Professional Documents

Culture Documents

United States: Patent Office

Uploaded by

Pappu Pandey0 ratings0% found this document useful (0 votes)

24 views3 pagesOriginal Title

Us 2057999

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views3 pagesUnited States: Patent Office

Uploaded by

Pappu PandeyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Patented Oct.

20, 1936

2,057,999

UNITED STATES PATENT OFFICE

2,057,999

CHORINATED RUBBER COATING

COMPOSITION

Walter D. Bowlby, Wilmington, Del, assignor to

Hercules Powder Company, Wilmington, Del, a

corporation of Delaware

No Drawing. Application October 18, 1934,

Serial No. 748,452

5 Claims. (C. 134-17)

This invention relates to an improved form of rine content of the chlorinated parafin. Thus

coating composition containing chlorinated rub chlorinated parafin containing less than 26-27%

ber as the base.

chlorine is incompatible in a ratio of 10 parts

Chlorinated rubber is produced by the action chlorinated rubber to 2 parts chlorinated par

of chlorine on raw or vulcanized rubber, and affin. Chlorinated paraffin containing 29% chlo

contains from 30% to 80% chlorine depending rine is, however, compatible 5

upon the procedure used in its production. U. S. in a ratio of 10:4,

Patents 1,234,381, 1544,529, 1544,530, and 1852 isandcompatible

a product containing 45% or more chlorine

10

043 among others describe in detail various therefore, thatin when a ratio of 10:10. It will be seen,

it is desired to include a

methods for the production of chlorinated rubber. relatively high percentage of chlorinated par 0.

While chlorinated rubber is readily soluble in affin in the coating composition, a product con

cheap solvents and is possessed of great resist

ance to weathering and to chemical action, it taining about 50% chlorine should be selected,

but that when only a relatively low percentage

cannot be used alone to form satisfactory pro of chlorinated paraffin is to be included, a prod

5 tective coatings because of the brittleness and

lack of adhesion of such coatings. It has accord uct containing as little as 30% chlorine may be

employed. The chlorinated rubber and chlorin

5

ingly been customary to modify the properties of

ated paraffin may be included in coating com

chlorinated rubber films used as protective coat

positions in accordance with this invention in

ings by the addition of a plasticizing agent to the

any proportions in which they are compatible.

20 coating composition from which the film is de As will be hereinafter shown, however, for certain 20

posited. It has, however, been difficult to plasti

purposes it is desirable to keep the ratio of these

cize chlorinated rubber satisfactorily without at two ingredients within certain limits.

the same time adversely affecting the resistance The composition will contain, in addition to

to weathering, light discoloration and chemical chlorinated rubber and a chlorinated paraffin,

25 attack of the protective coating produced. a suitable solvent or solvent mixture whereby 25

In accordance with this invention it has been the essential ingredients will be blended and a

found that chlorinated paraffin may advanta solution formed of viscosity or fluidity such as

geously be used to plasticize chlorinated rubber to

coating compositions, and that the protective as enable its application to a surface to be coated,

coatings formed from compositions so plasticized Thebysolvent

brushing, spraying, dipping, or otherwise.

or solvent mixture will be of a vola 30

are greatly superior to those hitherto known to tile nature and will act as a vehicle, being wholly

the art. The coating composition in accordance or

with this invention will accordingly comprise eS tionlargely removed by evaporation after applica

of the compositions to a surface for the for

sentially chlorinated rubber, chlorinated paraffin mation

and a solvent. In addition to these ingredients suitable of a film. The solvent may be of any

type for the purpose, for example, toluol, 35

the coating composition may contain, in any de xylol, ethyl acetate, butyl acetate, naphtha (high

sired amounts, resins, drying oils, pigments, etc. flash), or chlorinated solvents, as ethylene di

The chlorinated rubber used in the coating chloride, carbon tetrachloride, or mixtures there

compositions in accordance with this invention of. The solvent will be a solvent for other in

-0 may be either chlorinated raw rubber or chlorin

ated vulcanized rubber or both. For the best tion, gredients which may be included in the composi 40

results it should have a chlorine content above and will be used in amount to give the vis

50%, and preferably of about 67% or higher. cosity desired. In addition to the essential ingredients, chlo

It may be of any desired viscosity, although for rinated rubber and a chlorinated paraffin, the

-5 use in coating compositions which are to be composition may contain various other ingredi

sprayed a viscosity of about 60 centipoises in ents, as for example, a resin such as coumarone

45

20% solutions in xylol at 25 C. is to be preferred.

The chlorinated parafin used in coating COm resin, ester gum, etc.; a plasticizer, as dibutyl

positions in accordance with this invention may phthalate; and pigments. Ingredients which

50 be of any suitable type, either liquid or solid, and may be included in the composition, in addition

may be produced by any of the known methods to chlorinated rubber and chlorinated paraffin, 50

for its production, as, for example, those dis may be included in varying amounts, as may be

closed in U. S. Patents 1,129,165 and 1,380,067. dictated by the purpose for which the composi

The compatibility of chlorinated rubber and tion is intended.

55 chlorinated paraffin is dependent upon the chlo As illustrative of compositions in accordance s

2 2,057,999

similar to those for metal coating, and, of course,

with this invention, satisfactory for various uses, vary

the following formulae may be cited: with the type of finish desired. The follow

ing formulae have been found to give satisfactory

2 3. 4. 5

Wood finishing compositions:

Parta Parts Parts Paris Paras

gia 'Ein - 20 20 20 20 20 29

orinated paratin Chlorinated rubber---------

$39% Cl)----------

Solvent.-----------------

5

75

8

72

0

70

15

65

20

80

Chlorinated paraffin (50%

chlorine).----------------- 20 O

Resins, drying oils, pig Pigment (30 asbestine-70

ments, etc. in quantity titanium dioxide).---------

desired.----...------------------------------------------------- Ester gum------------

- - -- - - - Oil modified alkyd res

Polymerized indene resia

coating compositions having the above for High flash naphtha.--------

mulae will be found advantageous for various pur

poses, and more particularly, with respect to For On outdoor exposure, these formulae give better

15

mulae 2, 3, 4 and 5, for the formation of films or weathering than similar formulae in which di

coatings on metal surfaces. It will be found that butyl phthalate is used in place of chlorinated

the films so formed are very resistant to light paraffin. As with the metal coating composi

and to chemical action and have unusual adhe" tions, a ratio greater than 20:8 gives too brittle 20

sion to polished metal surfaces such as duralumi a film to be useful.

num and polished copper. They are also very Compositions of chlorinated rubber plasticized

resistant to mechanical abrasion, such as occurs With chlorinated paraffin are useful for coating

in the forming of metal sheets into particular cloth. The exact composition to be used depends

shapes. Formula 2, given above, produced with

eontaining 45% chlorine,

on the mechanical structure of the cloth and the

property desired. Thus, a composition contain

duraluminum panels

in. The panels ing equal parts by weight of chlorinated rubber

everal ittimes with and chlorinated parafin is rather soft, while one

from the '..containing: four parts chlorinated. rubber to one's

part chlorinated paraffin is rather stiff. These g

:30 metal. . The , - . adhesion may be coatings are practically fireproof, due to the high

obtained on duraluminum with a composition in

cluding chlorinated paraffin containing about chlorine content, and for this reason are very

Valuable for fireproofing draperies and similar

40% chlorine. articles of cloth. The compositions are Water

The degree of adhesion, like the compatibility, proof, and are hence valuable for waterproofing.

35 is a function of the chlorine content of the Likewise, these compositions are valuable for

paraffin. With the same content by weight of coating paper. As with cloth coatings, the exact

chlorinated paraffin in the chlorinated rubber composition to be used will depend on the use to

film, a chlorinated paraffin containing 30% be made of the paper.

chlorine gives poorer adhesion to metal Surfaces It will be understood that the details and ex 4.

than one containing 45% or 50% chlorine. . amples set forth hereinabove are illustrative only,

The light resistance of chlorinated rubber and that the invention as herein broadly de

films plasticized with chlorinated paraffin is ex-. scribed and claimed is not limited thereby.

cellent. Steel and duraluminum panels coated What I claim and desire to protect by Letters

with films plasticized with chlorinated paraffin Patent is: 45

45 containing 45% chlorine were exposed 20 hours 1. A chlorinated rubber coating composition

to the direct radiation of a mercury ultra-violet

characterized by its ability to deposit a film show

arc, in comparison with similar panels coated

with chlorinated rubber plasticized with dibutyl ing marked resistance to chemical attack and

abrasion and a high degree of adhesion to the

phthalate. The films plasticized with chlorin Surface covered thereby, said composition com 50

50 ated paraffin discolored very slightly, and much prising chlorinated rubber, chlorinated paraffin

less than those containing dibutyl phthalate.

The adhesion of the films plasticized with chlorin Wax having a chlorine content of at least 30%

ated paraffin was better, after the exposure, and a volatile solvent, the ratio of chlorinated

rubber to chlorinated paraffin wax being within

than the ones containing dibutyl phthalate, since the range of from about 20:25 to about 20:8. 55

55 the latter had become very brittle. 2. A chlorinated rubber coating composition

As protective coatings for use on metal Sur characterized by its ability to deposit a film show

faces pigmented chlorinated rubber-chlorinated ing marked resistance to chemical attack and

paraffin compositions are extremely valuable. abrasion and a high degree of adhesion to the

The following formulae are examples of useful Surface covered thereby, Said composition con 80

60 protective coatings for use on metals:

prising chlorinated rubber, chlorinated paraffin

6 7 Wax having a chlorine content of at least 45%,

and a volatile solvent, the ratio of chlorinated

Ports Parts rubber to chlorinated paraffin Wax being within 65

Chlorinated rubber (60 cp.)-----------------------

65 Chlorinated 20 20 the range of from about 20:25 to about 20:8.

paraffin (50% chlorine)- 20 15 3. A chlorinated rubber coating composition

Pigment (Indian red).------------ 15 5

Solvent (toluol or xylol).--------------------------- 65 65 characterized by its ability to deposit a film show

ing marked resistance to chemical attack and

If a lower ratio of chlorinated rubber to chlo abrasion and a high degree of adhesion to the 70

70rinated paraffin than 20:25 is used, the film is too surface covered thereby, said composition com

soft, and if much more than 20:8 the film is too prising chlorinated rubber, chlorinated paraffin

brittle. The lower the chlorine content of the Wax having a chlorine Content of at least 45%,

chlorinated paraffin, the greater the brittleness a resin, and a volatile solvent, the ratio of chlo

and, as stated above, the poorer the adhesion. rirated rubber to chlorinated paraffin wax being 75

75 Compositions for use in WOOd finishing are

2,057,999 3

within the range of from about 20:25 to about 5. A chlorinated rubber coating composition

20:8. characterized by its ability to deposit a film show

4. A chlorinated rubber coating composition ing marked resistance to chemical attack and

characterized by its ability to deposit a flin abrasion and a high degree of adhesion to the

showing marked resistance to chemical attack surface covered thereby, said composition come

and abrasion and a high degree of adhesion to prising chlorinated rubber, chlorinated parafin

the surface covered thereby, said composition wax having a chlorine content of at least 45%,

comprising chlorinated rubber, chlorinated par a pigment, and a volatile solvent, the ratio of

affin wax having a chlorine content of at least chlorinated rubber to chlorinated paraffin wax

0 45%, a drying oil, and a volatile solvent, the being within the range of from about 20:25 to 10

ratio of chlorinated rubber to chlorinated paraf about 20:8.

fin Wax being within the range of from about WAER, D. BOW3.

20:25 to about 20:8.

You might also like

- Erucic Acid PDFDocument3 pagesErucic Acid PDFVivek VikramNo ratings yet

- Soy Candle ModuleDocument17 pagesSoy Candle ModuleCla Rence0% (2)

- Chemical Plus - Paraffin WaxDocument5 pagesChemical Plus - Paraffin WaxFer Net100% (1)

- United States Patent Office: Patented Nov. 17, 1953Document5 pagesUnited States Patent Office: Patented Nov. 17, 1953Luis BejaranoNo ratings yet

- United States Patent Office 3,246,970: Patented Apr. 19, 1966Document3 pagesUnited States Patent Office 3,246,970: Patented Apr. 19, 1966Battuka BatjargalNo ratings yet

- US4435296Document4 pagesUS4435296mgamal1080No ratings yet

- Process For Dyeing AsphaltDocument4 pagesProcess For Dyeing AsphaltHendri HadisiNo ratings yet

- United States Patent (19) : HiiikataDocument4 pagesUnited States Patent (19) : HiiikataLiraNo ratings yet

- Tyre Puncture SolutionDocument3 pagesTyre Puncture SolutionShreyansh ShahNo ratings yet

- Us 2899327Document5 pagesUs 2899327Trades India InternationalNo ratings yet

- Us3438797 PDFDocument5 pagesUs3438797 PDFsiddpandit89No ratings yet

- US3057026Document4 pagesUS3057026ThomasNo ratings yet

- 577 - Chloro and Bromo As FR For FabricsDocument4 pages577 - Chloro and Bromo As FR For FabricsOzgur SelviNo ratings yet

- STPP Hybrid Resin DesignDocument4 pagesSTPP Hybrid Resin DesignPete WolanNo ratings yet

- United States Patent Office: Tion, It Will Be Understood To Have Been Calculated AsDocument2 pagesUnited States Patent Office: Tion, It Will Be Understood To Have Been Calculated Asthan zawNo ratings yet

- US4758615Document13 pagesUS4758615Alexander Franco CastrillonNo ratings yet

- US6060550Document4 pagesUS6060550VivekPatilNo ratings yet

- United States Patent: Nicks Et A1Document5 pagesUnited States Patent: Nicks Et A1Albert hikerNo ratings yet

- US2850403Document3 pagesUS2850403Nityanarayan KuntiNo ratings yet

- Us20090069498a1 PDFDocument11 pagesUs20090069498a1 PDFMamoon ShahidNo ratings yet

- Preparation and Characterization of Polyurethane /charcoal Foam CompositeDocument7 pagesPreparation and Characterization of Polyurethane /charcoal Foam CompositeTarani TharanNo ratings yet

- United States: Patent OfficeDocument2 pagesUnited States: Patent OfficeMURALIPRAKASH.S 18BIT131No ratings yet

- USRE25845Document4 pagesUSRE25845member2 mtriNo ratings yet

- US4790877Document4 pagesUS4790877indoarmy145No ratings yet

- Rhoplex Ei-3500Document5 pagesRhoplex Ei-3500Chirag PatelNo ratings yet

- 2005 PDFDocument14 pages2005 PDFBattuka BatjargalNo ratings yet

- Leveling Agent For Powder CoatingDocument5 pagesLeveling Agent For Powder Coatingsahajahan shaikhNo ratings yet

- Patent - Graphite Manufacturing ProcessDocument4 pagesPatent - Graphite Manufacturing ProcessAbrizal HaryadiNo ratings yet

- Method For Preparing Cyanoacrylate Adhesive CompositionsDocument3 pagesMethod For Preparing Cyanoacrylate Adhesive CompositionsAien Nabieyla1607No ratings yet

- US Patent For Polish Composition and Method of Use Patent (Patent # 6,193,791 Issued February 27, 2001) - Justia Patents SearchDocument37 pagesUS Patent For Polish Composition and Method of Use Patent (Patent # 6,193,791 Issued February 27, 2001) - Justia Patents SearchArcha UnniNo ratings yet

- Polymer Degradation and Stability: Ampornphan Siriviriyanun, Edgar A. O'Rear, Nantaya YanumetDocument8 pagesPolymer Degradation and Stability: Ampornphan Siriviriyanun, Edgar A. O'Rear, Nantaya YanumetYa siriviriyanunNo ratings yet

- United States Patent (19) : Malik Et Al. 45 Date of Patent: Jul. 7, 1987Document5 pagesUnited States Patent (19) : Malik Et Al. 45 Date of Patent: Jul. 7, 1987Mamoon ShahidNo ratings yet

- United States Patent Office: Oliensisnegative Asphalt ProductionDocument3 pagesUnited States Patent Office: Oliensisnegative Asphalt ProductionMehdi FarrokhiNo ratings yet

- StabilizeDocument4 pagesStabilizeARHNo ratings yet

- United States Patent 0: Patented Sept. 30, 1969Document2 pagesUnited States Patent 0: Patented Sept. 30, 1969هیمن مNo ratings yet

- Delayed-Action AcceleratorDocument3 pagesDelayed-Action AcceleratorMOHD FIRDAUSNo ratings yet

- EP0403302A2Document7 pagesEP0403302A2alimajnoonNo ratings yet

- q3 cGBPariantDocument4 pagesq3 cGBPariantGhasem BashiriNo ratings yet

- United States Patent (19) (11) 4,024,096: 11 Claims, No DrawingsDocument4 pagesUnited States Patent (19) (11) 4,024,096: 11 Claims, No DrawingsFrichs condori monzonNo ratings yet

- Highway Pavement Materials: 1.1.1 Road TarDocument2 pagesHighway Pavement Materials: 1.1.1 Road TarAngie PicoNo ratings yet

- General Foam Information 5Document1 pageGeneral Foam Information 5Mohammed HeshamNo ratings yet

- ,united States Patent Office: Patented Feb. 7, 1950Document4 pages,united States Patent Office: Patented Feb. 7, 1950erwerNo ratings yet

- 1924 Foundry Wash and Process of Manufacturing The SameDocument2 pages1924 Foundry Wash and Process of Manufacturing The SameAmmara AliNo ratings yet

- Patent 6Document6 pagesPatent 6ALEXANDER FRANCO CASTRILLONNo ratings yet

- Application of Rice Husk Ash As Fillers in Polypropylene Effect of Titanate, ZirconateDocument9 pagesApplication of Rice Husk Ash As Fillers in Polypropylene Effect of Titanate, Zirconatedungnv2733No ratings yet

- United States Patent Office: Patented June 16, 1964Document3 pagesUnited States Patent Office: Patented June 16, 1964Vansala GanesanNo ratings yet

- United States Patent Office: 2 Cating Oil. From A Practical Point of View, 0.25% To 10%Document9 pagesUnited States Patent Office: 2 Cating Oil. From A Practical Point of View, 0.25% To 10%Tristan Tabago ConsolacionNo ratings yet

- US3565658Document2 pagesUS3565658Nityanarayan KuntiNo ratings yet

- FORMATE MAN B9 Other CompatibilitiesDocument3 pagesFORMATE MAN B9 Other CompatibilitiesChris TNo ratings yet

- EP0711642A2Document7 pagesEP0711642A2youssef osamaNo ratings yet

- Agente de Pegajosidad Tackifier TactifierDocument6 pagesAgente de Pegajosidad Tackifier TactifierMelo2008No ratings yet

- 6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenDocument4 pages6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenAmeya SavnalNo ratings yet

- Clariant Article Ban of PFOA PCI Magazin 202009 enDocument5 pagesClariant Article Ban of PFOA PCI Magazin 202009 enGonzalo BenavidesNo ratings yet

- Wrinkle Free FinishingDocument4 pagesWrinkle Free FinishingkreeshnuNo ratings yet

- Patent Office: United StatesDocument2 pagesPatent Office: United StatesfebycholiebyNo ratings yet

- Salt Purification - 3Document4 pagesSalt Purification - 3Ruchita PoilkarNo ratings yet

- ch8 PDFDocument5 pagesch8 PDFRaghavendra Pratap SinghNo ratings yet

- Paraffin & Asphaltene Chemicals IES-World-Oil-ArticleDocument4 pagesParaffin & Asphaltene Chemicals IES-World-Oil-Article1mmahoneyNo ratings yet

- Antifog 2Document19 pagesAntifog 2Javier BecerraNo ratings yet

- Us 2563606Document4 pagesUs 2563606mgamal1080No ratings yet

- US2704278Document4 pagesUS2704278Pvd CoatingNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- BIOMOLECULEDocument76 pagesBIOMOLECULEUsha Dhamodharan100% (1)

- Notification: Description of Goods PCT Heading NoDocument8 pagesNotification: Description of Goods PCT Heading NoMohmmad HarisNo ratings yet

- Road-Marking-Paint Resin: Summit's Rosin, Resin & TerpenesDocument1 pageRoad-Marking-Paint Resin: Summit's Rosin, Resin & TerpenesElsa FaisalNo ratings yet

- Swix Katalog 2010-2011Document123 pagesSwix Katalog 2010-2011Jason TsangNo ratings yet

- Silicon Wax Emulsion For Polyurethane Water Release AgentDocument3 pagesSilicon Wax Emulsion For Polyurethane Water Release Agentmyosi laboratoriumNo ratings yet

- Tds E-340Document1 pageTds E-340Nicoleta HomescuNo ratings yet

- Chemistry of Fats Oils and Waxes PDFDocument33 pagesChemistry of Fats Oils and Waxes PDFShai VillalbaNo ratings yet

- Impregnation and EmbeddingDocument2 pagesImpregnation and Embeddinglucky mark navarroNo ratings yet

- 5fb9 PDFDocument12 pages5fb9 PDFAiiuSrikkNo ratings yet

- BIOMOLECULESDocument54 pagesBIOMOLECULESTanmayNo ratings yet

- Us 5028366Document7 pagesUs 5028366EdgarNo ratings yet

- Flexible Packaging Inks and Raw Materials Selection ProcessDocument5 pagesFlexible Packaging Inks and Raw Materials Selection ProcessNélida Araya RiveraNo ratings yet

- Paraffin Wax PDFDocument12 pagesParaffin Wax PDFNurhasanahNo ratings yet

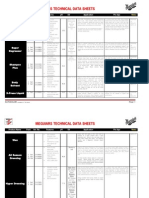

- Meguiars Tds by Sabet (English)Document38 pagesMeguiars Tds by Sabet (English)sabteNo ratings yet

- US20030075077A1Document12 pagesUS20030075077A1Kyaw Kyaw LinnNo ratings yet

- A New Experimental Method To Prevent Paraffin-Wax FormationDocument6 pagesA New Experimental Method To Prevent Paraffin-Wax FormationMichael MedinaNo ratings yet

- Ointments and Creams Basics of FormulationDocument4 pagesOintments and Creams Basics of FormulationJai MurugeshNo ratings yet

- HF 12 - SVM WRD1Document1 pageHF 12 - SVM WRD1Ysabel Cristina Yaguaracuto TorrealbaNo ratings yet

- Crude OilDocument8 pagesCrude OilPriyanka DeuriNo ratings yet

- Not Another Chevron Cutting Board PlanDocument8 pagesNot Another Chevron Cutting Board PlanRick0% (1)

- Vehicle WashDocument12 pagesVehicle Washyilmaz_uuurNo ratings yet

- Candle Making For Fun &businessDocument21 pagesCandle Making For Fun &businessDr Srinivasan Nenmeli -K100% (2)

- Edible Films and Coatings Sources Properties and ApplicationDocument12 pagesEdible Films and Coatings Sources Properties and ApplicationDanielNo ratings yet

- Handfoot Spa Machine Tools Supplies and Equipment Steps in Giving Hand Foot Spa Pre Hand Spa Tratment Hand Spa TreatmentDocument6 pagesHandfoot Spa Machine Tools Supplies and Equipment Steps in Giving Hand Foot Spa Pre Hand Spa Tratment Hand Spa TreatmentCris Cali EspeNo ratings yet

- Cosmetic Chemistry VocabularyDocument2 pagesCosmetic Chemistry Vocabularyapi-266663713No ratings yet

- Benzoic Acid Recovery Via Waste Poly (Ethylene Terephthalate) (PET) Catalytic Pyrolysis Using Sulphated Zirconia CatalystDocument11 pagesBenzoic Acid Recovery Via Waste Poly (Ethylene Terephthalate) (PET) Catalytic Pyrolysis Using Sulphated Zirconia CatalystMubeen KudiyaNo ratings yet

- Licocene®: Performance PolymersDocument4 pagesLicocene®: Performance PolymersguldavistNo ratings yet