Professional Documents

Culture Documents

Insert Type Check, Poppet Type: Special Cavity, 871

Uploaded by

tecnicomanelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insert Type Check, Poppet Type: Special Cavity, 871

Uploaded by

tecnicomanelCopyright:

Available Formats

1/2

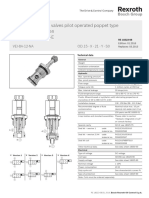

RE 18329-54/10.10

Insert type

Check, poppet type

Special cavity, 871

VUM1.180 0T.U6.04.00.99 - Z

Description

When pressure at 1 rises above the spring bias pressure, the poppet is

lifted and flow allowed from 1 to 2. The valve is closed (checked) from

2 to 1. Precision machining and hardening processes allow virtually

leak-free performance in the checked condition.

Note: to obtain a good leak proof performance coin the cavity seat

using a loose valve poppet (P/N 0F.S2.023) as a coining tool.

Impact energy: 7 ± 2 Nm.

Performance Technical data

Max. operating pressure bar (psi) 380 (5500)

Max. flow l/min. (gpm) 180 (48)

Max. internal

drops/min. 5

leakage

Fluid temperature range °C (°F) -30 to 100 (-22 to 212)

Installation torque Nm (ft-lbs) 50-55 (37-41)

Weight kg (lbs) 0.13 (0.29)

Special cavity 871

code RG0870020000100

Seal kit (*)

material no. R931002407

Mineral-based or synthetics

Fluids with lubricating properties at

viscosities of 5 to 800 mm2/s (cSt)

Nominal value max. 10µm (NAS 8)

Filtration ISO 4406 19/17/14

Installation No restrictions

Other Technical Data See data sheet RE 18350-50

(*) Only external seals for 10 valves

2/2 Bosch Rexroth Oil Control S.p.A. 0TU6040099Z RE 18329-54/10.10

Dimensions

Ordering code

0T.U6.04.00.99 Z *

Insert type - Series 0/A to L

Check, poppet type unchanged performances and dimensions

SPRINGS

Special cavity, 871 Cracking pressure bar (psi)

= 00 1 (15)

Type Material number Type Material number

0TU604009900000 R931002473

Bosch Rexroth Oil Control S.p.A. © This document, as well as the data, specifications and other

Via Leonardo da Vinci 5 information set forth in it, are the exclusive property of Bosch Rexroth

P.O. Box no. 5 Oil Control S.p.a.. It may not be reproduced or given to third parties

without its consent.

41015 Nonantola – Modena, Italy

Tel. +39 059 887 611 The data specified above only serve to describe the product. No

Fax +39 059 547 848 statements concerning a certain condition or suitability for a certain

application can be derived from our information. The information given

cartridges@oilcontrol.com does not release the user from the obligation of own judgment and

www.boschrexroth.com verification. It must be remembered that our products are subject to a

natural process of wear and aging.

Subject to change.

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- SOP For Compressed Air SystemDocument14 pagesSOP For Compressed Air SystemAbeer arif100% (1)

- Performance Test of Kaplan TurbineDocument3 pagesPerformance Test of Kaplan TurbineJhiGz Llausas de Guzman0% (1)

- Bit Hydraulics OptimizationDocument24 pagesBit Hydraulics OptimizationRebar Kaka100% (1)

- Chapter 3 Gas TurbineDocument120 pagesChapter 3 Gas TurbineGloria Del Carmen Muñoz100% (2)

- Pipeline Design For Onshore Pipelines: STD.4600 Engineering Standards and Specifications PipelineDocument23 pagesPipeline Design For Onshore Pipelines: STD.4600 Engineering Standards and Specifications PipelineEzequiel Guillermo Trejo NavasNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Michell Banki TurbineDocument5 pagesMichell Banki TurbinenurudinsatharNo ratings yet

- (EDITED-FINAL) Sludge - Storage CalculationDocument16 pages(EDITED-FINAL) Sludge - Storage CalculationAmro Ahmad AliNo ratings yet

- HydraulicPowerUnit PowerTransmissionDocument4 pagesHydraulicPowerUnit PowerTransmissionCesar Ruben SosaNo ratings yet

- Atlas Copco mb1700Document48 pagesAtlas Copco mb1700pecirepi0% (1)

- Paae221519spc en PDFDocument600 pagesPaae221519spc en PDFDenis NuñezNo ratings yet

- Counterbalance, Standard Poppet Type Zero Differential Area: Common Cavity, Size 20Document2 pagesCounterbalance, Standard Poppet Type Zero Differential Area: Common Cavity, Size 20tecnicomanelNo ratings yet

- Check, Poppet Type: Common Cavity, Size 16Document2 pagesCheck, Poppet Type: Common Cavity, Size 16HIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Check, Poppet Type: Common Cavity, Size 20Document2 pagesCheck, Poppet Type: Common Cavity, Size 20tecnicomanelNo ratings yet

- Check, Poppet Type: Common Cavity, Size 20Document2 pagesCheck, Poppet Type: Common Cavity, Size 20tecnicomanelNo ratings yet

- Logic Element, Flow Control With External Pilot: Common Cavity, Size 12Document2 pagesLogic Element, Flow Control With External Pilot: Common Cavity, Size 12tecnicomanelNo ratings yet

- Pressure Reducing and Relieving, Direct Acting Spool Damped TypeDocument2 pagesPressure Reducing and Relieving, Direct Acting Spool Damped TypetecnicomanelNo ratings yet

- Re18321 26 PDFDocument2 pagesRe18321 26 PDFAnonymous nPK85ZFzNo ratings yet

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- Counterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmentDocument2 pagesCounterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmenttecnicomanelNo ratings yet

- 041504X99Z RE18318-22 Compressed PDFDocument2 pages041504X99Z RE18318-22 Compressed PDFmhasansharifiNo ratings yet

- Relief, Direct Acting Poppet Type Differential Area Special Cavity, 004Document2 pagesRelief, Direct Acting Poppet Type Differential Area Special Cavity, 004mhasansharifiNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- 041157X99Z RE18318-20 CompressedDocument2 pages041157X99Z RE18318-20 CompressedmhasansharifiNo ratings yet

- Dual Contrabalance BoschDocument2 pagesDual Contrabalance BoschTiagoNo ratings yet

- Od940118yz Re18323-65Document4 pagesOd940118yz Re18323-65Mechanical2022No ratings yet

- 0M2403XY2 WayDocument2 pages0M2403XY2 Waysivaraman jaganathanNo ratings yet

- Relief, Direct Acting Guided Poppet Type, Hardened Seat Special Cavity, 008Document2 pagesRelief, Direct Acting Guided Poppet Type, Hardened Seat Special Cavity, 008mhasansharifiNo ratings yet

- Od15x21ys0 Vei 8a 12 Na PoppetDocument4 pagesOd15x21ys0 Vei 8a 12 Na PoppetGabrielNo ratings yet

- VSO-DE Pilot Operated Check, DualDocument2 pagesVSO-DE Pilot Operated Check, DualHector MoragaNo ratings yet

- RE18325-03 Solenoid Valve With Feedback OD15051841YZDocument4 pagesRE18325-03 Solenoid Valve With Feedback OD15051841YZMujahidin AhmadNo ratings yet

- Válvula Cilindro Inclinación Grúa Effer 120Document2 pagesVálvula Cilindro Inclinación Grúa Effer 120Sergio BelmarNo ratings yet

- Dual Counterbalance With Brake Release Port: DescriptionDocument2 pagesDual Counterbalance With Brake Release Port: DescriptionPhilNo ratings yet

- Relief, Direct Acting Poppet Type Pressure Compensated Special Cavity, 008Document2 pagesRelief, Direct Acting Poppet Type Pressure Compensated Special Cavity, 008mhasansharifiNo ratings yet

- r 930007142Document2 pagesr 930007142Andon XhumbaNo ratings yet

- High Performance Lubricants: Molykote HP-870 GreaseDocument2 pagesHigh Performance Lubricants: Molykote HP-870 GreaseBruno FranNo ratings yet

- Od92x12y00 Re18323-62Document4 pagesOd92x12y00 Re18323-62pttNo ratings yet

- Single Counterbalance: DescriptionDocument2 pagesSingle Counterbalance: DescriptionAtaa AssaadNo ratings yet

- PDS Poweroil Turbo Super AWDocument2 pagesPDS Poweroil Turbo Super AWNitant MahindruNo ratings yet

- PDS Poweroil TurboDocument2 pagesPDS Poweroil TurboNitant MahindruNo ratings yet

- 054981xyz PDFDocument2 pages054981xyz PDFmhasansharifiNo ratings yet

- Single Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - ZDocument2 pagesSingle Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - Znemi90No ratings yet

- XyzDocument4 pagesXyzJose SalvadorNo ratings yet

- L5235X00000000Document2 pagesL5235X00000000D.CORNEILLENo ratings yet

- Cartucho para rs210 - OD15X18YZ00 - RE18323-26Document4 pagesCartucho para rs210 - OD15X18YZ00 - RE18323-26Adrian MartinNo ratings yet

- Pressure Reducing and Relieving, Pilot Operated Spool Type Common Cavity, Size 10Document2 pagesPressure Reducing and Relieving, Pilot Operated Spool Type Common Cavity, Size 10mhasansharifiNo ratings yet

- Datasheet R901113682Document4 pagesDatasheet R901113682Carlos InfanteNo ratings yet

- Rexroth Dual Counterbalance ValveDocument2 pagesRexroth Dual Counterbalance ValveLucas ScioscioliNo ratings yet

- PDS Poweroil Turbo AWDocument2 pagesPDS Poweroil Turbo AWNitant MahindruNo ratings yet

- 041118X09Z Re18318-24 PDFDocument2 pages041118X09Z Re18318-24 PDFThalia CRNo ratings yet

- VSO-SE-DL 055211X03Z Pilot Operated Check SingleDocument2 pagesVSO-SE-DL 055211X03Z Pilot Operated Check SingleCarlos Andrés CuelloNo ratings yet

- Datasheet R930001664Document2 pagesDatasheet R930001664Анатолий РябухаNo ratings yet

- 084519xyz Re18307-49Document2 pages084519xyz Re18307-49NABEILNo ratings yet

- Tefabloc Tosi 431 65a PDFDocument5 pagesTefabloc Tosi 431 65a PDFAdriana UceanuNo ratings yet

- Procontrol Technical Description - 3!9!21Document6 pagesProcontrol Technical Description - 3!9!21samim_khNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Technical Data: 1. GeneralDocument12 pagesTechnical Data: 1. GeneraltecnicomanelNo ratings yet

- Re18350 50Document11 pagesRe18350 50Agustín TorresNo ratings yet

- Solenoid Operated Valves Pilot Operated Poppet Type 2-Way Normally Open Common Cavity, Size 08Document4 pagesSolenoid Operated Valves Pilot Operated Poppet Type 2-Way Normally Open Common Cavity, Size 08Alvin Smith BuelvasNo ratings yet

- Valve/ Actuator Torque Sizing Analysis Chart For Trunnion Ball ValvesDocument1 pageValve/ Actuator Torque Sizing Analysis Chart For Trunnion Ball ValvesagrovadoNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- RE18323 ValvesDocument4 pagesRE18323 Valvesalesker.alekperov71No ratings yet

- RE18301-91 - Cartridge Valves - NloDocument12 pagesRE18301-91 - Cartridge Valves - NloTaller PahrNo ratings yet

- Motion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - ZDocument2 pagesMotion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - Zvictor bastardoNo ratings yet

- ISO Certified Company Final Inspection ReportsDocument20 pagesISO Certified Company Final Inspection ReportsSandeep MauryaNo ratings yet

- Relief, Bi-Directional Direct Acting Poppet Type Differential Area Common Cavity, Size 10Document2 pagesRelief, Bi-Directional Direct Acting Poppet Type Differential Area Common Cavity, Size 10mhasansharifiNo ratings yet

- 049504X85Z Re18318-53Document2 pages049504X85Z Re18318-53dani sanNo ratings yet

- Product Information: Air Impact WrenchDocument56 pagesProduct Information: Air Impact WrenchApoorva Vikram SinghNo ratings yet

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- Swivel Connections: Coupling With An Integrated SwivelDocument1 pageSwivel Connections: Coupling With An Integrated SwiveltecnicomanelNo ratings yet

- Re18325 75Document6 pagesRe18325 75tecnicomanelNo ratings yet

- Old Code OLD R Number New Code NEW R Number Availability Phase Out Phase inDocument7 pagesOld Code OLD R Number New Code NEW R Number Availability Phase Out Phase intecnicomanelNo ratings yet

- New Plastic Coil NutsDocument1 pageNew Plastic Coil NutstecnicomanelNo ratings yet

- 049306X85ZDocument2 pages049306X85ZtecnicomanelNo ratings yet

- Stvu-08a - Stfu-08aDocument6 pagesStvu-08a - Stfu-08atecnicomanelNo ratings yet

- Technical Data: 1. GeneralDocument12 pagesTechnical Data: 1. GeneraltecnicomanelNo ratings yet

- Common Cavities & Tooling: 2-Way 3-Way / 3-Way Short 4-WayDocument6 pagesCommon Cavities & Tooling: 2-Way 3-Way / 3-Way Short 4-WaytecnicomanelNo ratings yet

- Bosch Rexroth Oil Control S.p.A.: Nonantola, 24th May 2010Document5 pagesBosch Rexroth Oil Control S.p.A.: Nonantola, 24th May 2010tecnicomanelNo ratings yet

- Re18325 75Document6 pagesRe18325 75tecnicomanelNo ratings yet

- Bosch Rexroth Oil Control S.p.A.: Nonantola, 24th May 2010Document5 pagesBosch Rexroth Oil Control S.p.A.: Nonantola, 24th May 2010tecnicomanelNo ratings yet

- Bosch Rexroth Oil Control S.p.ADocument5 pagesBosch Rexroth Oil Control S.p.AtecnicomanelNo ratings yet

- Counterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmentDocument2 pagesCounterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmenttecnicomanelNo ratings yet

- Pressure Reducing and Relieving, Direct Acting Spool Damped TypeDocument2 pagesPressure Reducing and Relieving, Direct Acting Spool Damped TypetecnicomanelNo ratings yet

- Orbitrol StuureenhedenDocument98 pagesOrbitrol Stuureenhedenkaoblekstena100% (1)

- Relief, Pilot Operated Poppet Type: Common Cavity, Size 10Document2 pagesRelief, Pilot Operated Poppet Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- Section Vi: Parts ListDocument19 pagesSection Vi: Parts ListtecnicomanelNo ratings yet

- Glo-Away SDS En-UsDocument5 pagesGlo-Away SDS En-UstecnicomanelNo ratings yet

- 7-Data Installation & Start-Up Notes For Axial Piston Units RA90400 - 0593Document28 pages7-Data Installation & Start-Up Notes For Axial Piston Units RA90400 - 0593tecnicomanelNo ratings yet

- Relief, Pilot Operated Spool Type External Drain: Common Cavity, Size 10Document2 pagesRelief, Pilot Operated Spool Type External Drain: Common Cavity, Size 10tecnicomanelNo ratings yet

- Lasercm: Portable Particle Counter Fluid Condition MonitoringDocument6 pagesLasercm: Portable Particle Counter Fluid Condition MonitoringtecnicomanelNo ratings yet

- OPK-541 Kit FlyerDocument1 pageOPK-541 Kit FlyertecnicomanelNo ratings yet

- Domestik KAP.400M : Dosing Pump ExistingDocument1 pageDomestik KAP.400M : Dosing Pump ExistingHanum PravitasariNo ratings yet

- Drawings For Approval 2013-11-12 Rev.00Document84 pagesDrawings For Approval 2013-11-12 Rev.00M Ridho AgungNo ratings yet

- Sanitary Price List 1-10-2022Document98 pagesSanitary Price List 1-10-2022syed masiuddinNo ratings yet

- Group 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Document8 pagesGroup 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)thierrylindoNo ratings yet

- Pratt & Whitney Canada Maintenance Manual Chapter on Accessory Gearbox AssemblyDocument54 pagesPratt & Whitney Canada Maintenance Manual Chapter on Accessory Gearbox AssemblyEstebanNo ratings yet

- Fluid MoversDocument10 pagesFluid MoversNishit KumarNo ratings yet

- Travel Motor, Installation: Service InformationDocument4 pagesTravel Motor, Installation: Service InformationDmitryNo ratings yet

- PLUMBING Final Handoutprof PDFDocument33 pagesPLUMBING Final Handoutprof PDFReinier Carrasco100% (1)

- Class A3A6Document15 pagesClass A3A6SalimNo ratings yet

- Dynamic COMPRESOR CATALOGUEDocument19 pagesDynamic COMPRESOR CATALOGUEJosé Guillermo Muñoz CamachoNo ratings yet

- Chapter 4 Compressible FlowDocument34 pagesChapter 4 Compressible FlowSanthoshinii Ramalingam100% (1)

- Pages From API 14c 2001 About Compressor BlowdownDocument5 pagesPages From API 14c 2001 About Compressor BlowdownkienlvNo ratings yet

- TAC Vs NFPADocument4 pagesTAC Vs NFPAS.KAMBAN50% (2)

- DMCI Numerical QuestionsDocument11 pagesDMCI Numerical Questionsshritik raj awadhiyaNo ratings yet

- Compressor WP81L - WP101L - Data - Leaflet - 2015Document2 pagesCompressor WP81L - WP101L - Data - Leaflet - 2015RizzoRo1No ratings yet

- CR, CRN High Pressure: Grundfos Product GuideDocument48 pagesCR, CRN High Pressure: Grundfos Product Guiderodriguez.gaytanNo ratings yet

- Dirty Service Anti-Cavitation Trim (DST) : Bulletin 80.2:021Document4 pagesDirty Service Anti-Cavitation Trim (DST) : Bulletin 80.2:021Datt NguyenNo ratings yet

- Steam Separator and Steam Trap Are Almost Same in FunctionDocument7 pagesSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNo ratings yet

- Inbal Deluge ValveDocument4 pagesInbal Deluge ValveNelson Eduardo Zárate SalazarNo ratings yet

- Pricelist Belgicast RSGV 2020Document1 pagePricelist Belgicast RSGV 2020fikry arifandaniNo ratings yet

- Unit 2: 1. Riser System 2. Sprinkler System 3. Spray SystemDocument11 pagesUnit 2: 1. Riser System 2. Sprinkler System 3. Spray Systemnimish ugemugeNo ratings yet

- SE - Dismantling Works Commercial ProposalDocument2 pagesSE - Dismantling Works Commercial ProposalSrinivasan EnterprisesNo ratings yet