Professional Documents

Culture Documents

Nissan Leaf (ZE0) - Vehicle Charging System PDF Free

Nissan Leaf (ZE0) - Vehicle Charging System PDF Free

Uploaded by

mebarki aberraouf100%(1)100% found this document useful (1 vote)

521 views146 pagesOriginal Title

Nissan Leaf (ZE0) - Vehicle Charging System Pdf Free

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

521 views146 pagesNissan Leaf (ZE0) - Vehicle Charging System PDF Free

Nissan Leaf (ZE0) - Vehicle Charging System PDF Free

Uploaded by

mebarki aberraoufCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

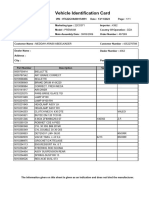

You are on page 1of 146

ELECTRIC POWER TRAIN

VEHICLE CHARGING sysTeMEy

SECTION V C

CONTENTS

PRECAUTION

PRECAUTIONS o.ssssssssssstnnensnsenenensene

Precaution for Technicians Using Medical Electric....4

Point to Be Checked Before Starting Maintenance

Work 4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER’ 4

Precaution for Procedure without Cow! Top Cover....6

Precautions for Removing Battery Terminal 6

High Voltage Precautions 6

PREPARATION ......ssssssssessssnseeee

PREPARATION

Special Service Tools

Commercial Service Tools

4

SYSTEM DESCRIPTION ......csccsssssssssseeeeseeel

COMPONENT PARTS .. a

‘Component Parts Location ...... eo

PDM (Power Delivery Module) .... eof

EVSE one . . nf

Charge Port . on f3

Charge Port Light .... . eo

Charge Connector Lock Actuator eves

Charge Connector Lock Switch evens 4

Immediate Charging Switch .. el

Charging Status Indicator... a

High Voltage Waring Label oo 16

SYSTEM a7

VEHICLE CHARGING SYSTEM «sss

VEHICLE CHARGING SYSTEM : System

SCTIpHION on vol

AT

LIMON BATTERY CHARGE CONTROL .. eo AT

LHION BATTERY CHARGE CONTROL : Systom

Description 7

Revision: June 2014

CHARGE PORT CONTROL 9

CHARGE PORT CONTROL : System Descrition..19

POWER VOLTAGE VARIABLE CONTROL SYS-

POWER VOLTAGE VARIABLE CONTROL SYS-

TEM : System Description nn. on

AUTOMATIC 12V BATTERY CHARGE CONTROL

AUTOMATIC 12V BATTERY CHARGE CON-

TROL : System Description 22

OPERATION

‘Switch Name and Function ... Dh

HANDLING PRECAUTION

Vehicle Charging System

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....27

Diagnosis Description a7

Counter System a7

DTC and Freeze Frame Data a7

DIAGNOSIS SYSTEM [PDM(POWER DELIV-

ERY MODULE)) ...

CONSULT Function 28

ECU DIAGNOSIS INFORMATION

PDM(POWER DELIVERY MODULE) ....

Reference Value

Fall-Safe

DTC Index

DTC Sub Type Index

WIRING DIAGRAM ..

VEHICLE CHARGING SYSTEM .

Wiring Diagram

BASIC INSPECTION ..

2015 Leaf NAM

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

Diagnostic Work Sheet

PERIODIC MAINTENANCE

CHARGE PORT

Inspection 83

DTCICIRCUIT DIAGNOSIS ..

POWER SUPPLY AND GROUND CIRCUIT ....

PDM (POWER DELIVERY MODULE) ..

PDM (POWER DELIVERY MODULE): Diagnosis

Procedure

U1000 CAN COMMUNICATION ..

Description

DTC Logie

Diagnosis Procedure

U1008, U100B QUICK CHARGER COMMU-

NICATION ..

Description 87

DTC Logie 87

Diagnosis Procedure 87

Component Inspection 58

U100A CAN COMMUNICATION ..ssssssesesees 60

Description 60

DTC Logie 60

Diagnosis Procedure 60

U1010 CONTROL MODULE (CAN) ...

DTC Logie . -

Diagnosis Procedure . Bt

B2801 QUICK CHARGE CONNECTOR

DTC Logie

TYPE A nsnnnninnnnininnnnnnnnsnnsie

TYPE A : Diagnosis Procedure

TYPE B .

TYPE 6 Diagnosis Procedure 64

Component inspection 65

B2802 QUICK CHARGER oesssssesensnsenennes 68

DTC Logie 68

Diagnosis Procedure 68

Component Inspection 7

B2803 QUICK CHARGER

DTC Logie . 8

Diagnosis Procedure . 68

Component Inspection sennnne sevens TO

B2814 QUICK CHARGE RELAY

DTC Logie

Diagnosis Procedure

82820 QUICK CHARGER

Revision: June 2014

VC-2

~ 73)

73

DIC Logic

Diagnosis Procedure .

2830 QUICK CHARGE VOLTAGE SENSOR... 74

Description 74

DTC Logic . 74

Diagnosis Procedure 74

B2840 PDM(POWER DELIVERY MODULE) ... 76

DTC Logic 76

TYPE A AND B

TYPE AAND

8

iagnosis Procedure:

TVPEC

TYPE C : Diagnosis Procedure 79

B2850 POM(POWER DELIVERY MODULE) 80

Description 80

DTC Logic 80

Diagnosis Procedure .

B2880 FIS CHG RELAY ....

DTC Logic

TYPE A. srsssssnsnnnnnnnnn

TYPE A: Diagnosis Procedure

TYPEB

TYPE B : Diagnosis Procedure ” 83

B2890 DC/DC CONVERTER .....

DTC Logic .

TYPE A AND E 7

TYPE AAND E : Diagnosis Procedure 85

TYPEB

TYPE B : Diagnosis Procedure vn... 86

TYPE © snninnnininnnnnnnannnninnnnnannsns 7

TYPE C : Diagnosis Procedure sn.n 87

TYPED

TYPE D: Diagi

2900, B2902 PDM(POWER DELIVERY

MODULE) .. 88

DTC Logic 88

Diagnosis Procedure 88

82980 QUICK CHARGE PORT .. 89

Description 89

DTC Logic 89

Diagnosis Procedure 89

‘Component inspection 31

B29A0 NORMAL CHARGE PORT o..sesnnnnne 93

DTC Logic 7 ns 88

TYPE A 98

TYPE A: Diagnosis Procedure 99

TVPEB 94

2015 Leaf NAM

TYPE B : Diagnosis Procedure... 88

Component Inspection . 95

B29C1 EVSE 98

DTC Logic . . 1 96

TYPE A, BAND E snnnnnnn nn

TYPE A, B AND E : Diagnosis Procedure «nn 97

TYPE CAND D ... sven 98

TYPE C AND D : Diagnosis Procedure 98

Component inspection 99

PDM(POWER DELIVERY MODULE) «sss: 100

Diagnosis Procedure 100

SYMPTOM DIAGNOSIS .......cscccssssessnseeeeee 101

VEHICLE CHARGING SYSTEM ...sssesssees 101

Description 101

NORMAL OPERATING CONDITION ...

‘Symptom Table

REMOVAL AND INSTALLATION

PDM(POWER DELIVERY MODULE) .

Exploded View

103

108

109

109

109

Revision: June 2014

vc-3

Removal and Installation 11

Disassembly and Assembly...

119

Inspection 125

QUICK CHARGE PORT aw

127

128

131

Exoloded View

Removal and Installation «..

Disassembly and Assembiy ....

NORMAL CHARGE PORT ...

Exploded View

Removal and Installation

Disassembly and Assembly

134

134

135

139

CHARGE CONNECTOR LOCK ACTUATOR .141

141

141

Exploded View

Removal and Installation

IMMEDIATE CHARGING SWITCH

Removal and Installation .

144

us

CHARGE CONNECTOR LOCK SWITCH

. 145,

Removal and Installation

CHARGING STATUS INDICATOR

Removal and Installation

146

148

2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Technicians Using Medical Electric proccoemcorrert

OPERATION PROHIBITION

WARNING:

+ Parts with strong magnet is used in this vehicle.

+ Technicians using a medical electric device such as pacemaker must never perform operation on the

Vehicle, as magnetic field can affect the device function by approaching to such parts.

NORMAL CHARGE PRECAUTION

WARNING:

a technician uses a medical electric device such as an implantable cardiac pacemaker or an

implantable cardioverter defibrillator, the possible effects on the devices must be checked with the

device manufacturer before starting the charge operation.

+ As radiated electromagnetic wave generated by PDM (Power Delivery Module) at normal charge

operation may affect medical electric devices, a technician using a medical electric device such as

implantable cardiac pacemaker or an implantable cardioverter defibrillator must not approach motor

room [PDM (Power Delivery Module)] at the hood-opened condition during normal charge operation.

PRECAUTION AT TELEMATICS SYSTEM OPERATION

WARNING:

+ If a technician uses implantable cardiac pacemaker or implantable cardioverter defibrillator (ICD),

avoid the device implanted part from approaching within approximately 220 mm (8.66 In) from Inte-

rior/exterior antenna.

+ The electromagnetic wave of TCU might affect the function of the implantable cardiac pacemaker or

the implantable cardioverter defibrillator (ICD), when using the service, etc.

+ If'a technician uses other medical electric devices than implantable cardiac pacemaker or implant-

able cardioverter defibrillator (ICD), the electromagnetic wave of TCU might affect the function of the

device. The possible effects on the devices must be checked with the device manufacturer before

TCU use.

PRECAUTION AT INTELLIGENT KEY SYSTEM OPERATION

WARNING:

+ If'a technician uses implantable cardiac pacemaker or implantable cardioverter defibrillator (ICD),

avoid the device implanted part from approaching within approximately 220 mm (8.66 in) from inte-

rlor/exterior antenna.

+ The electromagnetic wave of Intelligent Key might affect the function of the implantable cardiac

pacemaker or the implantable cardioverter defibrillator (ICD), at door operation, at each request

switch operation, or at engine starting.

+ Ifa technician uses other medical electric devices than implantable cardiac pacemaker or implant-

able cardioverter defibrillator (ICD), the electromagnetic wave of Intelligent Key might affect the

function of the device. The possible effects on the devices must be checked with the device manu-

facturer before Intelligent Key use.

Point to Be Checked Before Starting Maintenance Work wroecomcsoracere

The high voltage system may starts automatically. It is required to check that the timer air conditioner

and timer charge (during EVSE connection) are not set before starting maintenance work.

NOTE:

If the timer air conditioner or timer charge (during EVSE connection) is set, the high voltage system starts

automatically even when the power switch is in OFF state.

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" ws

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER’, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision, This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

Revision: June 2014 Vvc-4 2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

system uses the Seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual

WARNING:

* To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSANJINFINITI dealer. A

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal IM

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

+ Do not use electrical test equipment on any circult related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

+ When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

+ When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Procedure without Cowl Top Cover

‘When performing the procedure after removing cow! top cover, cover

the lower end of windshield with urethane, ete to prevent damage to

windshield

Precautions for Removing Battery Terminal

+ When removing the 12V battery terminal, turn OFF the power

switch and wait at least 5 minutes

NOTE:

ECU may be active for several minutes after the power switch is

tured OFF. if the battery terminal is removed before ECU stops,

then @ DTC detection error or ECU data corruption may ocour.

+ Always disconnect the battery terminal within 60 minutes after

tuming OFF the power switch. Even when the power switch is

OFF, the 12V battery automatic charge control may automatically

start after a lapse of 60 minutes from power switch OFF.

+ Disconnect 12V battery terminal according to the following steps

WORK PROCEDURE

4. Check that EVSE is not connected

NOTE:

If EVSE is connected, the air conditioning system may be automatically activated by the timer A/C func-

tion.

2. Tur the power switch OFF > ON —> OFF. Get out of the vehicle. Close all doors (including back door)

3. Check that the charge status indicator lamp does not blink and wait for 5 minutes or more.

NOTE:

Revision: June 2014 vc-5 2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

If the battery is removed within § minutes after the power switch is turned OFF, plural DTCs may be

detected.

4. Remove 12V battery terminal within 60 minutes after turning the power switch OFF > ON — OFF.

CAUTION:

+ After all doors (including back door) are closed, if a door (including back door) is opened before

battery terminals are disconnected, start over from Step 1

+ After turning the power switch OFF, if “Remote A/C” is activated by user operation, stop the air

conditioner and start over from Step 1.

NOTE:

Once the power switch is turned ON > OFF, the 12V battery automatic charge control does not start for

approximately 1 hour.

+ For vehicles with the 2-batteries, be sure to connect the main battery and the sub battery before turning ON

the power switch.

NOTE:

If the power switch is turned ON with any one of the terminals of main battery and sub battery disconnected,

then DTC may be detected.

+ After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC

NOTE:

The removal of 12V battery may cause a DTC detection error.

High Voltage Precautions

DANGER:

Adsince hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of

electric shock, electric leakage, or similar accidents if the high voltage component and vehicle are

handled incorrectly. Be sure to follow the correct work procedures when performing inspection and

maintenance.

WARNING:

+ Be sure to remove the service plug in order to disconnect the high voltage circuits before perform-

ing inspection or maintenance of high voltage system harnesses and parts.

+ The removed service plug must always be carried in a pocket of the responsible worker or placed in

the tool box during the procedure to prevent the plug from being connected by mistake.

+ Be sure to wear insulated protective equipment before beginning work on the high voltage system.

+ Never allow workers other than the responsible person to touch the vehicle containing high voltage

Parts. To keep others from touching the high voltage parts, these parts must be covered with an insu-

lating sheet except when using them.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise

Instructed in the Service Manual. A malfunction may occur If this Is not observed,

HIGH VOLTAGE HARNESS AND EQUIPMENT IDENTIFICATION

All the high voltage hamesses and connectors are orange. The Li-ion battery and other high voltage devices

include an orange high voltage label. Never touch these harnesses and high voltage parts.

HANDLING OF HIGH VOLTAGE HARNESS AND TERMINALS

Immediately insulate disconnected high voltage connectors and terminals with insulating tape

REGULATIONS ON WORKERS WITH MEDICAL ELECTRONICS

WARNING:

The vehicle contains parts that contain powerful magnets. If a person who is wearing a heart pace-

maker or other medical device is close to these parts, the medical device may be affected by the mag-

nets. Such persons must not perform work on the vehicle.

PROHIBITED ITEMS TO CARRY DURING THE WORK

Hybrid vehicles and electric vehicles contain perts with high voltage and intense magnetic force. Never carry

metal products and magnetic recording media (e.g. cash card, prepaid card) to repair/inspect high voltage

parts. If this is not observed, the metal products may create a risk of short circuit and the magnetic recording

media may lose their magnetic recording

POSTING A SIGN OF “DANGER! HIGH VOLTAGE AREA. KEEP OUT”

Revision: June 2014 VC-6 2015 Leaf NAM

PRECAUTIONS

VOLTAGE. DO NOT TOUGH* on the vehicle under repair/inspection to call attention to other

< PRECAUTION >

Indicate "HIGH

.

roBueyo ul UOSded

iHONOL LON OG

“SS3YHDOUd NI YIVdSy

ASVLIOA HDIH

‘YSDNVG

DANGER:

HIGH VOLTAGE

REPAIR IN PROGRESS.

DO NOT TOUCH!

Person in charge:

Copy this page and put it after folding on the roof of the vehicle in service.

PREPARATION

< PREPARATION >

PREPARATION

PREPARATION

Special Service Tools

“The actual shape ofthe tols may differ fom those ilustrated here

TTeol number Description

(TechMate No.)

Tool name

Removing and insaling high voltage

‘components

{Guaranteed insulation performance for

‘1000V/00A

insulated gloves

+ Removing and insaling high voltage

‘components

+ Protect insulated gloves

[Use leather gloves that can fasten the

\wrst ight]

Leather gloves.

+ Gloves for preventing static electric

Ant.statc gloves + Disassembly and reassembly ofthe

POM (Power Delivery Module)

Removing and insaling high voltage

insulated safety shoes. ‘components,

+ Removing and insaling high voltage

Components

+ To protect eye from the spatter on the

work to elect ine

[ANSI 267.1]

Safety glasses

Revision: June 2014 VC-8 2015 Leaf NAM

PREPARATION

< PREPARATION >

"Tool number Description

(Techate No.)

Tool name

+ Removing an installing high voltage

‘components

Fave shield + To protect face from the spatter on the

work to electric tine

Removing and instaling high voltage

Insulated neimet ing 19 high votag

components

Commercial Service Tools

Teams Desai

aera eng adnwating he POW Power

51080 Sehr

Sate pe

* A: 106 mm (4.17 in) / 1 pin

Gr 781/29

revasia00 When checking areas ater dssser-

soars) Einglssembing tion ate,

fvtek tester

ieeairaico ‘reat lowing dasserbi and

Gs) cory ofthe Pane! Delay Mode

fries oer wie

fn Atohment

25 era posure gauge

C:vae coupler

D: Female coupler for base mounting

Kv10720800

(J-51053)

Aaylic scraper

Removing iquld gasket

Revision: June 2014 vc-9

2015 Leaf NAM

PREPARATION

< PREPARATION >

Tool name Description

Kv09T72200 ‘Supporting and hovsting the PDM (Power

(J-51048), Delivery Module)

Siinger

NOTE:

‘The slinger comes as a set with 2

shackles,

Instaling POM (Power Delvery Module)

(Apply the liquid gasket)

“Tube presser [Gasket matertal apple

ator]

"Measuring insulation resistance, voltage,

‘and resistance

Insulation resistance tester

(Mutt tester)

Flat screwdriver For general purpose removal

Revision: June 2014 VC-10 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts Location aesmacnsce eee

Charge port (venice tont sie) Instrument lower panel LH

No Component Function

@ | EVE Vo-12, "VS"

@ | Charging stats incicator ‘VG-15, ‘Charging Status indicator

vee ‘Von performed integrated contra for vehicle charging system,

® Refer toEVC-15, “Component Parts Location, fr detailedinstalaton location.

@ | POM Power delivery module) \VG=12, POM (Power Delivery Module)”

© | auick charge por VG=13, "Charge Port

@ _ Charge por ight \VG-14, "Charge Port Light™

@ | Charge connector lock actuator VG-14, "Charge Gannector Lock Actuator

© | Norma charge port \VG=13, ‘Charge Por”

UUniock the charge part id aocording io operation signal rom VM.

@ | Charge por id opener actuator Refer to OLK-16, "Component Paris Location, for detailed installation ioca-

tin,

@ | Immediate charging switch VC-14, "immediate Charaing Switch"

Revision: June 2014 vc-11 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Ne ‘Component Function

@ _| Gharge connector lock switch ‘WG-14, “Charge. Connector Lack Switch”

Input charge port id opener switch signal fo VC,

@ __ Gharge port id opener switch Refer to DLK-16, “Component Parts Location" for detalled installation loca

tion.

jodel with quick charge port.

PDM (Power Delivery Module)

‘The PDM (Power Delivery Module)@ is installed to the upper part of

drive motor in the motor room together with drive motor inverter and

consists of a charger and DC/DC converter.

‘The charger converts extemal AC power source to DC power source

(260 — 410 V), and charges the Lion battery according to the type of

charging. The DC/DC converter charges the auxiliary 12V battery

according to the VCM command.

<2 Vehicle front

EVSE

fl

© Nomal charge connec © cae @ Conte box

@ Pte

The EVSE (Electric Vehicle Supply Equipment) is manufactured based on the specifications prescribed in

‘SAE~1772, and is for charging by connecting a commercial power source to the vehicle. The EVSE consists

ofa plug, cable, control box, and @ normal charge connector and supplies power to the vehicle using commer-

cial power. By conducting PWM communication with the PDM (Power Delivery Module), the EVSE performs

safe and suitable charging for the vehicle

Normal Charge Connector

The normal charge connector(@) is equipped with a release switch@

to maintain the connection between the normal charge port and the

charge connector.

Revision: June 2014 Vc-12 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

The charging connector is equipped with a release switch to main-

tain the connection between the normal charging port and the charg-

ing connector. In addition, a circuit for detecting the hold status is

incorporated into the release switch, which stops the charging tem-

Poranly if the release switch is pressed during charging.

NOTE:

+ When the release switch is pressed, the contacts tum OFF.

+ The release switch cannot be pressed while the charge connector

is locked.

Control Box

The control box® is equipped with an indicator@ that can be used to

check the charging status and matfunction detection status. The indi-

cator operates in the following cases when a commercial power suD-

ply is connected to the EVSE.

Us of Operations»

EVSE__ Normal charge port

Reoase

Sach

Conoaction detection

Ground =

Taman Sats

Venice conlton

READY CHARGE FAULT

When tere ne AG power sippy pit OFF OFF OFF

When AC power source fs connected ON AppIOKOSs) | ON Approx08s) ON Approx08)

hen ters AC power supply input andthe EVSE can

communicate wh the vehi charger hen ot char on oFF oF

ing)

Charging on oN oF

When the EVSE isnot operating OFF OFF OFF

When the EVSE detects elec leakage oN OFF Bink

When the EVSE detects a maltunton nisl on OFF oN

When ground isnot connected Bink OFF OFF

‘When the plugs igh temperature Bik OFF, Bink or ON Bink

Charge Port veces

‘The charge port is installed at the front of the vehicle and is equipped

with a normal charge port@ and a quick charge port@) (with quick

charge port models). For charging, connect the EVSE of quick

charge connector to the charge port according to the type of charg-

ing, and then start charging.

NOTE:

The figure shows a model with quick charge port

Revision: June 2014 vc-13

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Charge Port Light

The charge port light is installed to the inside of the charge port lid

The lighting conditions of charge port light are as follows.

+ When charge port lid is unlocked (I-key connector lock release

switch, Charge port lid opener switch)

+ When ‘charge connector lock is temporarily released (I-key con-

nector lock release switch, Charge port lid opener switch, door

Unlock operation)

Charge port light: LED

Charge Connector Lock Actuator

The charge connector lock actuator is installed to the normal charge

port upper portion, and is composed of the swing arm@ that locks

the charge connector and the actuator® that operates the swing

arm. The actuator operates according to the operation signal from

CM.

Charge Connector Lock Switch

‘The charge connector lock switch is installed on the left instrument

lower panel. It allows the charge connector lock mode to be selected

according to the charging type.

Immediate Charging Switch

The immediate charging switch is a switch that can be used to start

charging immediately when timer charging is set.

Revision: June 2014 VC-14

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Charging Status Indicator ico eneame een)

Charging status indicator is mounted at the upper part of the instru-

ment panel. It indicates the charge status of the Li-ion battery.

@ Charging status indicator 3

@ Charging status inicator 2

@ Charging status ingicator 1

Charging status indicator illuminates and blinks as per the following: E

Indicator illuminating pattem

enc coon Traanorane Taran nara a Conaon

ro 23 Sines,

Fatcrae ner tes

aoa a8 St

+ 23

5 onsen matte

ave 0 0 ‘charge 90096

ose te, ‘eooner)

beng cnege w Fa

eg # 0 or eg

ee

cf f *

ar asm osm

ao Ht F

wo Oo OFF Soe

pe (On OFF ep

Tinerchrge ON

‘Smonses

2:0 a

(ON 15min,

“Korat etary cng ox | axe pean

‘enunnok NC opeaee Q * & LI

intone ha orto

Che emacs cae ut ane

Normal ug eee Birt 9 scone P

Sone ome

[De notauminte Q):muminatng 39: ting

*: Models with Li-ion battery heater

Revision: June 2014 vc-15 2015 Leaf NAM

COMPONENT PARTS,

< SYSTEM DESCRIPTION >

High Voltage Warning Label

The high voltage warning labels@ are affixed to the up side of PDM

(Power Delivery Module).

o Vehicle front

CAUTION:

After replacing PDM (Power Delivery Module), check that the

labels are affixed in the original position.

Revision: June 2014 VC-16 2015 Leaf NAM

SYSTEM

< SYSTEM DESCRIPTION >

SYSTEM

VEHICLE CHARGING SYSTEM

VEHICLE CHARGING SYSTEM : System Description

DESCRIPTION

This section describes the controls related to the vehicle charging system eo

Tem Description Reterto

‘Automatically selecis a charge mode thats sullable for the ex

Lion battery charge contro ‘ema power source and controls Lon battery charging vet

Comprehensive control for improving the efciency of charging

Charge port control ‘work ported by the VOM, vets

wervohage vanabie control system Changes the DCIOC converter output inside the POM (Power

Power volage rol sys Delivery Module) accorcng tothe VOM commancs. vow

Controls the DGIDG converter inside the POM (Power Delivery

‘Automatic 12V battery charge contrat Module) according tothe VCM commands, and charges the 12 | Vox

battery

PDM (POWER DELIVERY MODULE)

Description

‘The charger uses a 2-converter system which consists of the PFC circuit and the DC/DC converter. It

improves charging efficiency, charge level accuracy, and the service life of the Li-ion battery. PDM (Power

Delivery Module) judges whether extemal power supply is 100 V or 200 V, and automatically switches to

charging that is appropriate for the power supply.

NOTE:

PFC (Power Factor Correction) circult is a power factor improvement circuit. It is a device that efficiently con-

verts AC power supply input from an external power source to a DC power supply.

Basic Charger Prince

soo on

seams tom stp

Semes e LHe Home Hew Hee me

vos Jee Pa

A on oO

“Current waveform v

1. AC power supply which Is extemally input is rectified to DC power with rectifier circuit 7.

2. The power factor of the rectified DC power supply is improved by the PFC circuit, and is boosted at the

same time,

3. The boosted DC power supply is converted again to AC power supply by the inverter.

4. The voltage of the AC power supply from the inverter is converted by the insulated transformer, and is rec-

tified to high-voltage DC power by rectifier circuit 2.

The rectified high-voltage DC power is output by the output circult

ti ION BATTERY CHARGE CONTROL

LI-ION BATTERY CHARGE CONTROL : System Description nroowommreoecese

OVERVIEW OF CHARGING FUNCTIONS

Revision: June 2014 VC-17 2015 Leaf NAM

SYSTEM

< SYSTEM DESCRIPTION >

There are two types of Lrion battery charging. Normal charging converts a commercial power supply to DC

ower, and quick charging uses a special charger.

For information about the charging sound system. refer to EV

System Descriptio

CHARGE MODE

2, "LION BATTERY CHARGE CONTROL :

eo

Tere FE ov-sonnainany

foo ‘AC 120 V: Approx. 21 hours

vero gon onan

‘Approx. 30 minutes

(When charged from the point

100%" where the battery level waming

NOTE: lamp tums ON to 60%.)

When the spectied time is passed, charging stops even ithe | NOTE:

charge levels not tl \When the battery temperature is

low or high, approx. 60— 90 min

or more may be required.

charge mode Remaining charge level

Normal

charge mode

(Quick charge mode

+7 Depending on the battery State, 100% may nat be reached.

“2: After charging stops, additional charging by quick charge Is possible.

NORMAL CHARGE MODE

In this mode, the EVSE is connected for charging. Normal charging includes immediate charge mode, timer

charge mode, and remote charge mode.

NOTE:

‘The method of setting the charge level varies according to the vehicle specifications

Seting avelaie

Charge level eating

Setting operation —___ ee eter to

Inmediate charge | Timercharge | _-Remote charge

+ B22 (Without

Navigation system BOSE system)

(Models with navigation systern) . . . : (win

BOSE system)

‘Comaination meter

(Models without navigation system) . ‘ —

Immediate Charge Mode

This mode immediately starts charging when the EVSE is connected. When timer charge is not set, the sys-

tem enters immediate charge mode when the EVSE is connected, When timer charge is set, immediate

charge mode can be selected by pressing the immediate charging switch

Timer Charge Mode

This mode starts and stops charging according to the timer that is set on VCM

NOTE:

‘The timer setting method varies according to vehicle specifications.

+ Models with navigation without BOSE system: Refer to AV-221, "MULTLAV SYSTEM : System Description’.

+ Models with navigation and BOSE system: Refer to AV-346, "MULTI AV SYSTEM : System Description”

+ Models without navigation system: Refer to MWI-35, "INFORMATION DISPLAY ; System Description”,

Remote Charge Mode

This mode starts charging by remote control with a mobile device

NOTE:

For information about operation, refer to AV-515, "TELEMATICS SYSTEM : System Description’

QUICK CHARGE MODE

Revision: June 2014 VC-18 2015 Leaf NAM

SYSTEM

< SYSTEM DESCRIPTION >

Mode that performs charging with quick charger. Even if charging is not completed, when the charge time set

‘on the quick charger or the time-out (approximately 30 - 60 minutes) set on the vehicle passes, charging

stops.

NOTE:

When the battery temperature is ambient temperature, charging stops after approximately 30 minutes.

When the battery temperature is low or high, charging stops after a maximum of 60 minutes.

+ If charging stops before charging is complete, addtional charging by quick charge can be performed again.

CHARGING STATUS INDICATOR AND CHARGING SOUND SYSTEM

‘The charge connector connection status and charge receiving status can be checked with the charging status

indicator and the electronic sound fram the Vehicle Sound for Pedestrians (VSP),

For charging status indicator, refer to VC-15, "Charging Status Indicator’.

For charging sound system, refer to VSP-22. “CHARGE SOUND SYSTEM : System Description"

CHARGE PORT CONTROL

CHARGE PORT CONTROL : System Description arco womnececins

DESCRIPTION

The full range of charge port control is performed by the VCM. This includes charge connector lock/unlock

control which automatically locks the charge connector during normal charging and at other times, and charge

Port light control which automatically turns ON the LED illumination inside the port to improve charge port visi-

bility when the charge connector is inserted or removed.

antral Description

“Automatically locks and unlocks the charge connector when the normal charge con-

‘Charge connector locklunlock control pectoris connected and during normal charging

‘Charge port light control ‘Automatically tums the LED lighting inside the charge por ONIOFF,

‘Charge port lid open control Performs unlocking ofthe charge por id

“Anwer-back control CGhecks operation of charge connector lockuniock control

CHARGE CONNECTOR LOCK/UNLOCK CONTROL

Function Description

Charge connector lock/unlock control automatically locks the charge connector according to the charging type

to prevent tampering during charging,

‘The VCM detects the status of the charge connector lock switch and charge port, and controls the charge con-

nector lock actuator according to the mode and vehicle conditions. For details of control, refer to EVC-62,

"CHARGE PORT CONTROL : System Description"

Lock Mode

‘Three lock modes can be selected according to the charging type. The mode can be changed by operating the

charge connector lock switch that is located on the switch panel on the left side of the driver’s seat, The

selected mode can also be checked on the vehicle information display.

Lock mode Basic operation

(Switch postion) Tock Tmo

mode Normal charge connector is always locked when COM | sock operation

LOCK modi Nowa Unlock operation

Locked only during the period of ime fiom start toend | when normal charging is competes

AUTO mode "

‘of normal charging + Uniock operation

amor mace Does not lok. _

(Neutral postion)

‘Also locks when only timer AIC, remote AVC, or de-ice control is operating,

Unlock

‘When the following operations are performed, the charge connector lock is temporarily released,

+ Operation of the charge port lid opener button on the Intelligent Key

Pressing of the charge port lid opener switch

Releasing the door lock

Revision: June 2014 vc-19 2015 Leaf NAM

SYSTEM

< SYSTEM DESCRIPTION >

CAUTION:

If the charge connector Is not disconnected, It Is locked again automatically after 30 seconds.

Also, itis immediately locked again if the door is locked without disconnecting the charge connector.

Operation Timing Chart

‘Atomat2V bteny aging

Tinguteraie AC operates

+ LOCK mode.

Charge por lid opener switch or on

‘easing he soak

anne 7 |

com

comecter non

ome |

eck

cmc

sock

- AUTOTEE

Sagan Sa aga Rar gu

ae

‘Charging |

burton cn

os |

a i

Norms chip

Disonnast —

oo

a

von

*- Models wit Lrion battery Heater

Operation Description

The swing arm of the charge port lock actuator fits into the latch

upper portion on the normal charge connector. This limits the move-

ment of the latch and locks the charge connector.

CAUTION:

‘ase switch cannot be pressed while the connector is

Roleaso switch

Revision: June 2014 Vc-20

2015 Leaf NAM

SYSTEM

< SYSTEM DESCRIPTION >

omen SOL] comnememnneam SOL

| Je y

Nonna charge comector

CAUTION:

If the charge connector lock cannot be released, use a flat-bladed screwdriver or a similar tool to

release it manually.

Countermeasure In Case Of Charge Connector Lock/Unlock Control Malfunction

If the charge connector lack does not release automatically, perform the following procedure to release the

lock manually

1, Open hood.

2. Insert a flat-bladed screwdriver or similar tool (A) into the radia~

tor grille upper hole@, and turn the screw portion of the charge

‘connector lock actuator clockwise approximately 45° to release

the charge connector lock.

Operation Timing Chart

hare poser: sutn oe ow

Sage guns eoneed orf ——t !

Charge penis

chee

Oeeomeet !

Charo por fl

CHARGE PORT LID OPEN CONTROL,

Function Description

An electromagnetic charge port lid opener is adopted and unlocks the charge port lid (depending on the vehi=

cle conditions) using the charge port lid opener switch installed to the right instrument lower panel or the

charge port lid opener button on the Intelligent Key,

The VCM controls the charge port lid actuator according to the signal from the charge port lid opener switch or

the Intelligent Key charge port lid opener button. For control, refer to EVC-62, "CHARGE PORT CONTROL ;

System Description’.

If the lock cannot be released due to a fully discharged battery, malfunction of the charge port lid opener actu-

ator, or other reason, release the lock manually. Refer to DLK-212, "Removal and Installation".

ANSWER-BACK CONTROL.

Function Description

‘Answer-back control allows the unlock status of charge connector lock/unlock control to be checked using the

charging status indicator and the electronic sound from the Vehicle Sound for Pedestrians (VSP).

ance Sana Pea

eran Gragg sani cr rae

fressn charge pid pener stn rnsigee ky | Tve bins SOP cans

charge port lid opener button. (Alllamps) (Electronic sound sounds three

tne

+ For charging status indicator, refer to “ i

VC-15, “Charging Status Indicator”.

+ For Vehicle Sound for Pedestrians, refer to VSP-22, "CHARGE SOUND SYSTEM : System Description’.

POWER VOLTAGE VARIABLE CONTROL SYSTEM

POWER VOLTAGE VARIABLE CONTROL SYSTEM : System Description sroocnsese

DESCRIPTION

Power voltage variable control reduces the electric power consumption from the Li-ion battery by varying the

DC/DC converter output in a range from 13 V to 15 V according to the use status of electric equipment and the

12V battery status.

For control, refer to

AUTOMATIC 12V. BATTERY CHARGE CONTROL

AUTOMATIC 12V BATTERY CHARGE CONTROL : System Description

DESCRIPTION

Revision: June 2014 VC-22 2015 Leaf NAM

SYSTEM

< SYSTEM DESCRIPTION >

The 12V battery automatic charge control reduces the frequency with which the 12V battery becomes fully dis-

charged by automatically charging the 12V battery if the 12V battery voltage is low when the power switch is

tumed to ON or the vehicle being left to sit for a long time.

The PDM (Power Delivery Module) controls the intemal DC/DC converter by using commands from the VCM,

and charges the 12V battery using power from the Li-ion battery.

For control, refer to EVC-60, "AUTOMATIC 12V BATTERY CHARGE CONTROL : System Description”.

Revision: June 2014 VC-23 2015 Leaf NAM

OPERATION

< SYSTEM DESCRIPTION >

OPERATION

Switch Name and Function roc cerwareesesst

a

\ sone

Instrument panel ea LH

No. ‘Switch name Operation Function

‘AUTO | Lock operation is performed only during normal charging

The charge cannectar lock does net operat.

MIDDLE | + The connector lock is released If the switch s moved tothe mid-

de postion while the charge connector lock is operating,

‘The lock operation is performed at al times when the normal

LOCK charge connector Is connected

‘When timer charge ls se, mediate charge mode Is engaged and

ormal charging is started.

@ __| Charge connector look switch

® _| immediate charging switch Pressed

NOTE:

+ For normal charge control, refer to VC-17, "LI-ION BATTERY CHARGE CONTROL : System Description”

For normal charge connector lack/unlock control, refer to VC-19, "CHARGE PORT CONTROL : System

Deseription’.

Revision: June 2014 VC-24 2015 Leaf NAM

HANDLING PRECAUTION

< SYSTEM DESCRIPTION >

HANDLING PRECAUTION

Vehicle Charging System

HANDLING OF CHARGE CABLE, CHARGE PORT, AND CHARGE CONNECTOR

+ Never touch metal terminals of the charge port or the charge connector.

+ Never modify or disassemble control box, socket, charge cable, charge connector, or charge port.

+ Never apply excessive force to the charge cable.

~ Never pul

~ Never twist

Never drag.

Never place a heavy item on charge cable.

Never place near a heating device (heater, etc.)..

Never drop or subject to strong impact.

When storing, be sure to attach the cap to the connector before storing

When storing, store in a location away from direct sunlight, not exposed to rain or wind, and where dust and

dirt do not enter.

Use only with a designated socket especially wired for EV/PHEV with NISSAN recommended work or equiv-

alent means. (This is because there is an extremely high risk of electric shock if the ground line is connected

incorrectly.)

+ Never allow the control box to be submerged in water.

+ Maximum service temperature: 45 °C (113 °F)

PRECAUTIONS FOR CHARGING

+ Use genuine NISSAN EVSE only.

+ Never use an extension cord or conversion adapter.

+ Never touch the plug with wet hands.

+ Ifthe plug is dirty or wet, wipe it with a clean, dry cloth,

+ Check that there is no foreign material such as water or dust in the charge port or the charge connector.

WARNIN

+ Adsince tnere may tea risk of electric shock, never touch the charge gun or charge port i they

contain foreign material.

+ Misince tnere may bo a risk of elacrte shock or electric leakage, never connect the charge gun

or charge port if they contain foreign material.

Never use the EVSE cord or cable if itis worn, or if there are any deep scratches or other damage where the

core wires are visible.

Never use the EVSE charge connector, control box, or plug if itis broken, scratched, cracked, or otherwise

damaged

Check that there is no rust, corrosion, or damage on the charge port or charge gun. Check that there is no

loosening at the time of connection.

WARNING:

Adsince olectric leakage, electric shock, short-circuit, or fre may occur, never charge it any mal-

function Is found.

Never perform charging when the connection is heavily exposed to water.

Never perform charging with the body cover attached.

Never perform charging when there may be a risk of lightning

‘Stop charging immediately when an unusual odor or smoke is found during charging

Never place hand near the cooling fan during charging.

NOTE:

The cooling fan may automatically start operation during charging when the power switch is tumed OFF.

After charging, securely close the cover and lid of the charge port fo prevent entry of water or dust.

To tu on READY after charging, operate after disconnecting the charge connector from the charge port.

NOTE:

When the charge connector is connected to the charge port, READY is disabled,

+ To prevent electric shock or fire arising from electric leakage, use a waterproof plug with grounding con-

nected to the ground fault interrupter.

+ Never connect to a socket providing other than the rated voltage.

Revision: June 2014 Vvc-25 2015 Leaf NAM

HANDLING PRECAUTION

< SYSTEM DESCRIPTION >

* For charging with AG 100 V, use 18 A rating or more plug. For charging with AC 200 V, use 20 A rating or

more plug,

WARNING:

Ifa plug with a low current rating is used or if a plug adapter Is installed and used in combination

with another device, the plug may cause abnormal heating, resulting in a fire.

+ For charging, never use a generator or any other power source other than specified

NOTE:

Charging may not be performed correctly or a malfunction may occur.

+ When quick charging is performed, be sure to use a quick charger compatible with the vehicle.

Revision: June 2014 VC-26 2015 Leaf NAM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

< SYSTEM DESCRIPTION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis Description eos

This system is an on board diagnostic system that detects a malfunction automatically. A malfunction is stored

in POM (Power Delivery Module) memory as a DTC. The diagnostic information can be obtained with CON-

SULT.

Counter System ws

Counter system counts up at every operation of power switch from OFF to ON under condition that the same

malfunction is not detected. On the other hand, if the same DTC as memorized one is detected again, the

count is reset and the counter system counts up again from *0"

DTC and Freeze Frame Data wo

‘The PDM (Power Delivery Module) can save multiple DTC but can only save one freeze frame data.

After the PDM (Power Delivery Module) has detected a malfunction and saves the DTC and freeze frame

data, if a different malfunction is detected, multiple DTC are confirmed, but only the freeze frame data that is

saved first can be confirmed,

‘The DTC and freeze frame data can be deleted when the self-diagnostic is deleted,

Revision: June 2014 VC-27 2015 Leaf NAM

DIAGNOSIS SYSTEM [PDM(POWER DELIVERY MODULE)]

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM [PDM(POWER DELIVERY MODULE)]

CONSULT Function

FUNCTION

Diagnastc test mode Function

Work Suppor This mode enables a technician to adjust some devices faster and more accurately by folowing the

Ppa ingications on the CONSULT.

Selt-cigonostic result Seltciagnasticresuls and freeze frame data can be read and erased quickly”

Data monitor Input/Output data in the POM (Power Delivery Module) can be read

‘Actve Test ‘Operable under the condition thatthe actuator is activated by CONSULT via the PDM (Power Deliv-

‘ery Module) or within the range that a (some of) command value is designated,

ECU Identiteation DM (Power Delivery Module) part number can be read.

"The folowing dlagnasis Information Is Geared when the PDM (power delivery module) memory ls erased,

+ Diagnostic trouble codes

+ Freeze frame data

WORK SUPPORT MODE.

Werk tem Description

‘CHARGE CURRENT LIMITA. | Displays the previous 10 charging current readings during normal charging, llowlng the history of

TION HISTORY Current limits and charging stops resulting from EVSE commands to be checked,

NOTE:

Ifthe minimum value is 7.2 A or less, the current limit display reads “Yes', indicating that the current is limited

or charging is stopped during charging. A possible cause is insufficient contact due to damage or wear of the

EVSE plug or socket.

Change the combination of socket and EVSE that are used and perform normal charging. The malfunctioning

component can be identified by checking “CHARGE CURRENT LIMITATION HISTORY"again.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

+ Regarding items of DTC, refer to VC-34, "DTC Index".

+ Regarding items of DTC’ sub type, refer to VC-35, "DTC Sub Type Index’

IGN Counter

IGN counter is displayed in Freeze Frame Data (FFD). It displays the number of operations of power switch

from OFF to ON after DTC recovery to normal.

+ CAN malfunction (U1000)

- The number is 0 when a malfunction is detected now.

~ The displayed number counts up at each operation of power switch from OFF to ON after recovery to nor-

mal, such as 1 > 2+ 3...38 + 39.

- The number is fixed to 39 until the self-diagnosis results are erased if it is over 38.

+ Other than CAN malfunction (Other than U1000)

~ The number is 0 when a malfunction is detected now.

~ The displayed number counts up at each operation of power switch from OFF to ON after recovery to nor-

mal, such as 1 > 2+ 3...254 = 255.

~ The number is fixed to 255 until the self-diagnosis results are erased if it is over 255.

Freeze Frame Data

‘The Freeze Frame Data shows the status of the vehicle when the DTC is detected and is useful for recreating

the status when the maifunction occurred.

Revision: June 2014 VC-28 2015 Leaf NAM

DIAGNOSIS SYSTEM [PDM(POWER DELIVERY MODULE)]

< SYSTEM DESCRIPTION >

Tes Fane aaa Desa

‘aicHs CoNNECT =.

a Dips ite camecten stu fe guck cage comer

QIGHE STARTISTOP Sane pu situs tthe care starlsup Sal om the uk carer,

QICHG STARTISTOP Displays the input status of the charge start/stop signal 2 from the quick charger.

see

GUIGKCHARGEPER- | Depa ne waning sats fe charge slat peison irl ing sen eq age

GICHSRELAY> piste conte Salus ote ick rg

OICHG RELAY spas cane Salus ofthe uc fro rely)

Pui sions. Dips een sis be PH pal being sex Fomine EVSE

EVSE STATE JUDG] Dsplays he engagement detecion das ere EVSE charge cmrecter

WELD DAG VOL Depinjsttepesenecr sbence cota ees hip vege emi fhe qekchare poe

POMGOULETENP,EG | Dspys he POM Pove Deter eee tepertue

EVSYSWALREG | Dla te status o7EVaystem waning iar dal Vansson hats sont toe VOM

Pea Dips ss of alae eqs sal Tansison ais sete VOM

QICHG PORT TEMP Displays the quick charge port temperature status.

FWM SIGNAL VOLTAGE | rypiays the voltage of a PVM signal transmitted from EVSE.

M

TIME Displays the number of DTC detected tips.

ELAPSED TIME Displays the te elapsed since the detection of the DTC.

DATA MONITOR MODE

NOTE:

‘The following table includes information (items) inapplicable to this vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items.

Tionitar fem Ua Description

CNCTIDISc. | Displays the connection status ofthe quick charge connector.

QICHG CONNECT DETECT Way S” | + GNCT: The quick charge connector is connected.

+ DISCNCT: The quick charge connecter is not connected,

Displays the input status ofthe charge start/stop signal 1 from the quick charger.

QICHG STARTISTOP SIG 1 ONIOFE | + OFF: The quick charger stan switch Is OFF and not under quick charge.

+ ON; The quick charger stat switch ON or under quick charge.

Displays the input status ofthe charge staristop signal 2 trom the quick charger.

(QICHG STARTISTOP SIG 2 ON/OFF | + OFF: Isolation check witha quick charger fs NG or not completed

+ ON: Isolation check with a quick charger completed normally

Display the transmission status ofthe charge stat permission signal being sent,

to the quick charger.

+ LOW: Allow quick charge start

+ HIGH: Quick charge start isnot alowed

QUICK CHARGE PERMIT LOWIHIGH

Displays the contol status of the quick charge relay (+).

+ On: Quick charge relay (+) i8 ON.

+ Off: Quick charge relay (+) is OFF.

QICHG RELAY +

Displays the control status ofthe quick charge relay (-)

+ On: Quick charge relay (-) is ON.

+ Off: Quick charge relay (-) is OFF

Displays the reception status of the PWM signal being sent trom the EVSE.

PWM SIGNAL OWNONE | + COMM: Communicating normaly

+ NO COME Not communicating

QICHG RELAY ~ oni

Revision: June 2014 vc-29 2015 Leaf NAM

DIAGNOSIS SYSTEM [PDM(POWER DELIVERY MODULE)]

< SYSTEM DESCRIPTION >

Monitor fem Unit Description

Displays the engagement detection stalus ofthe normal charge connector,

CNET | + CNCT. There is no AC input in the charge connector connected status.

INPUT/_| = INPUT: Thete Is AC input in the charge connecter connecte status

EVSE STATE JUDG NONEINO | + NONE: The charge connector isnot engaged or there is no PWM communi-

CNCTORER. | — cation rom the EVSE.

ROR + NO CNCT OR ERROR: The charge connectors not engaged and mafunce

tion of EVSE, or during @ power outage.

Displays the presence or absence of voltage between the high votage terminal

ofthe quick charge port

Wetp DIAG VoL PRESENTIAB. | - PRESENT: Detect votapeBeweentne igh lage omial otek cate

+ ABSENT: Not detects voltage Between the high voltage terminal of quick

charge pot.

PD MODULE TEMP ['O} deg | Displays the PDM (Power Delivery Module) intemal temperature

Displays the status of EV system warning lamp signal transmission that is sent

n 7 tothe VOM

EVSYSWILREQ OvOf | + On: Transmitthe signal

+ Off Nonransmit ne signa

Displays the status of fal-safe request signal transmission tha is sent othe

FIS REQ conor | VOM.

+ On: Transmit the sign

+ Off: Nonransmit ne signa.

Displays the quick charge por temperature status.

QIcHG PORT TEMP OKING + OK: Normal

+ NG: Temperature is high

PWM SIGNAL VOLTAGE v Dispays the voltage ofa PWM signa transmitted rom EVSE

i NOTE:

QUICK CHARGE ENABLE OKING This item is isplayed, but cannot be monitored.

ACTIVE TEST MODE

CAUTION:

After performing active test, always erase all DTC.

Testtem FurcionsGonattion ~woagment ‘Gheckitem (Remeay)

~ Remove the sevice pug eck thatthe quick charge | Harness and connector

arc RELAY + + Power suith ON rlaymates be oping | cage ey)

+ Use active test totum ON/OFF the " + POM (Power Delivery Mod.

‘uick charge relay sound, ule)

~ Remove the sevice pug vox charge | » Hamess end connector

chs RELAY - + ewer sen on resymmes eepring, | Sub chery

+ Use active test totum ON/OFF the + POM (Power Delivery Mod-

‘Quick charge reiay, sound wie)

‘Check continuity between

POM (Power Delivery Module)

QUICK CHARGE PERMIT | QUCK charge permit signal frlay | connectarteminals to check | poy Power Delivery Module)

output

that the transistor included in

the POM (Power Delivery

Module) is ON.

“rTfoperating noise is hard to hear, use @ Sound scope to check noise.

Revision: June 2014

VC-30 2015 Leaf NAM

PDM(POWER DELIVERY MODULE)

< ECU DIAGNOSIS INFORMATION >

ECU DIAGNOSIS INFORMATION

PDM(POWER DELIVERY MODULE)

Reference Value aesmacnsce eure

VALUES ON THE DIAGNOSIS TOOL

Specification data represents reference values.

NOTE:

+ The displayed data may differ from an actual signal/value/operation, as some of them are calculated by PDM

(Power Delivery Module), based on signals transmitted from POM (Power Delivery Module)-elated sensors

to PDM (Power Delivery Module).

+ Lion battery charge does not start when the power switch is ON. When it is required to charge with the

power switch ON, start charging before turning ON the power switch,

Wantortem Canaan Tana

ulek charging connector Con

nected oNCT

GICHG CONNECT DETECT POWERON aaa TS

vik charging connector

uk ea Disenct

The euck charger slat sich is OFF and not under quick care OFF

QICHG START/STOP SIG 4 ® ‘st 8 "st

“The ule charger saath ON or under uc care. on

Inthe proces of ak charge ate the normal eampeten eins on

QICHG STARTISTOP SIG2 _ tlon esistance check.

Fora ten secanés ter uring ON he qc carer rt en OFF

Cc cater stat utis OFF. Not in process of auik cere. HIGH

QUICK CHARGE PERMIT A lapse of afew seconds after turning ON the quick charger start HiGH-=Low

sien

Cok chargng in progress on

GICHG RELAY + ring in progr

Not uk charging of

Ceca n progress on

QICHG RELAY ~ rang in par

Not uk charging on

Normal charging im progress cont

PWM SIGNAL ‘ging in Proat

Except above NocoM

‘When te EVSE charge connectors connected cnet

‘ema ehrong proses inPur

EVSE STATE JUDG rang in roar

‘When he EVSE change connecaris nl comected NONE

Except above NOCNCTOR ERROR

(ek charging in prowess PRESENT

WELD DIAG VOL rangin par

Except above ABSENT

10-2156

PO MODULE TEMP Depending on he POM (Power DeveryModui) temperature, ‘dates depending on he

Ue) Temperate

EV system warring lamp ina

‘Transmission on

ev sys wi REQ Power sich: ON

EV system warring amp ia on

Nontanamisson

Step charging oes dng nomaneuck char On

ssreo 6 charging remake

Except above of

When te qk care pos abooaly ot NG

QICHG PORT TEMP s

Except above OK

Revision: June 2014 VC-31 2015 Leaf NAM

PDM(POWER DELIVERY MODULE)

< ECU DIAGNOSIS INFORMATION >

Monitor fem ‘Gendtion

Valuesisiatus

PWM SIGNAL VOLTAGE Normal charge

No”

‘This tem Is splayed, but cannat be mentored.

(QUICK CHARGE ENABLE

4-7V

TERMINAL LAYOUT

PHYSICAL VALUES

NOTE:

Specification data are reference values

Temnal No

(ifr coor Deserpion Value

Condition nae)

>|] - Signal name input (sep

a Output

@ | _ Guick charger communication | Input _ _

” (CAN) Output

7 | Gulek charger communication. Input! _ _

© (CAN) ouput

Daring quick chain 73-10V

8 | round FS CHG relay Input Dang qk charging

® Except above ov

10 During charging ov

Ground | Plug in signal Input

ow sins PT Except above 118-18V

rn

Gh — eveystem oan - - _

12 | Groung High voltage namess connector | no. a -

(2a) | "4 getectng circu power supply ‘MPU Power swtch: ON Soren

15 | young High votagehamess connector | G.. 1 -

G,_| rune Hon sola naress Output Power sven: ON 30-70

10 | Ground Power ON ws Input PWC eth ON B-18V

° fe Y eat Power switch: OFF ov

S| ecu) satey power sy pt | Pont ote ON av

19 Daring quick charging 708 132V

‘Ground Quick charger permit signa Input

o ‘ger permit sig 'put Except above ov

2 | During quik earn OPEN

0 | Ground Quick charger connection signal Input nn UE MOGNG

© Except above a-148V

mA During quik charging 708-192

Ground | Quick charger stavstp signal 2 | Input

% "3 a PAN Except above OPEN

Revision: June 2014 VC-32

2015 Leaf NAM

PDM(POWER DELIVERY MODULE)

< ECU DIAGNOSIS INFORMATION >

TTeminai No. con

(re colon) Desert sondton vane

. ‘Sina name input (AppI0x)

- s Output

During quick charg W08-192V

2 | round | Quick charger starstop signal 1 | Input | PAN SEK sarang

8) Except above OPEN

% (Quick charger port temperature vin ‘ -

Bay Grama | Quek charges Input | During quick charging 05-48

26 ‘Quick charger port temperature 5

3) Grand) Quek ones Input | During quick charging 05-45

2

— | eveystem cant - - -

w y

20 During nermal charging o-50V

— | EVSE connection signal ouput ng nenmelhargng OO

«s) PT xcept above 50V

20 input | Busing normal charging =126-26V

Ground | EVSE communication (PW)

wy (PANY ouput) Except anove ov

Fail-Safe scone eae

FAIL-SAFE

When there is a maifunction with the PDM (Power Delivery Module), charging is stopped as a fail-safe.

FAIL-SAFE LIST

~ Applicable —: Not applicable

Trem

ore (CONSULT screen terms)

Sub ype

(CONSULT screen terms)

Fallsate

MISSING MESSAGE

y1000-| CAN COMM CIRCUIT ERRATIC x

ELECTRICAL MALFUNCTION xs

MISSING MESSAGE :

1008. QUICK CHARGER COMM

ERRATIC x

U0 GAN COMM ERROR MISSING MESSAGE :

MISSING MESSAGE x

U1008 «QUICK CHARGER COMM

ERRATIC x

INTERNAL ELECTRICAL MALFUNCTION x

U1010 | CONTROL UNIT (CAN)

ELECTRICAL MALFUNCTION x

SIGNAL INVALID :

82801 ICH ACTIVATION SIG ERROR,

SIGNAL STUCK HIGH E

“SIGNAL STUCK LOW :

82802 ICH ISOLATION SIGNAL ERROR,

SIGNAL STUCK HIGH :

82808 | GICHG PERMIT SIGNAL ERROR SIGNAL STUCK LOW :

82614 QUICK CHARGE RELAY SIGNAL STUCK HIGH x

52620 QUICK CHARGER = =

82630 QUICK CHARGE VOLTAGE SENSOR CMPNENT INTERNAL MLENCTN =

ELECTRICAL MALFUNCTION x

82840 © PD MODULE ‘CMPNENT INTERNAL MLFNCTN x

‘COMPONENTISYS OVER TEMP x

52850 __| PD MODULE TEMP SENSOR SIGNAL STUCK LOW x

Revision: June 2014

VC-33

2015 Leaf NAM

PDM(POWER DELIVERY MODULE)

< ECU DIAGNOSIS INFORMATION >

Tes Sabo

ore (CONSULT screen terms) (CONSULT screen terms) Falesate

SIGNAL STUCK LOW

52880 | FISCHG RELAY

SIGNAL STUCK HIGH :

ELECTRICAL MALFUNCTION =

CIRG VOLT BELOW THRESHOLD =

82890 DCIDC CONVERTER CCHPNENT INTERNAL MLFNCTI =

CCOMPONENTISYS OVER TEMP

‘IRC VOLT ABOVE THRESHOLD =

PROGRAM MEMORY ERROR

82000 | PDMODULE

DATA MEMORY ERROR

MEMORY ERROR =

82002 | PDMODULE

CCMPNENT INTERNAL HLENGTN =

SIGNAL STUCK HIGH =

82860 QUICK CHARGE PORT TEMP

CCOMPONENTISYS OVER TEMP :

SIGNAL STUCK HIGH -

B20A0 | NICHG PORT ENGAGEMENT ERROR

SIGNALINVALID :

NO SIGNAL

SIGNAL STUCKLOW

eect EVE ‘UNEXPECTED OPERATION

SIGNAL STUCK HIGH

SIGNALINVALID

DTC Index sons

Assist — Nt alee

oo Tens Sib ype Evayelem |, | Reterence

(CONSULT sereen terms) (CONSULT seen terms) —_wamangiamp Phage

MISSING MESSAGE : 7

tee | CAN commeiRcuIT ERRATIC : T | yess

ELECTRICAL MALFUNCTION - 7

U1008 QUICK CHARGER COMM MISSING MESSAGE “ ‘ ve-s7

ERRATIC - 7

Ui00A| CAN COMB ERROR MISSING MESSAGE . +) ves

MISSING MESSAGE t

U100B | QUICK CHARGER COMM Ve-57

ERRATIC 2 1

INTERNAL ELECTRICMALFNOTN |= 7

U1010 CONTROL UNIT (CAN) ve-61

ELECTRICAL MALFUNCTION . t

SIGNALINVALID 7

B2801 | CHG ACTIVATION SIG ERROR ves

SIGNAL STUCK HIGH - 1

SIGNAL STUCKLOW . 1

22002 QICHG ISOLATION SIGNAL ERROR ves

SIGNAL STUCK HIGH - 4

82009 | GCHG PERMIT SIGNALERROR SIGNAL STUCKLOW =) yeas

Bde14 | QUIGK CHARGE RELAY SIGNAL STUCK HIGH : | vert

52620 | QUIGK CHARGER = =

82990 | QUICK CHARGE VOLTAGE SENSOR | CPNENTINTERNALMUFNCIN wor) 1) Voz

Revision: June 2014 VC-34 2015 Leaf NAM

PDM(POWER DELIVERY MODULE)

< ECU DIAGNOSIS INFORMATION >

pre

Ttems

(CONSULT screen terms)

‘Sub ype

(CONSULT sereen terms)

EV eysiom

warning amp |

THp

Reference

age

Beato

2850

82880

PDM (POWER DELIVERY MODULE)

PD MODULE TEMP SEN

FIS CHARGE RELAY

ELECTRICAL MALFUNCTION

(CMPNENT INTERNAL MLENCTN

COMPONENTISYS OVER TEMP

SIGNAL STUCK LOW

SIGNAL STUCK LOW

SIGNAL STUGK HIGH

7

2890

2002

82980

DC/DG CONVERTER

PDM (POWER DELIVERY MODULE)

PDM (POWER DELIVERY MODULE)

‘QUICK CHARGE PORT TEMP.

ELECTRICAL MALFUNCTION

CIRC VOLT BELOW THRESHOLD

‘CMPNENT INTERNAL MLENCTN

(COMPONENTISYS OVER TEMP

CIRC VOLT ABOVE THRESHOLD

PROGRAM MEMORY ERROR

DATA MEMORY ERROR

MEMORY ERROR

(CMPNENT INTERNAL MLFNCTN

SIGNAL STUCK HIGH

COMPONENTISYS OVER TEMP

ves

8290

2001

NICHG PORT ENGAGEMENT ERROR

EVSE

SIGNAL STUCK HIGH

SIGNAL INVALID

NO SIGNAL,

SIGNAL STUCK LOW

UNEXPECTED OPERATION

SIGNAL STUCK HIGH

SIGNAL INVALID

vo-s6

DTC Sub Type Index

items

(CONSULT screen terms)

Description

Remarks

ELECTRIGAL MALFUNCTION

SIGNAL STUCK LOW

‘SIGNAL STUCK HIGH

‘Signal Stuck Low

‘Signal Stuck High

Electrical Malfunction

‘SIGNAL INVALID ‘Signal Invalid

NO SIGNAL No Signal

MEMORY ERROR ‘General Memory Error

DATA MEMORY ERROR

Data Memory Error

PROGRAM MEMORY ERROR Program Memory Error

INTERNAL ELECTRIC MALFNCTN | Internal Electronic

INGRRGT COMPNT INSTALLED

(OVER TEMPERATURE

ALIVICNT INCRCTINOT UPDAT

Over Temperature

‘lve Sequence Counter Incorrect Not Updated

‘malfunction

Incorrect Component installed

This au ype Is used by the contol module

was received with-

to indicate that a sign

‘out the corresponding rong count value

being property updates,

Revision: June 2014

VC-35

2015 Leaf NAM

PDM(POWER DELIVERY MODULE)

< ECU DIAGNOSIS INFORMATION >

Teme

(CONSULT screen terms)

Deserption

Remarks

SIG PRTCTN CLCLTN INCRCT

MISSING MESSAGE

ERRATIC

PARAMETRIC

NO OPERATION

UNEXPECTED OPERATION

(CMPNENT INTERNAL MLENOTN

Value of Signal Protection Calculation incorrect

Missing Message

Enratic

Parametic malfunction

No Operation

Unexpected Operation

‘Component internal maifunction

This sub type Is used by the control module

toiindicate, hat a message was processed

vith an incorrect protection (checksum) cal-

culation.

This Sub type Is used for malfunctions

‘where one (or more) expected message(s)

Is not received

This sub type is used for malfunctions

where the serial data, Is momentary im-

plausible or elscontinuous.

CCOMPONENTISYS OVER TEMP

CIRC VOLT BELOW THRESHOLD

Component or System Over Temperature

Voltage reduction

CIRC VOLT ABOVE THRESHOLD

CIRC CURR ABOVE THRESHOLD

Overvatag

Overcurrent

Revision: June 2014

VC-36

2015 Leaf NAM

VEHICLE CHARGING SYSTEM

< WIRING DIAGRAM >

WIRING DIAGRAM

VEHICLE CHARGING SYSTEM

Wiring Diagram

VEHICLE CHARGING SYSTEM

Revision: June 2014 VC-37 2015 Leaf NAM

VEHICLE CHARGING SYSTEM

< WIRING DIAGRAM >

iG

Revision: June 2014 VC-38 2015 Leaf NAM

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Technical Note: I - Subject: Procedure To Follow For Apm FaultDocument11 pagesTechnical Note: I - Subject: Procedure To Follow For Apm Faultmebarki aberraouf100% (2)

- Technical Note: I - Subject: Air Suspension - Ecs SystemDocument12 pagesTechnical Note: I - Subject: Air Suspension - Ecs Systemmebarki aberraoufNo ratings yet

- J22CC38976 58980 4745898000Document11 pagesJ22CC38976 58980 4745898000mebarki aberraoufNo ratings yet

- J34TC124 49946 1764994600Document8 pagesJ34TC124 49946 1764994600mebarki aberraoufNo ratings yet

- Technical Note: I - Subject: Diagnostics of The Power Steering Hydraulic CircuitDocument2 pagesTechnical Note: I - Subject: Diagnostics of The Power Steering Hydraulic Circuitmebarki aberraoufNo ratings yet

- Technical Note: I - Subject: Dealing With "Engine Performance" ComplaintsDocument4 pagesTechnical Note: I - Subject: Dealing With "Engine Performance" Complaintsmebarki aberraoufNo ratings yet

- Technical Note: I - I - Subject: Abnormal Consumption of Engine OilDocument4 pagesTechnical Note: I - I - Subject: Abnormal Consumption of Engine Oilmebarki aberraoufNo ratings yet

- Technical Note: TrucksDocument16 pagesTechnical Note: Trucksmebarki aberraoufNo ratings yet

- Technical Note: I - Subject: Analysis, Measurement and Checking of BatteriesDocument7 pagesTechnical Note: I - Subject: Analysis, Measurement and Checking of Batteriesmebarki aberraoufNo ratings yet

- Nissan Leaf (ZE0) - EV Control System PDF FreeDocument425 pagesNissan Leaf (ZE0) - EV Control System PDF Freemebarki aberraouf100% (1)

- Nissan Leaf (ZE0) - Traction Motor System PDF FreeDocument114 pagesNissan Leaf (ZE0) - Traction Motor System PDF Freemebarki aberraouf100% (1)

- Seat Hardware, Trim, and UpholsteryDocument66 pagesSeat Hardware, Trim, and Upholsterymebarki aberraoufNo ratings yet

- Kia Picanto II Gen. (TA) EWD - Immobilizer System PDF FreeDocument3 pagesKia Picanto II Gen. (TA) EWD - Immobilizer System PDF Freemebarki aberraoufNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument47 pagesFastener Tightening Specifications: Application Specification Metric Englishmebarki aberraoufNo ratings yet

- Fixed and Moveable WindowsDocument54 pagesFixed and Moveable Windowsmebarki aberraoufNo ratings yet

- Steering Wheel and ColumnDocument33 pagesSteering Wheel and Columnmebarki aberraoufNo ratings yet