Professional Documents

Culture Documents

Nissan Leaf (ZE0) - EV Control System PDF Free

Nissan Leaf (ZE0) - EV Control System PDF Free

Uploaded by

mebarki aberraouf100%(1)100% found this document useful (1 vote)

1K views425 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views425 pagesNissan Leaf (ZE0) - EV Control System PDF Free

Nissan Leaf (ZE0) - EV Control System PDF Free

Uploaded by

mebarki aberraoufCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 425

ELECTRIC POWER TRAIN

sccron = WC

EV CONTROL SYSTEM Bg

CONTENTS

PRECAUTION

PRECAUTIONS .....0

Precaution for Technicians Using Medical Electric. ..8

Point to Be Checked Before Starting Maintenance

Work 8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER™ 8

Precaution for Procedure without Cow! Top Cover....9

Precautions for Removing Battery Terminal 9

0

1

High Voltage Precautions

General Precautions

PREPARATION ... ssssnneneesessnnnneecessessnnnne Td

PREPARATION ssssssssststansnennansessn

Commercial Service Tools

SYSTEM DESCRIPTION ......sssssssssssssseeeesensS

COMPONENT PARTS ..

‘Component Parts Location ...... eo 18

vem ve . . on 18

MIC Relay .. . on 18

FIS Relay ... . on 18

FIS CHG Relay ...... on 18

‘Charge Port Lid Opener Actuator Relay on 18

Charge Connector Lock Relay 18

AIC Relay . . on 19

‘System Main Relay 1 . on 19

System Main Relay 2 . on 19

Pre-charge Relay . 19

Reverse Lamp Relay . on 19

Accelerator Pedal Position Sensor on 19

Refrigerant Pressure Sensor . 19

‘Stop Lamp Switch . 0-20

ASCD Steering Switch — 20

Brake Pedal Position Switch... 20

Battery Current Sensor (With Battery Tempera-

ture Sensor) . . 20

Revision: June 2014

Evc-1

Coolant Temperature Sensor a1

Electric Water Pump 21

Cooling Fan Contro| Module 2

Combination Meter 2

ECO Indicator 23

Approaching Vehicle Sound for Pedestrians

(vsP) 23

WARNING LAMPSI/INDICATOR LAMPS sennssnene23

WARNING LAMPS/INDICATOR LAMPS : EV

System Warning Lamp vn. 8

WARNING LAMPS/INDICATOR LAMPS : Low

Battery Charge Warming Lamp ... 5

WARNING LAMPS/INDICATOR LAMBS : Plug In

Indigator Lamp nnn: 8

WARNING LAMPS/INDICATOR LAMPS : Power

Limitation Indicator Lamp 8

WARNING LAMPS/INDICATOR LAMPS : Ready

To Drive Indicator Lamp enn 8

WARNING LAMPS/INDICATOR LAMPS : 12V

Battery Charge Warming Lamp .... nt

WARNINGIINDICATOR (ON INFORMATION DIS-

PLAY)

WARNING/INDICATOR (ON INFORMATION

DISPLAY) : DC/DC Converter Warning 32

WARNING/INDICATOR (ON INFORMATION

DISPLAY) : Low Battery Charge Warning 34

WARNING/INDICATOR (ON INFORMATION

DISPLAY) : Power Limitation Warning 35

WARNING/INDICATOR (ON INFORMATION

DISPLAY): Shift P Warning 26

WARNING CHIME

WARNING CHIME : DC/DC Converter Warning

Chime 7

WARNING CHIME : Power Switch Reminder

Chime 39

WARNING CHIME : Shift P Warning Chime 40

SYSTEM

2015 Leaf NAM

ELECTRIC POWER TRAIN SYSTEM swnnnnnnnnn 42

ELECTRIC POWER TRAIN SYSTEM : System

Description .. 42

ELECTRIC POWER TRAIN SYSTEM : Fall-Safe...42

EV SYSTEM START UP CONTROL

EV SYSTEM START UP CONTROL : System De-

scription 45

a5;

HIGH VOLTAGE POWER SUPPLY CONTROL ...... 47

HIGH VOLTAGE POWER SUPPLY CONTROL

System Description 48

MOTOR POWER CONTROL swnnnnnnnse 49

MOTOR POWER CONTROL : System Desc

tion ve 24

MOTOR REGENERATION CONTROL

MOTOR REGENERATION CONTROL

Description

ECO MODE/B MODE SYSTEM

ECO MODE/B MODE SYSTEM : System Deseri

tion 51

LI-ION BATTERY CHARGE CONTROL ssnnsnsnne: 52

LLION BATTERY CHARGE CONTROL : System

Description .. 82

LEION BATTERY CHARGE CONTROL : Normal

Charge Control... 82

LLION BATTERY CHARGE CONTROL : Quick

Charge Control nnn BA

HIGH VOLTAGE SYSTEM COOLING CONTROL... 54

HIGH VOLTAGE SYSTEM COOLING CONTROL

System Description 54

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL : System De-

scription 3T

POWER VOLTAGE VARIABLE CONTROL SYS-

TEM sessnmnnmnnnnnnninnnmsnsnnnnnnnnns 5D

POWER VOLTAGE VARIABLE CONTROL SYS-

TEM : System Description... a)

AUTOMATIC 12V BATTERY CHARGE CONTROL,

59)

AUTOMATIC 12V BATTERY CHARGE CON-

TROL : System Description 60

POWER CUT OFF CONTROL 81

POWER CUT OFF CONTROL : System Descrip-

tion et

CHARGE PORT CONTROL snsisinnnnnnnnnnnees 2

CHARGE PORT CONTROL : System Description... 62

AUTOMATIC SPEED CONTROL DEVICE (ASCD).. 64

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : System Description 65

ECO INDICATOR CONTROL 85

Revision: June 2014

Evc-2

ECO INDIGATOR CONTROL : System Desap-

tion

WARNING/INDICATOR/CHIME LIST

WARNINGJINDICATORICHIME LIS

a

lampsiindicator lamps 66

WARNING/INDICATORICHIME LIST : Warning

Chime er

WARNING/INDICATORICHIME LIST : Warning/

Indicator (On Information Display) er

WARNING/INDICATORICHIME LIST : Indicator!

Information er

CAN COMMUNICATION 2

CAN COMMUNICATION : System Description ....69,

OPERATION .

AUTOMATIC SPEED CONTROL DEVICE (ASCD}...70

‘AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : Switch Name and Funetion ..70

ECO MODE SWITCH esnnsnnns soo 70

ECO MODE SWITCH : Switch Name and Func-

HOM ene TO

‘ON BOARD DIAGNOSTIC (080) s SYSTEM

Diagnosis Description

Counter System

DTC and Freeze Frame Data

DIAGNOSIS SYSTEM (VCM)

CONSULT Function

ECU DIAGNOSIS INFORMATION

.70

vem

Reference Value 85

Fail-Safe 98

DTC Inspection Priority Chart 101

DTC Index 103

WIRING DIAGRAM ..

vem

Wiring Diagram

BASIC INSPECTION ..

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

Diagnostic Work Sheet

ADDITIONAL SERVICE WHEN REMOVING

12V BATTERY NEGATIVE TERMINAL ..

Description

Work Procedure

ADDITIONAL SERVICE WHEN REPLACING

vem

Description

Work Procedure

2015 Leaf NAM

‘ACCELERATOR PEDAL RELEASED POSI-

TION LEARNING 135

Description . . 2195

Work Procedure . 2135

LIION BATTERY GRADUAL CAPACITY

LOSS DATA CLEAR .. 136

Description . . 136

Work Procedure . 136

LIION BATTERY JUNCTION BOX DATA.

CLEAR esssessnneuinsaieninnaieninaesinsase 197

Description 137

Work Procedure 137

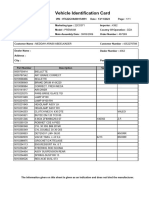

WRITE VEHICLE IDENTIFICATION NUMBER

DATA ... 138

Description 198

Work Procedure 198

LOAD BATTERY IDENTIFICATION DATA ....139

Description 138

Work Procedure . 138

DTCICIRCUIT DIAGNOSIS .........ssssssseeeeee 140

POWER SUPPLY AND GROUND CIRCUIT ...140

vem .. 140

VOM : Diagnosis Procedure 140

U1000 CAN COMM CIRCUIT so snsnssenne 143

Description 143

DTC Logic Senne 1493

Diagnosis Procedute «nnn son AB

U1010 CONTROL MODULE (CAN) ... 148

DTC Logic soon M4

Diagnosis Procedure .ncnanan eer)

POA00 COOLANT TEMPERATURE SENSOR

245

DTC Logic senns 148

Diagnosis Procedute «nnn sons AB

‘Component Inspection “a7

POAOB HIGH VOLTAGE CONNECTOR IN-

TERLOCK DETECT CIRCUIT sssssssses nesses 148

Description 148

DTC Logic 148

Diagnosis Procedure 148

POASD 12V BATTERY POWER SUPPLY ......152

DTC Logic . 182

Diagnosis Procedure — ves 182

POASE 12V BATTERY POWER SUPPLY ......154

DTC Logic 14

Diagnosis Procedure 154

Diagnosis Procedure on 188

POA94 DC/DC CONVERTER ... 159

DTC Logie

Diagnosis Procedure

POAAO SYSTEM MAIN RELAY .. 160

DTC Logie 160

Diagnosis Procedure 160

POAA1 SYSTEM MAIN RELAY + wsssscssssoes 165

DTC Logie 165

Diagnosis Procedure 165

POAA2 SYSTEM MAIN RELAY + 170

DTC Logic

Diagnosis Procedure

170

170

POAA4 SYSTEM MAIN RELAY -

DTC Logie

m2

172

Diagnosis Procedure 172

POAAS SYSTEM MAIN RELAY - wT

DTC Logic 17

Diagnosis Procedure 17

POAAG HIGH VOLTAGE SYSTEM ISOLA-

TION 179

Description 179

DTC Logic 179

Diagnosis Procedure 180

P1550, P1551, P1552 BATTERY CURRENT

SENSOR 187

DTC Logie snes 87

Diagnosis Procedure sen 8B

Component Inspection we. sen 90

P1554 BATTERY CURRENT SENSOR... 191

DTC Logic 191

Component Function Check 191

Diagnosis Procedure 191

Component inspection 193,

P1556, P1557 BATTERY TEMPERATURE

SENSOR 195

DTC Logie - fennne

Diagnosis Procedure sen 9B

Component Inspection we. 196

P155A BATTERY TEMPERATURE SENSOR. 197

DTC Logic 197

Diagnosis Procedure 197

Component Inspection 198

P1564 ASCD STEERING SWITCH 199

DTC Logic 109

Diagnosis Procedure 199

Component inspection (ASCD STEERING

SWITCH) 200

POASF 12V BATTERY POWER SUPPLY ......156

DTC Logie 458 P1572 BRAKE PEDAL POSITION SWITCH ...202

Revision: June 2014 Evc-3 2015 Leaf NAM

Ev

DTC Logic ToomnnB02 DTC Logic cnn BBS

Component Function Check =. "203 Diagnosis Procedure se 284

Diagnosis Procedure 208

Component inspection (Brake Pedal Position P312B EV SYSTEM RESTART ERROR .......237

Switoh) 208 DTC Logie ne

Component inspection (Stop Lamp Switch) ......207 Diagnosis Procedure : se 238

P1574 ASCD VEHICLE SPEED SENSOR ..... 208 P312C, P3130 TRACTION MOTOR INVERT-

Description “203 ER CONDENSER DISCHARGE ERROR ..

DTC Logic . . 208 DTC Logic

Diagnosis Procedure . 208 Diagnosis Procedure

P1805 BRAKE SWITCH 210 P312D QUICK CHARGE ERROR ..

DTC Logic 210 DTC Logic

‘Component Function Check 210 Diagnosis Procedure

Diagnosis Procedure 210

P312E READY OFF ERROR

Component Inspection (Stop Lamp Switch) wuinn21t PO Soe

P2122, P2123 APP SENSOR wwiennnsnnnnnn 213 Diagnosis Procedure

DTC Logic 213

Diagnosis Procedure 313 P312F CHARGE OFF ERROR esnsennnnnnn 243

Component Inspection (Accelerator Pedal Posi- DTC Logie 243

tion Sencor) 213 Diagnosis Procedure 24

P2127, P2128 APP SENSOR .. gig P3131 SYSTEM SHUTOFF ERROR ..

DTC Logic mene DTC Logic

Diagnosis Procedure “215 Diagnosis Procedure.

Component Inspection (Accelerator Pedal Posi P3135 SLIGHT COLLISION DETECTION

tion Sensor) - vovmenne 218” DTC Logic

P2138 APP SENSOR 219 Diagnosis Procedure

DTC Logie z ~ 219 P3137 CAR CRASH DETECTION ..

Diagnosis Procedure “219 " DTC Logic

Component Inspection (Accelerator Pedal Posi- Diagnosis Procedure

tion Sensor) - 2220

P3100 EV SYSTEM CAN COMMUNICATION. 221 anil (POWER DELIVERY MODULE) ..253

Description 221 DTC Logic 263

DTC Logic 221 Component Function Check 253

Diagnosis Procedure 222 Diagnosis Procedure 283

Porelse 223 P315C CHARGE RELAY .

ji DTC Logic

Diagnosis Procedure 223 Diagnose Procedure .

P3102 LI-ION BATTERY ... 224 p315E ABSIVDC .

Description +224" DTC Logie

DTC Logic ” vmnsnn824 Diagnosis Procedure 256

Diagnosis Procedure 224

P316A MOTOR SPEED ..

P3117 AIC SYSTEM ... 22 "OTC Logic oer

Description ; - 228 Diagnosis Procedure 257

DTC Logie ene 228

Diagnosis Procedure 227 P316C, P316D, P316E PDM (POWER DELIV-

P311C HIGH VOLTAGE CIRCUIT .. 228 eR rele, Le)

DTC Logic 228 °

Diagnosis Procedure 228 _ Diagnosis Procedure se

P312A EV SYSTEM CAN COMMUNICATION. 233 rere Leoe (POWER DELIVERY MODULE) .259

Description 283 Diagnosis Procedure 258

Revision: June 2014 Evc-4 2015 Leaf NAM

P3170, P3171 PDM (POWER DELIVERY

MODULE) 261

DTC Logic “261

Diagnosis Procedure 2261

P3172, P3173 PDM (POWER DELIVERY

MODULE) 262

OTC Logic 1 262

Diagnosis Procedure "262

P3175 VCM 263

DTC Logic 2.263

Diagnosis Procedure 1.263

P3176 TRACTION MOTOR INVERTER CON-

DENSER ...

DTC Logic

Diagnosis Procedure

264

264

264

Diagnosis Procedure 282

P318A ELECTRIC SHIFT 203

DTC Logie 283

Diagnosis Procedure 283

P318B ELECTRIC SHIFT 285

DTC Logie 285

Diagnosis Procedure 285

P318C ELECTRIC SHIFT .sssssssnsssessneonse 286

DTC Logie 288

Diagnosis Procedure 287

P318D CAN COMMUNICATION .. 288

DTC Logic 288

Diagnosis Procedure

P3191, P319C, P31A7 EV SYSTEM CAN

288

P3177 ECU ACTIVATION ERROR 269 COMMUNICATION nnnnnrnnennnnne 280

DTC Logie 269 DTC Logie 380

Diagnosis Procedure 289

TYPE 4 sssnsnnnsnnnnnsnnnnnsnnnnnnnns 270

P3193, P319E, P31A9 EV SYSTEM CAN

TYPE 1" Diagnosis Procedure avo P9193, PS19E, Pot vet

TYPE 2... DTC Logic 201

TYPE 2° Diagnosis Procedure 270 Diagnosis Procedure 201

TYPE 3... P3194, P319F, P31AA CAN COMMUNICA-

TYPE 5 : Diagnosis Procedure 271 TION ... 299

DTC Logic 203

P3178 ECU ACTIVATION ERROR ...

are ecu 273 iagnosis Procedure 203

Diagnosis Procedure 273 P3195, P31A0, P31AB CAN COMMUNICA-

P3179, P317A, P317B TRACTION MOTOR TION 298

INVERTER 275 Diagnosis Procedure ms

DTC Logie 275 Diasnost 7

Diagnosis Procedure 275 P3196, P31A1, P31AE EV SYSTEM CAN

P317D TRACTION MOTOR INVERTER ........276 COMMUNICATION a

DTC Logic ze BTC Logie ee

De roosdure 278 Diagnosis Procedure “297

P317E, P3180, P3182 LION BATTERY ......278 POyaT; AUAds PAID EV SYSTEM CAN

DTC Logic n27e CONN ne

agnosis Pr ge “|

Diagnosis Procedure “278 Diagnosis Procedure 209

P8183 LION BATTERY 378 P31AF, P31B3 EV SYSTEM CAN COMMUNI-

ogie 279

Diagnosis Procedure 1279 CATION swrsnnsnnnnnnnannnnnnnnnnne 30D

DTC Logic 300

P3187 ELECTRIC SHIFT . 280 Diagnosis Procedure 300

DTC Logie 280

Diagnose Procedure Zoo P31B0, P31B4 CAN COMMUNICATION ....... 302

DTC Logic “302

P3188 ELECTRIC SHIFT . 281 Diagnosis Procedure 302

DTC Logie 281

Bingnonn Procedure 31 P3182, P31B5 CAN COMMUNICATION .......304

DTC Logie 304

P3189 ELECTRIC SHIFT .... snene282 Diagnosis Procedure 304

PTE Leaie ~?82p31B6 CAN COMMUNICATION .. 308

Revision: June 2014 Evc-5 2015 Leaf NAM

Ev

DTC Losi. co Tans DIC Logie nnn

Diagnosis Procedure a “1308 Diagnosis Procedure »..vsswssvssnnnsnvnnencren 343

P31B7 CAN COMMUNICATION .. 308 P31DE SYSTEM MAIN RELAY

DTC Loaic.. e808 DTC LOgie rns

Diagnosis Procedure oo “308 Diagnosis Procedure

P31B8 EV SYSTEM CAN COMMUNICATION. 310 P31EO HIGH VOLTAGE CIRCUIT INTER-

DTC Logic 310 LOCK ERROR . 34

Diagnosis Procedure 310 Description wasn se aas

OTC Logic .. shonnnannnn 6

P31BA CAN COMMUNICATION wos 312 or

cen cae 312 Diagnosis Procedure. 346

Diagnosis Procedure 312 P31E1 HIGH VOLTAGE CIRCUIT INTER-

P31C5, P31C6 VCM ang LOCICERROR

DTC Logie : TU Brow. ae

Diagnosis Procedure oo “314 Biagnosis Procedure ».vssnssvsennsnsnneeeren 360

recs, 318 P31E5 VCM POWER SUPPLY

Diagnosis Procedure "318 ogneae piseedlne’

PS1CA, P31CB QUICK CHARGE RELAY .....318 _p31£7 RESTART INHIBITION

DTC Logi a8 No Leaie

Diagnosis Procedure 318 Dhagnoels cede

P31D3 MIC RELAY..... sat

DTC Logie oT a ER PUMP

Diagnosis Procedure 321 ae

Component Inspection (WIC Relay) 322 _ Diagnosis Procedure

P31D4 PRE-CHARGE RELAY ae POTS WATER PUMP

DTC Logic. ee’) ae

Diagnosis Procedure a Sag _ Disgnosis Procedire

P31D5 PRE-CHARGE RELAY os POU MATER PUMP

DTC Losic.. e826 Soejane

Diagnosis Procedure oo “323 _ Diagnosis Procedure

3106 Fis RELAY .. gai PSTEE REFRIGERANT PRESSURE SEN-

DTCL SOR

oat $3 pre Logie

Diagnosis Procedure Beene ccsdure

P3107 FIS RELAY .. 383_p31F2 AV INFORMATION MISMATCH ..

DTC Logie $88 DTC Logie ssn

Diagnosis Procedure Bee ae dure

P31D8 CHARGING CONNECTOR LOCKRE- cooing FAN

AY 6“ Component Function Check 369

eee 388 Diagnosis Procedure 260

agnosis Procadure 386 Component Inspection (Cooling Fan Motor)... 372

P31DB SYSTEM MAIN RELAY # ccsussnnne 389 Component Inspection (Cooling Fen Relay) ....272

DTC Logie 339

Diagnosis Procedure ne ve

P31DC SYSTEM MAIN RELAY - sax Component Inspection (M/C Relay) ama

DTC Logic . comm BIS CHG RELAY

Diagnosis Procedure oo ~341 Diagnosis Procedure on 378

P31DD PRE-CHARGE RELAY 343. Component Inspection (F/S CHG Relay) ssn. 377

Revision: June 2014 Evc-6 2015 Leaf NAM

CHARGING CONNECTOR LOCK RELAY .....378

Diagnosis Procedure 378

CHARGE PORT LID OPENER RELAY ..o.n..381

Diagnosis Procedure 381

‘Component Inspection (Charge Port Lid Opener

Actuator Relay) 388

REVERSE LAMP RELAY 384

‘Component Function Check ..

Diagnosis Procedure

384

384

‘Component Inspection (Reverse Lamp Relay) «386

AIC RELAY 387

Diagnosis Procedure 387

‘Component Inspection (A/C Relay) 388

CHARGING STATUS INDICATOR 300

‘Component Function Check 380

Diagnosis Procedure 380

IMMEDIATE CHARGING SWITCH sss sosose0.392

Diagnosis Procedure 302

‘Component Inspection (immediate Charging

Switch) 304

CHARGING CONNECTOR LOCK

‘Component Function Check ..

Diagnosis Procedure

Component Inspection (Charge Connector Lock

395

395

395

Actuator) nnnnennnnnnnnmnnnnnnnneseesee: 35

CHARGE PORT LID OPENER 397

‘Component Function Check 397

Diagnosis Procedure 397

‘Component Inspection (Charge Port Lid Opener

Actuator) 398

CHARGING CONNECTOR LOCK SWITCH ...399

Diagnosis Procedure 309

Component inspection (Charge Connedor Loek

Switch).

CHARGE PORT LID OPENER SWITCH

Diagnosis Procedure

A038

Gompenent Inspection (Charge Port Lid Opener’

Switch) ..

CHARGE PORT LAMP

Component Function Check’

Diagnosis Procedure

SYMPTOM DIAGNOSIS

EV CONTROL SYSTEM ..

‘Symptom index

407

READY Status Cannot Be Achieved 412

Unable to Travel

Low Electrical Consumption

Power Switch Does Not Turn OFF

No Regeneration

Decelerating Force Changes

Normal Charge Does Not Start

Timer Charge and Remote Charge Does Not Start

419

Immediate Charge Does Not Start 420

Normal Charge Is Not Completed 420

Quick Charge Does Not Start 421

Quick Charge Is Not Completed 421

Full Charge Cannot Be Achieved 422

Climate Ctrl, Timer Does Not Start 422

Remote climate control Does Not Start 423

NORMAL OPERATING CONDITION ...,

Description

REMOVAL AND INSTALLATION ............ 425

VEM os sssse

Exploded View

Removal and Installation

Revision: June 2014 Evc-7

2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Technicians Using Medical Electric woe coven

OPERATION PROHIBITION

WARNING:

+ Parts with strong magnet is used in this vehicle.

+ Technicians using a medical electric device such as pacemaker must never perform operation on the

Vehicle, as magnetic field can affect the device function by approaching to such parts.

NORMAL CHARGE PRECAUTION

WARNING:

a technician uses a medical electric device such as an implantable cardiac pacemaker or an

implantable cardioverter defibrillator, the possible effects on the devices must be checked with the

device manufacturer before starting the charge operation.

+ As radiated electromagnetic wave generated by PDM (Power Delivery Module) at normal charge

operation may affect medical electric devices, a technician using a medical electric device such as

implantable cardiac pacemaker or an implantable cardioverter defibrillator must not approach motor

room [PDM (Power Delivery Module)] at the hood-opened condition during normal charge operation.

PRECAUTION AT TELEMATICS SYSTEM OPERATION

WARNING:

+ If a technician uses implantable cardiac pacemaker or implantable cardioverter defibrillator (ICD),

avoid the device implanted part from approaching within approximately 220 mm (8.66 In) from Inte-

rior/exterior antenna.

+ The electromagnetic wave of TCU might affect the function of the implantable cardiac pacemaker or

the implantable cardioverter defibrillator (ICD), when using the service, etc.

+ If'a technician uses other medical electric devices than implantable cardiac pacemaker or implant-

able cardioverter defibrillator (ICD), the electromagnetic wave of TCU might affect the function of the

device. The possible effects on the devices must be checked with the device manufacturer before

TCU use.

PRECAUTION AT INTELLIGENT KEY SYSTEM OPERATION

WARNING:

+ If'a technician uses implantable cardiac pacemaker or implantable cardioverter defibrillator (ICD),

avoid the device implanted part from approaching within approximately 220 mm (8.66 in) from inte-

rlor/exterior antenna.

+ The electromagnetic wave of Intelligent Key might affect the function of the implantable cardiac

pacemaker or the implantable cardioverter defibrillator (ICD), at door operation, at each request

switch operation, or at engine starting.

+ Ifa technician uses other medical electric devices than implantable cardiac pacemaker or implant-

able cardioverter defibrillator (ICD), the electromagnetic wave of Intelligent Key might affect the

function of the device. The possible effects on the devices must be checked with the device manu-

facturer before Intelligent Key use.

Point to Be Checked Before Starting Maintenance Work neoe concn

The high voltage system may starts automatically. It is required to check that the timer air conditioner

and timer charge (during EVSE connection) are not set before starting maintenance work.

NOTE:

If the timer air conditioner or timer charge (during EVSE connection) is set, the high voltage system starts

automatically even when the power switch is in OFF state.

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" ws

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER’, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision, This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

Revision: June 2014 Evc-8 2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

system uses the Seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual

WARNING:

* To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSANJINFINITI dealer.

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal fig

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

+ Do not use electrical test equipment on any circult related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

+ When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

+ When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Procedure without Cowl Top Cover

‘When performing the procedure after removing cow! top cover, cover

the lower end of windshield with urethane, ete to prevent damage to

windshield

Precautions for Removing Battery Terminal

+ When removing the 12V battery terminal, turn OFF the power

switch and wait at least 5 minutes

NOTE:

ECU may be active for several minutes after the power switch is

tured OFF. if the battery terminal is removed before ECU stops,

then @ DTC detection error or ECU data corruption may ocour.

+ Always disconnect the battery terminal within 60 minutes after

tuming OFF the power switch. Even when the power switch is

OFF, the 12V battery automatic charge control may automatically

start after a lapse of 60 minutes from power switch OFF.

+ Disconnect 12V battery terminal according to the following steps

WORK PROCEDURE

4. Check that EVSE is not connected

NOTE:

If EVSE is connected, the air conditioning system may be automatically activated by the timer A/C func-

tion.

2. Tur the power switch OFF > ON —> OFF. Get out of the vehicle. Close all doors (including back door)

3. Check that the charge status indicator lamp does not blink and wait for 5 minutes or more.

NOTE:

Revision: June 2014 Evc-9 2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

If the battery is removed within § minutes after the power switch is turned OFF, plural DTCs may be

detected.

4. Remove 12V battery terminal within 60 minutes after turning the power switch OFF > ON — OFF.

CAUTION:

+ After all doors (including back door) are closed, if a door (including back door) is opened before

battery terminals are disconnected, start over from Step 1

+ After turning the power switch OFF, if “Remote A/C” is activated by user operation, stop the air

conditioner and start over from Step 1.

NOTE:

Once the power switch is turned ON > OFF, the 12V battery automatic charge control does not start for

approximately 1 hour.

+ For vehicles with the 2-batteries, be sure to connect the main battery and the sub battery before turning ON

the power switch.

NOTE:

If the power switch is turned ON with any one of the terminals of main battery and sub battery disconnected,

then DTC may be detected.

+ After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC

NOTE:

The removal of 12V battery may cause a DTC detection error.

High Voltage Precautions

DANGER:

Adsince hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of

electric shock, electric leakage, or similar accidents if the high voltage component and vehicle are

handled incorrectly. Be sure to follow the correct work procedures when performing inspection and

maintenance.

WARNING:

+ Be sure to remove the service plug in order to disconnect the high voltage circuits before perform-

ing inspection or maintenance of high voltage system harnesses and parts.

+ The removed service plug must always be carried in a pocket of the responsible worker or placed in

the tool box during the procedure to prevent the plug from being connected by mistake.

+ Be sure to wear insulated protective equipment before beginning work on the high voltage system.

+ Never allow workers other than the responsible person to touch the vehicle containing high voltage

Parts. To keep others from touching the high voltage parts, these parts must be covered with an insu-

lating sheet except when using them.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise

Instructed in the Service Manual. A malfunction may occur If this Is not observed,

HIGH VOLTAGE HARNESS AND EQUIPMENT IDENTIFICATION

All the high voltage hamesses and connectors are orange. The Li-ion battery and other high voltage devices

include an orange high voltage label. Never touch these harnesses and high voltage parts.

HANDLING OF HIGH VOLTAGE HARNESS AND TERMINALS

Immediately insulate disconnected high voltage connectors and terminals with insulating tape

REGULATIONS ON WORKERS WITH MEDICAL ELECTRONICS

WARNING:

The vehicle contains parts that contain powerful magnets. If a person who is wearing a heart pace-

maker or other medical device is close to these parts, the medical device may be affected by the mag-

nets. Such persons must not perform work on the vehicle.

PROHIBITED ITEMS TO CARRY DURING THE WORK

Hybrid vehicles and electric vehicles contain perts with high voltage and intense magnetic force. Never carry

metal products and magnetic recording media (e.g. cash card, prepaid card) to repair/inspect high voltage

parts. If this is not observed, the metal products may create a risk of short circuit and the magnetic recording

media may lose their magnetic recording

POSTING A SIGN OF “DANGER! HIGH VOLTAGE AREA. KEEP OUT”

Revision: June 2014 Evc-10 2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

To call the attention of other workers, indicate “High voltage work in progress. Do not touch!” on vehicles

where work is being performed on the high voltage systems.

roBueyo ul UOSded

iHONOL LON Od

“SS3Y5O0ud NI YIVd4u

ASVLIOA HDIH

‘YAONVG

DANGER:

HIGH VOLTAGE

REPAIR IN PROGRESS.

DO NOT TOUCH!

Person in charge:

Copy this page and put it after folding on the roof of the vehicle in service.

General Precautions

+ Never disassemble VCM.

+ If the 12V battery is disconnected, the diagnostic information will be lost within 3 minutes.

Revision: June 2014 Evc-11 2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

+ When connecting or disconnecting harness connectors into

gr Tom VCM, take care not to damage pin terminals (bend or

reak)..

Check that there are not any bends or breaks on VEM pin ter-

minal, when connecting harness connectors.

After performing each TROUBLE DIAGNOSIS, perform DTC

confirmation procedure or Component Function Check.

The DTC should not be displayed in the DTC Confirmation

Procedure if the repair is completed. The Component Func-

tion Check should be a good result if the repair is completed.

+ When measuring ECU signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECU power transistor.

Revision: June 2014 Evc-12

2015 Leaf NAM

PRECAUTIONS

< PRECAUTION >

* When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body.

—,

eS

E5|o00000@

Revision: June 2014 Evc-13 2015 Leaf NAM

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Commercial Service Tools

Tool name

Description

Insulated gloves

Leather gloves

Removing and instaling high valiage com

Ponents

[Guaranteed insulation pertormance tor

‘1000V3008

+ Removing and installing high votage

‘components

+ Protect insulated gloves

[Use leather gloves tha can fasten the wist

tight)

insulated safety st \ Removing and instaling igh voltage com.

Insulated safety shoes \¢ Beno

Y

+ Removing and installing high votage

‘components

Salety glasses + To protect eye from the spatter on the

Work to electric line

[ANSI 87.1]

+ Removing and installing high vetage

Face shield Semponents

Insulated helmet

Revision: June 2014

Evc-14

+ To protect face trom the spatter on the

Work to electric line

Removing and instaling high valiage com

Ponents

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts Location

MOTOR ROOM COMPARTMENT

Electric power train [By Cooling fan assembly and radiator gy Charge por

assembly

‘Component Parts Description

Ne. Component pars Function

@ | FSreay (POM EMR) VG-18, "FS Rela”

@ | MCway VC-18, "WIC Relay”

@ | Reverse amp relay EVG-19, "Reverse Lamp Relay"

@ | 12vbattery G82, “Exploded View

© _ Eeecticaly-criven intligent brake unit ‘BR12,"Eleccally-diven Inteligent Brake Unit

@ _| Retigerant pressure sensor (wth eat pump) EVG-19, Refrigerant Pressure Sensor

Revision: June 2014 Evc-15 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Conran pas Fancan

© _| Sharp par opener ctr FEE Charge Pat Opener Actor

© | Nereay VG, 80 Rela?

@ | coomgtnniy Tre snr nr Se Fer nae

@ | FSCHOray VCS 7S CHO Rey”

@ _| Paving actuator aay TALE, Pang Actuator Ra A

@ _|Retigerant pressure sensor wha! pare) VG 18 Regent Pressure Sensor

€& | faery cure snser(nbatey epee sensny | FVGZ0 ain Curtat Sensor tan Bates:

@ _| Garg connector ck lay (POM ER) FV, “Charge Conecor Lack Relay

@ | POM (over Bevery Modu) E12 POM Povey Moai

@ | Traeton motor ener "S19, "acon Meer nvee

@® Traction motor ‘TMS-18, "Traction Motor”

@ | Paving acter TALS Pains Acar

@ _| Cootntteperate sener FEZ, Conan Temperate Sensor

@ _| Coal on cone nde TEVEZ, Coning Fan Cont Moai

@ || Bere water pune EVE,“ water Put

@ | Charge connector lock actuator ‘VC-14, "Charge Connector Lock Actuator”

@ | Chage por or visu “cage Bo Loe

@ | Quek erage por wea cha Port

® Charge port lid opener actuator ‘DLK-22, "Charge Port Lid Opener Actuator”

@ _| Neal cage pot ver, chee Fert

BODY COMPARTMENT

Revision: June 2014

Evc-16

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

I). Lbon battery junction box: Accelerator pedal and brake pedal

Upper part

‘Component Parts Description

¥ Compare Farce

© _| Wiener conte 6 lo at Conte?

~ AVZHT. “TO Nagaten wind BOSE)

© TOU lentes commision ne 1 AVSEt aur Nangaton aim B0Se)

1 Aisi Tat eaten

@ ver conta unt Seba Sore uot shot te

@ _| BOW (6 Conte Node} 305.5, RODY CONTRO SYSTEM: SiienDescnion®

@ Charge striate vO=5. "Chai Sas nical

@ | ASCDsetng sth #20 :ASOD Sena Sit

© Continaton eter £022, "Conbraton eter

@ _— Charge port lid opener switch DLK-22, "Charge Port Lid Opener Switch"

@ Crags connect sen "hate nner Lock Sue

@ loess rg sen C8 “mest Cai See

@ | Peston ssn TDS5 2 Psion Sir

@ SHecorinseae "5, "Sleor nator

@ | Bose snnsoecor 34," Set

Revision: June 2014 EVc-17 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

No. ‘Component parts Function

+ HACG-25,"AIG Auta Amp [Auto AIC (with heat pump]

® | ACautoamp. + HAC226, "NC Auto Amp. [Auto AIC (without heat

pump

@ _| VOM \enicle contol module) EVC-18 "vow"

@ | System main relay 2 EVO-19, "System Main Relay 2"

@ | Precharge relay EVG-19, Pre-charge Relay”

@ | System maireiay 4 G19, “System Man Relay 7

@ | Sopiamp swteh EVC20."Sop Lamp Swltt

@ _| Brake pedal postion ston 2 :

®

Accelerator pedal position sensor

VCM ‘nvo0 corenceoesses

VECM (Vehicle control module) judges the vehicle status according to

signals from various sensors and ECUs, and VCM controls EV sys~

tem in a comprehensive manner, VCM also has a gateway function

for EV system CAN communication and CAN communication, which

enables communication between an ECU performing EV system

CAN communication and an ECU performing CAN communication.

In addition, VCM contains an electric shift control module and per-

forms shift control

For electric shift control module. Refer to TM-31, “Description”.

MIC Relay sesounvnain

‘The MIC (motor control) relay supplies the main power to the EV system. VM activates the M/C relay and

supplies power to the EV system when the EV system needs to be started.

F/S Relay

The F/S (fail-safe) relay supplies the driving power for the system main relay inside the

activates the F/S relay to make the system main relay controllable when the system is set to READY or when

the battery is charged.

‘When VCM detects a malfunction in the EV system and judges that the system main relay must be deacti-

vated, VCM deactivates the FIS relay to shut off the system main relay driving power.

F/S CHG Relay ‘nre swoconesnes

The F/S CHG (fail-safe charge) relay supplies the driving power for the quick charge relay inside the PDM

(Power Delivery Module). When VCM recognizes a quick charge start, VCM activates the F/S CHG relay to

make the quick charge relay operable. During driving, F/S CHG relay remains OFF so that the quick charge

relay is not activated,

Charge Port Lid Opener Actuator Relay en

The charge port lid opener actuator relay is controlled by VCM and supplies power to the charge port lid

opener actuator.

Charge Connector Lock Relay sesoune

The charge connector lock relay is controlled by VCM and supplies power to the charge connector lock actua~

tor.

Revision: June 2014 Evc-18 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

AC Relay

The AVC (air conditioner) relay supplies power to the air conditioner system. VCM activates the A/C relay to

supply power to the air conditioner system when the power is turned on or an air conditioner operation request

signal is received.

System Main Relay 1

The system main relay 1 is integrated in the Li-ion battery and controlled by VCM. The system main relay 1 Jae

connects and disconnects the high-voltage circuit (+) side and Li-ion battery.

It the pre-charge to the inverter condenser is complete while high voltage power is supplied, VCM activates

the system main relay 1 to supply power from the Li-ion battery to the EV system. Also when charging, VCM

activates the system main relay 1 to supply power from an external charger to the Li-ion battery.

System Main Relay 2 secon

‘The system main relay 2 is integrated in the Li-ion battery and controlled by VCM. The system main relay 2

connects and disconnects the high-voltage circuit (~) side and Li-ion battery. When high voltage power is sup-

plied, VCM activates the system main relay 2 fo supply power from the Li-ion battery to the EV system. When

charging, power from an external charger is supplied from the system main relay 2 to the Li-ion battery.

Pre-charge Relay secon

‘The pre-charge relay is integrated in the Li-ion battery and controlled by VCM. When high voltage power is

required, VCM activates the pre-charge relay before activating the system main relay to prevent abrupt appli-

cation of high voltage.

Reverse Lamp Relay woos

When VCM receives a reverse range information from the electric shift selector, VOM activates the reverse

lamp relay to turn ON the reverse lamp.

Accelerator Pedal Position Sensor

The accelerator pedal sensor is integrated with the accelerator

pedal. This sensor is a potentiometer that detects the acceleration

Pedal stroke, converts it to a voltage signal, and transmits the signal

to VCM. The sensor transmits its signals through dual lines, provid-

ing a minimum driving function even if either line malfunctions.

Upon a POWER ON cycle, VCM leams the fully closed position of

the acceleration pedal from the accelerator pedal position sensor

signal.

‘Rassloralor pedal poslion sensor

Sensor 1

Sensor 2

je8 =—= Deprese

Accelerator pedal operation

Refrigerant Pressure Sensor e006

‘The sensor uses an electrostatic volume pressure transducer to convert refrigerant pressure to voltage, VCM

calculates refrigerant pressure based on the voltage and sends a refrigerant pressure signal to the A/C auto

amp. via EV system CAN communication.

Co _ monomer 7H

bf z /

sont nominin i -

S Sor a

HHL) © Nese tira pon o ue

‘ wba ora8fene

Dona Cin maoes nen

Revision: June 2014 Evc-19 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Stop Lamp Switch

The stop lamp switch is installed to the brake pedal bracket. The

switch detects the state of the brake pedal and transmits an ON/OFF

signal to VM.

The contact of the stop lamp switch is usually open. When the brake

pedal is depressed, it closes and the stop lamp switch signal is

transmitted as a voltage signal

ASCD Steering Switch

ASCD steering switch has various values of electrical resistance for

each button. VCM reads voltage variation of switch, and determines

which button is operated

Brake Pedal Position Switch

The brake pedal position switch is installed to the brake pedal

bracket. The switch detects the state of the brake pedal and trans-

mits an ON/OFF signal to VM.

‘The contact of the brake pedal position switch is usually closed

‘When the brake pedal is depressed, it opens to disconnect the cit-

cuit, and shut off the output voltage. This constitutes an brake pedal

position switch signal.

Battery Current Sensor (With Battery Temperature Sensor)

BATTERY CURRENT SENSOR

The battery current sensor is installed to the negative cable of the

battery. The battery current sensor detects the battery charge/dis-

charge current and transmits signals to VCM. VCM judges the bat-

tery load based on these signals and controls the power generation

by converting the target generation voltage to @ power generation

command signal and transmitting it to the DC/DC converter.

CAUTION:

Never connect the electrical component or the ground wire

directly to the battery terminal. The connection causes the mal-

function of the power voltage variable control, and may cause

the battery to discharge.

BATTERY TEMPERATURE SENSOR

Battery temperature sensor is integrated in battery current sensor.

The sensor measures temperature around the battery,

Evc-20

Revision: June 2014

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

This sensor uses a thermistor and its electrical resistance varies as the temperature varies. VOM detects a

voltage change caused by the change in electrical resistance.

Reference date

Temperature PC (FIL Vorage ) Resistance (KO)

25077) 3.998 19-24

90 (184) 0.968 0.222 -0.258

Coolant Temperature Sensor

‘The coolant temperature sensor is detects the coolant temperature

This sensor uses a thermistor that changes its electrical resistance

according to the temperature. VCM detects a voltage change

according to electrical resistance change.

se

Aeceaae

-Reterence vatue>

Coolant temperature PO CFL Votage Vy Resistance (ka)

10 (14) 44 70-114

20 (68) 35 235-273

50122) 22 068 - 1.00,

90 (184) 09 0.236 - 0.260

Electric Water Pump

The electric water pump @ feeds coolant by pressure, which circu-

lates in the high voltage system cooling circuit. They are controlled

by VCM independently so that the amount of pressure feed is

adjusted according to the vehicle speed and water temperature.

The electric water pump also integrates an interface circuit that mon-

itors the pump function for any malfunction, and it transmits a mal-

function signal to VOM if necessary.

38

oe ee ee

B & Bout toed

‘Tonporaure Cr

Revision: June 2014 Evc-21

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Cooling Fan Control Module roo cesmreeset

The cooling fan control module is mounted on the cooling fan and

drives the cooling fan motor.

The cooling fan control module conducts communication between

CM via the PWM communication. The cooling fan control module

drives the cooling fan motor so that the cooling fan speed is con-

trolled in accordance with the control signal from VOM.

Combination Meter nce cuowacooses

VOM controls the following Wems on the combination meter,

LI-ION BATTERY INFORMATION

Licion Battery Capacity Level Gauge ®

VCM receives the Li-ion battery capacity signal from the Li-ion battery controller, and VCM transmits the signal

to the combination meter to display the maximum capacity of the Li-ion battery. When the capacity of the Lion

battery decreases with age and usage, the level of the gauge is also decreased.

Li-ion Battery Available Charge Gauge @

\VCM receives the Li-ion battery available charge signal from the Li-ion battery controller, and VCM transmits

the signal to the combination meter to display the available Li-ion battery charge to run the vehicle.

Licion Battery Temperature Gauge @

\VCM receives the Li-ion battery temperature signal from the Li-ion battery controller, and VCM transmits the

signal to the combination meter to display the Li-ion battery temperature.

Distance Range ®

‘The driving range (km or miles) provides an estimated distance that the vehicle can be driven before recharg-

ing is necessary. The driving range is constantly being calculated, based on the amount of available Li-ion bat-

tery charge and the actual power consumption average,

VVCM calculates average electricity consumption at a specified travel distance, according to total power con-

sumption of the vehicle. Based on the average electricity consumption and the Li-ion battery available charge

signal received from the Li-ion battery, VCM calculates driving range and transmits a driving range signal to

the combination meter.

POWER METER

Maximum Power ©

Revision: June 2014 Evc-22 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

VOM receives a maximum motor output power signal from the traction motor inverter and a maximum regen-

erative power signal from the Li-ion battery controller. VCM transmits these signals to the combination meter

and displays the upper limit of available output power and regenerative electric power.

Current Motor Power @

VCM receives the current motor power signal from the traction motor inverter, and VCM transmits the signal to

the combination meter to display the power currently being output.

ECO Indicator roe conse esa

‘The ECO indicator shows the instantaneous ECO drivabilty in the

instant ECO indicator @, and shows the cumulative ECO drivabilty,

during 1 trip in the ECO tree @.

For information regarding control, refer to EVC-66, "ECO INDICA

‘TOR CONTROL : System Description’.

Approaching Vehicle Sound for Pedestrians (VSP)

VSP informs the user of various information by electronic sounds.

In the following cases, VCM transmits a operation signal to VSP.

‘Conation Operation satus

EVSE Is connected to the normal charge port “Short beep (once)

When normal charging starts

‘Short beeps in sequence (tice)

When timer charge goes Into standby mode pe insesi ?

Press the charge pot lid opener switch or the charge por lid open-

er button of intligent key Three short beeps

(Hazard ana buzzer reminaer)

When EVSE Is not connected corecty Three short beeps continue repeatedly for 30 seconds

For details of the charge sound system of VSP, Refer to VSP-22, "CHARGE SOUND SYSTEM : System

Description”.

WARNING LAMPS/INDICATOR LAMPS

WARNING LAMPS/INDICATOR LAMPS : EV System Warning Lamp

DESIGN/PURPOSE

The EV system warning lamp turns ON if a maffunction occurs with

the EV system.

BULB CHECK

For approximately 2 seconds after the power switch is turned ON.

SYNCHRONIZATION WITH MASTER WARNING LAMP,

Revision: June 2014 EVC-23 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

‘Synchronization is applied.

For master warming lamp, refer to MWI-31, "MASTER WARNING LAMP : System Description",

OPERATION AT COMBINATION METER CAN COMMUNICATION CUT-OFF OR UNUSUAL SIG-

NAL

For actions on CAN communications blackout in the combination meter, refer to MWI-64, "Fail- Safe"

SYSTEM DIAGRAM

==)

(Sascen a [ORG

Each estar Paco

tf

| ES

Emenaonai un

eee aT VE |

contrat o TC

Pair awer aren mos

Eveysiem

‘queen

Ev eytam waning am

Tract Wat Fare

gern of ing ON

‘FC detston|

Ev eysom warning ame

ten easy conuaior

sexe CAN omrmunicalon eV syst CAN communion,

SIGNAL PATH

+ IfVCM detects a malfunction or receives an EV system warning lamp request signal from any other ECUs,

\VCM transmits an EV system waning lamp request signal to the combination meter via CAN communica-

tion,

+ Combination meter illuminates EV system warning lamp according to the input signal

LIGHTING CONDITION

‘When all of the following conditions are satisfied:

+ Power switch: ON or READY

+ EV system-telated DTC is confirmed,

NOTE:

For DTCs that the EV system waming lamp turns ON, refer to EVC-103. "DTC Index".

SHUTOFF CONDITION

When any of the following conditions are satisfied:

+ Power switch: OFF

+ DTC is erased.

NOTE:

+ The warning lamp may turn ON even after the power switch is turned OFF, depending on a detected DTC.

+ For DTC erasing method, refer to EVC-73, "CONSULT Function",

Revision: June 2014 Evc-24 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

TIMING CHART

Power sch

orr

ore

on

Eveysem

orr i

‘OFF (oven ater matunction is removed)

WARNING LAMPS/INDICATOR LAMPS : Low Battery Charge Warning Lamp

DESIGN/PURPOSE

The low battery charge warning lamp turns ON when the Li-ion bat-

tery remaining energy is lowered.

BULB CHECK

Not applicable

SYNCHRONIZATION WITH MASTER WARNING LAMP

Synchronization is applied

For master warning lamp, refer to MWI-31, "MASTER WARNING LAMP : System Description”

OPERATION AT COMBINATION METER CAN COMMUNICATION CUT-OFF OR UNUSUAL SIG-

NAL

For actions on CAN communications blackout in the combination meter, refer to MWI-64, "Fail-Safe"

Revision: June 2014 Evc-25 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

SYSTEM DIAGRAM

Un baton,

renaines enegy pal

Low van cargo

naming amp request sia. | Corinaon rater

ow bakery evar

‘anng ane

[ERED | CAN cammuncson or EV system CAN commen,

SIGNAL PATH

+ LBC transmits a Li-ion battery remained eneray signal to VCM

+ VCM calculates a remaining Li-ion battery power according to a signal received from LBC. When judging low

remaining battery power, VCM transmits @ low battery charge warming lamp request signal to the combina~

tion meter.

LIGHTING CONDITION

When all of the following conditions are satisfied:

+ Power switch: ON or READY

+ When Li-ion battery remaining energy is Approx. 4 kWh or less.

SHUTOFF CONDITION

When Li-ion battery remaining energy recovers to 4.5 kWh or more.

TIMING CHART

aby

ow Lon Recovery of ion

Sey power bear Somer

tern ee

Low baler charge

‘rome ome

ore

rage warns

WARNING LAMPS/INDICATOR LAMPS : Plug In Indicator Lamp

DESIGN/PURPOSE

Revision: June 2014 Evc-26 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

The plug in indicator lamp turns ON when a charge connector is con-

nected to the normal charge port or the quick charge port.

BULB CHECK

For approximately 2 seconds after the power switch is turned ON.

SYNCHRONIZATION WITH MASTER WARNING LAMP,

Not applicable

SYSTEM DIAGRAM

LEVSE comnacg signal

Pom ‘Quck srg carnecig ig

Pome stnery Mei)

vom Comsioation meter

cme EY systom CAN communication,

SIGNAL PATH

+ When the charge connector is connected to the normal charge port, PDM (Power Delivery Module) transmits

an EVSE connecting signal to VCM

+ When the charge connector is connected to the quick charge port, PDM (Power Delivery Module) transmits

a quick charger connecting signal to VOM

+ When receiving an EVSE connecting signal or quick charger connecting signal, VCM supplies power to the

plug in indicator lamp located in the combination meter and turns ON the plug in indicator lamp.

NOTE:

When EVSE is connected to the normal charge port, the indicator lamp turns OFF if no operation is per-

formed for ten consecutive seconds or more.

LIGHTING CONDITION

‘The charge connector is connected to the normal charge port or the quick charge port.

BLINKING CONDITION

While charging

SHUTOFF CONDITION

‘When any of the following conditions are satisfied:

+ No operation for 10 seconds or more after connecting EVSE

+ Disconnect charge connector.

Revision: June 2014 EVC-27 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

TIMING CHART

Power teh

comet

one

ones

cores

ora

Pid

et

coro

on

Pugin [] [

faa ane

ore L

a cnc Inds cage dct cg

Serna _

WARNING LAMPS/INDICATOR LAMPS : Power Limitation Indicator Lamp

DESIGN/PURPOSE

The power limitation indicator lamp turns ON when the traction motor

output is limited

BULB CHECK

For approximately 2 seconds after the power switch is turned ON.

SYNCHRONIZATION WITH MASTER WARNING LAMP

Synchronization is applied

For master warning lamp, refer to MWI-31, "MASTER WARNING LAMP : System Description’

OPERATION AT COMBINATION METER CAN COMMUNICATION CUT-OFF OR UNUSUAL SIG-

NAL

For actions on CAN communications blackout in the combination meter, refer to MWI-64, "Fail-Safe".

Revision: June 2014 Evc-28 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

SYSTEM DIAGRAM

carne: CAN canmrunicason o EV stm CAN commune,

Ev

SIGNAL PATH

+ The traction motor inverter transmits a motor torque limit signal to VCM when the traction motor needs to be

protected

+ LBC transmits a motor torque limit signal o VCM when Li-ion battery cannot output power normally

+ When receiving a motor torque limit signal from the traction motor inverter or LBC, VCM transmits a power

limitation indicator lamp request signal to the combination meter.

+ The combination meter turns ON the power limitation indicator lamp according to the signal.

LIGHTING CONDITION

For lighting condition, refer to EVC-49, "MOTOR POWER CONTROL : System Description’.

SHUTOFF CONDITION

‘The traction motor or Li-ion battery returns from the output limiting state

TIMING CHART

READY

Pomerat on

on

nal ever

ore

Motor tre

poser ition

Spal BC) cre

on :

Io crock vipa requested uputttaton

ea Srtacken sor weer requosod by LBC

WARNING LAMPS/INDICATOR LAMPS : Ready To Drive Indicator Lamp

DESIGN/PURPOSE

Revision: June 2014 Evc-29

2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

The READY to drive indicator lamp indicates that the vehicle is in a

state allowing vehicle travel.

BULB CHECK

Not applicable

SYNCHRONIZATION WITH MASTER WARNING LAMP.

Not applicable

SYSTEM DIAGRAM

ecw |___necaoy__

vowon ower ON pome uny

vou

Han orage

we (Secnrge pet gal

Hh otage

TTasionmaer —|_ Secrtoe sort gal

meme | CA cormaricaton or syst GAN comin

SIGNAL PATH

+ BCM transmits a READY signal to VCM when the driver operates the power switch to READY.

+ The high voltage circuit is connected when VCM receives a READY signal. When the high voltage circuit is

connected normally, LBC and the traction motor inverter transmit a high voltage discharge permit signal to

cM.

+ When receiving a high voltage discharge permit signal, VCM judges that the vehicle is in a drivable condition

and transmits a READY to drive indicator lamp request signal to the combination meter for turning ON the

READY to drive indicator lamp,

LIGHTING CONDITION

+ Vehicle: READY state.

SHUTOFF CONDITION

+ Power switch: OFF

+ When a malfunction occurs in EV system.

BLINKING CONDITION

+ When operating from power switch ON to READY

Revision: June 2014 Evc-30 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

TIMING CHART

READY

Shingo EADY

Sacra oe 1.1.

Bicking un the nceatee varie a eto READY

Ev

WARNING LAMPS/INDICATOR LAMPS : 12V Battery Charge Warning Lam|

DESIGN/PURPOSE

The 12V battery charge warning lamp tums ON when a matfunction

‘occurs in the DC/DC converter simultaneously with @ 12V battery

voltage drop.

BULB CHECK

For approximately 2 seconds after the power switch is turned ON.

SYNCHRONIZATION WITH MASTER WARNING LAMP,

Synchronization is applied

For master warning lamp, refer to MWI-31, "MASTER WARNING LAMP : System Description".

OPERATION AT COMBINATION METER CAN COMMUNICATION CUT-OFF OR UNUSUAL SIG-

NAL

For actions on CAN communications blackout in the combination meter, refer to MWI-64, "Fail-Safo"

SYSTEM DIAGRAM

120 batery

(Pou Dery Mose)

lacinc conn sa a

ire soc]

[Dee conerer |

12 pata

Tacgementer —] | empe wamra we [Combiner wer

turing ON eaves sa

tevtatery

ange nani amp

‘=> CAN communication o EV stm CAN conmuncaten

Revision: June 2014 EVC-31

2015 Leaf NAM

COMPONENT PARTS,

< SYSTEM DESCRIPTION >

SIGNAL PATH

+ VCM monitors the status of DC/DC converter by receiving a DC/DC converter status signal from PDM

(Power Delivery Module)

+ When detecting @ malfunction in the DC/DC converter simultaneously with a 12V battery voltage drop, VCM

transmits a 12V battery charge warning lamp request signal to the combination meter for turning on the 12V

battery charge waming lamp.

LIGHTING CONDITION

‘When any of the following conditions are satisfied:

+ Power switch: ON.

+ When VCM detects a malfunction in the DG/DC converter during the READY state simultaneously with a

12V battery voltage drop (approximately 12.5 V or less) for a few seconds.

NOTE:

+ When 12V battery voltage drops sharply while in READY state, the READY state is also cancelled.

+ When 12V battery voltage becomes low, the 12V battery charge warning lamp turns ON and the buzzer

sounds if the shift position is notin P position.

SHUTOFF CONDITION

When all of the following conditions are satisfied

+ When 12V battery voltage retums to normal, the 12V battery charge waming lamp turns OFF.

+ The DC/DC converter operates normally

TIMING CHART

Ausomate READY

eam ‘anestson

Powe en on

of

BCC eemener

oma

Shap votage sp in

{av taney Testo ‘ev oan,

vetage value

ot :

12 baer cha

veanina en

‘ub check Power atch On 1 2V baer tare wag

‘Go06 conererhopeave)

WARNING/INDICATOR (ON INFORMATION DISPLAY)

WARNING/INDICATOR (ON INFORMATION DISPLAY) : DC/DC Converter Warning

DESIGN/PURPOSE

DCIDC converter warning wars the driver of 12V battery voltage drop.

Revision: June 2014 Evc-32 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

Symbar Message

+ Stop vehicle"

+ Apply parking brake’? ev

“7; When 12V battery voltage drops while driving.

*2: When 12V battery voltage drops with the shift position not in P position

SYNCHRONIZATION WITH MASTER WARNING LAMP

Synchronization is applied

For master warning lamp, refer to MWI-31, "MASTER WARNING LAMP - System Description”.

SYNCHRONIZATION WITH WARNING CHIME

Synchronization is applied

For warning chime, refer to EVC-37, "WARNING CHIME ; DC/DC Converter Warning Chime".

SYSTEM DIAGRAM

vom

wees oo

chic she sco

‘oN [C/O comerter weming request signa

tev patery Cembinason meter

change wary amp

“neo :CAN communication

SIGNAL PATH

+ VCM monitors 12V battery voltage, and ifthe voltage drops, then VCM transmits a DC/DC converter warning

request signal to the combination meter to display a DC/DC converter warning.

+ When receiving a P range signal fram the electric shift selector, VCM cancels a DC/DC converter warning

WARNING/INDICATOR OPERATING CONDITION,

When all of the following conditions are satisfied:

+ Shift position: Except P range

+ 12V battery voltage stays low (approximately 10 - 12 V or less)’ for a few consecutive seconds.

{ Tiugsnoe vetage depends on vehicle speeds

When 12V battery voltage drops sharply while in READY state, the READY state is also cancelled

WARNING/INDICATOR CANCEL CONDITION

When any of the following conditions are satisfied

+ Shift position: P range

+ The 12V battery voltage retums to approximately 12.5 V or more.

Revision: June 2014 EVC-33 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

TIMING CHART.

owe

stp

tev botany Trrstolt

veep ve

PPpoaten

‘hit posilon

xcs

Poston

on

Pang re

Fr

Pasting

2¢10C eomaner Mau

ee ‘Stop requst

FF i

Sem Paring bake

Irseation ——oparatenmaestion

on

Tah pias one

uate (eorenucis ore)

cre

WARNING/INDICATOR (ON INFORMATION DISPLAY) : Low Battery Charge Warning

DESIGN/PURPOSE

Low battery charge warning is displayed when Li-ion battery power becomes low.

‘Symbor Message

= Batiery levels iow

SYNCHRONIZATION WITH MASTER WARNING LAMP

Synchronization is applied.

For master warning lamp. refer to MVVI-31. "

SYSTEM DIAGRAM

vow

eT errr

en

partes ale | cnn

mm | CAN communication of EV system CAN commision

SIGNAL PATH

+ LBC transmits a Li-ion battery remaind energy signal to VCM.

Revision: June 2014 Evc-34 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

* VCM calculates a remaining L-ion battery power according to a signal received from LBC. When judging low

remaining battery power, VCM transmits a low battery charge waming lamp request signal to the combina~

tion meter.

WARNING/INDICATOR OPERATING CONDITION

When all ofthe following conditions are satisfied

+ Power switch: ON or READY

+ When Li-ion battery power is 4 kWh or less.

WARNING/INDICATOR CANCEL CONDITION

When Li-ion battery power returns to 4.5 kWh or more,

TIMING CHART

Low battery charge warning is displayed in synchronization with the low battery charge warning lamp.

Ev

Pome wtih on

Low Lion Recovery a en

‘ron Testo valve NX x

on i

Low satay coarge

wang are

WARNING/INDICATOR (ON INFORMATION DISPLAY) : Power Limitation Warning

DESIGN/PURPOSE

Power limitation warning shows that traction motor output is limited.

Symbol Message

= Motor power I inited

SYNCHRONIZATION WITH MASTER WARNING LAMP.

Synchronization is applied

For master warning lamp, refer to MWI-31, "MASTER WARNING LAMP : System Description"

SYSTEM DIAGRAM

oto ee it ga

racion morn

omer inten naatorame requsst gna) | Combianion mele.

FO ee ae S| poner meaien

oto tore mt ah

Be

meme CAN communication or EV system CAN communication,

SIGNAL PATH

+ The traction motor inverter transmits a motor torque limit signal to VCM when the traction motor needs to be

protected.

Revision: June 2014 EVC-35 2015 Leaf NAM

COMPONENT PARTS,

< SYSTEM DESCRIPTION >

+ When Li-ion battery cannot output power normally, a motor torque limit signal is transmitted to VOM.

WARNING/INDICATOR OPERATING CONDITION

For warning/indicator operating condition, refer to EVC-49. "MOTOR POWER CONTROL : System Descrip-

tion’.

WARNING/INDICATOR CANCEL CONDITION

The traction motor or Lision battery returns from the output limiting state.

TIMING CHART

Power limitation warning is displayed in synchronization with the power limitation indicator lamp.

READY

Power sae on

orr —4

on i

Sal wer

Sioa Cec) orr

on t

Pon intston

inlet lame

or |

bul check ‘upuimtaon requested put tetaton

Dyacten meso ener ‘equestoa by LBC

WARNING/INDICATOR (ON INFORMATION DISPLAY) : Shift P Warning s::02ss:0s:0

DESIGN/PURPOSE

Shift P warning wars that the driver is getting off the vehicle with the shift position not in P position.

‘Symbor Message

=

=

¥ Select P

SYNCHRONIZATION WITH MASTER WARNING LAMP

‘Synchronization is applied

For master warning lamp, refer to MWI-31, "MASTER WARNING LAMP ; System Description”,

SYNCHRONIZATION WITH WARNING CHIME,

Revision: June 2014 EVC-36 2015 Leaf NAM

COMPONENT PARTS

< SYSTEM DESCRIPTION >

‘Synchronization is applied

For waming chime, refer to EVC-40, "WARNING CHIME : Shift P Waming Chime".

SYSTEM DIAGRAM

aces econ

Ccmiton mete cn

ace

mA CAN coruicaton

SIGNAL PATH

+ The electric shift selector sends shift position information to VM.

+ BCM transmits a door switch signal to VCM.

+ VCM judges the vehicle condition according to shift position information and a door switch signal. VCM

transmits a shift P range request display signal to the combination meter if the driver's door is opened with

the shift position not in P position,

WARNING/INDICATOR OPERATING CONDITION

‘When all of the following conditions are satisfied:

+ Shift position: Except P range

+ Front door (driver side): Open

WARNING/INDICATOR CANCEL CONDITION

The indication is cancelled when any of the following conditions are satisfied:

+ The shift position is changed to P position

+ The driver's door is closed.

TIMING CHART

~

oe oe sc

WARNING CHIME

WARNING CHIME : DC/DC Converter Warning Chime row inns

PURPOSE

‘The DC/DG converter warning chime warns the driver that 12V battery voltage is low.

SYNCHRONIZATION WITH WARNING LAMP/INDICATOR LAMP.

Not applicable

SYNCHRONIZATION WITH WARNING/INDICATOR (INFORMATION DISPLAY)

Revision: June 2014 EVC-37 2015 Leaf NAM

COMPONENT PARTS,

< SYSTEM DESCRIPTION >

‘Synchronization is applied.

For information display, refer to “ i IF

‘Converter Warning”.

SYSTEM DIAGRAM

va

ieveo |

Else anf enecor

SEH CAN communcaton

SIGNAL PATH

+ VCM monitors 12V battery voltage, and if the voltage drops, then VCM transmits a DC/DG converter waming

request signal to the combination meter to operate a DC/DC converter warning chime

+ When VCM receives a P position signal from the electric shift selector, the operation of DC/DC converter

warning chime is cancelled.

WARNING OPERATING CONDITION

‘When all of the following conditions are satisfied:

+ Shift position: Except P range

+ 12V battery voltage stays low (approximately 10 - 12 V or less)" for a few consecutive seconds.

* Threshold voltage depends on vehicle speeds,

NOTE:

‘When 12V battery voltage drops sharply while in READY state, the READY state is also cancelled.

WARNING CANCEL CONDITION

‘When any of the following conditions are satisfied:

+ Shift position: P range

+ The 12V battery voltage retums to approximately 12.5 V or more.

TIMING CHART.

oven

o a

“ ‘ev oaey

voto ao}

tev, Tol i

vitoe me ;

sritpostn

wee

ston

on _———_}_

Patna ane

Pring ta {eran ae

ci0¢ camer eee

core Sere

oo — I :

Sep Reng a

iaeston Speen |

on

Tanpaserene

ase (Goda)

Revision: June 2014 EVc-38 2015 Leaf NAM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nissan Leaf (ZE0) - Traction Motor System PDF FreeDocument114 pagesNissan Leaf (ZE0) - Traction Motor System PDF Freemebarki aberraouf100% (1)

- Technical Note: I - Subject: Air Suspension - Ecs SystemDocument12 pagesTechnical Note: I - Subject: Air Suspension - Ecs Systemmebarki aberraoufNo ratings yet

- Nissan Leaf (ZE0) - Vehicle Charging System PDF FreeDocument146 pagesNissan Leaf (ZE0) - Vehicle Charging System PDF Freemebarki aberraouf100% (1)

- J34TC124 49946 1764994600Document8 pagesJ34TC124 49946 1764994600mebarki aberraoufNo ratings yet

- J22CC38976 58980 4745898000Document11 pagesJ22CC38976 58980 4745898000mebarki aberraoufNo ratings yet

- Technical Note: I - Subject: Procedure To Follow For Apm FaultDocument11 pagesTechnical Note: I - Subject: Procedure To Follow For Apm Faultmebarki aberraouf100% (2)

- Technical Note: I - Subject: Diagnostics of The Power Steering Hydraulic CircuitDocument2 pagesTechnical Note: I - Subject: Diagnostics of The Power Steering Hydraulic Circuitmebarki aberraoufNo ratings yet

- Technical Note: I - Subject: Dealing With "Engine Performance" ComplaintsDocument4 pagesTechnical Note: I - Subject: Dealing With "Engine Performance" Complaintsmebarki aberraoufNo ratings yet

- Technical Note: TrucksDocument16 pagesTechnical Note: Trucksmebarki aberraoufNo ratings yet

- Technical Note: I - I - Subject: Abnormal Consumption of Engine OilDocument4 pagesTechnical Note: I - I - Subject: Abnormal Consumption of Engine Oilmebarki aberraoufNo ratings yet

- Technical Note: I - Subject: Analysis, Measurement and Checking of BatteriesDocument7 pagesTechnical Note: I - Subject: Analysis, Measurement and Checking of Batteriesmebarki aberraoufNo ratings yet

- Kia Picanto II Gen. (TA) EWD - Immobilizer System PDF FreeDocument3 pagesKia Picanto II Gen. (TA) EWD - Immobilizer System PDF Freemebarki aberraoufNo ratings yet

- Seat Hardware, Trim, and UpholsteryDocument66 pagesSeat Hardware, Trim, and Upholsterymebarki aberraoufNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument47 pagesFastener Tightening Specifications: Application Specification Metric Englishmebarki aberraoufNo ratings yet

- Steering Wheel and ColumnDocument33 pagesSteering Wheel and Columnmebarki aberraoufNo ratings yet

- Fixed and Moveable WindowsDocument54 pagesFixed and Moveable Windowsmebarki aberraoufNo ratings yet