Professional Documents

Culture Documents

Specifying Bolt Length For High-Strength Bolts: Manual of Steel Construction

Uploaded by

albertoxinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifying Bolt Length For High-Strength Bolts: Manual of Steel Construction

Uploaded by

albertoxinaCopyright:

Available Formats

Specifying Bolt Length for High-Strength Bolts

CHARLES J. CARTER

INTRODUCTION conservative for all bolts less than or equal to 6-in. long.

Two tables that are useful in determining the proper bolt For bolts longer than 6 inches, the values are conservative

length for high-strength bolts are provided in the AISC for 1 1/8-in. diameter bolts and negligibly unconservative

Manual of Steel Construction:1 Table 8-2, which includes (within 3/64-in.) for ¾-in., 7/8-in., and 1-in. diameter bolts

constants to be added to the grip and washer thickness assuming. This is considered to be negligible because the

(RCSC Specification Table C2 2 is the basis for these worst-case accumulation of tolerances assumed is a

constants) and a table in Figure 8-3, which indicates the statistical improbability. The nominal bolt length is then

outer-ply thickness required to exclude the threads from the selected as the next larger increment based on the minimum

faying surface of the connection. While it is a simple possible length. As is general industry practice, for bolt

operation to select bolt lengths using these tables, the lengths less than 5 inches, a nominal length increment of

repetitive calculation becomes somewhat tedious and could ¼-in. is used; otherwise, a nominal length increment of ½-

be simplified. in. is used.

In this paper, a design aid is presented for the selection In the installed condition, even if the nominal length is

of high-strength bolt lengths for bearing (snug-tightened exactly equal to the minimum possible length, the end of

and fully tensioned) and slip-critical connections. Nominal the bolt will be at least flush with the end of the nut. Some

bolt lengths are tabulated based upon the grip for ¾-in., project specifications include a stick-through requirement

7/8-in., 1-in., and 1 1/8-in. diameter ASTM A325 and A490 (minimum protrusion of the bolt point beyond the nut).

bolts with zero, one, or two 5/32-in.-thick ASTM F436 flat However, because the threaded length for any given bolt

washer(s) and an ASTM A563 nut; bevelled washers are diameter is constant regardless of the bolt length, a stick-

not considered in this paper. Additionally, the outer-ply through requirement may require a longer bolt and thereby

thickness required when it is desired to exclude the threads increases the risk of jamming the nut on the thread run-out.

from the shear plane is tabulated. Example problems are Because a stick-through requirement does not improve the

included to illustrate use of the table. The following topics performance of the bolt, its specification is discouraged.

are also briefly addressed in this paper: (1) tolerances on In Table 2, bolt lengths L have been tabulated for ¾-in.,

bolt length, nut thickness, and washer thickness; (2) thread 7/8-in., 1-in., and 1 1/8-in. diameter ASTM A325 and A490

run-out, stick-through requirements, and risk of jamming bolts with zero, one, or two 5/32-in.-thick ASTM F436

the nut; (3) washer requirements; and, (4) excluding threads washer(s). Because 8 inches is generally the maximum

from the shear plane of the connection. stock bolt length available except by special order,

tabulated values for combinations requiring longer lengths

MINIMUM BOLT LENGTH have been omitted. The tabulated values are valid for

conventional high-strength bolts and alternative design

The minimum possible length of high strength bolts is fasteners, such as tension-control or twist-off bolts. If

calculated by summing the nominal grip, the nominal direct tension indicator devices are to be used, the tabulated

thickness of washer(s), and the appropriate value from values remain useful if the thickness of such devices is

Table C2 of the Specification for Structural Joints Using considered to be part of the grip.

ASTM A325 or A490 Bolts. 2 Values in RCSC Specification In many cases when one washer is used, the minimum

Table C2 provide for the nominal thickness of the heavy possible bolt length exceeds a nominal length increment by

hex nut and the following tolerances: (1) the minus 1/32-in. For example, a ¾-in. diameter bolt with one 5/32-

tolerance on bolt length; (2) the plus tolerance on washer in.-thick washer and a 7/8-in. grip would require a length of

thickness; and (3) the plus tolerance on nut thickness. By

7 5

one order of magnitude, the tolerance on bolt length is the + + 1 = 2 1 32 in.

most significant; see Appendix. Taking the worst case 8 32

accumulation of these three tolerances, Table 1 illustrates where 1 inch is the value from RCSC Specification Table

that the values in RCSC Specification Table C2 are C2. In this and other such cases, the tabulated minimum

bolt length has been rounded down to the shorter nominal

length increment because 1/32-in. is negligible. In all other

Charles J. Carter is senior staff engineer, American Institute of Steel

cases, the tabulated minimum bolt length is rounded to the

Construction, Inc., Chicago, IL.

next longer nominal length increment.

ENGINEERING JOURNAL / SECOND QUARTER / 1996 43

Shading in the table indicates that the combination of connection has been tabulated in Table 2. It is calculated as

grip, bolt length, and number of washers is such that the nut the grip plus the threaded length minus the bolt length. A

may jamb on the thread run-out; this occurs only for bolts dash indicates that, for the given grip, the threads will be

longer than 5 inches (i.e., when ½-in. length increments are excluded regardless of the actual thickness of the ply

used). The use of additional washers, which may also closest to the nut (i.e., t ≤ 0). A common solution when it is

require a longer bolt, is a common solution. Jamming may desired to exclude the threads but the minimum thickness is

occur when the bolt length minus the threaded length not present is to use a longer bolt with additional washer(s)

exceeds the grip plus the minimum thickness of washer(s) under the nut. Nominal dimensions are used in this

minus an allowance for the elongation of the bolt during calculation for two reasons: (1) RCSC Specification

tensioning. For most bolts, a nut rotation of one-half to Commentary Section C2 permits thread run-out into the

two-thirds from snug-tight is required to achieve full shear plane; and, (2) the control dimension in bolt

tensioning; longer bolts may require one full turn. threading is the distance from the underside of the bolt

Conservatively assuming one full turn, and because the nut head to the first useable thread; i.e., the bolt underlength

surface is countersunk by approximately one third of one tolerance is absorbed in the threaded length. In calculating

thread pitch, the appropriate allowance (see Appendix) for the tabulated values of t, washers (if used) are assumed to

elongation of the bolt during tensioning is two-thirds of one be installed under the nut. If washer(s) are present under

thread pitch;3 this will be conservative for snug-tightened the bolt head, their thickness must be added to the tabulated

bolts, which may have significantly less elongation. value of t. When a dash is shown and washer(s) are to be

placed under the bolt head, the value of t can be determined

WASHER REQUIREMENTS as indicated above; alternatively, the washer thickness may

be considered as part of the grip.

RCSC Specification Section 7(c) indicates the cases in A common rule of thumb2 can be generalized from the

which 5 32 -in.-thick ASTM F436 washers must be used with tabulated values for minimum outer-ply thickness. With no

ASTM A325 and A490 bolts. Such washers are not washers, the threads will always be excluded from the shear

required for these high-strength bolts in standard, plane (regardless of the grip) for ¾-in. and 7 8 -in. diameter

oversized, and short-slotted holes except: bolts if the outer ply thickness is not less than 3 8 -in.; the

1. under the turned element when the bolt is fully same is true for 1-in. and 1 1 8 -in. diameter bolts if the outer

tensioned by the calibrated wrench method. ply thickness is not less than ½-in. With one washer under

2. under the head and nut when ASTM A490 bolts are the nut, these values may be reduced by 18 -in. Because this

used in combination with material with a specified

yield point below 40 ksi. rule of thumb is based upon the worst case combination of

3. to cover an oversized or short-slotted hole in an grip and bolt length, reference to the tabulated values for

outer ply. For ASTM A490 bolts over 1 inch in lesser outerply thicknesses will often be beneficial.

diameter through an oversized or short-slotted hole A supplementary provision has been added to ASTM

A325 for full-length threading (ASTM A325T). This

in an outer ply, the washer must be 516 -in.-thick;

provision may be specified for ASTM A325 bolts of length

two 5 32 -in.-thick washers do not meet this less than or equal to four times the bolt diameter only; there

requirement. is no similar provision in ASTM A490. Note that if ASTM

A325T bolts are specified, it is impossible to exclude the

Some alternative design fasteners provide a bearing circle

threads from the shear plane. Thus, for these bolts, the

on the bolt head and/or nut of diameter equal to or greater

tabulated values of t are meaningless.

than the diameter of an ASTM F436 washer. When such

fasteners are used, the need for washers in cases 1 and 2

above is eliminated. ILLUSTRATIVE EXAMPLES

When high-strength bolts are used through long-slotted The following examples illustrate the use of Table 2.

holes in an outer ply, a plate washer with standard holes

that completely covers the slot must be provided; the plate Example 1

washer must be made from structural grade material with a

Given:

minimum thickness of 516 -in., but need not be hardened.

For ASTM A490 bolts over 1 inch in diameter through Select the bolt length for ¾-in. diameter ASTM A325-N

long-slotted holes in an outer ply, single 516 -in.-thick bolts in standard holes in a 3 8 -in. single-plate connection

5 supporting a W21×50 beam (nominal tw= 3 -in.).

ASTM F436 washers must be used; two 32 -in.-thick 8

washers do not meet this requirement. Solution:

EXCLUDING THREADS FOR The grip is 3 8 + 3 8 = ¾-in. From Table 2, for ¾-in.

BEARING X CONNECTIONS diameter bolts with zero washers, use 1¾-in. bolt length.

The minimum thickness t of the outer connected ply closest

to the nut to exclude threads from the shear plane of the

44 ENGINEERING JOURNAL / SECOND QUARTER / 1996

Example 2 APPENDIX

Given: The following table is from the RCSC Specification. 2

Select the bolt length for ¾-in. diameter ASTM A325-X Table C2.

bolts in standard holes in a double-angle connection with To Determine Required Bolt

2L5×3× 516 supporting a W27×84 beam (nominal tw = 7 16 - Nominal Bolt Size, inches Length Add to Grip, In inches

in.). ½ 11

16

5 7

8 8

Solution:

¾ 1

The grip is 516 + 7 16 + 516 = 1 116 in. From Table 2, for ¾- 7

8

1 18

in. diameter bolts with zero washers, try 2¼-in. bolt length.

Also from Table 2, the minimum thickness of the ply 1 1¼

closest to the nut to exclude the threads is 316 -in. Since this 1 18 1½

5 1¼ 1 58

is less than the 16 -in. angle thickness, use 2¼-in. bolt

length. 1 38 1¾

1½ 178

Example 3

The following tables are summarized from Fastener

Given: Standards.3

Select the bolt length for fully tensioned ¾-in. diameter Bolt length tolerance

ASTM A325-N bolts connecting a ½-in.-thick angle to a

Bolt length, in.

W14×500 column flange (nominal tw = 3½ in.). The

calibrated wrench method will be used to tension the bolts Dia., in. 6 or less over 6

requiring one washer under the turned element. ¾ –0.19 –0.25

Solution:

7

8

–0.19 –0.25

1 –0.19 –0.25

The grip is ½ + 3½ = 4 in. From Table 2, for ¾-in. diameter –0.25 –0.25

11 8

bolts with one washer, the table cell is shaded, indicating

that this combination or grip, number of washers, and bolt

Washer thickness tolerances

length is such that the nut may jamb on the thread run-out.

Therefore, try two washers. From Table 2, for ¾-in. Washer thickness, in.

diameter bolts with two washers, use 5½-in. bolt length. Dia., in. Max. Nom. Min.

¾ 0.177 5

32 (0.156)

0.122

Example 4 7

8

0.177 5

32 (0.156) 0.136

Given: 1 0.177 5

32 (0.156) 0.136

Select the bolt length for 7 8 -in. diameter ASTM A490-N 1 18 0.177 5

32 (0.156) 0.136

bolts in standard holes in an extended end-plate moment

connection (1-in. thick) to a W14×132 column flange Nut thickness tolerances

(nominal tf = 1 in.). The column and end-plate material are Nut thickness, in.

ASTM A572 grade 50 material. Bolts will be tension- Dia., in. Max. Nom. Min.

control-type alternative design fasteners.

¾ 0.758 47

64 (0.734)

0.710

Solution: 7 0.885 55 0.833

8 64 (0.859)

The grip is 1 + 1 = 2 in. From Table 2, for 7 8 -in. diameter 1 1.012 63

64 (0.984) 0.956

bolts with zero washers, use 3¼-in. bolt length. 11 1.139 17 (1.109) 1.079

8 64

REFERENCES Allowance for elongation due to full tensioning

1. American Institute of Steel Construction, Manual of Steel Threads Thread

Construction—Load and Resistance Factor Design, Volume II— Dia., in. per inch pitch, p, in. 2p/3

Connections, p. 8-11 and 8-18, Chicago, IL, 1994.

2. Research Council on Structural Connections, Load and

¾ 10 0.100 0.067

Resistance Factor Design Specification for Structural Joints 7

8

9 0.111 0.074

Using ASTM A325 or A490 Bolts, AISC, Chicago, IL, 1988. 1 8 0.125 0.084

3. Industrial Fasteners Institute, Fastener Standards, Sixth Ed.,

1 18 7 0.143 0.096

IFI, Cleveland, OH, 1988.

ENGINEERING JOURNAL / SECOND QUARTER / 1996 45

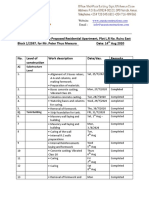

Table 1.

Bolt, Nut, and Washer Tolerances vs. RCSC Specification Table C2 Allowance

(all values in inches)

Bolts less than or equal to 6-in. long

Tolerances from Appendix RCSC Spec. Table C2 conservative by:

RCSC Spec.

Bolt Table C2 Nut Bolt Nut Washer Number of washers

Diameter Allowance Thickness Underlength Overthick Overthick Zero One Two

¾ 1 47

64

0.19 0.024 0.021 3

64

1

32

1

64

7

8

1 18 55

64

0.19 0.026 0.021 3

64

1

32

1

64

1 1¼ 63

64

0.19 0.028 0.021 3

64

1

32 0

1 18 1½ 1 7 64 0.25 0.030 0.021 7

64

3

32

1

16

Bolts over 6-in. long

Tolerances from Appendix RCSC Spec. Table C2 conservative by:

Bolt RCSC Nut Bolt Nut Washer Number of washers

Diameter Table C2 Thickness Underlength Overthick Overthick Zero One Two

¾ 1 47

64

0.25 0.024 0.021 − 1 64 − 1 32 − 3 64

7

8

1 18 55

64

0.25 0.026 0.021 − 1 64 − 1 32 − 3 64

1 1¼ 63

64

0.25 0.028 0.021 − 1 64 − 1 32 − 3 64

1 18 1½ 7

1 64 0.25 0.030 0.021 7

64

3

32

1

16

Shading indicates that RCSC Specification Table C2 values result in negligibly unconservative bolt lengths.

46 ENGINEERING JOURNAL / SECOND QUARTER / 1996

Table 2.

ASTM A325 and A490 Bolts with

zero, one, or two 5 32 -In.-thick washer(s)

¾-in. dia. 7 -in. dia.

8

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

3 1

½ 1½ 8 1¾ 8 2 — 1¾ ¼ 1¾ ¼ 2 —

9 1¾ 3 1¾ 3 2 — 1¾ 5 2 1 2 1

16 16 16 16 16 16

5 1¾ ¼ 1¾ ¼ 2 — 1¾ 3 2 1 2¼ —

8 8 8

11 1¾ 5 2 1 2 1 2 3 2 3 2¼ —

16 16 16 16 16 16

¾ 1¾ 3 2 1 2¼ — 2 ¼ 2 ¼ 2¼ —

8 8

13 2 3 2 3 2¼ — 2 5 2¼ 1 2¼ 1

16 16 16 16 16 16

7 2 ¼ 2 ¼ 2¼ — 2 3 2¼ 1 2½ —

8 8 8

15 2 5 2¼ 1 2¼ 1 2¼ 3 2¼ 3 2½ —

16 16 16 16 16 16

1 2 3 2¼ 1 2½ — 2¼ ¼ 2¼ ¼ 2½ —

8 8

1 116 2¼ 3 2¼ 3 2½ — 2¼ 5 2½ 1 2½ 1

16 16 16 16 16

1 18 2¼ ¼ 2¼ ¼ 2½ — 2¼ 3

8 2½ 1

8 2¾ —

1 1 3 3

1 316 2¼ 5

16 2½ 16 2½ 16 2½ 16 2½ 16 2¾ —

1¼ 2¼ 3 2½ 1 2¾ — 2½ ¼ 2½ ¼ 2¾ —

8 8

3 5 1 1

1 516 2½ 3

16 2½ 16 2¾ — 2½ 16 2¾ 16 2¾ 16

13 2½ ¼ 2½ ¼ 2¾ — 2½ 3 2¾ 1 3 —

8 8 8

1 7 16 2½ 5 2¾ 1 2¾ 1 2¾ 3 2¾ 3 3 —

16 16 16 16 16

1½ 2½ 3 2¾ 1 3 — 2¾ ¼ 2¾ ¼ 3 —

8 8

9 3 3 5 1 1

1 16 2¾ 16 2¾ 16 3 — 2¾ 16 3 16 3 16

3 1

1 58 2¾ ¼ 2¾ ¼ 3 — 2¾ 8 3 8 3¼ —

1 1 3 3

11116 2¾ 5

16 3 16 3 16 3 16 3 16 3¼ —

1¾ 2¾ 3 3 1 3¼ — 3 ¼ 3 ¼ 3¼ —

8 8

113 16 3 3

16 3 3

16 3¼ — 3 5

16 3¼ 1

16 3¼ 1

16

178 3 ¼ 3 ¼ 3¼ — 3 3

8 3¼ 1

8 3½ —

115 16 3 5

16 3¼ 1

16 3¼ 1

16 3¼ 3

16 3¼ 3

16 3½ —

2 3 3 3¼ 1 3½ — 3¼ ¼ 3¼ ¼ 3½ —

8 8

2 116 3¼ 3

16 3¼ 3

16 3½ — 3¼ 5

16 3½ 1

16 3½ 1

16

2 18 3¼ ¼ 3¼ ¼ 3½ — 3¼ 3

8 3½ 1

8 3¾ —

2 3 16 3¼ 5

16 3½ 1

16 3½ 1

16 3½ 3

16 3½ 3

16 3¾ —

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

ENGINEERING JOURNAL / SECOND QUARTER / 1996 47

Table 2.

ASTM A325 and A490 Bolts

with zero, one, or two 5 32 -In.-thick washer(s)

1-in. dia. 1 18 -in. dia.

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

½ 1¾ ½ 2 ¼ 2¼ — 2 ½ 2¼ ¼ 2½ —

9 2 5 2 5 2¼ 1 2¼ 5 2¼ 5 2½ 1

16 16 16 16 16 16 16

5 2 3 2 3 2¼ 1 2¼ 3 2¼ 3 2½ 1

8 8 8 8 8 8 8

11 2 7 2¼ 3 2¼ 3 2¼ 7 2½ 3 2½ 3

16 16 16 16 16 16 16

¾ 2 ½ 2¼ ¼ 2½ — 2¼ ½ 2½ ¼ 2¾ —

13 2¼ 5 2¼ 5 2½ 1 2½ 5 2½ 5 2¾ 1

16 16 16 16 16 16 16

7 2¼ 3 2¼ 3 2½ 1 2½ 3 2½ 3 2¾ 1

8 8 8 8 8 8 8

15 2¼ 7 2½ 3 2½ 3 2½ 7 2¾ 3 2¾ 3

16 16 16 16 16 16 16

1 2¼ ½ 2½ ¼ 2¾ — 2½ ½ 2¾ ¼ 3 —

1 116 2½ 5

16 2½ 5

16 2¾ 1

16 2¾ 5

16 2¾ 5

16 3 1

16

1 18 2½ 3

8 2½ 3

8 2¾ 1

8 2¾ 3

8 2¾ 3

8 3 1

8

1 316 2½ 7

16 2¾ 3

16 2¾ 3

16 2¾ 7

16 3 3

16 3 3

16

1¼ 2½ ½ 2¾ ¼ 3 — 2¾ ½ 3 ¼ 3¼ —

1 516 2¾ 5

16 2¾ 5

16 3 1

16 3 5

16 3 5

16 3¼ 1

16

1 38 2¾ 3

8 2¾ 3

8 3 1

8 3 3

8 3 3

8 3¼ 1

8

1 7 16 2¾ 7

16 3 3

16 3 3

16 3 7

16 3¼ 3

16 3¼ 3

16

1½ 2¾ ½ 3 ¼ 3¼ — 3 ½ 3¼ ¼ 3½ —

1 9 16 3 5

16 3 5

16 3¼ 1

16 3¼ 5

16 3¼ 5

16 3½ 1

16

1 58 3 3

8 3 3

8 3¼ 1

8 3¼ 3

8 3¼ 3

8 3½ 1

8

11116 3 7

16 3¼ 3

16 3¼ 3

16 3¼ 7

16 3½ 3

16 3½ 3

16

1¾ 3 ½ 3¼ ¼ 3½ — 3¼ ½ 3½ ¼ 3¾ —

113 16 3¼ 5

16 3¼ 5

16 3½ 1

16 3½ 5

16 3½ 5

16 3¾ 1

16

178 3¼ 3

8 3¼ 3

8 3½ 1

8 3½ 3

8 3½ 3

8 3¾ 1

8

115 16 3¼ 7

16 3½ 3

16 3½ 3

16 3½ 7

16 3¾ 3

16 3¾ 3

16

2 3¼ ½ 3½ ¼ 3¾ — 3½ ½ 3¾ ¼ 4 —

2 116 3½ 5

16 3½ 5

16 3¾ 1

16 3¾ 5

16 3¾ 5

16 4 1

16

2 18 3½ 3

8 3½ 3

8 3¾ 1

8 3¾ 3

8 3¾ 3

8 4 1

8

2 316 3½ 7

16 3¾ 3

16 3¾ 3

16 3¾ 7

16 4 3

16 4 3

16

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

48 ENGINEERING JOURNAL / SECOND QUARTER / 1996

Table 2.

ASTM A325 and A490 Bolts

with zero, one, or two 5 32 -in.-thick washer(s)

7

¾-in. dia. 8 -in. dia.

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

2¼ 3¼ 3 3½ 1 3¾ — 3½ ¼ 3½ ¼ 3¾ —

8 8

25 16 3½ 3

16 3½ 3

16 3¾ — 3½ 5

16 3¾ 1

16 3¾ 1

16

2 38 3½ ¼ 3½ ¼ 3¾ — 3½ 3

8 3¾ 1

8 4 —

2 7 16 3½ 5

16 3¾ 1

16 3¾ 1

16 3¾ 3

16 3¾ 3

16 4 —

2½ 3½ 3 3¾ 1 4 — 3¾ ¼ 3¾ ¼ 4 —

8 8

2 9 16 3¾ 3

16 3¾ 3

16 4 — 3¾ 5

16 4 1

16 4 1

16

2 58 3¾ ¼ 3¾ ¼ 4 — 3¾ 3

8 4 1

8 4¼ —

2 1116 3¾ 5

16 4 1

16 4 1

16 4 3

16 4 3

16 4¼ —

2¾ 3¾ 3 4 1 4¼ — 4 ¼ 4 ¼ 4¼ —

8 8

2 1316 4 3

16 4 3

16 4¼ — 4 5

16 4¼ 1

16 4¼ 1

16

2 78 4 ¼ 4 ¼ 4¼ — 4 3

8 4¼ 1

8 4½ —

2 1516 4 5

16 4¼ 1

16 4¼ 1

16 4¼ 3

16 4¼ 3

16 4½ —

3 4 3 4¼ 1 4½ — 4¼ ¼ 4¼ ¼ 4½ —

8 8

3 116 4¼ 3

16 4¼ 3

16 4½ — 4¼ 5

16 4½ 1

16 4½ 1

16

3 18 4¼ ¼ 4¼ ¼ 4½ — 4¼ 3

8 4½ 1

8 4¾ —

3 316 4¼ 5

16 4½ 1

16 4½ 1

16 4½ 3

16 4½ 3

16 4¾ —

3¼ 4¼ 3 4½ 1 4¾ — 4½ ¼ 4½ ¼ 4¾ —

8 8

35 16 4½ 3

16 4½ 3

16 4¾ — 4½ 5

16 4¾ 1

16 4¾ 1

16

3 38 4½ ¼ 4½ ¼ 4¾ — 4½ 3

8 4¾ 1

8 5 —

3 7 16 4½ 5

16 4¾ 1

16 4¾ 1

16 4¾ 3

16 4¾ 3

16 5 —

3½ 4½ 3 4¾ 1 5 — 4¾ ¼ 4¾ ¼ 5 —

8 8

39 16 4¾ 3

16 4¾ 3

16 5 — 4¾ 5

16 5 1

16 5 1

16

3 58 4¾ ¼ 4¾ ¼ 5 — 4¾ 3

8 5 1

8 5½ —

31116 4¾ 5

5 1 5 1 5 3 5 3 5½ —

16 16 16 16 16

3¾ 4¾ 3 5 1 5½ — 5 ¼ 5 ¼ 5½ —

8 8

313 16 5 3

16 5 3

16 5½ — 5 5

16 5½ — 5½ —

378 5 ¼ 5 ¼ 5½ — 5 3

8 5½ — 5½ —

31516 5 5

16 5½ — 5½ — 5½ — 5½ — 5½ —

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

ENGINEERING JOURNAL / SECOND QUARTER / 1996 49

Table 2.

ASTM A325 and A490 Bolts

with zero, one, or two 5 32 -in.-thick washer(s)

1-in. dia. 1 1 8 -in. dia.

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

2¼ 3½ ½ 3¾ ¼ 4 — 3¾ ½ 4 ¼ 4¼ —

25 16

3¾ 5

16

3¾ 5

16

4 1

16

4 5

16

4 5

16

4¼ 1

16

2 38 3¾ 3

8

3¾ 3

8

4 1

8

4 3

8

4 3

8

4¼ 1

8

2 7 16 3¾ 7

16

4 3

16

4 3

16

4 7

16

4¼ 3

16

4¼ 3

16

2½ 3¾ ½ 4 ¼ 4¼ — 4 ½ 4¼ ¼ 4½ —

2 9 16 4 5

16

4 5

16

4¼ 1

16

4¼ 5

16

4¼ 5

16

4½ 1

16

2 58 4 3

8

4 3

8

4¼ 1

8

4¼ 3

8

4¼ 3

8

4½ 1

8

2 1116 4 7

16

4¼ 3

16

4¼ 3

16

4¼ 7

16

4½ 3

16

4½ 3

16

2¾ 4 ½ 4¼ ¼ 4½ — 4¼ ½ 4½ ¼ 4¾ —

2 1316 4¼ 5

16

4¼ 5

16

4½ 1

16

4½ 5

16

4½ 5

16

4¾ 1

16

2 78 4¼ 3

8

4¼ 3

8

4½ 1

8

4½ 3

8

4½ 3

8

4¾ 1

8

2 1516 4¼ 7

16

4½ 3

16

4½ 3

16

4½ 7

16

4¾ 3

16

4¾ 3

16

3 4¼ ½ 4½ ¼ 4¾ — 4½ ½ 4¾ ¼ 5 —

3 116 4½ 5

16

4½ 5

16

4¾ 1

16

4¾ 5

16

4¾ 5

16

5 1

16

3 18 4½ 3

8

4½ 3

8

4¾ 1

8

4¾ 3

8

4¾ 3

8

5 1

8

3 316 4½ 7

16

4¾ 3

16

4¾ 3

16

4¾ 7

16

5 3

16

5 3

16

3¼ 4½ ½ 4¾ ¼ 5 — 4¾ ½ 5 ¼ 5½ —

3 516 4¾ 5

16

4¾ 5

16

5 1

16

5 5

16

5 5

16

5½ —

3 38 4¾ 3

8

4¾ 3

8

5 1

8

5 3

8

5 3

8

5½ —

3 7 16 4¾ 7

16

5 3

16

5 3

16

5 7

16

5½ — 5½ —

3½ 4¾ ½ 5 ¼ 5½ — 5 ½ 5½ — 5½ —

3 9 16 5 5

16

5 5

16

5½ — 5½ 1

16

5½ 1

16

5½ 1

16

3 58 5 3

8

5 3

8

5½ — 5½ 1

8

5½ 1

8

5½ 1

8

31116 5 7

16

5½ — 5½ — 5½ 3

16

5½ 3

16

5½ 3

16

3¾ 5 ½ 5½ — 5½ — 5½ ¼ 5½ ¼ 6 —

31316 5½ 1

16

5½ 1

16

5½ 1

16

5½ 5

16

5½ 5

16

6 —

378 5½ 1

8

5½ 1

8

5½ 1

8

5½ 3

8

5½ 3

8

6 —

31516 5½ 3

16

5½ 3

16

5½ 3

16

5½ 7

16

6 — 6 —

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

50 ENGINEERING JOURNAL / SECOND QUARTER / 1996

Table 2.

ASTM A325 and A490 Bolts

with zero, one, or two 5 32 -in.-thick washer(s)

¾-in. dia. 7

8 -in. dia.

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

4 5 3 5½ — 5½ — 5½ — 5½ — 5½ —

8

1

4 16 5½ — 5½ — 5½ — 5½ 1 5½ 1 5½ 1

16 16 16

4 18 5½ — 5½ — 5½ — 5½ 1

8 5½ 1

8 6 —

4 316 5½ 1

16 5½ 1

16 5½ 1

16 5½ 3

16 5½ 3

16 6 —

4¼ 5½ 1 5½ 1 6 — 5½ ¼ 5½ ¼ 6 —

8 8

45 16 5½ 3

16 5½ 3

16 6 — 5½ 5

16 6 — 6 —

4 38 5½ ¼ 5½ ¼ 6 — 5½ 3

8 6 — 6 —

4 7 16 5½ 5

16 6 — 6 — 6 — 6 — 6 —

4½ 5½ 3 6 — 6 — 6 — 6 — 6 —

8

49 16 6 — 6 — 6 — 6 1

16 6 1

16 6 1

16

4 58 6 — 6 — 6 — 6 1

8 6 1

8 6½ —

4 1116 6 1

16 6 1

16 6 1

16 6 3

16 6 3

16 6½ —

4¾ 6 1 6 1 6½ — 6 ¼ 6 ¼ 6½ —

8 8

4 13 16 6 3

16 6 3

16 6½ — 6 5

16 6½ — 6½ —

4 78 6 ¼ 6 ¼ 6½ — 6 3

8 6½ — 6½ —

4 15 16 6 5

16 6½ — 6½ — 6½ — 6½ — 6½ —

5 6 3 6½ — 6½ — 6½ — 6½ — 6½ —

8

51 16 6½ — 6½ — 6½ — 6½ 1

16 6½ 1

16 6½ 1

16

5 18 6½ — 6½ — 6½ — 6½ 1

8 6½ 1

8 7 —

5 316 6½ 1

16 6½ 1

16 6½ 1

16 6½ 3

16 6½ 3

16 7 —

5¼ 6½ 1 6½ 1 7 — 6½ ¼ 6½ ¼ 7 —

8 8

55 16 6½ 3

16 6½ 3

16 7 — 6½ 5

16 7 — 7 —

5 38 6½ ¼ 6½ ¼ 7 — 6½ 3

8 7 — 7 —

5 7 16 6½ 5

16 7 — 7 — 7 — 7 — 7 —

5½ 6½ 3 7 — 7 — 7 — 7 — 7 —

8

59 16 7 — 7 — 7 — 7 1

16 7 1

16 7 1

16

5 85 7 — 7 — 7 — 7 1 7 1 7½ —

8 8

5 1116 7 1

16 7 1

16 7 1

16 7 3

16 7 3

16 7½ —

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

ENGINEERING JOURNAL / SECOND QUARTER / 1996 51

Table 2.

ASTM A325 and A490 Bolts

5

with zero, one, or two 32 -in.-thick washer(s)

1-in. dia. 1 18 -in. dia.

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

4 5½ ¼ 5½ ¼ 6 — 5½ ½ 6 — 6 —

4 116 5½ 5 5½ 5 6 — 6 1 6 1 6 1

16 16 16 16 16

4 81 5½ 3 5½ 3 6 — 6 1 6 1 6 1

8 8 8 8 8

4 316 5½ 7

16 6 — 6 — 6 3

16 6 3

16 6 3

16

4¼ 5½ ½ 6 — 6 — 6 ¼ 6 ¼ 6½ —

45 16 6 1

16 6 1

16 6 1

16 6 5

16 6 5

16 6½ —

4 38 6 1

8 6 1

8 6 1

8 6 3

8 6 3

8 6½ —

4 7 16 6 3

16 6 3

16 6 3

16 6 7

16 6½ — 6½ —

4½ 6 ¼ 6 ¼ 6½ — 6 ½ 6½ — 6½ —

4 9 16 6 5

16 6 5

16 6½ — 6½ 1

16 6½ 1

16 6½ 1

16

4 58 6 3

8 6 3

8 6½ — 6½ 1

8 6½ 1

8 6½ 1

8

4 1116 6 7

16 6½ — 6½ — 6½ 3

16 6½ 3

16 6½ 3

16

4¾ 6 ½ 6½ — 6½ — 6½ ¼ 6½ ¼ 7 —

4 13 16 6½ 1

16 6½ 1

16 6½ 1

16 6½ 5

16 6½ 5

16 7 —

4 78 6½ 1

8 6½ 1

8 6½ 1

8 6½ 3

8 6½ 3

8 7 —

4 15 16 6½ 3

16 6½ 3

16 6½ 3

16 6½ 7

16 7 — 7 —

5 6½ ¼ 6½ ¼ 7 — 6½ ½ 7 — 7 —

51 16 6½ 5

16 6½ 5

16 7 — 7 1

16 7 1

16 7 1

16

5 18 6½ 3

8 6½ 3

8 7 — 7 1

8 7 1

8 7 1

8

5 316 6½ 7

16 7 — 7 — 7 3

16 7 3

16 7 3

16

5¼ 6½ ½ 7 — 7 — 7 ¼ 7 ¼ 7½ —

5 5 16 7 1

16 7 1

16 7 1

16 7 5

16 7 5

16 7½ —

5 38 7 1

8 7 1

8 7 1

8 7 3

8 7 3

8 7½ —

5 7 16 7 3

16 7 3

16 7 3

16 7 7

16 7½ — 7½ —

5½ 7 ¼ 7 ¼ 7½ — 7 ½ 7½ — 7½ —

5 9 16 7 5

16 7 5

16 7½ — 7½ 1

16 7½ 1

16 7½ 1

16

5 58 7 3

8 7 3

8 7½ — 7½ 1

8 7½ 1

8 7½ 1

8

5 1116 7 7

16 7½ — 7½ — 7½ 3

16 7½ 3

16 7½ 3

16

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

52 ENGINEERING JOURNAL / SECOND QUARTER / 1996

Table 2.

ASTM A325 and A490 Bolts

5

with zero, one, or two 32 -in.-thick washer(s)

¾-in. dia. 7 -in. dia.

8

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

5¾ 7 1 7 1 7½ — 7 ¼ 7 ¼ 7½ —

8 8

5 13 16 7 3

16 7 3

16 7½ — 7 5

16 7½ — 7½ —

5 78 7 ¼ 7 ¼ 7½ — 7 3

8 7½ — 7½ —

5 15 16 7 5

16 7½ — 7½ — 7½ — 7½ — 7½ —

6 7 3 7½ — 7½ — 7½ — 7½ — 7½ —

8

6 116 7½ — 7½ — 7½ — 7½ 1

16 7½ 1

16 7½ 1

16

6 18 7½ — 7½ — 7½ — 7½ 1

8 7½ 1

8 8 —

6 316 7½ 1

16 7½ 1

16 7½ 1

16 7½ 3

16 7½ 3

16 8 —

6¼ 7½ 1 7½ 1 8 — 7½ ¼ 7½ ¼ 8 —

8 8

65 16 7½ 3

16 7½ 3

16 8 — 7½ 5

16 8 — 8 —

6 38 7½ ¼ 7½ ¼ 8 — 7½ 3

8 8 — 8 —

6 7 16 7½ 5

16 8 — 8 — 8 — 8 — 8 —

6½ 7½ 3 8 — 8 — 8 — 8 — 8 —

8

69 16 8 — 8 — 8 — 8 1

16 8 1

16 8 1

16

6 58 8 — 8 — 8 — 8 1

8 8 1

8

6 1116 8 1

16 8 1

16 8 1

16 8 3

16 8 3

16

6¾ 8 1 8 1 8 ¼ 8 ¼

8 8

6 13 16 8 3

16 8 3

16 8 5

16

67 8 8 ¼ 8 ¼ 8 3

8

6 1516 8 5

16

7 8 3

8

Note: bolt lengths exceeding 8 inches are not generally available except by special order

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

ENGINEERING JOURNAL / SECOND QUARTER / 1996 53

Table 2.

ASTM A325 and A490 Bolts

with zero, one, or two 5 32 -in.-thick washer(s)

1-in. dia. 1 18 -in. dia.

no washers 1 washer 2 washers no washers 1 washer 2 washers

Grip L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in. L, in. t, in.

5¾ 7 ½ 7½ — 7½ — 7½ ¼ 7½ ¼ 8 —

5 13 16 7½ 1

16 7½ 1

16 7½ 1

16 7½ 5

16 7½ 5

16 8 —

5 78 7½ 1

8 7½ 1

8 7½ 1

8 7½ 3

8 7½ 3

8 8 —

5 15 16 7½ 3

16 7½ 3

16 7½ 3

16 7½ 7

16 8 — 8 —

6 7½ ¼ 7½ ¼ 8 — 7½ ½ 8 — 8 —

6 116 7½ 5

16 7½ 5

16 8 — 8 1

16 8 1

16 8 1

16

6 18 7½ 3

8 7½ 3

8 8 — 8 1

8 8 1

8 8 1

8

6 316 7½ 7

16 8 — 8 — 8 3

16 8 3

16 8 3

16

6¼ 7½ ½ 8 — 8 — 8 ¼ 8 ¼

6 516 8 1

16 8 1

16 8 1

16 8 5

16 8 5

16

6 38 8 1

8 8 1

8 8 1

8 8 3

8 8 3

8

6 7 16 8 3

16 8 3

16 8 3

16 8 7

16

6½ 8 ¼ 8 ¼ 8 ½

6 9 16 8 5

16 8 5

16

6 58 8 3

8 8 3

8

6 1116 8 7

16

6¾ 8 ½

Note: bolt lengths exceeding 8 inches are not generally available except by special order

Notes:

1. Minimum bolt length calculated per RCSC Specification Table C2

2. Below 5-in. bolt length, minimum length increment is ¼-in.; otherwise, ½-in.

3. When washer(s) are under bolt head, increase t by thickness of washer(s)

4. Shaded cells indicate longer bolt and additional washers may be required to prevent nut from jamming on the thread run-out

5. "—" indicates that threads are excluded regardless of ply thickness

54 ENGINEERING JOURNAL / SECOND QUARTER / 1996

You might also like

- Specifying Bolt Length of High strength BoltsDocument12 pagesSpecifying Bolt Length of High strength BoltsUpadrasta HarishNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717No ratings yet

- 06c PDFDocument29 pages06c PDFProcess EngineerNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Article - Structural BoltsDocument6 pagesArticle - Structural Boltsing_weroNo ratings yet

- Predilla Assignment Module 3Document15 pagesPredilla Assignment Module 3Justine PredillaNo ratings yet

- 169 PD0192ThreadsStandardReferenceGuiderev4Document21 pages169 PD0192ThreadsStandardReferenceGuiderev4Coman ovidiuNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Analysis of Bolt Torquing and Stress CalculationsDocument7 pagesAnalysis of Bolt Torquing and Stress CalculationsEleonor MaderazoNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- AD 386 Clarification of Notch Dimensions and Shear Resistances in SCI P358 Green Book On Simple JointDocument2 pagesAD 386 Clarification of Notch Dimensions and Shear Resistances in SCI P358 Green Book On Simple JointΤε ΧνηNo ratings yet

- Rosca Acme 3-2 MasmecánicaDocument6 pagesRosca Acme 3-2 MasmecánicaBachoNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Steel Structures Fasteners GuideDocument34 pagesSteel Structures Fasteners GuideEmreNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- AN BoltsDocument8 pagesAN BoltsAnthony McfayNo ratings yet

- Connections and Tension Member DesignDocument9 pagesConnections and Tension Member DesignVigneshwari MahamuniNo ratings yet

- WEIGHT LOSS COUPONS AND HOLDERSDocument4 pagesWEIGHT LOSS COUPONS AND HOLDERSShruti SrinivasNo ratings yet

- Column DetailDocument3 pagesColumn DetailKmrnKhnNo ratings yet

- Untitled 1Document1 pageUntitled 1juanNo ratings yet

- BRG Pad ExampleDocument16 pagesBRG Pad ExamplecarlosestayNo ratings yet

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978No ratings yet

- Sigma FastenersDocument5 pagesSigma Fastenerskhafif01No ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Bryan : England. Printed in Great BritainDocument24 pagesBryan : England. Printed in Great BritainSohini MishraNo ratings yet

- Structural Design of Reinforcements For Fittings in Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsDocument18 pagesStructural Design of Reinforcements For Fittings in Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsAleksei AvilaNo ratings yet

- Lecture - 5 - Tension MembersDocument67 pagesLecture - 5 - Tension Membersayoub aliousalahNo ratings yet

- Section 2 PDFDocument5 pagesSection 2 PDFimanNo ratings yet

- The Interaction of Ductility, Strength, and Stiffness IN Simple Shear Connections With Shear and Axial LoadDocument21 pagesThe Interaction of Ductility, Strength, and Stiffness IN Simple Shear Connections With Shear and Axial LoadsaudimanNo ratings yet

- 1.Chiều dài ống gió mềm-SMACNA 1995Document4 pages1.Chiều dài ống gió mềm-SMACNA 1995Long MaiNo ratings yet

- Fasteners Guide - Threaded, Non-Threaded Types and Design for Fatigue StrengthDocument41 pagesFasteners Guide - Threaded, Non-Threaded Types and Design for Fatigue StrengthGcwalisile DlaminiNo ratings yet

- Analysis and Design of Members For TensionDocument84 pagesAnalysis and Design of Members For TensionicpertacortaNo ratings yet

- Section 13.2: 343R-154 Aci Committee ReportDocument2 pagesSection 13.2: 343R-154 Aci Committee ReportSana FatimaNo ratings yet

- Clampstar Data Chart UsDocument1 pageClampstar Data Chart Usanurag_jay12464No ratings yet

- Pipeline Transportation Systems for LiquidsDocument3 pagesPipeline Transportation Systems for LiquidsKrystle FlowersNo ratings yet

- A FEDS Structural BoltsDocument6 pagesA FEDS Structural BoltsCrimsonPoshNo ratings yet

- Effective Length Factors For Gusset Plate BucklingDocument12 pagesEffective Length Factors For Gusset Plate Bucklingkaranderohan100% (2)

- Gusset PlatesDocument12 pagesGusset PlatesJason GarnerNo ratings yet

- Welding and bolting requirements for structural steelDocument10 pagesWelding and bolting requirements for structural steelIndra SidikNo ratings yet

- Scope: General Requirements For Bolted JointsDocument1 pageScope: General Requirements For Bolted Jointsrondana1No ratings yet

- 7.1 Longitudinal Reinforcement: S.No Description Status Remarks 7 Columns and Inclined MembersDocument4 pages7.1 Longitudinal Reinforcement: S.No Description Status Remarks 7 Columns and Inclined MembersJagadish kumar.kNo ratings yet

- Minimum Threads Exposed at Each NutDocument11 pagesMinimum Threads Exposed at Each NutSingaravel GanesanNo ratings yet

- Preliminary Section Design FinalDocument10 pagesPreliminary Section Design FinalblaqhaqarNo ratings yet

- unit 2 design of boiler revited jointDocument7 pagesunit 2 design of boiler revited jointaditya.1540011No ratings yet

- A325 and A490 BoltsDocument9 pagesA325 and A490 BoltsCHECcorp100% (1)

- Tin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedDocument8 pagesTin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedsamehNo ratings yet

- C I 3304 Detailing CornerDocument5 pagesC I 3304 Detailing CornerNono_geotecNo ratings yet

- Riveted Joints ASME IDocument7 pagesRiveted Joints ASME ICastoriadisNo ratings yet

- Bearing Pad Design ExampleDocument16 pagesBearing Pad Design ExampleAhirul Yahya100% (1)

- Round Timber Piles: Standard Specification ForDocument7 pagesRound Timber Piles: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Procedures For Drill String Design Engineering EssayDocument16 pagesProcedures For Drill String Design Engineering EssayGerardy Cantuta AruniNo ratings yet

- BOLTS (New Section) 972Document6 pagesBOLTS (New Section) 972Nisa_nisheNo ratings yet

- Section 1: Steel For Reinforcement: Physical/ Mechanical Properties - TheDocument12 pagesSection 1: Steel For Reinforcement: Physical/ Mechanical Properties - TherakshitaNo ratings yet

- V-Machine Design 1Document37 pagesV-Machine Design 1roamer10No ratings yet

- In-Plane Fatigue Strength of Plates With Laminar DiscontinuitiesDocument8 pagesIn-Plane Fatigue Strength of Plates With Laminar DiscontinuitiesalbertoxinaNo ratings yet

- Engineering Journal: Fourth Quarter 2021 - Volume 58, No. 4Document88 pagesEngineering Journal: Fourth Quarter 2021 - Volume 58, No. 4albertoxinaNo ratings yet

- AISC Engineering Journal Q1 2010Document76 pagesAISC Engineering Journal Q1 2010albertoxinaNo ratings yet

- Engineering Journal: Third Quarter 2022 - Volume 59, No. 3Document84 pagesEngineering Journal: Third Quarter 2022 - Volume 59, No. 3albertoxinaNo ratings yet

- Angle Tables For The Design Strength of Eccentrically-Loaded Single Angle StrutsDocument10 pagesAngle Tables For The Design Strength of Eccentrically-Loaded Single Angle StrutsalbertoxinaNo ratings yet

- The New Guide To Stability Design Criteria For Metal StructuresDocument3 pagesThe New Guide To Stability Design Criteria For Metal StructuresalbertoxinaNo ratings yet

- Time Saving Design Aids For Reinforced Concrete Fanella PCADocument19 pagesTime Saving Design Aids For Reinforced Concrete Fanella PCAalbertoxinaNo ratings yet

- WT2017 CompresionDocument20 pagesWT2017 CompresionalbertoxinaNo ratings yet

- 13 2 058Document2 pages13 2 058albertoxinaNo ratings yet

- Tension Field Design of Tapered WebsDocument7 pagesTension Field Design of Tapered WebsTigredesudafricaNo ratings yet

- Directional Moment Connections - A Proposed Design Method For Unbraced Steel FramesDocument6 pagesDirectional Moment Connections - A Proposed Design Method For Unbraced Steel FramesalbertoxinaNo ratings yet

- A Simple Approach To Truss Deflections: N-Braced TypeDocument6 pagesA Simple Approach To Truss Deflections: N-Braced Typealbertoxina100% (1)

- Design Example For Beams With Web Openings: Ue ToDocument9 pagesDesign Example For Beams With Web Openings: Ue ToalbertoxinaNo ratings yet

- Discussion: Seismic Design Practice For Steel BuildingsDocument2 pagesDiscussion: Seismic Design Practice For Steel BuildingsalbertoxinaNo ratings yet

- Rapid Selection of Column Base Plates: Construction, 7th Edition, Are Relatively Simple, The SelectionDocument5 pagesRapid Selection of Column Base Plates: Construction, 7th Edition, Are Relatively Simple, The SelectionalbertoxinaNo ratings yet

- Structural Steel and Fire - More Realistic AnalysisDocument8 pagesStructural Steel and Fire - More Realistic AnalysisalbertoxinaNo ratings yet

- The Effective Length of Unbraced Single Story Columns: Q G F EDocument4 pagesThe Effective Length of Unbraced Single Story Columns: Q G F EalbertoxinaNo ratings yet

- Flange Lateral Bending Stress (F) Under The Wind Pressure: Atorod Azizinamini, Ph.D.,P.EDocument41 pagesFlange Lateral Bending Stress (F) Under The Wind Pressure: Atorod Azizinamini, Ph.D.,P.EalbertoxinaNo ratings yet

- Stiffness Design of Unbraced Steel Frames: h m n s E I I L P P = total story load Q ψ /h) / /LDocument3 pagesStiffness Design of Unbraced Steel Frames: h m n s E I I L P P = total story load Q ψ /h) / /LalbertoxinaNo ratings yet

- A Closer Examination of The Axial Capacity of Eccentrically Loaded Single Angle StrutsDocument4 pagesA Closer Examination of The Axial Capacity of Eccentrically Loaded Single Angle StrutsalbertoxinaNo ratings yet

- AISC Column Design Logic Makes Sense For Composite Columns, TooDocument7 pagesAISC Column Design Logic Makes Sense For Composite Columns, TooalbertoxinaNo ratings yet

- A Simplified Method For The Flexural Design of Stiffened Hybrid GirdersDocument2 pagesA Simplified Method For The Flexural Design of Stiffened Hybrid GirdersalbertoxinaNo ratings yet

- Comparative Effectiveness of Tightening TechniquesDocument4 pagesComparative Effectiveness of Tightening TechniquesalbertoxinaNo ratings yet

- Strengthening of Existing Composite Beams Using LRFD ProceduresDocument8 pagesStrengthening of Existing Composite Beams Using LRFD Proceduresalbertoxina100% (3)

- Skewed Curved Steel Bridges August 2016 FinalDocument47 pagesSkewed Curved Steel Bridges August 2016 FinalEnrique LineroNo ratings yet

- Fatigue Life of Double Angle Tension MembersDocument10 pagesFatigue Life of Double Angle Tension MembersalbertoxinaNo ratings yet

- Fit Up Consider For Steel I Girder BR 2018-Wsbs-Final-Paper - ColettiDocument18 pagesFit Up Consider For Steel I Girder BR 2018-Wsbs-Final-Paper - ColettiAdrian DumitruNo ratings yet

- Practical Implementation Stability Bracing Strength Stiffness Guidelines Steel I-Girder BridgeDocument14 pagesPractical Implementation Stability Bracing Strength Stiffness Guidelines Steel I-Girder Bridgeclam2014No ratings yet

- Ontents: Section 1 - AbutmentsDocument10 pagesOntents: Section 1 - AbutmentsmicomakNo ratings yet

- Construction Engineer 1572435932Document2 pagesConstruction Engineer 1572435932Lovemore MalakiNo ratings yet

- Richard D. Dickerson P.E. QualificationsDocument1 pageRichard D. Dickerson P.E. QualificationsshawkishahrhNo ratings yet

- Submittal For Cast Iron PipesDocument2 pagesSubmittal For Cast Iron PipesAli EuropeNo ratings yet

- UCSanDiegoBEPTemplate v1.1 CompleteSampleDocument26 pagesUCSanDiegoBEPTemplate v1.1 CompleteSampleMarvvvNo ratings yet

- Digital Museum - General Information and Description of The Project and Architect - PRESS RELEASEDocument3 pagesDigital Museum - General Information and Description of The Project and Architect - PRESS RELEASEClaudiu IonescuNo ratings yet

- Dow-Corning - Molykote P-37Document2 pagesDow-Corning - Molykote P-37ramnadh803181No ratings yet

- Dukkaboard CatalogueDocument40 pagesDukkaboard CatalogueAbhinav SainiNo ratings yet

- Thread Gage in APE SystemDocument27 pagesThread Gage in APE SystemRosendo RizoNo ratings yet

- Considerations For A Safe in Situ PWHT of A Corrosion Process TowerDocument23 pagesConsiderations For A Safe in Situ PWHT of A Corrosion Process Towerعزت عبد المنعمNo ratings yet

- Architecture of MaharashtraDocument13 pagesArchitecture of MaharashtraDarshita ShetyeNo ratings yet

- Company Profile and Services for Atrium ConsultDocument31 pagesCompany Profile and Services for Atrium ConsultAbdulBasithNo ratings yet

- M10 - Partial Replacement of Fine Aggregate Using Polystyrene in Lightweight CHB-CE-503Document19 pagesM10 - Partial Replacement of Fine Aggregate Using Polystyrene in Lightweight CHB-CE-503Michelle LeeNo ratings yet

- ASTM A775 - A775M-07b Std. Specs For Epoxy Coated Reinforcing BarsDocument11 pagesASTM A775 - A775M-07b Std. Specs For Epoxy Coated Reinforcing BarsILSEN N. DAET100% (2)

- Labor Productivity Decline TeicholzDocument15 pagesLabor Productivity Decline Teicholzmit ramiNo ratings yet

- Discussion: Shear Peeling of Steel Plates Adhesively Bonded To The Sides of Reinforced Concrete BeamsDocument2 pagesDiscussion: Shear Peeling of Steel Plates Adhesively Bonded To The Sides of Reinforced Concrete BeamsAbualtayef KhalilNo ratings yet

- History of Philippine Architecture TypesDocument22 pagesHistory of Philippine Architecture TypesJohn Nichole Hernandez DacanayNo ratings yet

- Downloads - Customer Erco Price List 2020 - Update 2020 07 PDFDocument973 pagesDownloads - Customer Erco Price List 2020 - Update 2020 07 PDFmindaugas karaliusNo ratings yet

- MPWT - Defect WorkDocument118 pagesMPWT - Defect WorkVorn Ra VuthNo ratings yet

- Progress Report for Proposed Apartment ConstructionDocument2 pagesProgress Report for Proposed Apartment ConstructionJOSEPH MWANGINo ratings yet

- Pipesfitting PDFDocument35 pagesPipesfitting PDFNavin KumarNo ratings yet

- API 570 - 01 API 570 and B31.3 PracticeDocument5 pagesAPI 570 - 01 API 570 and B31.3 PracticeMegan KirbyNo ratings yet

- DesignPlus User Guide - Eurocode RCDocument34 pagesDesignPlus User Guide - Eurocode RCFabian GutierrezNo ratings yet

- Breaking Down Construction Management FoundationsDocument15 pagesBreaking Down Construction Management FoundationsJuan Pablo CortésNo ratings yet

- Estudo de Caso Ponte de Oresund - Saleema HughesDocument10 pagesEstudo de Caso Ponte de Oresund - Saleema HughesHelyson Andrew de SáNo ratings yet

- YCAB ManDocument44 pagesYCAB Manttt44967% (3)

- Mds 116sp51 Support StandardsDocument52 pagesMds 116sp51 Support Standardsdario840% (1)

- Course Code: BLD 802 TOPIC: Stages of Planning: Operational Lecture Note: Week 5 Lecturer: Dr. O.J. OladiranDocument11 pagesCourse Code: BLD 802 TOPIC: Stages of Planning: Operational Lecture Note: Week 5 Lecturer: Dr. O.J. OladiranRAHAMAN NAFISATNo ratings yet

- Basic Slickline 1Document60 pagesBasic Slickline 1Fauzan Rahman Haq100% (11)

- Proposed layout file of residential houseDocument1 pageProposed layout file of residential houseAman TakkarNo ratings yet

- BrochureDocument13 pagesBrochure13421301508No ratings yet