Professional Documents

Culture Documents

Series LS-800, LS-800 Adjustable Multi-Station Level Switches

Uploaded by

Dayro MontefuscoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series LS-800, LS-800 Adjustable Multi-Station Level Switches

Uploaded by

Dayro MontefuscoCopyright:

Available Formats

Instruction Bulletin No.

72978 (Rev P)

Integrated Temperature Sensors Options

1. Thermistor for Continuous Indication

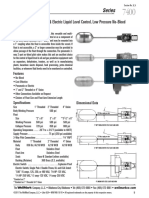

Series LS-800, LS-800 Adjustable

Excellent Repeatability Multi-Station Level Switches

Temperature

Value: 10,000 ohms @ 77°F (25°C) Sensor (Includes LS-800’s with Temperature Sensors)

Assembly

Tolerance: ±0.2°C from 32°F to 158°F (0°C to 70°C)

Operating Temperature: 302°F (150°C), Max. Installation Multi-station level switches install vertically in tank top (mounting up) or in tank bottom (mounting down).

Level switches will operate normally inclined up to 30°.

Alpha @ 25°C: -4.39%/°C

Bottom of Unit Mounting Types Type 1 Type 2 Type 3 Type 4

Dissipation Constant: 1mW/°C in Still Air

*Note: Units greater than 72” 1/2” NPT 1-1/4” NPT 2” NPT 3” Dia., 150# Flangeype

8 mW/°C in Oil Bath overall length are supplied with 6” Bolt

collars with setscrews (made of Circle

Note 1/2”

same material as stem and 1/2”

End of unit stem must be submerged a 1/2” NPT NPT

mounting), in place of float-stop NPT

minimum of 2-3/4” for level switch

rings. Collars are optional on 3/4”

actuation. Dia.

2. Thermostat for Switch Action units less than 72” overall length.

Units requiring 316 SS float 1” SQ. 1-1/4” SQ.

7-1/2” Dia. 1/2”

Settings from 150°F to 175°F stops must be special-ordered NPT

with 316 SS collars instead of

Open or close switch on increasing temperature 1-1/4”

grip rings. 2”

NPT NPT 1”

Typical Wiring Diagram

Note

Contact Gems Sensors for Additional Information. Stem and Mounting Material Flange: Carbon Steel or 316 SS

Brass or 316 Stainless Steel

Stem: 316 SS

Max. Length (LO) 36” 60” 140”

Mounting Position Vertical ±30° Inclination

* Float Stops (See *Note Above) Brass Units: Beryllium Copper Grip Rings; Stainless Steel Units: S.S. ARMCO PH-15-7MO Grip Rings

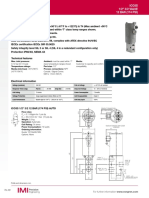

Type 5 - External Mount

2-5/8” (66.7mm)

1/2” FNPT Dia. Ref. LS-800 Adjustable Mounting

Return Policy

Returns are accepted on stock items up to 30 days from date of order. You must contact our Returns Department for O-Ring 2-1/4”-12 Unit Stem

a Return Authorization (RA) number. Return the goods - freight prepaid - in the original container and include original UNF-2A Thread Adjusted

Adjustable mounting is available for Upward

packing slip. C. O. D. returns are not accepted. Gems reserves the right to apply restocking charges.

1-3/4” (44.5mm) LS-800 Series Mounting Types 2, 3,

Tel: 860-793-4357 and 4. A special cinch nut on the

Fax: 860-793-4563 LO Union

± 1/6” mounting allows the stem to travel

Important Points: Unit Length

up or down for fine tuning of the

LO +2” Mounting

• Gems products must be maintained and installed in strict accor- the life and operation of Gems products. Take care in the proper actuation points. The extent of ad-

dance with the National Electrical Code and the applicable Gems selection of materials of construction, testing is required.

justment depends on the unit length

product instruction Bulletin that covers installation, operation and • NSF-approved sensors are made of materials approved for potable 3/4” NPT Ports (2X) Max

proper maintenance. Failure to observe this information may result water applications according to Standard 61. and the distance from the mounting

2” (50.8mm) Adjust

in serious injury or damages. • Stainless steel is generally regarded as safe by NSF and FDA. to the highest float stop.

• For hazardous area applications involving such things as, but not • Life expectancy of switch contacts varies with application. Contact

limited to, ignitable mixtures, combustible dust and flammable Gems if life cycle testing is required.

materials, use an appropriate explosionproof enclosure or intrinsi- Housing Material Brass 316 Stainless Steel Note

• Ambient temperature changes do affect switch set points, since the

cally safe interface device. Stem & Mounting Brass 316 Stainless Steel Float

gravity of a liquid can vary with temperature. Maximum overall length is limited

• *** Warning: To prevent ignition of flammable or combustible Stop

• Our sensors have been designed to resist shock and vibration. Port Sizes 3/4” NPT to 72” with this option.

atmospheres, disconnect power before servicing. However, shock and vibration should be minimized.

• Please adhere to the pressure and temperature limitations shown Max. Length (LO) 120”

• Filter liquid media containing particulate and/or debris to ensure the

throughout this catalog for our level and flow sensors. These proper operation of our products. *Float Stops Beryllium Copper S. S. ARMCO PH-15-7 MO

limitations must not be exceeded. These pressures and tempera- • Electrical entries and mounting points in an enclosed tank may

tures take into consideration possible system surge pressures/ require liquid/vapor sealing.

temperatures and their frequencies.

• Our sensors must not be field-repaired. Installation Procedure for Model LS-802 - Two-Piece Level Switch

• Selection of materials for compatibility with the media is critical to

• Physical damage sustained by product may render it unserviceable.

1. Unpack unit from shipping crate. coupling nut securely to stem (~ 1 turn past handtight).

2. Position unit near tank and unstrap stem assemblies. Check and tighten the upper section nut, if necessary.

3. The lower stem section (section with floats) can be 5. Cable exiting from the upper section conduit connector can

Gems Sensors Inc. inserted into tank to facilitate ease of installation, but be lightly pulled taught through grommet to prevent excess

One Cowles Road must be retained to install upper section. cable slack in upper stem.

Plainville, CT 06062-1198 6. Install unit in tank and tighten mounting plug.

4. With lower stem in desired position, insert tube coupling

Toll-Free: 1-800-378-1600

from upper stem section into lower section. Tighten 7. Connect level switch wires per wiring diagram.

Electrical Specifications Switch Ratings - Maximum Resistive Load

Float Types Switch (N.O. or N.C.): VA Volts Amps AC Amps DC

Float Material Buna N 316 Stainless Steel SPST: 20 VA or 100 VA 0-50 .2 .13

SPDT: 20 VA 10

Compatible Mounting Types 2 1, 3, 4, 5 1, 3, 4, 5 (Units <72”) 3, 4, 5 (Units >72”) General Use 120 .08 N.A.

Lead Wires: #22 AWG, 24” L., Polymeric

100 N.A. .1

)

m

0 . 2”

1-30 .4 .3

8m

1-3/4” 1-13/16” 2-11/16” Typical Wiring Diagrams 20

(5

2-3/32” 120 .17 .13

Float Dimensions (44.5mm) (46.0mm) (53.3mm) (68.3mm) Pilot Duty

For clarity, only two actuation levels are shown in 240 .08 .06

each group diagram.

1-1/4” Dia. 0-50 0.5 0.5

1-7/8” Dia. 2-1/16” 2-1/16” Dia.

(31.8mm)

(52.4mm) Group I Group II 50

(47.6mm) (52.4mm) 120 .4 .4

SPST SPST General Use

Part Number 26032 10558 14569 15666 240 .2 .2

Water: To 180°F (82.2°C) 120 .8** N.A.

Operating Temperature

Oil: -40°F to +230°F (-40°C to 110°C)

-40°F to +300°F (-40°C to +148.9°C) 100*

240 .4 N.A.

Min. Media Specific Gravity .75 .55 .75 .75

Group III Group IV * Level switch units with 50 VA and 100 VA swtiches are

SPDT SPDT not UL recognized or CSA approved.

** Limited to 50,000 operations

Pressure Ratings Chart

(PSI, Max.) Switch actuation levels are determined following the

Float Part Number Actuation Level Dimensions guidelines below:

26032 10558 14569 15666 All units 72" or less length overall with stainless steel or

1, 2, 3 Buna N floats. Also Type 5 units over 72" length overall with

150 750 300

Buna N floats:

4 150

Mounting

Brass 100 @ +70°F (21.1°C) A = 1-1/2" minimum distance to highest level (2", Type 5 only)

Type 5 B = 2" minimum distance from end of unit to lowest level

316 S.S. 150 750 300 C = 3" minimum distance between levels

L6

D = 1/4" minimum distance between actuation levels (Note: One

float for two levels can be used only when low level is N.C. dry

L5 and high level is N.O. dry.)

A

Wiring Color Codes L4

Types 1, 3, 4 and 5 units with stainless steel float P/N 15666:

SPST Switches SPDT Switches 20 VA A = 1-5/8" minimum distance to highest level (2", Type 5 only)

LO B = 2-1/2" minimum distance from end of unit to lowest level

Wiring Group I Group II Group III Group IV L3

(Length C = 4" minimum distance between levels

Com. Wire Black None Black None D = 1/4" minimum distance between actuation levels (Note: One float

Overall)

NO/NC Sw. Com. NO/NC NO NC Sw. Com. NO NC for two levels can be used only when low level is N.C. dry and

D high level is N.O. dry.)

L1 Red Red Red Red Wh/Red Red Wh/Red Wh/Blk/Red L2

L2 Yellow Yellow Yellow Yellow Wh/Yel Yellow Wh/Yel Wh/Blk/Yel Notes:

L3 Blue Blue Blue Blue Wh/Blu Blue Wh/Blu Wh/Blk/Blu

C 1. A, B, and C dimensions are based on liquid specific gravity of 1.0.

L4 Brown Brown Brown Brown Wh/Brn Brown Wh/Brn Wh/Blk/Brn L1

L5 Orange Orange Orange Orange Wh/Orn Orange Wh/Orn Wh/Blk/Orn 2. One float for two levels can be used only when 20VA switch is

B used.

L6 Gray Gray Gray Gray Wh/Gray Gray Wh/Gray Wh/Blk/Gra

Notes: 3. Actuation levels are calibrated on descending fluid level, with

1. Multi-station units included in shaded areas of chart can be supplied in UL-recognized configurations. water as types for maximum length values. the calibrating fluid,

2. Wire size is #18 AWG for units of UL-recognized configurations and #22 AWG (Teflon) for unless otherwise specified.

non-UL- recognized configurations.

3. Units with 50 or 100 VA switches are not UL-recognized.

*Actuation level distances and L O (overall unit length) are

4. Tolerance on actuation levels is ±1/8".

measured from inner surfaces of mounting plug or flange.

** Length Overall L O = L1 + Dimension B. See mounting types for

maximum length values.

You might also like

- S-Series Temperature Switches GuideDocument4 pagesS-Series Temperature Switches GuideJhon PaulNo ratings yet

- ASCO™ Solenoid Valves 356: Features & BenefitsDocument10 pagesASCO™ Solenoid Valves 356: Features & BenefitssrushtiNo ratings yet

- Potter Signal 5401206 - VSRSDocument3 pagesPotter Signal 5401206 - VSRSJulio Cabrera RuizNo ratings yet

- Model FS-2 Paddle Flow Switch: Specifications - Installation and Operating InstructionsDocument2 pagesModel FS-2 Paddle Flow Switch: Specifications - Installation and Operating InstructionsMinh Nhut LuuNo ratings yet

- Circuit heating load analysisDocument1 pageCircuit heating load analysisMOHAMED ATTIANo ratings yet

- DanfossDocument10 pagesDanfossconstantin balanNo ratings yet

- 1 8 Ported Manually Operated ValvesDocument10 pages1 8 Ported Manually Operated ValvesSaeed QahremaniNo ratings yet

- Cables Mecánicos AviaciónDocument1 pageCables Mecánicos AviaciónArmando CasasNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNo ratings yet

- Solenoid Valves 3/2 327: No Voltage Release (Tamperproof)Document6 pagesSolenoid Valves 3/2 327: No Voltage Release (Tamperproof)hamz786No ratings yet

- Torque ToolDocument2 pagesTorque ToolcristianoclemNo ratings yet

- Instalation Guide TGE 10 20 40Document2 pagesInstalation Guide TGE 10 20 40Ivan KurniadiNo ratings yet

- MWD LWD DD Fishing DiagramsDocument39 pagesMWD LWD DD Fishing DiagramsRazvan RaduNo ratings yet

- 9211-A01u-01 - 05 03 2017Document2 pages9211-A01u-01 - 05 03 2017spazzastura showNo ratings yet

- 327 MR PDFDocument6 pages327 MR PDFPriya KaleNo ratings yet

- Solenoid Valves 3/2 327: No Voltage Release (Tamperproof)Document6 pagesSolenoid Valves 3/2 327: No Voltage Release (Tamperproof)Priya KaleNo ratings yet

- 2/2-Way Angle-Seat Valve For Medium Up To +180°C, Threaded Port Connection, DN 15-65Document13 pages2/2-Way Angle-Seat Valve For Medium Up To +180°C, Threaded Port Connection, DN 15-6588jdccNo ratings yet

- General Pipe Cleaners General Root 66Document2 pagesGeneral Pipe Cleaners General Root 66sugeyNo ratings yet

- Datasheet, Technical Data Maneurop Reciprocating Compressor, MTZ072-4Document10 pagesDatasheet, Technical Data Maneurop Reciprocating Compressor, MTZ072-4maftmutoNo ratings yet

- 7400 Snaptrol Liquid Level ControlDocument2 pages7400 Snaptrol Liquid Level Controljose nuñezNo ratings yet

- DWDFXAN Full en Us LetterDocument3 pagesDWDFXAN Full en Us LetterPartagon PowNo ratings yet

- T350 Ultraheat 2WR6 enDocument6 pagesT350 Ultraheat 2WR6 enSandi ČretnikNo ratings yet

- Accuflow Series Low Flow Rate Waterflow Detectors: Sprinkler Systems MonitoringDocument2 pagesAccuflow Series Low Flow Rate Waterflow Detectors: Sprinkler Systems MonitoringArgile-assholeNo ratings yet

- Versa Bulletin BPS 2019: High/Low Pressure SensorsDocument4 pagesVersa Bulletin BPS 2019: High/Low Pressure SensorsJuan Pablo LoperaNo ratings yet

- 12607-12608-04 InstructivoDocument24 pages12607-12608-04 InstructivoaspegoodworkNo ratings yet

- Cat - InduSENSOR - En-13Document1 pageCat - InduSENSOR - En-13losvak removakNo ratings yet

- VSR-optimizedDocument3 pagesVSR-optimizedmotaNo ratings yet

- SZ185Document9 pagesSZ185TÁ CURRUTNo ratings yet

- DMDAMNN224-ECT en Us LetterDocument2 pagesDMDAMNN224-ECT en Us LetterLUIS SANCHEZ SANZCHEZNo ratings yet

- 12627-26-25Document24 pages12627-26-25eva maria cruzNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- Burkert Valve CatalogueDocument13 pagesBurkert Valve CatalogueRoopa MahtoNo ratings yet

- DS2000 Threaded EU enDocument13 pagesDS2000 Threaded EU enSamuel MarquezNo ratings yet

- HDM Island Valve PDFDocument26 pagesHDM Island Valve PDFvitgahiNo ratings yet

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- Connector: 5.0mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsDocument3 pagesConnector: 5.0mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsЕвгений ИвановNo ratings yet

- Lifeco Sprinkler SystemDocument30 pagesLifeco Sprinkler SystemSuhail EhtishamNo ratings yet

- Signet 8850-3 Conductivity/Resistivity Transmitter: Caution!Document12 pagesSignet 8850-3 Conductivity/Resistivity Transmitter: Caution!mohsen alzamelyNo ratings yet

- Flow Switch BWTSDocument5 pagesFlow Switch BWTSIvo MozaraNo ratings yet

- Miniature Rocker Solenoid Valve With Isolating Diaphragm, 16 MMDocument4 pagesMiniature Rocker Solenoid Valve With Isolating Diaphragm, 16 MMFrancisco Mones RuizNo ratings yet

- Series 541 542 543 - Joucomatic Air Operated Spool Valve 1Document4 pagesSeries 541 542 543 - Joucomatic Air Operated Spool Valve 1Talabarteria RaygozaNo ratings yet

- TS2 40 4 Axis Product Data Sheet ENDocument3 pagesTS2 40 4 Axis Product Data Sheet ENCHAMOUXNo ratings yet

- VTSA Valve terminalDocument2 pagesVTSA Valve terminalŁukasz OlszewskiNo ratings yet

- IMI Maxseal ICO3S 1-2, 3-Way, 174 PdiDocument2 pagesIMI Maxseal ICO3S 1-2, 3-Way, 174 PdiHamed YadegariNo ratings yet

- Operating Instruction TE 25 GE 01 EN US Operating Instruction PUB 5070809 000Document4 pagesOperating Instruction TE 25 GE 01 EN US Operating Instruction PUB 5070809 000teamloseNo ratings yet

- 2/2-Way Solenoid Valve, Servo-Assisted With Servo Diaphragm: Type 280Document4 pages2/2-Way Solenoid Valve, Servo-Assisted With Servo Diaphragm: Type 280Francisco Mones RuizNo ratings yet

- Latching SolenoidDocument2 pagesLatching SolenoidjosaugustNo ratings yet

- Ar-Mite Low Flow Armored FlowmeterDocument12 pagesAr-Mite Low Flow Armored FlowmeterVasabinskiyNo ratings yet

- Submersible Drainage Pump XJ 25: SpecificationDocument2 pagesSubmersible Drainage Pump XJ 25: SpecificationDavid SoaresNo ratings yet

- Related Products: Auto Drain Valve: PrecautionsDocument10 pagesRelated Products: Auto Drain Valve: Precautionsteknik otomotifNo ratings yet

- TA-Modulator NPT ANSI US LowDocument16 pagesTA-Modulator NPT ANSI US LowPablo CastroNo ratings yet

- AVTA Thermostatically Controlled Cooling Water ValveDocument2 pagesAVTA Thermostatically Controlled Cooling Water ValveclintNo ratings yet

- Datasheet, Technical Data Performer Scroll Compressor, SM185-4Document8 pagesDatasheet, Technical Data Performer Scroll Compressor, SM185-4Sebastian OctavianoNo ratings yet

- Kotron Model 811 RF Point Level Switch: DescriptionDocument8 pagesKotron Model 811 RF Point Level Switch: Descriptionsalim salimNo ratings yet

- TFP725 08 2016Document8 pagesTFP725 08 2016Jun AntonioNo ratings yet

- Valvula Diafragma Buschjost 82630Document2 pagesValvula Diafragma Buschjost 82630Base SistemasNo ratings yet

- Beyma sm112nDocument2 pagesBeyma sm112nIsus AudioNo ratings yet

- ABB - Auto - Aquaprobe-1 - SpecDocument5 pagesABB - Auto - Aquaprobe-1 - SpecNishanNo ratings yet

- Aplisens_ERH-xx-20_18Document5 pagesAplisens_ERH-xx-20_18angel delgadoNo ratings yet

- GP Series: Model 5723-0Document2 pagesGP Series: Model 5723-0Dayro MontefuscoNo ratings yet

- GP Series: Model 5724-0Document2 pagesGP Series: Model 5724-0Dayro MontefuscoNo ratings yet

- GP5500 Spec Sheet 0189270SBYDocument2 pagesGP5500 Spec Sheet 0189270SBYDayro MontefuscoNo ratings yet

- Manual Power Wizard 1.0Document80 pagesManual Power Wizard 1.0Eduard Machado100% (5)

- Large Size - Engineered Plastics: LS-800PVC Series - Our Most Economical Large Size UnitDocument2 pagesLarge Size - Engineered Plastics: LS-800PVC Series - Our Most Economical Large Size UnitDayro MontefuscoNo ratings yet

- Man Rider BrochureDocument9 pagesMan Rider Brochurerj4ronyNo ratings yet

- Worked Samples Choosing The Best Solution 1Document21 pagesWorked Samples Choosing The Best Solution 1Fokhruz ZamanNo ratings yet

- MaterialsDocument3 pagesMaterialsRevanNo ratings yet

- Ferritic Stainless Stell 1.4003Document4 pagesFerritic Stainless Stell 1.4003rusf123No ratings yet

- World Class Pump Line: Models 3181/3186Document7 pagesWorld Class Pump Line: Models 3181/3186Israel ColinaNo ratings yet

- Steel Castings, General Requirements, For Pressure-Containing PartsDocument14 pagesSteel Castings, General Requirements, For Pressure-Containing PartsJerry BeanNo ratings yet

- Corrosion Science: S. Ningshen, U. Kamachi Mudali, S. Ramya, Baldev RajDocument7 pagesCorrosion Science: S. Ningshen, U. Kamachi Mudali, S. Ramya, Baldev RajNaveen KumarNo ratings yet

- Corroplast: The Ultimate Stainless Steel For All Stainless Plastic MouldsDocument6 pagesCorroplast: The Ultimate Stainless Steel For All Stainless Plastic MouldsmichaelguzziNo ratings yet

- WKM Dynaseal 310 Metal Seated Ball Valves 2Document2 pagesWKM Dynaseal 310 Metal Seated Ball Valves 2Khai HuynhNo ratings yet

- Passivation On Chemical TankerDocument15 pagesPassivation On Chemical TankerRonald MesinaNo ratings yet

- Technology 5 Constant CurrentDocument7 pagesTechnology 5 Constant CurrentnoorNo ratings yet

- Evaluation of Heat Treatments For Additively Manufactured 316L Simpson PDFDocument7 pagesEvaluation of Heat Treatments For Additively Manufactured 316L Simpson PDFOlivier DubetNo ratings yet

- Bursting and Collapsing Pressures of ASTM A312 Stainless Steel PipesDocument1 pageBursting and Collapsing Pressures of ASTM A312 Stainless Steel PipesManuKumarMittalNo ratings yet

- ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1Document5 pagesASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1David VegaNo ratings yet

- Filter FW, F & TF Series (MS-01-92) R3Document8 pagesFilter FW, F & TF Series (MS-01-92) R3herysyam1980No ratings yet

- VT BHR BHQ BHM BHK Bhma BhaDocument24 pagesVT BHR BHQ BHM BHK Bhma BhaMadhu KrishnaNo ratings yet

- AERMOTOR Pump Page02Document1 pageAERMOTOR Pump Page02cristobal_tl2277No ratings yet

- Centravis - Product Catalogue - HEX TubesDocument22 pagesCentravis - Product Catalogue - HEX TubesVictor PomboNo ratings yet

- Shield Air Catalog 2Document70 pagesShield Air Catalog 2Pratikno SajaNo ratings yet

- Thecnical Catalog 2011 (English)Document168 pagesThecnical Catalog 2011 (English)felipeobradorNo ratings yet

- Start-Up and CommissioningDocument10 pagesStart-Up and Commissioningsandystays100% (1)

- Ebara DSZDocument5 pagesEbara DSZflaviusgrozaNo ratings yet

- Count Description BM 17-38N: Company Name: Bimal Water Solutions PVT LTD Created By: Phone: Email: DateDocument6 pagesCount Description BM 17-38N: Company Name: Bimal Water Solutions PVT LTD Created By: Phone: Email: DateJaved HasanNo ratings yet

- Bob Engnath On QsteelqDocument6 pagesBob Engnath On QsteelqJason BowmanNo ratings yet

- Pressed PDFDocument108 pagesPressed PDFSantript Sinha0% (1)

- Catalog Ledux OfficeDocument46 pagesCatalog Ledux OfficeIuliaDamianNo ratings yet

- Guidelines For Selecting Materials For Downhole Completions Equipment (Jewellery)Document32 pagesGuidelines For Selecting Materials For Downhole Completions Equipment (Jewellery)Slim.BNo ratings yet

- Oetiker Miniature Clamps Catalog - 08901050Document12 pagesOetiker Miniature Clamps Catalog - 08901050Danilo FagundesNo ratings yet

- YKP External Coating SpecificationDocument34 pagesYKP External Coating SpecificationAnonymous jLVLP4w3m100% (2)