test conditions Value Unit

VTM (1) ITM = 1.1 A, tp = 500 µs Tj = 25 °C Max. 1.3 V

(1)

VTO Threshold voltage Tj = 125 °C Max. 0.90 V

(1)

RD Tj = 125 °C Max. 300 mΩ

IDRM Tj = 25 °C 2 µA

VOUT = 600 V Max.

IRRM Tj = 125 °C 0.2 mA

1. For both polarities of OUT referenced to COM

Table 5. Thermal resistance

Symbol Parameter Value Unit

Rth (j-t) Junction to tab (AC) Max. 14 °C/W

Rth (j-a) Junction to ambient S = 5 cm² Max. 75

Doc ID 11962 Rev 4 3/12

Characteristics ACS108-6S

Figure 2. Maximum power dissipation Figure 3. On-state rms current versus tab

versus on-state rms current temperature (full cycle)

(full cycle)

P(W) IT(RMS)(A)

0.9 1.00

180°

0.8 0.90

0.7 0.80

0.70

0.6

0.60

0.5

0.50

0.4

0.40

0.3

0.30

0.2 0.20

0.1 0.10

IT(RMS)(A) TC(°C)

0.0 0.00

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0 25 50 75 100 125

Figure 4. On-state rms current versus Figure 5. Relative variation of thermal

ambient temperature impedance junction to ambient

(free air convection) versus pulse duration

IT(RMS)(A) K = [Zth(j-a)/Rth(j-a)]

1.0 1.E+00

0.9

0.8

0.7

0.6

0.5 1.E-01

0.4

0.3

0.2

0.1

tp(s)

Ta(°C) 1.E-02

0.0

0 25 50 75 100 125 1.E-03 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

Figure 6. Relative variation of, holding and Figure 7. Releative variation of IGT and VGT

latching current versus junction versus junction temperature

temperature

IGT, VGT[Tj] / IGT, VGT[Tj = 25 °C]

IH, IL[Tj] / IH, IL[Tj = 25 °C] 2.8

2.0 2.6

1.8 2.4

2.2 IGT

1.6

2.0

1.4 1.8

1.6

1.2

1.4

1.0 1.2

VGT

0.8 1.0

0.8

0.6 IH 0.6

0.4 0.4

IL 0.2

0.2 Tj(°C)

Tj(°C) 0.0

0.0 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

4/12 Doc ID 11962 Rev 4

ACS108-6S Characteristics

Figure 8. Non repetitive surge peak on-state Figure 9. Non repetitive surge peak on-state

current versus number of cycles current for a sinusoidal pulse, and

corresponding value of I²t

ITSM(A) 2

10 ITSM(A), I t (A2s)

100.0

9 Tj initial = 25 °C

8 t = 20 ms

Non repetitive ITSM

7 Tj initial = 25 °C One cycle

10.0

6

5

pulse with width tp<10 ms, and corresponding value of I²t

4

Repetitive 1.0

3

Tc = 75 °C

2 I²t

1 tp(ms)

Number of cycles 0.1

0

0.01 0.10 1.00 10.00

1 10 100 1000

Figure 10. On-state characteristics (maximal Figure 11. Relative variation of critical rate of

values) decrease of main current versus

junction temperature

ITM(A) (dl / dt)c [Tj] / (dl / dt)c [Tj = 125 °C]

10.00 8

Tjmax: 7

Vto = 0.9 V

6

Rd = 300 mΩ

1.00

5

Tj = 125 °C

4

Tj = 25 °C

3

0.10

2

1

VTM(V) Tj(°C)

0.01 0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 25 50 75 100 125

Figure 12. Relative variation of static dV/dt Figure 13. Relative variation of the maximal

immunity versus junction clamping voltage versus junction

temperature temperature (min. value)

dV / dt [Tj] / dV / dt [Tj = 125 °C] VCL[Tj/VCL[Tj = 25°C]

8 1.15

7

1.10

6

1.05

5

4 1.00

3

0.95

2

0.90

1

Tj(°C) Tj(°C)

0 0.85

25 50 75 100 125 -30 -10 10 30 50 70 90 110 130

Doc ID 11962 Rev 4 5/12

Characteristics ACS108-6S

Figure 14. Relative variation of critical rate Figure 15. Thermal resistance junction to

ofdecrease of main current (di/dt)c ambient versus copper surface

versus (dV/dt)c under tab

(dI/dt)c [ (dV/dt) c ] / Specified (dI/dt) c

2.0 Rth(j-a)(°C/W)

VOUT = 400 V 170

1.8 turn-off time < 20 ms 160 Epoxy printed circuit board FR4,

copper thickness 35 µm

1.6 150

1.4 140

130

1.2

120

1.0 110

0.8 100

0.6 90

80

0.4

70

0.2 (dV/dt)c (V/µs)

60 S(cm²)

0.0 50

0.1 1 10 100 0 1 2 3 4 5

6/12 Doc ID 11962 Rev 4

ACS108-6S Alternating current line switch - basic application

2 Alternating current line switch - basic application

The ACS108-6S switch is triggered by a negative gate current flowing from the gate pin G.

The switch can be driven directly by the digital controller through a resistor as shown in

Figure 16.

Thanks to its overvoltage protection and turn-off commutation performance, the ACS108-6S

switch can drive a small power high inductive load with neither varistor nor additional turn-off

snubber.

Figure 16. Typical application program

Valve

AC Mains

Vss

Rg

MCU ACS108-6S

Power supply Vdd

2.1 Protection against overvoltage: the best choice is ACS

In comparison with standard triacs, which are not robust against surge voltage, the

ACS108-6S is over-voltage self-protected, specified by the new parameter VCL. This feature

is useful in two operating conditions: in case of turn-off of very inductive load, and in case of

surge voltage that can occur on the electrical network.

2.1.1 High inductive load switch-off: turn-off overvoltage clamping

With high inductive and low RMS current loads the rate of decrease of the current is very

low. An overvoltage can occur when the gate current is removed and the OUT current is

lower than IH.

As shown in Figure 17 and Figure 18, at the end of the last conduction half-cycle, the load

current decreases (1). The load current reaches the holding current level IH (2), and the

ACS turns off (3). The water valve, as an inductive load (up to 15 H), reacts as a current

generator and an overvoltage is created, which is clamped by the ACS (4). The current flows

through the ACS avalanche and decreases linearly to zero. During this time, the voltage

across the switch is limited to the clamping voltage VCL. The energy stored in the inductance

of the load is dissipated in the clamping section that is designed for this purpose. When the

energy has been dissipated, the ACS voltage falls back to the mains voltage value (5).

Doc ID 11962 Rev 4 7/12

Alternating current line switch - basic application ACS108-6S

Figure 17. Effect of the switching off of a high Figure 18. Description of the different steps

inductive load - typical clamping during switching off of a high

capability of ACS108-6S inductive load

4

I OUT

VPEAK = V CL

I OUT 1

(5 mA/div)

3 2 3

VOUT IH

(200 V/div) 4

1

5 VOUT

IH VCL

2

100µs/div

2.1.2 Alternating current line transient voltage ruggedness

The ACS108-6S switch is able to withstand safely the ac line transients either by clamping

the low energy spikes or by breaking over under high energy shocks, even with high turn-on

current rises.

The test circuit shown in Figure 19 is representative of the final ACS108-6S application, and

is also used to test the ac switch according to the IEC 61000-4-5 standard conditions.

Thanks to the load limiting the current, the ACS108-6S switch withstands the voltage spikes

up to 2 kV above the peak line voltage. The protection is based on an overvoltage crowbar

technology. Actually, the ACS108-6S breaks over safely as shown in Figure 20. The

ACS108-6S recovers its blocking voltage capability after the surge (switch off back at the

next zero crossing of the current).

Such non-repetitive tests can be done 10 times on each ac line voltage polarity.

Figure 19. Overvoltage ruggedness test Figure 20. Typical current and voltage

circuit for resistive and waveforms across the

inductive ACS108-6S

loads with conditions equivalent to during IEC 61000-4-5 standard test

IEC 61000-4-5 standards

VPEAK

I OUT

Surge generator

(2 A/div)

"1.2/50 waveform"

Model of the load VOUT

Rgene R L (200 V/div)

2 150 5µH

ACS108-6Sx

2.4 kV surge

Rg

220

200ns/div

8/12 Doc ID 11962 Rev 4

ACS108-6S Ordering information scheme

3 Ordering information scheme

Figure 21. Ordering information scheme

ACS 1 08 - 6 S UF -TR

AC switch series

Number of switches

Current

08 = 0.8 A rms

Voltage

6 = 600 V

Sensitivity

S = 10 mA

Package

UF = SMBflat-3L

Packing

TR = 13”, 5000 pieces

Doc ID 11962 Rev 4 9/12

Package information ACS108-6S

4 Package information

● Epoxy meets UL94, V0

● Lead-free packages

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

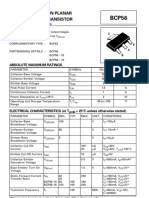

Table 6. SMBflat-3L dimensions

Dimensions

Ref. Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 0.90 1.10 0.035 0.043

A

c b 0.35 0.65 0.014 0.026

D e

b 2x b4 1.95 2.20 0.07 0.087

L 2x L2 2x

c 0.15 0.40 0.006 0.016

L1

E E1 D 3.30 3.95 0.130 0.156

L1

E 5.10 5.60 0.201 0.220

L L2

E1 4.05 4.60 0.156 0.181

b4

L 0.75 1.50 0.030 0.059

L1 0.40 0.016

L2 0.60 0.024

e 1.60 0.063

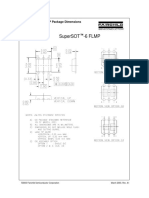

Figure 22. SMBflat-3L footprint dimensions

5.84

0.51 (0.230)

(0.020)

2.07 2.07

(0.082) (0.082)

0.51

(0.020)

1.20 3.44 1.20

(0.047) (0.136) (0.047)

millimeters

(inches)

10/12 Doc ID 11962 Rev 4

ACS108-6S Ordering information

5 Ordering information

Table 7. Ordering information

Order code Marking Package Weight Base Qty Delivery mode

ACS108-6SUF-TR ACS1086S SMBflat-3L 46.91 mg 5000 Tape and reel

6 Revision history

04

Table 8. Document revision history

Date Revision Changes

05-Jan-2005 1 Initial release.

07-Jun-2006 2 Reformatted to current standard. Replaced Figure 9.

Added Epoxy meets UL94, V0 in Package information. Updated

14-Dec-2010 3 ECOPACK statement. Added SMBflat-3L package. Updated

graphics.

Information regarding TO-92 and SOT-223 packages transferred to

12-Jun-2012 4

STMicroelectronics datasheet ACS108.

Doc ID 11962 Rev 4 11/12

ACS108-6S

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

12/12 Doc ID 11962 Rev 4

You might also like

- Acs108 6sa PDFDocument11 pagesAcs108 6sa PDFJahangir JinguNo ratings yet

- Acs108-8tn TriacDocument14 pagesAcs108-8tn TriacIgnacio ReyesNo ratings yet

- TriacDocument11 pagesTriacalitoparanaNo ratings yet

- Overvoltage Protected AC Switch (ACS™) : DescriptionDocument13 pagesOvervoltage Protected AC Switch (ACS™) : DescriptionlagarteraNo ratings yet

- Acst 12Document13 pagesAcst 12Eduardo MontielNo ratings yet

- 0.8 A - 800 V Overvoltage Protected AC Switch (ACS™)Document14 pages0.8 A - 800 V Overvoltage Protected AC Switch (ACS™)guidoNo ratings yet

- Acs 1026Document11 pagesAcs 1026José InácioNo ratings yet

- Acs108 6sn PDFDocument14 pagesAcs108 6sn PDFedwinNo ratings yet

- Acst2: Overvoltage Protected AC SwitchDocument14 pagesAcst2: Overvoltage Protected AC Switchdinny blancoNo ratings yet

- Acst6: Over Voltage Protected Ac Power SwitchDocument10 pagesAcst6: Over Voltage Protected Ac Power SwitchJose Carlos SoaresNo ratings yet

- ACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilyDocument10 pagesACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilySamerNo ratings yet

- Acst2 8SBDocument13 pagesAcst2 8SBoguiaNo ratings yet

- Acs 102Document8 pagesAcs 102Alexis RamonNo ratings yet

- Acst 4Document14 pagesAcst 4Eduardo MontielNo ratings yet

- btw69 1200nDocument9 pagesbtw69 1200nYou LookNo ratings yet

- T1235T-8FP: 12 A Snubberless™ TriacDocument9 pagesT1235T-8FP: 12 A Snubberless™ TriacArguetaManuelNo ratings yet

- Datasheet Acs 120 PDFDocument11 pagesDatasheet Acs 120 PDFyudi heriyantoNo ratings yet

- ACST4 Series: Ac Power Switch Asd™ AC Switch FamilyDocument9 pagesACST4 Series: Ac Power Switch Asd™ AC Switch FamilyMohsenNo ratings yet

- 12 A 800 V Snubberless Triac in TO-220AB Package: FeaturesDocument11 pages12 A 800 V Snubberless Triac in TO-220AB Package: FeaturesDelos Santos JojoNo ratings yet

- 80 A 800 V High Temperature Thyristor (SCR) in D PAK PackageDocument10 pages80 A 800 V High Temperature Thyristor (SCR) in D PAK PackageL oNo ratings yet

- btw69 1200Document9 pagesbtw69 1200Kumar ShresthaNo ratings yet

- Acs 120Document17 pagesAcs 120Mafia BetawiNo ratings yet

- BT137Document7 pagesBT137Gabriel RacovskyNo ratings yet

- Acs 108Document13 pagesAcs 108Giovanni ManzolilloNo ratings yet

- BTW67 and BTW69 Series: 50A SCRDocument7 pagesBTW67 and BTW69 Series: 50A SCRAdrian FerreyraNo ratings yet

- Stp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageDocument12 pagesStp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageOsmir MonteiroNo ratings yet

- BT151Document8 pagesBT151Javier ParedesNo ratings yet

- stth60rq06 M2yDocument12 pagesstth60rq06 M2yRahul SinghNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- MCR100W 10M 0-2902672Document12 pagesMCR100W 10M 0-2902672chawkigenieNo ratings yet

- Snubberless Triac: FeaturesDocument5 pagesSnubberless Triac: FeaturesImam MoyoNo ratings yet

- ACS102-5Tx: Ac Line Switch Asd™ AC Switch FamilyDocument8 pagesACS102-5Tx: Ac Line Switch Asd™ AC Switch FamilyeduardopercicaroliNo ratings yet

- Triacs BT137 Series: General Description Quick Reference DataDocument3 pagesTriacs BT137 Series: General Description Quick Reference DataLidice BarreraNo ratings yet

- Triacs BT137X Series D Logic Level: General Description Quick Reference DataDocument6 pagesTriacs BT137X Series D Logic Level: General Description Quick Reference DataSantiago SerranoNo ratings yet

- btw69 800Document9 pagesbtw69 800YusufNo ratings yet

- Bta08 600c PDFDocument18 pagesBta08 600c PDFsidhom saidNo ratings yet

- BCR8PM-12L RenesasTechnologyDocument8 pagesBCR8PM-12L RenesasTechnologyAriel GarciaNo ratings yet

- BT137 PhiDocument6 pagesBT137 PhiJavierJBVNo ratings yet

- Thyristors BTA151 Series Sensitive Gate: General Description Quick Reference DataDocument6 pagesThyristors BTA151 Series Sensitive Gate: General Description Quick Reference DatarogeriocorreaNo ratings yet

- Datasheet BT151XDocument1 pageDatasheet BT151XJanet WaldeNo ratings yet

- datasheet4Document6 pagesdatasheet4echkomNo ratings yet

- D Data Sheet: BT131W SeriesDocument9 pagesD Data Sheet: BT131W Seriesuser_scribd54635No ratings yet

- BT138 SeriesDocument8 pagesBT138 SeriesYogi RuliemNo ratings yet

- Jiejie Microelectronics Co., LTD: Jst137 Series 8A Triacs DescriptionDocument7 pagesJiejie Microelectronics Co., LTD: Jst137 Series 8A Triacs DescriptioncarlosNo ratings yet

- BT 151Document6 pagesBT 151Oscar FernandezNo ratings yet

- BT151 Series 2Document7 pagesBT151 Series 2Louie Derek OrtizNo ratings yet

- High surge silicon controlled rectifierDocument5 pagesHigh surge silicon controlled rectifierBuitinės Technikos RemontasNo ratings yet

- 1SDSDSDDocument8 pages1SDSDSDBEHROZNo ratings yet

- Datasheet 1 4Document5 pagesDatasheet 1 4HJavi MPNo ratings yet

- BTW69 1200Document5 pagesBTW69 1200GiraldoCarpioRamosNo ratings yet

- TN6050-12PI: 60 A, 1200 V Standard SCRDocument11 pagesTN6050-12PI: 60 A, 1200 V Standard SCRluis lopezNo ratings yet

- BTW67 STANDARD 50A SCRs - STMicroelectronicsDocument5 pagesBTW67 STANDARD 50A SCRs - STMicroelectronicsAndis MashudNo ratings yet

- Stps 10120 CDocument9 pagesStps 10120 CLEWIS RODRIGUEZNo ratings yet

- Triacs BT137-600D Logic Level: General Description Quick Reference DataDocument7 pagesTriacs BT137-600D Logic Level: General Description Quick Reference DataGabriel Alexander R. MNo ratings yet

- BTW68-1200 Es Un SCR PDFDocument5 pagesBTW68-1200 Es Un SCR PDFeddyNo ratings yet

- FQP8P10 1009587Document11 pagesFQP8P10 1009587Hdhm TdhNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Upc2748 1186850Document6 pagesUpc2748 1186850SamerNo ratings yet

- BCP56Document1 pageBCP56SamerNo ratings yet

- 2sc5615 Ne681m13Document2 pages2sc5615 Ne681m13SamerNo ratings yet

- Upc1675g NecDocument8 pagesUpc1675g NecSamerNo ratings yet

- TIC216 Series Silicon Triacs DatasheetDocument3 pagesTIC216 Series Silicon Triacs DatasheetBreno MagalhãesNo ratings yet

- bcv26 bcv46Document8 pagesbcv26 bcv46SamerNo ratings yet

- 2SD2216 PanasonicSemiconductorDocument2 pages2SD2216 PanasonicSemiconductorSamerNo ratings yet

- Sot23 NPN Silicon Planar High Voltage Transistor: Absolute Maximum RatingsDocument1 pageSot23 NPN Silicon Planar High Voltage Transistor: Absolute Maximum RatingsGeovanny SanJuanNo ratings yet

- 【b】hybridinvertersun 3.6 5k sg0103lp1 euDocument2 pages【b】hybridinvertersun 3.6 5k sg0103lp1 euCris ELNo ratings yet

- ST24C02FM6TRDocument1 pageST24C02FM6TRSamerNo ratings yet

- Deye 8KW Hybrid InverterDocument2 pagesDeye 8KW Hybrid InverterSamerNo ratings yet

- 【b】hybridinvertersun 3 6k sg04lp1Document2 pages【b】hybridinvertersun 3 6k sg04lp1SamerNo ratings yet

- Ssot6flmp DimDocument1 pageSsot6flmp DimSamerNo ratings yet

- Datasheet - 2019-08-13T182643.838Document1 pageDatasheet - 2019-08-13T182643.838SamerNo ratings yet

- AP8263Document10 pagesAP8263SamerNo ratings yet

- JinkoSolar N-Type Mono-facial 450-470W Solar PanelDocument2 pagesJinkoSolar N-Type Mono-facial 450-470W Solar PaneldetailsNo ratings yet

- Dsa 00363718Document1 pageDsa 00363718SamerNo ratings yet

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- AP8025Document12 pagesAP8025SamerNo ratings yet

- AP8012ADocument13 pagesAP8012ASamerNo ratings yet

- AP8836 AC-DC PWM Controller <40Document15 pagesAP8836 AC-DC PWM Controller <40SamerNo ratings yet

- AD823 SchemeDocument20 pagesAD823 SchemeLance DarmawanNo ratings yet

- General Description: 4Q TriacDocument17 pagesGeneral Description: 4Q TriacSamerNo ratings yet

- Is Now Part ofDocument8 pagesIs Now Part ofSamerNo ratings yet

- Important Notice: Kind RegardsDocument23 pagesImportant Notice: Kind RegardsSamerNo ratings yet

- P-Channel Powertrench Mosfet: Features General DescriptionDocument8 pagesP-Channel Powertrench Mosfet: Features General DescriptionSamerNo ratings yet

- BZT52-Series: Vishay SemiconductorsDocument8 pagesBZT52-Series: Vishay SemiconductorsSamerNo ratings yet

- Product Profile: VHF Variable Capacitance Double DiodeDocument7 pagesProduct Profile: VHF Variable Capacitance Double DiodeSamerNo ratings yet

- 1 N 5400Document4 pages1 N 5400Irfan Indra KurniawanNo ratings yet

- ACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilyDocument10 pagesACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilySamerNo ratings yet

- Burridge and Knopoff 1964 BSSA BodyForceEquivalentsForSeismicDislocationsDocument14 pagesBurridge and Knopoff 1964 BSSA BodyForceEquivalentsForSeismicDislocationsFrancisco Javier Villaseca AhumadaNo ratings yet

- What This Module Is About: Force and MotionDocument10 pagesWhat This Module Is About: Force and MotionCeasar Epsilonian MundalaNo ratings yet

- Transformer: Iftikhar Reza Contact: 01715 591 542Document64 pagesTransformer: Iftikhar Reza Contact: 01715 591 542Sanjid ElahiNo ratings yet

- Nehs06780001 - Multimeter OperationDocument8 pagesNehs06780001 - Multimeter OperationMontell JordanNo ratings yet

- Plastic Analysis LectureDocument20 pagesPlastic Analysis LecturemartrantNo ratings yet

- Magnet Made of Rare-Earth MetalsDocument44 pagesMagnet Made of Rare-Earth MetalsbmomeraliNo ratings yet

- BLDC 1Document9 pagesBLDC 1vishiwizardNo ratings yet

- Problem Set DC GeneratorsDocument1 pageProblem Set DC Generatorsrebecca pullitanNo ratings yet

- Rocket Equation Derivation NotesDocument7 pagesRocket Equation Derivation NotesSrikar GhooliNo ratings yet

- Instruments NotesDocument116 pagesInstruments Notesprithvih40% (1)

- 15 Magnetism LabDocument3 pages15 Magnetism Labapi-297802969No ratings yet

- BLR CM InstallDocument8 pagesBLR CM Installthy thy thyNo ratings yet

- Questions & Answers On Synchronous MotorsDocument28 pagesQuestions & Answers On Synchronous Motorskibrom atsbha100% (1)

- IEEE Transactions on Power Electronics Model Analyzes Static Induction Thyristor PerformanceDocument11 pagesIEEE Transactions on Power Electronics Model Analyzes Static Induction Thyristor PerformanceAbdulAzizNo ratings yet

- Index/ Instructor's Evaluation of Experiment ReportsDocument22 pagesIndex/ Instructor's Evaluation of Experiment Reportssirajudeen INo ratings yet

- Calculation Algorithm PDFDocument11 pagesCalculation Algorithm PDFAnonymous zuM28o8IyNNo ratings yet

- College of Engineering: - Topic: BLDC MotorDocument38 pagesCollege of Engineering: - Topic: BLDC MotorjitbakNo ratings yet

- Introduction Robot Drive SystemsDocument17 pagesIntroduction Robot Drive SystemsTemesgen100% (2)

- S1892R211M Service Manual GuideDocument23 pagesS1892R211M Service Manual GuideRicardo Cinjiro Conte100% (1)

- 14 - 15 - H2 - COE - Notes Final PDFDocument18 pages14 - 15 - H2 - COE - Notes Final PDFeltytanNo ratings yet

- Weekly Home Learning PlanDocument5 pagesWeekly Home Learning PlanMelodina AcainNo ratings yet

- MCGGDocument14 pagesMCGGJesica Diaz Rodriguez100% (1)

- Seminar Report On WitricityDocument24 pagesSeminar Report On WitricityAliraza76No ratings yet

- 4PH1 2PR Que 20201124Document20 pages4PH1 2PR Que 20201124Simam Rista50% (2)

- Syllabus BS Physics For BOS 30-11-2018Document78 pagesSyllabus BS Physics For BOS 30-11-2018Tanzil urehmanNo ratings yet

- What is weight and mass? The difference explainedDocument13 pagesWhat is weight and mass? The difference explainedPrince SanjiNo ratings yet

- 03 Equilibrio Cpo RigDocument8 pages03 Equilibrio Cpo RigAldo ArteagaNo ratings yet

- Presentation On Relays and Circuit BreakersDocument29 pagesPresentation On Relays and Circuit BreakersNeeraj Piplani100% (2)

- G761 SeriesDocument8 pagesG761 SeriesDipti BhanjaNo ratings yet

- KHead GravityDocument11 pagesKHead GravityJuanHerrera100% (1)